Load switch: purpose, device, features of selection and installation

To repair a part of the electrical network that is under load or replace equipment, it is necessary to interrupt the current supply to the system. A load switch will help you do this.It will correctly disconnect the current-carrying circuit and, thanks to the presence of a camera, extinguish the electric arc that occurs when the contacts are opened.

The article we have presented describes in detail the types and principles of operation of devices that ensure the safety of equipment and the safety of subsequent work. The technical characteristics of models in demand in everyday life are given. Recommendations are given for the selection and operation of a protective device.

The content of the article:

Detailed description of the device

The load switch is a progressive switching device equipped with an arc chute and a drive for automatic or mechanical control.

Designed for mechanical opening/closing of a group of contacts in a section of an AC electrical circuit under load. Suitable for switching low and high voltage circuits with workloads.

It is not used during a short circuit, as it is designed to extinguish a low-power arc and remove the rated load.

It belongs to the class of high-voltage devices and, as a rule, is located in electrical installations operating under a voltage of 6-10 kilovolts, not equipped with an automatic system that protects the network from short circuits.

The device is equipped with reinforced contacts that have a prolonged service life, significantly exceeding the service life of contact connections in simple automatic machines. This makes it possible to absolutely safely de-energize a line under load and carry out all the necessary measures.

The load shedding device consists of a durable welded frame equipped with a special shaft. There are 6 support insulators on it.

The contact knives are hingedly attached to the three located at the bottom, and the main and arc-extinguishing contacts are held on the remaining elements located at the top. Insulating rods correctly transfer motion from the shaft lever elements directly to the contact knives.

The contacts responsible for arc extinguishing open in special arc extinguishing chambers made of phenolic plastic. This material has high mechanical and corrosion resistance, demonstrates extreme strength and has unprecedented high electrical insulating characteristics.

The internal liners located in the chambers are made of glass-filled polyamite, characterized by a dense structure and impact resistance. The arcuate shape of the chambers and liners allows the movable arcing contacts to enter inside easily and without tension.

When the device is activated, the arc extinguishing contacts close first, and then the knives close the main contacts. At the moment of shutdown, everything happens the other way around: first the main contacts open and only after them the arc-extinguishing contacts.

In inactive mode, the movable arcing contact creates a clearly visible air gap with the arcing chamber, exactly the same as in a traditional disconnector. Immediately at the moment of shutdown, an arc forms between the arcing contacts.

When exposed to high arc temperatures, the glass-filled polyamide liner releases specific gases. This flow that appears in the chamber extinguishes the arc, providing further safety for working with the current circuit and electrical equipment.

The elements responsible for turning off/on the load differ from each other in the following technical characteristics:

- fastening method;

- rated current level;

- basic equipment;

- availability and number of additional functions;

- design features of the module;

- Rated voltage.

Most household switches, unlike industrial devices, are manually controlled and cut off a current flow of no more than 100 amperes. To prevent the contacts from overheating during operation and potentially overloading, the product is purchased so that its rated current necessarily exceeds the total current flow of consumer loads.

Unlike a classic circuit breaker, the load deactivator is equipped with reinforced contacts that can withstand prolonged operation.

Increased reliability of the module is ensured by such items as:

- automatic blocking of the control handle from unauthorized activation;

- the presence of viewing windows that allow you to visually verify that contacts are broken and make it possible to control the situation at all stages of work;

- double break of circuit contacts, ensuring a complete shutdown of power and guaranteeing the safety of all repair and maintenance activities carried out.

All these parameters make voltage switches very useful for use and encourage the consumer to purchase such devices and integrate them into the electrical system to increase reliability and ensure operational safety.

Classification of switching modules

Products responsible for deactivating the load in the electrical network are produced in several different versions. The classification of devices is carried out according to the method of extinguishing the arc that occurs when the load is deactivated, and according to the type of arc-extinguishing chamber.

Manufacturers operating in the electrical equipment market produce the following types of load switches:

- autogas – the walls of the chamber, heating under the influence of an electric arc, emit a special gas that absorbs it;

- vacuum - V vacuum circuit breakers the properties of the environment in which the electric arc does not propagate are used;

- electromagnetic – electromagnetic relays influence the arc with an electromagnetic field and in this way change its direction;

- autopneumatic – extinguish the electric arc by compressing the air in the chamber with a powerful spring element;

- SF6 – absorption chamber cavity SF6 circuit breakers filled with electrical gas consisting of sulfur hexafluoride. This colorless, heavy element is six times heavier than air and very quickly extinguishes the electric arc that occurs when the contact is disconnected.

Autogas devices are the most widespread today and are in greatest demand. However, they are literally “treading on their heels” by vacuum units, recognized by experts as the most promising, progressive, efficient and reliable voltage switches.

Direct control of the devices is carried out using a lever-type manual drive, equipped with a built-in electromagnet that allows remote shutdown.

In addition to the parameters described above, load switches differ from each other in the number of contact poles. Today, the market offers one-, two- and three-pole modules designed to correctly disconnect the load in the current supply system.

Another important feature is the design of the actuator.

This node can be:

- electromagnetic;

- thermal;

- semiconductor;

- combined.

The last feature concerns the principle of installing the module. It can be retractable, stationary or fixed. The choice is made depending on the location of the electrical network and external weather conditions at the location.

Device Specifications

Devices that switch off the load by opening the electrical circuit have different technical characteristics. All of them are important and become decisive when choosing a unit suitable for purchase and its subsequent installation.

Index rated voltage reflects the operating voltage of an electrical device for which it was originally designed by the manufacturer.

Maximum operating voltage shows the extremely possible permissible high voltage at which the switch is able to function in normal mode without compromising its performance. Typically this figure exceeds the rated voltage by 5-20%.

The flow of electric current, during the passage of which the level of heating of the insulating coating and parts of the conductor does not interfere with the normal operation of the system and can be withstood by all elements for an unlimited time, is called rated current. Its value must be taken into account when choosing and purchasing a load switch.

Magnitude through current permissible limits demonstrates how much current flowing through the network in short circuit mode can be withstood by the load switch installed in the system.

Electrodynamic withstand current reflects the magnitude of the short circuit current, which, acting on the device during the first few periods, does not have any negative effect on it and does not mechanically damage it in any way.

Thermal current determines the maximum current level whose heating effect over a certain period of time does not damage the load switch.

The technical performance of the drive and the physical parameters of the devices, which determine the overall size and weight of the device, are also very important. By focusing on them, you can understand where it will be more convenient to place the devices so that they work correctly and accurately perform the assigned tasks.

Among the unconditional positive qualities of devices responsible for disconnecting the load are the following positions:

- simplicity and accessibility in production;

- elementary method of operation;

- very low cost of the finished product compared to other types of switches;

- possibility of comfortable activation/deactivation of rated load currents;

- a gap between the contacts visible to the eye, ensuring complete safety of any work on outgoing lines (installation of an additional disconnector is not required);

- inexpensive protection against overcurrent flow by means of fuses, usually filled with quartz sand (type PKT, PC, PT).

Of the disadvantages of switches of all types, the most often mentioned is the ability to switch only rated powers, without working with emergency currents.

Autogas modules are usually reproached for their limited operating life, which is caused by the gradual burnout of internal parts that generate gas formation in the arc-extinguishing chamber.

However, this issue can be completely resolved, and with little money, since gas generation elements and paired contacts intended for arc absorption are very inexpensive and can be easily replaced, not only by professionals, but also by workers with low qualifications.

What to consider when choosing?

When planning to purchase a load switch, you should remember that the device is primarily designed not to protect electrical appliances, but to protect wiring from overheating, burnout and overvoltage.

In order for the purchase to be correct, and for the device to cope with the assigned tasks, you must first find out the cross-section of the cable entering the apartment or house panel and the current level for which it is designed.

Once this information is received, it is compared with the factory specifications of the load switch.The operating current of the device should be slightly less than the maximum permissible current for the wire.

If the cable capacity is much higher than the load current consumption, consider purchasing an automatic load module.

To determine the required parameters of the device, first sum up the power of all electrical appliances in the living room. To the resulting amount add from 5 to 15% for the reserve and, using the formula of Ohm's law, determine the total total current consumption. Then they buy a machine that has an operating current slightly higher than the calculated one.

Scope of application of switches in everyday life

Usually used in private houses and apartments circuit breakers. With their help, if necessary, they de-energize living quarters and carry out all necessary installation work related to scheduled maintenance or repair of electrical networks.

However, these devices are by no means a panacea. The machines primarily serve to protect pantographs and electrical wiring from the aggressive effects of overcurrents. Breaking the circuit is one of the secondary tasks that these devices perform.

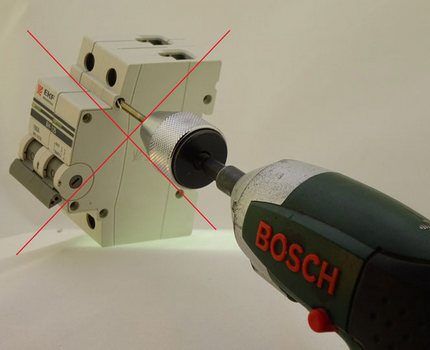

Regularly turning off power using a machine is not a good idea. Especially if the load is not removed from the outlet.In this case, the module wears out much faster and reaches its working life in a shorter time than stated by the factory characteristics.

Inside the case, the contacts gradually burn out and turn black, and the product itself loses its nominal throughput, ceases to perform its tasks and then fails. The owners in this situation have to urgently change the device.

If you ignore this point, the next short circuit will damage the wiring, cause the machine to catch fire, and possibly even lead to more serious consequences.

That is why experts recommend using not ordinary circuit breakers, but progressive and reliable load switches for frequent shutdowns.

These elements will increase the safety of electrical panels, ensure high-quality, uninterrupted power supply to any residential premises and allow, if necessary, to conveniently and quickly open the circuit, carry out repair and installation activities of any complexity and reconnect the housing to the general energy supply system.

Installation of a device to deactivate loads at the input distribution board allows you to remove voltage from the panel itself and correctly replace failed circuit breakers.

With such a device, it is very easy to disconnect any room from the centralized power supply network for the purpose of scheduled maintenance or performing necessary repairs. The unit will ensure complete safety for the technician and will allow you to quickly eliminate all detected problems.

Conclusions and useful video on the topic

Even more about load switches can be found in the videos below, where specialists share their experience and installation nuances.

Installation features of the load switch. Step-by-step instructions from the master.

A detailed and clear description, rules for correct use and the direct purpose of the device from a professional electrician.

Review of modular load switch manufactured by Hyundai. Using this device, you can inexpensively solve the issue of switching an electrical circuit.

Features of the functioning of the VN32-100 load switch and the practice of using this device as a switch in electrical circuits of alternating current 50-60 Hz with a rated mains voltage of 230-400V.

A practical and reliable load switch helps to increase the level of operational safety of the electrical network and helps to promptly open the current circuit in the right place and eliminate the breakdown or replace failed equipment.

The presence of a switch ensures the safety of intra-house or intra-apartment wiring, protects it from premature wear and significantly increases its service life.

Would you like to talk about how you selected a protective device for the electrical network in your own home/apartment? Do you have information that will be useful to site visitors? Please write comments in the block below, ask questions, share information and photos on the topic of the article.