Vacuum switch: device and principle of operation + nuances of selection and connection

An electrical device, a vacuum circuit breaker, is a device intended for operation as part of electrical high-voltage networks.It got its name from a design feature - a vacuum chamber, thanks to which instant extinction of the electric arc is achieved.

The device is used as switches designed to shut down equipment in case of emergency situations or as part of routine operation. Let's take a closer look at what a vacuum commutator is and why it is needed.

The content of the article:

How does a high voltage vacuum switch work?

The basis for the functionality of vacuum chambers used in the design of switches is the physical properties of the gas in a discharged state. Under such conditions, the gas property, characterized as electrical strength, changes significantly towards an increase.

This effect of a highly rarefied environment (range from 10-6 to 10-8 N/cm2) is successfully used in switch designs supplemented with gas vacuum chambers through which electrical contact groups pass.

The current flowing through the contact groups (at the moment the contact is disconnected) forms an electric discharge - an arc.Arc combustion occurs due to partial ionization of metal vapors, inevitably formed from high temperature. The passage of current between the contacts through the formed plasma is maintained until the current transitions to the zero bus.

As soon as the moment of transition through “zero” comes, the electric arc goes out. The overall process takes no more than 7-10 microseconds.

Design of vacuum switches

The variety of vacuum circuit breakers, taking into account their design, is quite large. Therefore, it is difficult to give characteristics of these devices as a whole. Meanwhile, regardless of design differences, the principle of operation remains unchanged.

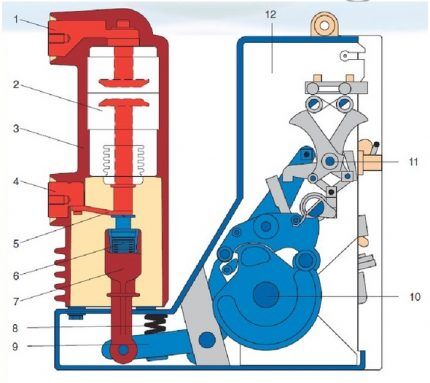

Let's consider for general information three-pole vacuum switch, equipped with a spring-motor drive. This device is designed for indoor or outdoor installation. In any case, its installation is carried out inside special distribution metal boxes.

The devices can be used in a variety of areas of the national economy. However, there are some limitations.

Thus, vacuum circuit breakers are not intended for installation and subsequent operation in the following conditions:

- rooms where there is a fire or explosive atmosphere;

- installations that are designed to provide for frequent switching;

- mobile (mobile) type installations;

- energy systems of sea and river vessels.

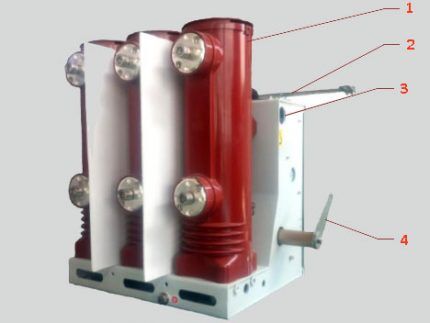

Vacuum-type circuit breakers usually have two types of design:

- For permanent installation.

- For installation with a hardware cart.

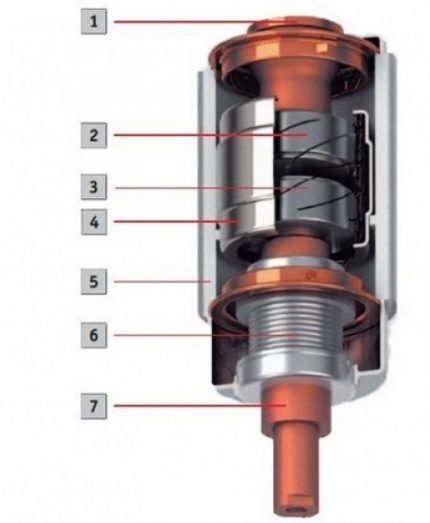

Regardless of the design, the body area of the device contains three poles equipped with arc-extinguishing chambers.

Inside the vacuum chambers there are movable contactors driven by a spring-motor mechanism. The device body is complemented by a front panel, which contains display elements and control devices.

The three poles of the main circuit are made in the form of columns. The location of the poles is usually at the rear of the spring motor drive chassis. Each pole is equipped with an arc extinguishing chamber, which is enclosed inside a polymer insulator. In order to enhance the electrical strength, the insulator body has a ribbed shape.

Inside each vacuum chamber, a contact group of two elements is mounted - movable and fixed. The moving contact element is connected to the switching mechanism through a traction insulator. Next is the connection with the lower contact pin. And the fixed contact is connected through a conical fit to the upper contact terminal of the device.

How does the switch drive work?

The moving contacts of the vacuum chambers are mechanically connected to the shaft of the spring-motor drive. Due to the power spring, which is pre-cocked (set to the tension state), the drive can be easily activated by simply pressing a control button or other mechanism.

The spring (usually two springs) is charged by a chain drive. The normal operating mode of the equipment involves charging the spring using an electric motor equipped with a gearbox. At the same time, there is a manual cocking handle, which is used in case of accidents or loss of power.

The cocked spring is fixed by the trigger mechanism. This mechanism is controlled via an electromagnetic drive or via a power button. As soon as the activation mode is activated, the locking is released, the tensile force of the spring activates the cam mechanism. This, in turn, acts on the shaft, which is mechanically connected to the switching mechanism of the moving contacts of the vacuum chambers.

The operation to turn off the vacuum circuit breaker is performed by activating the “Off” mode - with an electromagnet or a button. The sequence of actions is almost the same as the first mode. Trip power springs are also involved here, the state of which is set by the trip trigger.

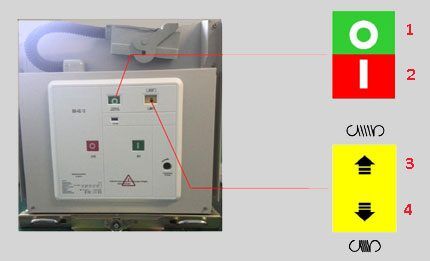

Convenience of operation and control of the operation of the device is provided by the control panel. Along the front of the panel there are elements: a cycle counter, a charging spring status indicator, and a vacuum switch status indicator.

Features of withdrawable structures

The withdrawable equipment is assembled on the basis of a special equipment trolley. Using this accessory, the switch is inserted into or out of the cabinet.

The hardware trolley acts not only as transport for the device, but also acts as a controller for switching the device into test mode or into operating mode as soon as the switch is pushed into the cabinet.

The vacuum switch is attached directly to the moving part of the trolley. Fastening is carried out using bolted connections. Meanwhile, the hardware trolley also has a stationary part, where the drive of the moving part is fixed. The movement of the movable module relative to the stationary one is carried out by the screw of the trolley control handle.

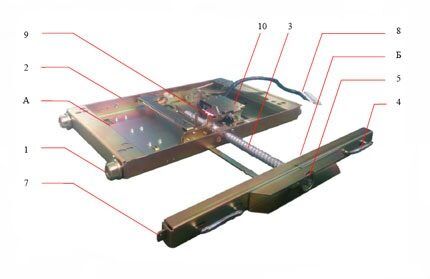

The moving part is a metal base on four wheels, treated with galvanic coating. There is an external mechanical locking (pressure bar) of the ground electrode, a drive screw lock, block contacts, a switch locking mechanism and other elements that ensure movement or fixation.

Installation and connection of the device

Before starting to install a vacuum circuit breaker, it is necessary to inspect all externally accessible elements to ensure that there are no damages or defects. Then the insulating surfaces of the poles are cleaned using a dry, lint-free cloth.

It is not allowed to introduce equipment into the system if there are chips, cracks, or deformed areas on the insulating surfaces. The circuit of the secondary circuits must be checked, as well as the connection of the chassis bus.

Before installation, the functionality of the switch should be checked by manual switching on (idle without power) and make sure that the control panel indicators are in the correct position. Then you need to check the presence of the pole covers. If equipment rated 1600A and higher is used, the protection covers must be removed before installation.

Connect directly to the network

The terminals of the contact tips of the power cable conductors must be cleaned before connecting to the switch terminals.

The stripping procedure differs depending on the terminal material used:

- For copper and aluminum terminals without additional coating, cleaning is carried out with sandpaper of M20 grit or lower, followed by degreasing the metal surface.

- If the terminals are copper or aluminum coated with a layer of silver, they can simply be cleaned with a lint-free cloth.

It is unacceptable to use cables whose silver coating on the terminals is damaged over an area of more than 5%. In this case, the damaged element must be replaced. More information about terminals for connecting wires can be found in this material.

External conductors are connected to the terminals of the vacuum switch in such a way that no mechanical forces are created on the terminals of the device from the external conductors. Connections are made by means of a bolt coupling using flat elastic metal washers.

How is grounding done?

Stationary devices are connected to the “earth” platform using a bolted connection (M12) directly at the point marked “Grounding”.

The area of the “Grounding” contact point must be degreased before connection. The grounding conductor should be a bus of sufficient cross-section (Electrical Installation Rules), a flexible wire or a braided conductor. Before placing the conductor on the contact pad, lubricate the contact surfaces with a special lubricant (CIATIM-203).

The draw-out type design is grounded using the elements of the equipment cart. Grounding of the vacuum circuit breaker is carried out through the structure of the hardware trolley, for which there are also fastening elements.

Putting the device into operation

The device is put into operation after an additional check of the installed and prepared equipment. In particular, the reliability of grounding, the state of fastening of assembly components, and access of the cooling medium to potentially heating elements are checked.

The surfaces of the current-carrying rods in contact with the lamellas of the rosette contact groups must be treated with a small amount of CIATIM lubricant. In general, it is necessary to carry out all the procedures provided for by the PES in the event of acceptance tests and ensure that the operating voltage corresponds to the permissible limits.

Personnel who have permission to service electrical installations operating at voltages above 1000 volts are allowed to operate the vacuum circuit breaker. The approved access group for service personnel must be no lower than third. Before starting to work with equipment, personnel undergo a technical minimum in order to study the intricacies of a specific equipment model.

How to choose a vacuum circuit breaker?

The device is selected taking into account its nominal parameters, which are considered in relation to the parameters of the existing network at the installation site. The choice is made according to the criterion of the maximum loaded operating modes expected for operating conditions.

The rated voltage of the vacuum circuit breaker is allowed to be equal to (or increased) in relation to the rated voltage of the system powered through the circuit breaker.

The rated long-term current parameter is selected higher than the rated current of the supplied system. The rated cut-off current parameter is selected above the maximum value rated current Short circuit (the moment of contact divergence is taken into account).

From the point of view of possible short circuit conditions, the choice is made taking into account the most severe conditions.

The aperiodic component value is calculated taking into account the short circuit conditions with zero voltage in any of the phase lines. In this case, the aperiodic current parameter set by the equipment manufacturer should be taken into account.

Conclusions and useful video on the topic

You can learn even more material about the device, operating principle and installation conditions of a vacuum circuit breaker from the following video:

Vacuum switches differ from other types of devices in their relatively simple and reliable structure. Therefore, this type of equipment serves for a long time without any complaints. The natural wear life is determined by the number of operations equal to at least 20,000. Provided that maintenance is carried out in a timely manner, this life increases by 5-10%.Meanwhile, explosive maintenance is limited to a small number of light operations.

If, while reading the information, you have questions about the topic of the article or have valuable information that you can share with our readers, please leave your comments, share your experience, and ask questions in the block below the article.

Can you find out in more detail why such grounding of the switch is needed?

Good afternoon, Artem. The main purpose of such grounding is to guarantee the safety of work.

The first image is a fragment of a diagram of an outdoor switchgear. What appears to be shown (the letters are not clear) is a vacuum circuit breaker and current transformers. The latter are technologically related to explosives. Such areas of switchgear must be “fenced” with stationary grounding blades, which guarantee the safety of the work of personnel repairing, servicing explosives, transformers, and other elements of the circuit section. These grounding switches are regulated by clause 4.2.28. PUE. Screenshot attached.

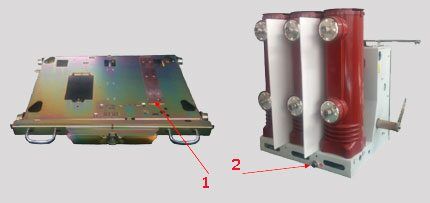

The second image is a fragment of a complete closed 10 kV switchgear. The purpose of these knives is similar. While performing work, the personnel uses disconnectors to isolate the work area (cuts off power from all sides of possible erroneous voltage supply), and uses grounding knives to connect the equipment taken out for repair to the “ground.”