How to make an indirect heating boiler with your own hands: instructions and manufacturing tips

The presence of running water with hot water is part of the usual comfort for a modern home.However, it is not always possible to solve the problem of connecting centralized communications to suburban real estate.

Therefore, owners of private households arrange an autonomous supply of hot water, using a heating circuit as a heating source. To solve the problem, you just need to build an indirect heating boiler with your own hands.

We will tell you how to make a useful device for everyday life. The article describes in detail the rules for installing and connecting equipment that supplies sanitary water to water collection points. You will learn how to prepare the boiler for startup and how to put it into operation.

The content of the article:

Indirect heating boiler device

In essence, the device is a regular heat exchanger.

True, heat exchangers are traditionally built according to the “pipe-in-pipe” principle, and in this case, the elements of heat exchange are a vessel and a tubular coil. The storage vessel plays the role of an external “pipe”, inside of which an internal “pipe” or coil is placed.

Passes through a tubular coil heating system coolant, and the inner area of the vessel is filled with cold water. The coolant heats the walls of the tubular coil, and they, in turn, heat the cold water in the vessel.

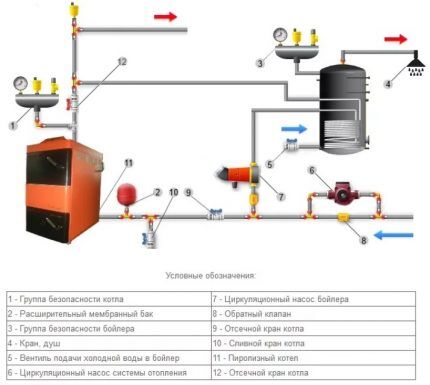

Scheme indirect heating boiler usually done using the technology of counterflow of two media, different in temperature level. In other words, if the heated water outlet is provided in the lower part of the tank, and the cold water make-up pipe is located higher, in this case the coolant is supplied to the coil at the upper level.

The reverse configuration is performed if the cold water inlet and outlet are reversed. In practice, schemes with an upper outlet of heated water are more common.

Considering that an indirect heating boiler belongs to thermal plumbing equipment, the device and the adjacent piping are subject to thermal insulation.

It is wise to install the system in close proximity to heating system boiler. This approach will ensure lower costs for installing equipment, and heat losses on the way from the heating system to the indirect heating boiler will be significantly reduced.

The following photo selection will show you an example of making a simple indirect heating boiler:

DIY project and installation

The main task at the do-it-yourself design stage is to select a storage tank whose volume would cover the needs for hot water.

Selecting storage capacity

For most cases of system operation, the calculation of the need is made for 3-4 people (an average family). According to standards, one person consumes about 70 l/day. That is, for the average family it is quite enough to install an indirect heating boiler with a volume of 200 liters. With such a capacity, the need is fully satisfied.

A tank for heating cold water is usually chosen for vertical installation, but the option of installation in a horizontal position is also possible. As a boiler tank, it is permissible to use containers made of durable heat-resistant materials.

Of course, the container material should be selected taking into account its high anti-corrosion properties, permissible thermal expansion, and other performance characteristics.

Suitable materials include:

- aluminum;

- stainless steel;

- special polymers.

It should be remembered: boilers of any type are pressure vessels.In addition, the heating fluid can heat up to high temperatures (90ºC and above). Based on these properties of boiler installations, you should design and build the system yourself.

In practice, you often come across really absurd designs, also made by yourself, for example, based on an ordinary milk flask or a dining pan. Such decisions should be avoided.

The DIY indirect heating boiler project also includes the calculation of a tubular coil. Here it is necessary to calculate the required thermal power of this device in order to determine the length of the coil pipe and its diameter based on the calculation results.

Calculation of coil length

The traditional material for making boiler coils is copper or brass. It is recommended to choose one of these materials, since both materials have a high heat transfer coefficient.

To calculate the required values for the manufacture of a boiler coil, the following formula is suitable:

L = Q / D* (Tg – Tx) * 3.14

Letter designations here:

- L – tube length,

- Q – thermal power of the coil,

- D – tube diameter,

- Tg – hot water temperature,

- Tx – cold water temperature.

Let's look at an example of how to calculate the length of a copper pipe for a 20 kW spiral for an indirect heating boiler.

There is a copper pipe with a diameter of 10 mm, purchased at the market in the bay. A vessel with a capacity of 200 liters is taken under the boiler. Calculated temperatures of cold and hot water: 15ºС and 80ºС, respectively.

It is required to determine the length of copper pipe sufficient to produce a heat exchange tubular spiral with a power of 20 kW. The following calculation is carried out using the formula: 20/0.01*(80-15)*3.14. Calculation result: the required length of the copper pipe will be 10 meters.

Manufacturing and processing of coils

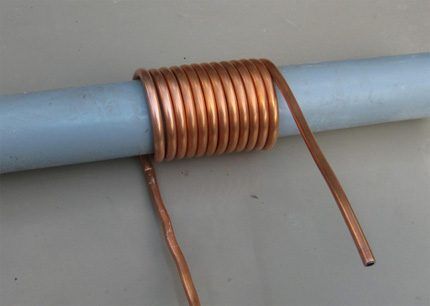

To make an indirect heating boiler coil with a capacity of 150-200 liters, as a rule, a copper or brass tube with a diameter of 10 - 20 mm is taken. The tube is twisted into a spiral, taking into account a residual gap of 5-7 mm between the turns.

It is necessary to make a gap (it is allowed to move the turns apart after winding), since it is necessary to compensate for the expansion of the metal. In addition, with this design of the spiral, full contact of water with the surface of the copper (brass) tube is achieved.

In principle, copper or brass coils can be found ready for use. For example, take a coil from some technological equipment. But then you will have to take into account the size of the existing container and the correspondence of the spiral in terms of heat transfer power.

Often it is not possible to select in exact accordance with the parameters. Therefore, in order not to waste precious time in this sense, it is more profitable to make a tubular spiral heater yourself.

It is difficult to make a coil with your own hands without experience, but this task is doable.The main thing here is to perform high-quality winding of the spiral. It is recommended to use a drum made of suitable material for winding a copper (brass) tube.

The drum diameter is approximately 10-15% smaller than the internal diameter of the boiler tank. As a result, if the internal diameter of the tank is 500 mm, then the value of the coil diameter will be: (500 – 500/10) = 450 mm.

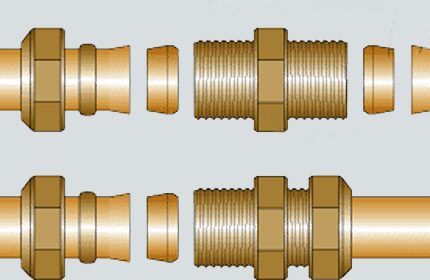

At the end parts of the tube, twisted into a spiral, you will need to mount contact threaded fittings. To solve this problem you need:

- Get an even cut on the ends of the pipe by treating them with a pipe cutter.

- Place crimp nuts on the ends of the pipe.

- Process the edges of the pipe with a reamer.

- Install the fittings and tighten them tightly to the pipe with nuts.

It is not necessary to use exclusively threaded double-sided fittings. If you have the skills to solder copper pipes and the appropriate tools, you can install single-sided threaded fittings using the soldering method.

Also, depending on the material of the vessel body, the option of soldering directly to the walls of the container cannot be ruled out. However, when making an indirect heating boiler yourself, this step is not recommended due to the complex technological operation.

Once assembled with fittings or soldered, the heat exchange element (boiler coil) can already be considered ready for installation and subsequent operation. All that remains is to prepare a place for installation directly on the boiler tank and integrate the water heater into the vessel.

Preparing the boiler tank

How to place a finished copper (brass) spiral inside a boiler tank if the container is solid? In this case, you will have to carefully cut off the top part and make a lid that will be attached to the body of the vessel with bolts.

The seats of the lid and tank are leveled, polished, and equipped with a rubber gasket. Meanwhile, internal installation (and maintenance) seems more convenient if there are two covers on the container - top and bottom.

After installing the lid on the boiler tank, the problem with installing the coil inside the tank disappears by itself. Now it is enough to drill two holes on the body of the vessel, focusing on the location of the end parts of the spiral pipe. The diameter of the holes must correspond to the diameter of the threaded part of the fittings with a margin of 1-2 mm.

The threaded parts of the fittings are passed into the holes, having previously installed sealing gaskets. Then counter fittings are screwed on the outside of the tank wall and the connection is tightened tightly.

With this type of mounting, the heating coil is quite stable, but additional supports are necessary. The flow of coolant under pressure inside the pipe is often accompanied by the appearance of vibrations. Additional supports will compensate for the defect.

On the body of the indirect heating boiler, you also need to make holes for collecting and draining water, press short pipes into them, and install shut-off valves on the pipes.If desired, you can supplement the device with a dial thermometer.

Having completed the installation of all components, the vessel body is closed from the outside with insulating material. Mineral wool with a top foil coating is suitable here.

Instructions for connecting and starting the system

First of all, a homemade homemade indirect heating boiler needs to be connected to the heating main. Where an autonomous heating system is used, boiler included into the home boiler network.

Mechanical connection is made with the lid on the boiler tank open. After connecting, you need to slightly open the shut-off valve connecting to the return coolant line and make sure that there are no leaks both from the outside of the device and inside.

If no leaks are found, open the coolant supply line. It is necessary to wait some time for the coil to warm up to the temperature of the heating system. In full heating mode, carefully check the coil and all connection points again for possible leaks.

If the check shows the integrity of the system, close the lid of the vessel and connect feeding and disassembling lines heated water. The system is tested in real heat transfer mode.

Conclusions and useful video on the topic

A used gas cylinder is often used to make homemade devices. We present a video on how to make a BKN from a cylinder body.

Here we describe only one option out of all the possible ones that exist and are successfully used.It should be noted that there are many options for independent designs of indirect heating boilers.

For example, instead of a cylindrical storage tank, rectangular vessels are used. The winding of the coil spiral is not single-layer, but multi-layer. The water heater is supplemented with an electric heating element. Design ideas have no boundaries.

Would you like to share your own experience in making an indirect heating boiler or useful information on the topic? Please write comments in the block below. Here you can ask questions, express your opinion and post photos.

I won’t even try to make an indirect heating boiler myself. It's too difficult for me. What kind of specialist do you need to be? There are so many different pipes that need to be connected, and some kind of coil needs to be made according to the formula. Choose a storage container, and then think about whether it will flow or not, whether it will fit or not, etc. Should you weld your own boiler? I can't cook at all. Not a welder!

I won’t even try to make a nuclear reactor myself. This is too difficult for me...

In principle, it is quite possible to make an indirect heating boiler from a gas cylinder yourself. But other methods are quite complicated, since they require expert knowledge, without which it is really scary to start working. The main message of this idea is that it is necessary to gather knowledgeable acquaintances, and with a joint effort to do everything right; you simply cannot do it alone.

The article does not address the issue of inserting a boiler into the heating network. Not a word about pressure testing, but in batteries P>5 atm.How will you install the device: illegally or officially, with acceptance certificates? Either way it's a headache. If your house has a communal heat energy meter, you are passing on the cost of hot water to your neighbors; no one is likely to like it.

This is all for private homes, don’t worry :)

It's not a matter of whether I can do it or not, but rather the cost. I set myself this goal - for the price it turns out you win a couple of thousand. This thing is not worth the candle.

I think there is nothing complicated about this. He did all the heating of the house himself, including heated floors and a water supply system with a pipeline from the well to the taps. The question arose of replacing the boiler.

We have a 200 liter Electrolux. Vertical model, with dry heating elements aged 25 years. The second set of internals is nearing completion - it has started to drip.

I was interested in a 200 liter indirect heating boiler with the prospect of connecting to an air-to-water heat pump. Prices from 400 to 1000 euros.

I decided to buy new internals for my boiler and implant an indirect heating coil in them. I looked at the options - nothing complicated.

Go to a turner - he will make any coil for inexpensively. You just need to take the correct dimensions and buy a copper tube. Good luck to all!

I live in a private house and decided to make something similar from an old 200 liter boiler, I didn’t try to be too clever, I took out the heating element, cut off the spirals, and welded two tubes with a 1/2 thread into the heating element’s mount.

I screwed on a 5 meter stainless steel gas hose, somehow stuffed this miracle spiral into the boiler and screwed it back into place of the heating element.the heating will pass through the spiral, I’m waiting for the winter, if it doesn’t warm up I’ll add another five meters, and for the summer I’m thinking of installing a solar collector, I’ll throw a coil of black plastic pipes and a pump on the roof, in sunny weather I’ll turn on the pump, well, or some kind of automation from aliexpress I’ll try let the sun warm. These are my plans.