Electromagnetic relay: device, marking, types + details of connection and adjustment

Converting electrical signals into the corresponding physical quantity - movement, force, sound, etc.etc., is carried out using drives. A drive should be classified as a converter because it is a device that changes one type of physical quantity to another.

The drive is usually activated or controlled by a low voltage command signal. It is further classified as a binary or continuous device based on the number of stable states. Thus, an electromagnetic relay is a binary drive, taking into account two available stable states: on - off.

The presented article examines in detail the principles of operation of an electromagnetic relay and the scope of use of the devices.

The content of the article:

Drive design basics

The term "relay" is characteristic of devices that provide an electrical connection between two or more points through a control signal.

The most common and widely used type of electromagnetic relay (EMR) is the electromechanical design.

The fundamental control scheme for any equipment always provides the ability to turn it on and off. The easiest way to perform these steps is to use power lock switches.

Manually operated switches can be used for control, but have disadvantages. Their obvious drawback is setting the “on” or “off” states physically, that is, manually.

Manual switching devices are usually large-sized, slow-acting, capable of switching small currents.

Meanwhile, electromagnetic relays are mainly represented by electrically controlled switches. The devices have different shapes, dimensions and are divided according to their rated power level. The possibilities for their application are extensive.

Such devices, equipped with one or more pairs of contacts, can be part of a single design of larger power actuators - contactors, which are used for switching mains voltage or high-voltage devices.

Fundamental principles of EMR operation

Traditionally, electromagnetic-type relays are used as part of electrical (electronic) switching control circuits. In this case, they are installed either directly on printed circuit boards or in a free position.

General structure of the device

The load currents of the products used are usually measured from fractions of an ampere to 20 A or more. Relay circuits are widespread in electronic practice.

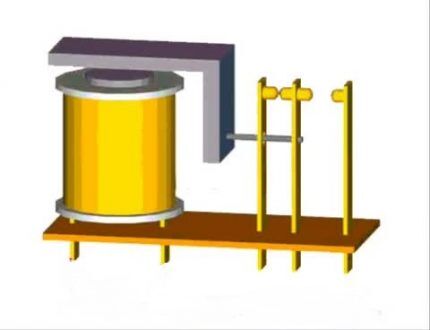

The design of an electromagnetic relay converts the magnetic flux generated by the applied AC/DC voltage into mechanical force. Thanks to the resulting mechanical force, the contact group is controlled.

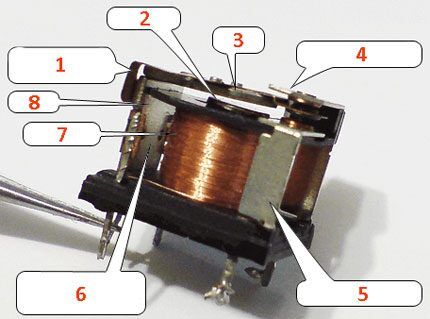

The most common design is a product form that includes the following components:

- exciting coil;

- steel core;

- support chassis;

- contact group.

The steel core has a fixed part called the rocker and a movable spring-loaded part called the armature.

Essentially, the armature complements the magnetic field circuit by closing the air gap between the stationary electric coil and the moving armature.

The armature moves on hinges or rotates freely under the influence of the generated magnetic field. This closes the electrical contacts attached to the fittings.

Typically, a return spring(s) located between the rocker arm and the armature returns the contacts to their original position when the relay coil is de-energized.

Operation of the relay electromagnetic system

A simple classical EMR design has two sets of electrically conductive contacts.

Based on this, two states of the contact group are realized:

- Normally open contact.

- Normally closed contact.

Accordingly, a pair of contacts is classified as normally open (NO) or, in a different state, normally closed (NC).

For a relay with a normally open contact position, the "closed" state is achieved only when the field current passes through the inductive coil.

In another option, the normally closed position of the contacts remains constant when there is no excitation current in the coil circuit. That is, the switch contacts return to their normal closed position.

Therefore, the terms “normally open” and “normally closed” should refer to the state of the electrical contacts when the relay coil is de-energized, that is, the relay supply voltage is turned off.

Electrical relay contact groups

Relay contacts are usually electrically conductive metal elements that touch each other and complete a circuit, acting similarly to a simple switch.

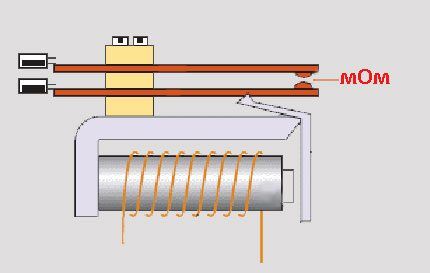

When the contacts are open, the resistance between the normally open contacts is measured as a high value in megaohms. This creates an open circuit condition when the passage of current in the coil circuit is eliminated.

If the contacts are closed, the contact resistance should theoretically be zero - the result of a short circuit.

However, this condition is not always observed.The contact group of each individual relay has a certain contact resistance in the “closed” state. This resistance is called stable.

Features of the passage of load currents

For the practice of installing a new electromagnetic relay, the switching contact resistance is noted to be small, usually less than 0.2 Ohm.

This is explained simply: new tips remain clean for now, but over time the resistance of the tip will inevitably increase.

For example, for contacts carrying a current of 10 A, the voltage drop will be 0.2x10 = 2 volts (Ohm's law). From this it turns out that if the supply voltage supplied to the contact group is 12 volts, then the voltage for the load will be 10 volts (12-2).

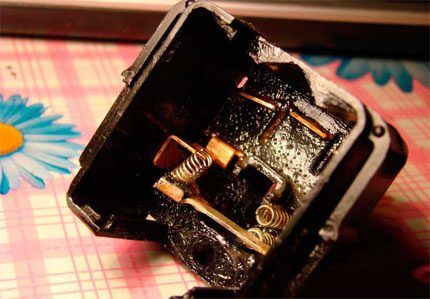

When metal contact tips wear out without being properly protected from high inductive or capacitive loads, arc damage is inevitable.

An electric arc—sparking at the contacts—leads to an increase in the contact resistance of the tips and, as a consequence, to physical damage.

If you continue to use the relay in this condition, the contact tips may completely lose their physical contact properties.

But there is a more serious factor when arc damage ends up welding the contacts together, creating short circuit conditions.

In such situations, there is a risk of damage to the circuit controlled by the EMR.

So, if the contact resistance increases due to the influence of the electric arc by 1 Ohm, the voltage drop across the contacts for the same load current increases to 1 × 10 = 10 volts DC.

Here, the magnitude of the voltage drop across the contacts may be unacceptable for the load circuit, especially when working with supply voltages of 12-24 V.

Relay contact material type

In order to reduce the influence of the electric arc and high resistances, the contact tips of modern electromechanical relays are made or coated with various silver-based alloys.

In this way it is possible to significantly extend the service life of the contact group.

In practice, the following materials are used to process the tips of contact groups of electromagnetic (electromechanical) relays:

- Ag - silver;

- AgCu - silver-copper;

- AgCdO - silver-cadmium oxide;

- AgW - silver-tungsten;

- AgNi - silver-nickel;

- AgPd - silver-palladium.

Increasing the service life of the tips of the relay contact groups by reducing the number of electric arcs is achieved by connecting resistive-capacitor filters, also called RC dampers.

These electronic circuits are connected in parallel with contact groups of electromechanical relays. The voltage peak, which is noted at the moment of opening the contacts, with this solution seems to be safely short.

The use of RC dampers makes it possible to suppress the electric arc that forms at the contact tips.

Typical design of EMR contacts

In addition to the classic normally open (NO) and normally closed (NC) contacts, the mechanics of relay switching also involves classification based on action.

Features of the design of connecting elements

Electromagnetic type relay designs in this embodiment allow for one or more separate switch contacts.

The design of the contacts is characterized by the following set of abbreviations:

- SPST (Single Pole Single Throw) - single-pole unidirectional;

- SPDT (Single Pole Double Throw) - single-pole bidirectional;

- DPST (Double Pole Single Throw) – bipolar unidirectional;

- DPDT (Double Pole Double Throw) – bipolar bidirectional.

Each such connecting element is designated as a “pole”. Any of them can be connected or reset, simultaneously activating the relay coil.

Subtleties of using devices

Despite the simplicity of the design of electromagnetic switches, there are some subtleties in the practice of using these devices.

Thus, experts categorically do not recommend connecting all relay contacts in parallel in order to switch a high-current load circuit in this way.

For example, connect a 10 A load by connecting two contacts in parallel, each of which is rated for a current of 5 A.

These installation subtleties are due to the fact that the contacts of mechanical relays never close or open at the same time.

As a result, one of the contacts will be overloaded in any case.And even taking into account a short-term overload, premature failure of the device in such a connection is inevitable.

Electromagnetic products can be used as part of electrical or electronic circuits with low power consumption as switches of relatively high currents and voltages.

However, it is strictly not recommended to pass different load voltages through adjacent contacts of the same device.

For example, switch between 220V AC and 24V DC. Separate products should always be used for each option to ensure safety.

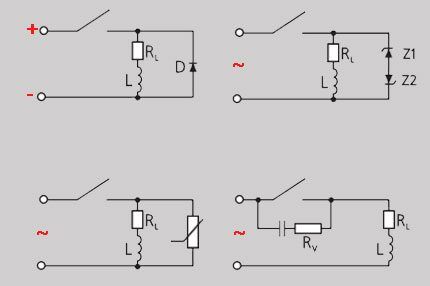

Reverse voltage protection techniques

A significant part of any electromechanical relay is the coil. This part is classified as a high inductance load because it is wire wound.

Any wire-wound coil has some impedance, consisting of inductance L and resistance R, thus forming a series circuit LR.

As current flows through the coil, an external magnetic field is created. When the current flow in the coil is stopped in the "off" mode, the magnetic flux increases (transformation theory) and a high reverse EMF (electromotive force) voltage is generated.

This induced reverse voltage value can be several times greater than the switching voltage.

Accordingly, there is a risk of damage to any semiconductor components located near the relay. For example, a bipolar or field effect transistor used to apply voltage to a relay coil.

One way to prevent damage to a transistor or any switching semiconductor device, including microcontrollers, is to connect a reverse biased diode to the relay coil circuit.

When the current flowing through the coil immediately after switching off generates an induced back EMF, this reverse voltage opens the reverse biased diode.

Through the semiconductor, the accumulated energy is dissipated, which prevents damage to the control semiconductor - transistor, thyristor, microcontroller.

The semiconductor often included in the coil circuit is also called:

- flywheel diode;

- bypass diode;

- reversed diode.

However, there is not much difference between the elements. They all perform one function. In addition to the use of reverse bias diodes, other devices are used to protect semiconductor components.

The same chains of RC dampers, metal-oxide varistors (MOVs), zener diodes.

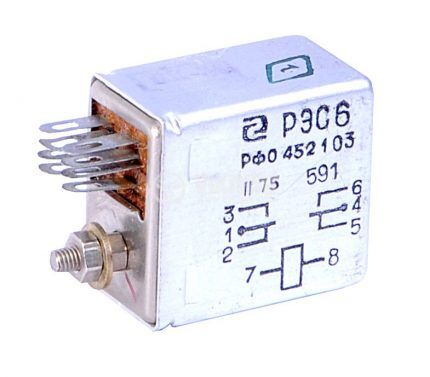

Marking of electromagnetic relay devices

Technical designations that carry partial information about the devices are usually indicated directly on the chassis of the electromagnetic switching device.

This designation looks like an abbreviation and a number set.

Example of case marking of electromechanical relays:

RES32 RF4.500.335-01

This entry is deciphered as follows: low-current electromagnetic relay, 32 series, corresponding to the design according to the RF passport 4.500.335-01.

However, such designations are rare. More often there are abbreviated versions without explicit indication of GOST:

RES32 335-01

Also, the date of manufacture and batch number are marked on the chassis (on the body) of the device. Detailed information is contained in the technical data sheet for the product. Each device or batch is supplied with a passport.

Conclusions and useful video on the topic

The video popularly explains how electromechanical switching electronics operate. The subtleties of designs, connection features and other details are clearly noted:

Electromechanical relays have been used as electronic components for quite some time. However, this type of switching devices can be considered obsolete. Mechanical devices are increasingly being replaced by more modern devices - purely electronic. One such example is solid state relays.

Have questions, found bugs, or have interesting facts on the topic that you can share with visitors to our site? Please leave your comments, ask questions, and share your experience in the contact block below the article.

Good afternoon. Can you tell me what methods exist to suppress interference from relay operation?

Good afternoon, Roma. The fight against interference is a separate story, practically not affected by the PUE.

The relay generates electromagnetic waves when the contacts are closed/opened. Propagating waves induce EMF in wires and metal structures through which they pass.Let me remind you that a triggered relay starts a chain of “events” that ends with the start-up of power equipment, starting currents, which are also generated by electromagnetic waves.

You can protect yourself and suppress interference of this nature by concentrating the relays in separate shields, remote from devices and equipment that the waves can harm. Panel casings must be grounded. Control cables and operational circuit cables that are at risk of interference must have a protective sheath, braid, or armor that is grounded. Power and control cables laid in buildings are carried apart.

Design organizations involved in power supply have departments that work on issues of electromagnetic compatibility of electrical networks, communication networks, automation, etc.

Attached is a screenshot of the PUE points related to interference and a list of GOSTs containing issues of combating interference.