Water-to-water heat pump: device, principle of operation, rules for arranging heating based on it

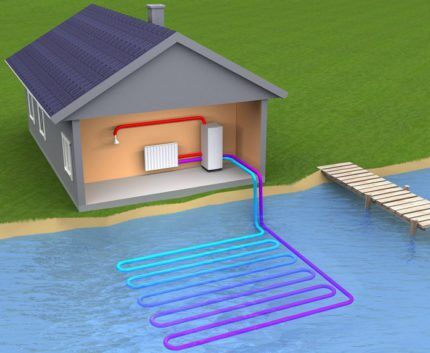

For heating and providing hot water to private homes, it is advisable to use a water-to-water heat pump powered by natural sources - groundwater, rivers, reservoirs, etc. The system is absolutely environmentally safe and does not require regular costs for consumables, which is why it is becoming increasingly in demand.

We will talk about options for a heat pump that uses eco-energy from water to transfer it to household heating systems. For inquisitive home craftsmen, we have described the operating principles of popular device options and construction technology. Here you will find out what equipment is required for the system to operate.

The content of the article:

Operating principle of a water-to-water heat pump

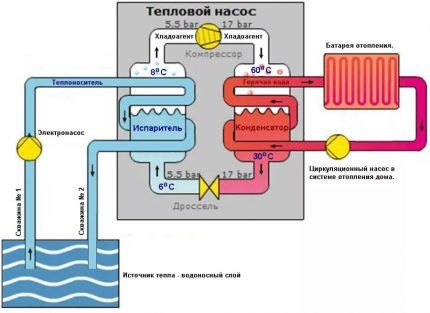

The heat pump embodies the principle of the Carnot cycle.It lies in the fact that a substance moving through a closed system and changing its state of aggregation from liquid to gaseous under the influence of chemical, physical or thermal factors releases and absorbs a huge amount of thermal energy.

The working substance is a thermal carrier - water from a well or reservoir.

Even in winter, natural springs at a certain depth maintain a positive temperature, so thermal energy can be extracted from them all year round. The only drawback of the installation is the high power consumption and the need to purchase additional equipment.

The main elements of a water-to-water heat pump:

- compressor;

- evaporator;

- capacitor;

- expansion induction valve;

- automatic system that monitors indicators;

- multiple lines of copper pipes;

- working substance (refrigerant).

Using a special pump, water flows through tubes from the source to the heating unit, after which it interacts with gas (freon), which boils at a temperature of +2-3 degrees. Freon absorbs some of the heat from the water and is sucked into the compressor, where its temperature rises during compression.

Next, the refrigerant enters the condenser, after which the hot substance heats the water to a given temperature (from +40 to +80 degrees), which is transported through the pipes of the heating system.

Cooled water enters the evaporator and then drains into the receiving well.After passing through the condenser, the refrigerant becomes liquid and collects at the bottom of the element, then returns through the throttle to its original location. Then the cycle repeats.

What to look for when arranging such heating?

There are a large number of different modifications of heat pumps designed for premises of any purpose and size, as well as operating in different conditions. The equipment is intended for heating houses with a total area of 50 to 150 square meters.

Guideline No. 1 - water hardness

The water quality of a well or reservoir plays an important role when choosing equipment. Not all models are able to work on hard water containing large amounts of manganese and iron.

A high concentration of these elements harms the system - corrosion forms on the pipes faster, which leads to a decrease in the efficiency of the equipment and its service life.

Therefore, before purchasing a heat pump, take water sample and analyze it for the presence of these and other trace elements - hydrogen sulfide, ammonia, chlorine, etc. Usually, if the temperature in the pond exceeds +13 degrees, then there is a high probability that there are a lot of iron and manganese ions in the water.

Thus, the water-to-water heat pump is selected taking into account the water hardness. There are systems whose elements are maximally protected from corrosion, but they are more expensive.

Guideline No. 2 - operating mode

The heat pump can be used as the sole heat source or in conjunction with other systems. Therefore, before choosing a model, it is important to determine in which mode the device will operate.

There are two types of system operation:

- Monovalent. The devices have great power and are suitable for heating a home.

- Bivalent. Less efficient devices complement the main heating equipment.

To build an autonomous system with a main water-to-water heating unit, you need a monovalent type.

Guideline No. 3 - pump power

Power is an important indicator when choosing a heat pump, since the performance of the system depends on it. The higher the power, the higher the efficiency of the equipment, but the higher the energy consumption.

If you choose a device with insufficient power, the efficiency of the system will decrease if the heat loss in the house exceeds the amount of energy supplied by the system.The heat pump can operate around the clock, but it will have no effect due to the drop in water temperature.

When the heat loss of a building is lower than the heat transfer of the system, the pump usually automatically starts for a few minutes, heats the water to the set temperature, and transports it through the system. Then it turns off until the temperature drops a few degrees. Then the cycle repeats.

Guideline No. 4 - functionality of a specific model

Heat pumps may have additional functions, these are:

- An automatic control system that will allow you to adjust the microclimate of the room to your taste. Control is usually carried out using a remote control.

- Water heating function for hot water supply.

- Soundproof housing.

- Possibility of connection to other heating systems, solar collectors, which will make the heating equipment completely autonomous.

The service life of water-to-water heat pumps usually exceeds 30 years.

Equally important when choosing equipment is the cost of installation and assembly.

Calculation of the required heat pump power

Before purchasing a system, it is important to first draw up a project and calculate the required equipment power. Productivity is calculated taking into account the actual needs for thermal energy. Heat consumption, heat loss at home and the presence or absence of a circuit are taken into account DHW.

Calculation algorithm:

- We calculate the total area of heated premises.

- We determine the required amount of energy for heating. The optimal indicator per 1 square meter is 0.07 kW.

- To heat a house of N square meters, you will need N*0.07 kW.

- For DHW an additional 15-20% is added to the resulting number, that is, N*0.07*0.85 or N*0.07*0.80.

This calculation will be optimal for rooms with ceilings not exceeding a height of 2.7 m. More accurate calculations will be made by specialists during the preparation of the project.

Preparatory work before operation

Preparation for assembly, connection and commissioning of a heat pump from the water-to-water series includes a number of standard steps, which we will get acquainted with later.

Choosing the optimal water source

It should be noted that not every open source or water well suitable for uninterrupted operation of the heat pump. Water quality plays an important role, but filters will help solve the problem of contamination.

It is permissible to use a reservoir or pond located within a radius of 100 meters from the building. If there is no such source, then the need to drill wells arises.

The behavior of an open source is more predictable than groundwater, so if possible, it is better to give preference to reservoirs.

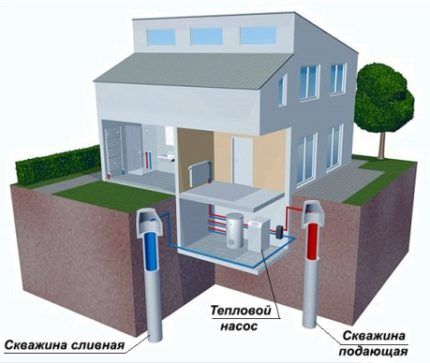

Installation of a thermal system using a well

To install a system using a heat pump, you will need two wells. One of the wells is usually called debit. It is into this that a special pump is immersed, with the help of which water is taken for subsequent processing in the system. The second well is a receiving well. Cooled water is drained into it.

The depth of the debit well should not exceed 50 meters. The deeper the water source is, the more powerful the pump required to supply it, which will increase the amount of energy consumed.

Construction of a debit well

Before starting to operate a debit well, it is important to find out how much water it can produce and how much liquid is needed to provide heat to the entire room. The higher the water temperature, the less it will be needed for heating.

It is important to pre-calculate the volume V, which must be pumped out of the well within an hour to heat the room. Let's say there is a pump whose heat output is equal to a certain number Q kW, and power consumption - to the number P kW. You will also need to find out the temperature of the groundwater (t1) and their temperature after temperature exchange (t2).

Then the formula for calculating the volume of the required amount of water per hour looks like this:

V = (Q-P)/(t1-t2).

It is analytically impossible to determine the ability of a debit well to produce the required volume of water, so it is tested. For 3 days, the pump uninterruptedly pumps water from the well. In this way, the receiving well is also checked for its ability to receive the required amount of water under high load.

It is important to understand that groundwater behaves unpredictably, so the amount of water from a debit well may become less over time. For example, in spring there are high tides, but in winter, on the contrary, the water decreases. If there is not enough water in the well, the system automatically turns off and heating does not occur.

Features of the receiving well

The receiving tube well is located downstream of the groundwater. It is analytically impossible to determine in which direction the water is moving. Therefore, in practice, an arbitrary well is selected as a debit well and launched into it submersible pump.

If the water level does not drop during operation of the system, then the choice was made correctly.If the level has dropped and the water temperature has dropped, then it is necessary to change the positions of the wells - move submersible pump into another hole.

The drain pipe into the receiving well must be immersed a few centimeters in water, without reaching the bottom. If you dump waste liquid from above, it will lead to waterlogging. The tube well may stop receiving water and become clogged.

The result threatens overflow, and in winter, possible icing. The best options for a receiving source are a river or pond. If these objects are not nearby, then there is a need to drill one or more receiving wells in order to insure against overflow.

It is impossible to find out whether a well will receive water either analytically or by testing. Practice shows that a drain well can uninterruptedly absorb water for many years, or it can completely fail in one season.

There are technologies that allow you to use one well as a debit and a receiving well, but this method is not effective - operation will be accompanied by difficulties, a decrease in water temperature, waterlogging and a number of other problems are possible.

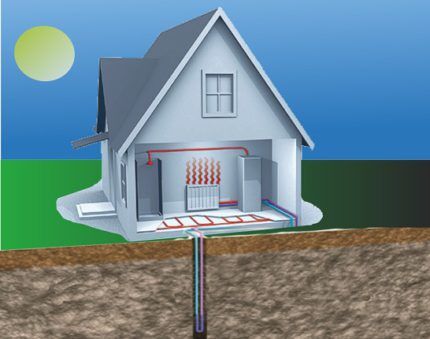

Design of a system using a reservoir

The selected pond must be deep enough so that the lower layers of water do not freeze during severe frosts. In the Southern regions, the optimal depth will be approximately 1 meter; in the Northern regions, a source with a depth of 3 meters will be required. Also, the pond must be stable - fluctuations in the water level and its decrease are unacceptable.

It is recommended to use models made of HDPE, characterized by durability and reliability. It is important to protect pipes from freezing by additionally insulating them, and from breakthroughs.

Preparing your home for a heat pump installation

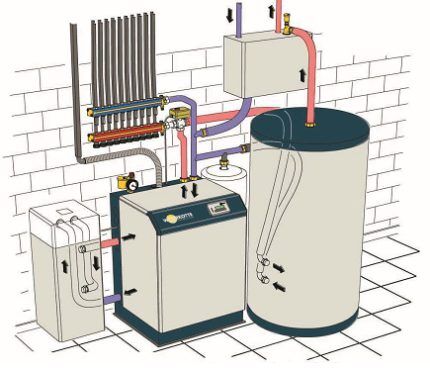

To interact with a water-to-water heat pump, the house must be equipped with a water-based heating system, presented in the form of pipes and radiator batteries. For better insulation, it is also permissible to install heating pipes in the floor and walls.

If the equipment will be used to supply hot water, then the house must have a collection system. To operate the pump, you need to be connected to an electrical network with unlimited power.

Without additional measures for thermal insulation of the house (insulation from outside, installation of double-chamber windows, etc.) operating a heat pump does not make sense.

Experts recommend additionally installing supply ventilation system with an air heating mechanism. The freon used in the equipment is harmful to humans. If in the system circuit there are microfractures, the gas will be released and thereby displace air from the room. The refrigerant can cause exacerbation of lung diseases and asthma attacks in humans.

A heat pump is heavy equipment, its weight can reach a ton (depending on the power and size), so in some cases its installation requires the construction of its own foundation, not connected to the foundation of the cottage.

Before installing the equipment, you need to take into account the permissible dimensions of the room and maintain the distance to the walls specified in the product passport.

Optional equipment

Choice additional equipment for heat pump - a responsible task, the solution of which largely determines the long-term service life of the heating system as a whole and the absence of problems in operation.

Submersible pump for wells and reservoirs

If the system uses a heat pump to supply hot water, then a device with low power can reduce the pressure in the taps. A powerful pump will solve this problem, but it consumes more energy. Minimum permissible power during operation FGP — 1 kW.

There are many different modifications submersible pumps The choice is made taking into account three criteria, these are:

- Liquid quantityused for pumping (the more water has to be transported, the higher the pump power must be).

- Well depth (the deeper the well, the greater the power of the equipment should be);

- Well diameter (traditionally, 4-inch shafts are preferred because they have the largest number of pumps, as opposed to 3-inch ones).

To determine the depth of the well, it is necessary to attach a weight to a rope and lower it into the shaft. The wet part of the rope will indicate the full depth of the well, the dry part will determine the distance from the beginning of the water to the surface.

Both universal pumps and equipment specifically designed for wells can be suitable for mines. If the mine was developed by professionals, then it is less clogged with sand, so you can safely use a universal pump.

Pumps designed specifically for wells are more expensive, but they cope well with sand and dirt and become less clogged. Universal ones are sensitive to high organic content; they must be regularly cleaned of dirt, as a result of which their service life is reduced.

Preference should be given to pumps with automation, since if the motor overheats, there is excessive blockage or there is no water in the well, they turn off on their own, as a result of which the motor does not overheat and fail.

Based on the operating principle, there are 2 types submersible pumps:

- Centrifugal.

- Vibrating.

For work in wells producing water in limestone, centrifugal deep models are preferable. They are sensitive to water with grains of sand and clay suspension.

If the heat pump will be connected to an open reservoir, it is better to use surface pumping equipment designed for pumping dirty water, or an inexpensive vibration device.

Heat pump intermediate heat exchanger

In heat pumps, the freon may not be cooled well enough during circulation, causing the compressor to overheat due to excessive discharge temperatures. Therefore, it is important to improve the cooling of the substance, thereby reducing the pressure in the circuits.

There is another problem that is common to all heat pumps - the refrigerant can mix with water vapor. If liquid enters the compressor, it may occur water hammer. In this case, repair or replacement of the part will be necessary. Also, water can get into the oil, and it is difficult to remove it from there.

All the problems described above are solved by installing an intermediate heat exchanger.There are three types of heat exchangers - open type, shell-and-tube and coil.

The open type modification neutralizes the liquid that gets into the freon during circulation, which minimizes the likelihood water hammer compressor. The device features high performance with minimal power consumption.

Properly selected pipes will neutralize the possibility of boiling liquid. In this case, the valve must have sufficient throughput so that liquid can penetrate into the device at a low pressure difference.

The shell-and-tube heat exchanger is presented in the form of a closed structure. Heat exchange occurs through the walls of the pipes, and the liquid and refrigerant in it do not mix, unlike open ones, which provides high pressure for the circulation of steam and air.

The coil heat exchanger is distinguished by the presence of a flow regulator that controls the flow of liquid freon. The size of the device directly depends on the power of the heat pump. It is necessary to select a product taking into account the functionality and the amount available. It is advisable to give preference to collapsible models.

Heat pump filters

Water from wells or reservoirs does not come in pure form. It may contain sand, dirt, various trace elements - iron, hydrogen sulfide, manganese, chlorine, ammonia, etc. Before entering the heat pump, the water must be filtered.

First of all, it is necessary to eliminate large substances - stones, sand, dirt, silt. To remove them from the water, installation is required hydrocyclone.

Next, it is important to install filters that eliminate iron, hydrogen sulfide, manganese, and ammonia. These microelements shorten the life of the equipment and expose it to corrosion.

You can use filters reverse osmosis, softeners, iron removers and their modifications. To provide drinking hot water, you should additionally equip it with carbon filters and a UV sterilizer that destroys bacteria and viruses.

Electric generator for backup power

Heat pumps operate from the electrical network, so if there is a power outage, the house will be left without heating. It is advisable to additionally purchase an electric generator that runs on flammable substances.

Features of operation of such a heat pump

Once a year, it is necessary to conduct an independent visual inspection of the pump components, follow the recommendations for maintenance - lubricate the parts in a timely manner, monitor the correct operation of the device when pumping water.

Some types of equipment require regular inspection (usually 1-2 times a year) by service center specialists. During the inspection, the following is revealed:

- engine oil leaks through cracks in the circuit;

- quality of fastenings and connections;

- pressure level in tanks and circuits;

- malfunctions in the power wiring.

The installation of a water-to-water heat pump should be carried out by trained specialists. The ineffectiveness of the system is most often due to its incorrect installation. Thermal equipment is suitable for use by both residents of the Southern and Northern regions.

Conclusions and useful video on the topic

The video will introduce you to the principle of operation and features of the device:

As a result, we can conclude that a water-to-water heat pump is considered an effective environmentally friendly equipment designed to heat houses up to 150 square meters. Arranging a larger area may require quite complex engineering surveys.

If you have any questions while reading the information provided, please ask them in the block below. We are waiting for your comments, questions on the topic, stories and photos about the construction of a mini-hydroelectric power station with your own hands. We are interested in your opinion.

Any heating system that requires electricity has one significant drawback. And the water-to-water heat pump is no exception. If there is a power outage, the system will “unfreeze”, that is, the water will turn into ice and burst the pipes. An electric generator will only help if there is someone to start it. Is there always someone in your house who knows how to use a generator?

Nikolay, you described the situation too critically. There should always be an uninterruptible power supply unit that will regulate the flow of energy and also power the system in cases of short outages. So you shouldn’t immediately scare people after one rash thought. That and even if you use an electric generator, I am sure that there are now many solutions for quick and easy starting.

Have you ever thought about antifreeze? in a closed loop?)))

Your calculation (per 1 square meter - 0.07 kW) scared away the dream of a heat pump.It is much cheaper to buy an electric boiler and get heat at the same cost (per 1 square meter - 0.1 kW), which is what we already have. Chasing savings of 0.03 kW is more expensive and reduces reliability (a lot of additional equipment and automation).

Vladimir, the calculation meant thermal power in the amount of 0.07 kW/m2, and not electrical power. Thermal power must be divided by a COP factor of 2-5 depending on a number of factors.

What is the minimum water temperature? The heat pump doesn't really heat, I can't figure it out. Maybe someone can advise?

I’ve had an air-to-water heat pump running for a year now, and even at -20 degrees below zero, its efficiency is better than a conventional electric boiler.

However, do not forget the main thing - this is a low-temperature heat source!

My heat pump works for warm walls and warm floors, and at 30 degrees the coolant in the house is 22-23 degrees. Since my family is happy with 20 degrees, I set the coolant temperature to 26-27 degrees, while the COP (conversion coefficient) does not fall below 2.5 even at a frost of -22. For reference, COP of a conventional electric boiler = 0.99 (no more).

If you have exclusively radiator heating, then the heat pump will be effective down to -5 (maximum up to -10) degrees, and at temperatures lower you will have to use a boiler.

Is it possible to use a water-to-water heat pump to heat up hot water, for example, from 700 C to 90-1100 C, while cooling a closed hot water circuit from 700 C to, for example, 20-100 C. Are there such refrigerants?

Thank you in advance for your response

Have you ever thought about antifreeze? in a closed loop?