How to make a wind generator with your own hands: device, operating principle + best homemade products

It is difficult not to notice how the stability of electricity supplies to suburban facilities differs from the provision of urban buildings and enterprises with electricity. Admit that you, as the owner of a private home or cottage, have more than once encountered interruptions, associated inconveniences and damage to equipment.

The listed negative situations, along with the consequences, will no longer complicate the lives of lovers of natural spaces. Moreover, with minimal labor and financial costs. To do this, you just need to make a wind power generator, which we describe in detail in the article.

We have described in detail the options for manufacturing a system that is useful in the household and eliminates energy dependence. According to our advice, an inexperienced home craftsman can build a wind generator with his own hands. This practical device will help to significantly reduce your daily expenses.

The content of the article:

Legality of installing a wind generator

Alternative energy sources are the dream of any summer resident or homeowner whose plot is located far from central networks.However, when we receive bills for electricity consumed in a city apartment and look at the increased tariffs, we realize that a wind generator created for domestic needs would not hurt us.

After reading this article, perhaps you will make your dream come true.

In order not to waste money, effort and time, let's decide: are there any external circumstances that will create obstacles for us during the operation of the wind generator?

To provide electricity for a summer house or small cottage, it is enough small wind power plant, the power of which will not exceed 1 kW. Such devices in Russia are equated to household products. Their installation does not require certificates, permits or any additional approvals.

There is no taxation on the production of electricity, which is spent on meeting one’s own household needs. Therefore, a low-power windmill can be safely installed, using it to generate free electricity, without paying any taxes to the state.

However, just in case, you should ask if there are any local regulations regarding individual power supply that could create obstacles in the installation and operation of this device.

Your neighbors may have claims if they experience inconvenience caused by the operation of the windmill. Don't forget that our rights end where other people's rights begin.

Therefore, when purchasing or making your own wind generator for home You need to pay serious attention to the following parameters:

- Mast height. When assembling a wind generator, you need to take into account the restrictions on the height of individual buildings that exist in a number of countries around the world, as well as the location of your own site. Please be aware that structures taller than 15 meters are prohibited near bridges, airports and tunnels.

- Noise from gearbox and blades. The parameters of the generated noise can be determined using a special device, and then the measurement results can be documented. It is important that they do not exceed established noise standards.

- On-air interference. Ideally, when creating a windmill, protection against TV interference should be provided where your device can cause such troubles.

- Environmental Services Claims. This organization can prevent you from operating the installation only if it interferes with the migration of migratory birds. But this is unlikely.

When creating and installing a device yourself, learn these points, and when purchasing a finished product, pay attention to the parameters that are in its passport. It’s better to protect yourself in advance than to be upset later.

The principle of operation of a wind turbine

A wind generator or wind power plant (WPP) is a device that is used to convert the kinetic energy of wind flow into mechanical energy. The resulting mechanical energy rotates the rotor and is converted into the electrical form we need.

Operating principle and device kinetic windmill are described in detail in the article, which we recommend reading.

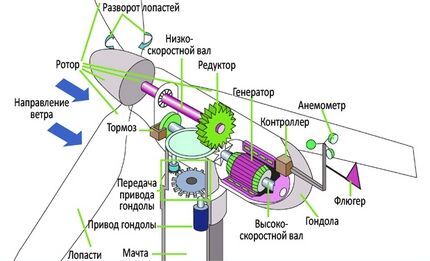

The wind turbine includes:

- blades forming a propeller,

- rotating turbine rotor,

- the generator axis and the generator itself,

- an inverter that converts alternating current into direct current, which is used to charge batteries,

- battery.

The essence of wind turbines is simple. As the rotor rotates, three-phase alternating current is generated, which then passes through the controller and charges the DC battery. The inverter then converts the current so that it can be consumed to power lights, radios, TVs, microwaves, and so on.

In general, the operating principle of a wind generator of any type and design is as follows: during the rotation process, three types of force effects occur on the blades: braking, impulse and lifting.

The last two forces overcome the braking force and set the flywheel in motion.On the stationary part of the generator, the rotor forms a magnetic field so that electric current flows through the wires.

Classification of types of energy generators

There are several criteria by which wind power plants are classified. How to choose the best device for a country property is described in detail in one of most popular articles on our website.

So, windmills differ in:

- number of blades in the propeller;

- blade manufacturing materials;

- the location of the axis of rotation relative to the surface of the earth;

- pitch feature of the screw.

There are models with one, two, three blades and multi-blades.

Products with a large number of blades begin to rotate even in light winds. They are usually used in work where the rotation process itself is more important than generating electricity. For example, to extract water from deep wells.

The blades can be sail or rigid. Sailing products are much cheaper than rigid ones, which are made from metal or fiberglass. But they have to be repaired very often: they are fragile.

Regarding the location of the axis of rotation relative to the earth's surface, there are vertical wind turbines and horizontal models. And in this case, each variety has its own advantages: vertical ones react more sensitively to every breath of wind, but horizontal ones are more powerful.

Wind generators are divided according to step characteristics into models with fixed and variable pitch. The variable pitch allows you to significantly increase the rotation speed, but this installation has a complex and massive design. Wind turbines with a fixed pitch are simpler and more reliable.

Wind-electric installation of rotor type

Let's figure out how to make a simple windmill with a vertical axis of rotation of the rotor type with your own hands. Such a model can easily meet the electricity needs of a garden house, various outbuildings, and also illuminate the local area and garden paths at night.

Our goal is to produce a wind turbine with a maximum power of 1.5 kW.

To do this we will need the following elements and materials:

- 12 V car generator;

- 12 V gel or acid battery;

- semi-hermetic switch of the “button” variety for 12 V;

- converter 700 W – 1500 W and 12V – 220V;

- a bucket, large-capacity pan or other capacious container made of stainless steel or aluminum;

- car charge or battery charging warning lamp relay;

- car voltmeter (you can use any one);

- bolts with nuts and washers;

- wires with a cross section of 4 square mm and 2.5 square mm;

- two clamps for securing the generator to the mast.

In the process of completing the work, we will need a grinder or metal scissors, a construction pencil or marker, a tape measure, wire cutters, a drill, a drill, keys and a screwdriver.

You can also assemble a controller for a system that generates electricity yourself. With rules and manufacturing schemes wind turbine controller will familiarize you with the article, the contents of which we advise you to familiarize yourself with.

Starting stage of installation manufacturing

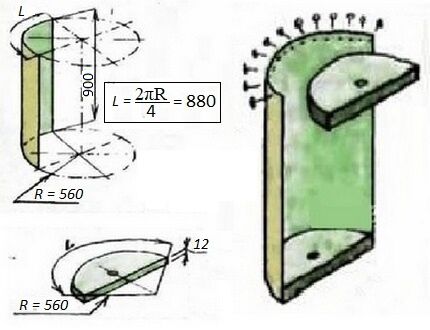

We start making a homemade windmill by taking a large cylindrical metal container. Usually, old boiling water, a bucket or pan is used for this purpose. This will be the basis for our future wind turbines.

Using a tape measure and a construction pencil (marker), apply markings: divide our container into four equal parts.

The metal will have to be cut. For this you can use a grinder. It is not used for cutting containers made of galvanized steel or painted sheet metal, because this type of metal will certainly overheat. For such cases, it is better to use scissors. We cut out the blades, but do not cut them all the way through.

Options, diagrams and recommendations for the manufacture of various models blades for wind generator you will find in our recommended article.

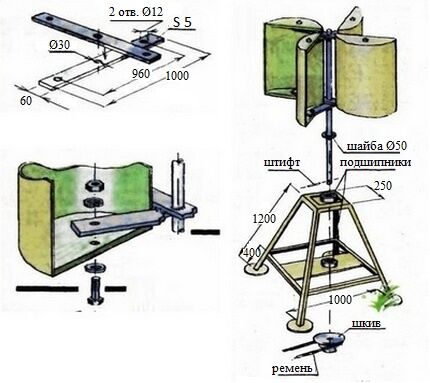

Simultaneously with the continuation of work on the tank, we will remodel the generator pulley. In the bottom of the former pan and in the pulley you need to mark and drill holes for the bolts. The work at this stage must be treated with the utmost care: all holes must be located symmetrically so that no imbalance occurs during the rotation of the installation.

We bend the blades so that they do not stick out too much. When we perform this part of the work, we be sure to take into account which direction the generator will rotate.

Usually the direction of its rotation is clockwise. The bending angle of the blades affects the area of influence of air flows and the speed of rotation of the propeller.

Now you need to attach a bucket with blades prepared for work to the pulley. We install the generator on the mast, securing it with clamps. All that remains is to connect the wires and assemble the circuit. Be prepared to write down the wiring diagram, wire colors, and pin markings. You will certainly need it later. We fix the wires on the mast of the device.

To connect the battery, you need to use wires with a cross section of 4 mm². It is enough to take a segment of 1 meter in length. That's enough.

And in order to connect a load to the network, which includes, for example, lighting and electrical devices, wires with a cross-section of 2.5 mm² are sufficient. Install the inverter (converter). For this you will also need a 4 mm² wire.

Advantages and disadvantages of the rotary windmill model

If you did everything carefully and consistently, then this wind generator will work successfully. In this case, no problems will arise during its operation.

If you use a 1000 W converter and a 75A battery, this installation will provide electricity for video surveillance devices, security alarms and even street lighting.

The advantages of this model are:

- economical;

- elements can be easily replaced with new ones or repaired;

- no special conditions are required for operation;

- reliable in operation;

- provides complete acoustic comfort.

There are also disadvantages, but not too many: the performance of this device is not very high, and it has a significant dependence on sudden gusts of wind. Air currents can simply disrupt an improvised propeller.

In order to accurately select the model of wind generator of the required power before starting work, we advise make a calculation according to the formulas given in the recommended article.

Assembly of an axial wind turbine on neodymium magnets

Since neodymium magnets appeared in Russia relatively recently, axial wind generators with iron-free stators began to be made not so long ago.

The appearance of magnets caused a rush of demand, but gradually the market became saturated, and the cost of this product began to decline. It became available to craftsmen, who immediately adapted it to their various needs.

If you have a hub from an old car with brake discs, then we will take it as the basis for the future axial generator.

It is assumed that this part is not new, but has already been used. In this case, it is necessary to disassemble it, check and lubricate the bearings, thoroughly clean away sedimentary deposits and all rust. Don't forget to paint the finished generator.

Distributing and securing magnets

Neodymium magnets must be glued to the rotor disks. For our work, we will take 20 magnets 25x8mm.

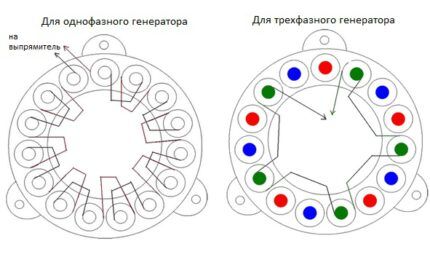

Of course, you can use a different number of poles, but the following rules must be observed: the number of magnets and poles in a single-phase generator must match, but if we are talking about a three-phase model, then the ratio of poles to coils should be 2/3 or 4/3 .

When placing magnets, the poles alternate. It's important not to make a mistake. If you are not sure that you will place the elements correctly, make a hint template or apply the sectors directly to the disk itself.

If you have a choice, buy rectangular rather than round magnets. In rectangular models, the magnetic field is concentrated along the entire length, and in round ones - in the center.

Opposing magnets must have different poles. You won't confuse anything if you use a marker to mark them with minus or plus signs. To determine the poles, take magnets and bring them close to each other.

If the surfaces attract, put a plus on them, if they repel, then mark them with minuses. When placing magnets on disks, alternate poles.

To securely fasten the magnet, you need to use high-quality and as strong glue as possible.

To enhance the reliability of fixation, you can use epoxy resin. It should be diluted as indicated in the instructions and filled with it on the disc. The resin should cover the entire disc, but not run off it. You can prevent the possibility of dripping if you wrap the disk with tape or make temporary plasticine barriers made of a polymer strip around its perimeter.

Single-phase and three-phase generators

If we compare single-phase and three-phase stators, the latter will be better. A single-phase generator vibrates when loaded. The cause of vibration is the difference in the amplitude of the current, which arises due to its inconsistent output at a time.

The three-phase model does not have such a disadvantage. It is characterized by constant power due to phases that compensate each other: when the current increases in one, it decreases in the other.

According to the testing results, the output of the three-phase model is almost 50% greater than that of the single-phase model. Another advantage of this model is that in the absence of unnecessary vibration, acoustic comfort increases when the device operates under load.

That is, a three-phase generator practically does not hum during its operation. When vibration is reduced, the service life of the device logically increases.

Rules for winding a reel

If you ask a specialist, he will say that before winding the coils, you need to perform a careful calculation. A practitioner in this matter will rely on his intuition.

We chose a generator that was not very fast. Our charging procedure for a twelve-volt battery should begin at 100-150 rpm. Such initial data require that the total number of turns of all coils be 1000-1200 pieces. We just have to divide this figure between all the coils and determine how many turns there will be on each.

A windmill at low speeds can be more powerful if the number of poles increases. The frequency of current oscillations in the coils will increase. If you use a larger cross-sectional wire to wind the coils, the resistance will decrease and the current will increase. Don't lose sight of the fact that higher voltage can "eat up" current due to winding resistance.

The winding process can be made easier and more efficient if you use a special machine for this purpose.

The performance characteristics of homemade generators are greatly influenced by the thickness and number of magnets that are located on the disks. The total total power can be calculated by winding one coil and then spinning it in a generator. The future power of the generator is determined by measuring the voltage at specific speeds without load.

Let's give an example. With a resistance of 3 ohms and 200 rpm, 30 volts comes out.If you subtract 12 volts of battery voltage from this result, you get 18 volts. Divide this result by 3 ohms and get 6 amperes. The volume is 6 amperes and will go to the battery. Of course, in the calculation we did not take into account the losses in the wires and on the diode bridge: the actual result will be less than the calculated one.

Usually the coils are made round. But, if you stretch them out a little, you will get more copper in the sector and the turns will be straighter. If you compare the size of the magnet and the diameter of the inner hole of the coils, then they should match each other or the size of the magnet may be slightly smaller.

The thickness of the stator we make must be correctly related to the thickness of the magnets. If the stator is made larger by increasing the number of turns in the coils, the interdisk space will increase and the magnetic flux will decrease. The result may turn out to be this: the same voltage is generated, but due to the increased resistance of the coils, we will receive less current.

Plywood is used to make the stator mold. However, sectors for coils can be marked on paper using plasticine as borders.

If you place fiberglass fabric on top of the coils at the bottom of the mold, the strength of the product will increase. Before applying epoxy resin, you need to lubricate the mold with Vaseline or wax, then the resin will not stick to the mold. Some people use tape or film instead of lubricant.

The coils are fixed to each other. In this case, the ends of the phases are brought out. The six wires brought out should be connected in a star or triangle. By rotating the assembled generator by hand, it is tested.If the voltage is 40 V, then the current will be approximately 10 amperes.

Final assembly of the device

The length of the finished mast should be approximately 6-12 meters. With such parameters, its base must be concreted. The windmill itself will be fixed to the top of the mast.

In order to be able to reach it in the event of a breakdown, it is necessary to provide a special mount at the base of the mast, which will allow the pipe to be raised and lowered using a hand winch.

To make a screw, you can use a PVC pipe with a diameter of 160 mm. It will be used to cut a two-meter propeller consisting of six blades from its surface. It is better to develop the shape of the blades yourself experimentally. The goal is to increase torque at low rpm.

The propeller should be protected from excessive wind. To solve this problem, use a folding tail. The generated energy is stored in batteries.

We have provided our readers with two options for self-made 220 V wind generators, which enjoy increased attention not only from country property owners, but also from ordinary summer residents.

Both wind turbine models are effective in their own way. These devices can demonstrate especially good results in steppe areas with frequent and strong winds. They are effective enough to be used in an organization alternative home heating and in the supply of electricity. And they are not so difficult to build with your own hands.

Conclusions and useful video on the topic

This video shows an example of a wind turbine with a horizontal axis of rotation. The author of the device explains in detail the nuances of the design of a do-it-yourself installation, draws the audience's attention to mistakes that can be made in the process of making a wind generator yourself, and gives practical advice.

Please note that getting to the device, raised to a decent height, is not so easy. Reinstalling such a wind turbine will most likely be problematic. Therefore, the folding design of the mast in this case will not be superfluous at all.

This video shows a rotary windmill with a vertical axis of rotation. This installation is located low, made in an original way and is highly sensitive: even a slight wind sets the blades of the device in motion.

If you live in an area where winds are not considered a rare phenomenon, using this particular source of alternative energy may be the most effective for you. The above examples of self-made windmills prove that making them with your own hands is not so difficult. Wind energy is a publicly accessible and renewable resource that can and should be used.

We invite site visitors interested in the topic of the article to express their opinions in the comments and ask questions that arose while reading the material.

A very interesting idea if you want to do something interesting and fundamental with your own hands. Unfortunately, in our realities, the practical value is rather dubious. In other countries, this is beneficial, since electricity prices there are noticeably higher and it is profitable for them to come up with alternative sources.With us, it’s profitable to do this only if you have free access to the parts. Although, of course, I cannot deny that such technologies are the future.

I don't think you're right. Having a free source of energy at hand, you could do things that you wouldn’t do with paid energy, because it won’t pay off—heating a barn with livestock for the winter, lighting a greenhouse. You can organize a fountain or pond. Heater in winter in every room, street lighting, heated floors. All this requires energy.

It is a very tempting idea to provide yourself with an independent source of energy using a wind generator. I myself was once captivated by this idea and dug through a lot of literature. But there is one very significant drawback. All wind generators are very noisy installations. If you use it in a rural area or a cottage village, the noise level produced by the installation will exceed all norms permissible for a populated area.

For handy craftsmen, this is probably an interesting experiment - to assemble a wind generator with your own hands. But as a practical person, I have several questions. Firstly, the cost of the idea, not everyone has an engine from an old car, it will also need to be purchased, like other parts. Plus the time it takes to assemble. Secondly, in Russia, electricity is quite cheap and there is no certainty that this idea is advisable at all... I think this is more entertainment for enthusiasts than a really useful and practical idea. But it's interesting, of course.

Engine from an old car?

Not an engine, but a generator from an old car (this seems to be a significant difference...).

We tried to make a wind generator with a neighbor and install it in our dacha. Just with blades from paint barrels. They wanted to generate electricity for their own needs. But so far everything has come down to the search for a normal generator and stabilizer. We found an idea with neodymium magnets on your website - we’re thinking of trying it. Unfortunately, this post does not cover the topic of voltage stabilization at all - and this, as far as I understand, is of fundamental importance.

Here many people say that email. Energy is cheap in Russia, and there is no point in bothering. It’s immediately clear that these people don’t know what it’s like to live in the wilderness with a high probability of power outage. energy. For example, in my bearish corner, where there are not even roads, not to mention power lines, where electricity is provided by a local diesel power station, where any bad weather threatens to short circuit the old, Soviet-era local electricity. lines, breakdowns of the diesel engines themselves, the human factor (a neighbor’s home sawmill on a network without transformers - God forbid you have such electricity :)) And then there’s autonomy... I understand that many people don’t have to see this, but I wouldn’t call autonomy an entertainment for enthusiasts.

A generator from disassembly costs 500-1000 rubles...

Take any 12V motor (for example, a car fan), a working car battery, a 12v/220v voltage converter, preferably 6000w (can be ordered from China), and 4kW. power is guaranteed to you. And the propeller can be taken from an old home fan.

Denis, my car battery is not working - is it possible to take a battery from an uninterruptible power supply instead? And also, is it possible to take a cooler with a processor propeller, and will they provide 4 kW of power?

Either I don't understand something, or are you really going to use a CPU cooler in a wind generator? How can you expect to get 4 kW of power from it if this part is designed to cool a PC processor that does not consume that much power per hour in total? A battery from a UPS will not suit you, as it has a completely different principle of operation.

As for using a car battery, it must be working, at least reconditioned. The author of the comment above recommends using a propeller from a household fan, but not from a PC cooler. However, a power of 4 kW cannot be achieved with such a propeller, even at high wind speeds; longer blades are needed here.

“If surfaces attract, put a plus on them, if they repel, then mark them with minuses.” What a joke! The author definitely smoked his 4th grade natural history lessons behind the garages, so he lives to this day in blissful ignorance that magnets are attracted exclusively by opposite ones, i.e. opposite poles, but repel like poles. Against this background, all the author’s writings are not worth the time spent reading it. And it very much seems that the “specialist” checking this nonsense was smoking nearby.

Hello! I watched your videos of wind generators.Question: if the generator rotates in the wind, is the cable that comes from it (the generator) wound around the mast? Please tell me.

I understand the essence of your question. Here you need to carefully think through everything during the design process in order to avoid such obvious, but nevertheless difficult to solve problems. This concerns the installation of wind generators on your own; factory solutions use internal cable routing (inside the mast). With the help of special adapters, hinges and fasteners, it is possible to organize the connection in such a way that the cable will not wrap around the mast in any way.

I'll say it again! The only correct solution is to lay the cable inside the mast! Look at the pictures, there is simply nothing to wrap around the mast, no matter how tall it is!

ordinary generator brushes and slip rings will solve the problem with cable winding

Cool. About the bucket and the generator - this is just a masterpiece! Did the author himself assemble a windmill with at least 100 watts? The article contains one theory and photos of other people's windmills.

I completely agree with the last comment, plus the unreasonable attitude towards the UPS battery, now car batteries have exactly the same design, the only difference is in power, car ones are more powerful, but there are UPSs that use batteries of more than 20A/h. Many things in the article are described vaguely, Apparently the author is not an expert in this field and has no personal experience.