How to tap into an existing water supply system under pressure

Do you want to organize water supply for a country house by connecting it to the existing central highway? Automatic water supply will greatly simplify the life of household members, right? But to implement your plan, there is no way to shut off the water in the main pipeline and you need to tap into the water supply under pressure?

We will tell you how to make the connection in practice, avoiding disconnecting consumers powered from the main line - the article discusses the process of making the connection, taking into account all legal requirements. The material is supplied with thematic photographs and useful video recommendations.

Carefully studying the stages of connecting your household to the central water supply will help you avoid fines for violating existing standards when unauthorizedly tapping into a pipeline. If you wish, you can also save money by doing some of the excavation work yourself.

The content of the article:

Permission to perform work

Work on tapping into water mains, either through welding or without it, cannot be carried out without obtaining the appropriate permits.

Illegal tapping traditionally ends with the owner being brought to financial and administrative liability.

The site plan can be obtained from the Federal Center for Registration of Land Ownership, and technical specifications from the central department of the water utility.

The technical conditions for connection will indicate:

- connection location;

- diameter of the main pipeline;

- data required for insertion.

In addition to the local structure of Vodokanal, the development of design and estimate documentation is carried out by specialized design organizations that have the appropriate license.

You can order design and estimate documentation from them for implementation highway tie-ins centralized water supply network. Perhaps their services will be cheaper, but it is possible that problems may arise with the approval of the project development by Vodokanal.

Then the documentation for the insert should be registered at the local SES office. Simultaneously with submitting the collected package of documents to the SES branch for registration, you are required to leave an application for the issuance of a conclusion on the need to connect to the water supply.

According to generally accepted standards, the insertion of pipes under pressure and the installation of metering devices must be carried out by qualified specialists with the appropriate approval. It is prohibited to arbitrarily perform such work on your own.

You can save money by making your own efforts to connect only on excavation work during the development and backfilling of the trench.

Conditions under which insertion cannot be carried out:

- if the main network pipeline has a large diameter;

- if the land ownership is not connected to the central sewer system;

- if the tie-in is intended to bypass metering devices.

Even if all permits are available, pipe insertion into an existing network should only be carried out by qualified specialists.

These include: excavation work (digging and backfilling of trenches), delivery of material and other types of auxiliary work that are not directly related to the insertion procedure.

Of course, no one can prevent the owner from doing the tie-in himself. Therefore, the article describes in detail the sequence of actions.

Construction of a well for the construction of a site

To simplify insertion into an existing water supply system, it is convenient to use manhole. The diameter of the structure should be about 70 cm. This space is enough to place shut-off fittings (in the form of a valve or gate valve), as well as perform all the necessary manipulations for insertion.

In the future, during the period of operation, the presence of such a structure will facilitate the work of repairing the home water supply system.

To construct a well, a new pit of the appropriate size is dug. The bottom of the pit is covered with a gravel “pillow”, forming a layer 10 cm high.

To make a reliable foundation, sections of roofing material are spread over the leveled gravel fill and a concrete screed 10 cm thick is poured. When creating the fill, concrete grades M150 and M200 are used.

After three to four weeks, when the concrete has acquired the necessary strength, a shaft is erected above the slab. To do this, the walls of the pit are lined with bricks, cement blocks or reinforced concrete rings. The neck of the structure must reach zero level.

If the well is to be installed in an area where the groundwater level rises to one meter during the flood period, it is necessary to construct a waterproof structure.

It is most convenient to purchase a ready-made plastic container for this purpose. From below it is anchored to a concrete slab, from above this structure is covered with a cast slab equipped with a hole for installing a hatch.

Insertion depending on the type of pipes

Since main water pipelines are assembled from polymer, galvanized and cast iron pipes, we will consider all the available options for arranging the insert.

No. 1 - working with polymer reinforcement

When dealing with polymer reinforcement, insertion technology is carried out in the following sequence. Having decided on the place where the pipe will be inserted, prepare the area. To do this, a flat area in the puncture area of the pipe body is thoroughly cleaned using sandpaper to remove any accumulations of rust and paint residues.

A clamp equipped with terminals for connecting a welding machine is fixed to the prepared place using bolts. After installing the unit and connecting the contacts of the welding machine to the terminals, voltage is applied to it.

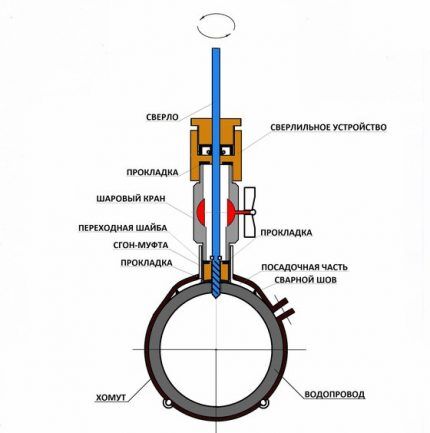

When installing an electric-welded collapsible clamp on a polymer pipe, the structure is first disconnected into a vertical pipe with a valve, through the cavity of which the drilling nozzle is buried, and direct-flow pipes.

At the other end of the lining, in the area where the drill will be buried, a valve with a sleeve is mounted. Drilling equipment is attached to it, after which a hole is carefully made in the line using a regular drill.

The drill must be inserted only through the shut-off valve in order to block the flow of water after “breaking through” the pipe body and freely remove the cutting tool. To ensure the tightness of the joint when drilling, use a special nozzle.

The new section of the input pipe is connected to the flange located on the valve. The clamp is mounted above the insertion point, and then by heating the spiral of the welding machine is soldered to the pipe body. The result is a high-strength, sealed connection.

No. 2 - connecting cast iron pipes

If there is a cast iron pipe, which is much harder than its polymer analogues, the procedure is performed in the following sequence:

- At the site of the future “breakdown”, clean the area from rust and remove the layer of hot cast iron with a grinder.

- Install the saddle on the area, not forgetting to lay the rubber seals.

- A shut-off valve is attached to the flange outlet, into the cavity of which a crown is inserted.

- They begin to drill the pipe, not forgetting to cool the cut site and replace dull bits in a timely manner. You need to drill in several stages: first with a small-diameter drill, and then with a slightly larger one.

- After removing the crown from the valve, close the valve, cutting off the water supply from the pipe.

- Restore anti-corrosion coating and insulation.

To create holes in the cavity of cast iron pipes, crowns equipped with carbide cutting plates or drills with feather sharpening are used. When working with them, it is important to prevent overheating of the tool by periodically wetting the cutting parts with water.

To protect the power tool from water entering when the cutting part is removed from the hole, a protective screen is constructed from thick cardboard or rubber. It is placed between the body and the cartridge.

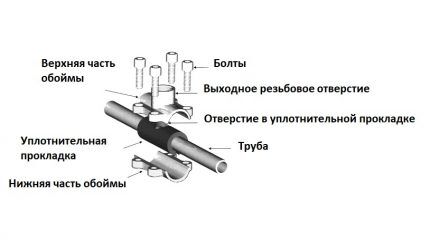

When using a saddle clamp to insert into a metal pipeline, rubber seals are used to ensure a tight fit to the surface.

A special machine can be additionally attached to such a device, the main elements of which are:

- locking bolt;

- handle with ratchet;

- flush tap;

- shaft with drill.

All structural elements are enclosed in a metal case. The presence of a guide coupling makes it possible to simplify the drilling process, in which the drill can be conveniently positioned in any direction.

No. 3 - features of working with steel pipes

Steel pipes are not inferior in ring rigidity to cast iron fittings. But steel is a more ductile iron-carbon alloy. Therefore, the insertion can be carried out by implementing a different technology, in which the joining method resembles that used when installing polymer pipes.

The technology of tapping into a steel pipeline includes a number of main stages:

- The area to be cut is excavated and cleaned of rust.

- A threaded or flanged pipe is mounted onto the pipe section by welding.

- The seams are welded.

- Check the seams for leaks.

- A flanged or threaded valve is fixed to the nozzle.

- The main pipe is drilled through the valve.

- A branch of the external water supply is installed behind the mounted valve.

Ideally, the pipe should be made of “main” fittings. But it is also possible to use any other type of rolled pipe, the basis for which is structural steel.

This “trick” will help to clearly determine the tightness of the seams: they are coated with kerosene from the inside, and outlined with chalk contours from the outside. Defects in the tightness of the joint will be indicated by oil stains that appear on the outside of the structure.

The specifics of inserting into a plastic pipe when assembling a water supply system are described in detail in another popular article our site.

Main stages of the procedure

The choice of insertion method depends on the pipe material, operating pressure in the system and its operating conditions. It can be performed at an angle of 45 and 90 degrees, positioned upward or to the side.

Step #1 - determining the insertion area

Before you start cutting into the water supply system, it is necessary to clearly determine the location of the route. The central highway should be located in a straight line.

For mid-latitude regions, this figure varies in the range of 1.2-1.5 meters.

At this stage, it is also necessary to determine what other communications “lie” within the site, so as not to accidentally damage them during the excavation and installation process.

Step #2 - selecting the necessary materials

For connection, pipelines made of polyethylene, cast iron or galvanized steel with a diameter of 50 mm and above are used. Work on highways with pipelines made of polyethylene excludes the use of electric and gas welding.

When working with cast iron, it is worth considering that it is a rather fragile material. Therefore, the pressure on the tool during operation should be minimal, and drilling should be performed at low speeds.

When choosing pipes for tapping, it should be taken into account that the diameter of the outlet pipe should not exceed the size of the one in which the hole is made. To connect to a plastic pipeline, the pressure of which is about 1.6 MPa, saddle clamps are used.

The devices are equipped with a heating coil and a cutter necessary to create a hole. The presence of a barcode on the body of the part allows you to set welding parameters with the required accuracy.

To make a tie-in without turning off the water supply on pipes made of asbestos-cement, steel or cast iron, use a saddle or saddle clamp. It consists of two parts and is equipped with bolts, thanks to which it tightly compresses the pipe on both sides. The device is attached to the pipeline using a bracket.

Recently, clamps are often used, the modules of which are equipped with a cutter and built-in valves. They are used for inserting pipelines with a pressure within 16 bar. Such devices are equipped with couplings and allow insertion by welding.

The main advantage of these clamps is their resistance to corrosion, thanks to which they can last more than half a century. Craftsmen often use drilling clamps to insert pipes under pressure. They are sold complete with attachments and swivel connectors.

There are several types of drilling clamps on sale that can be installed on pipes with a diameter of 80 to 300 mm.

You also need to prepare the following tools:

- bayonet and shovel;

- hammer drill with drill;

- cutter device;

- crown;

- Bulgarian;

- a piece of sandpaper.

When choosing a drill diameter, they are guided by the rule of equality of the size of the tool and the internal cross-section of the pipe being cut into.

Step #3 - excavation work

To expose the highway, they dig a pit. It can be dug by hand or using an excavator. But even when performing excavation work using mechanization, as soon as the metal strip laid on top of the highway is exposed, further manipulations should be performed manually.

Having exposed a section of pipe, they begin to dig a trench in the direction of the house. It is laid below the freezing level of the soil.

Any manipulations with a pipeline under pressure require strict adherence to safety precautions and strict implementation of all stages of the operation.

Step #4 - diverting from the main line

Using one of the methods described above, a connection is made into the existing water supply system under pressure. At the final stage, the pipe of the external branch of the water supply system is laid in a trench and connected to the shut-off valve using a crimp coupling.

When diverting the water supply line from the main, the beginning new water supply will be located on the clamp valve, and the end - on the water flow meter. The meter, the main purpose of which is to record the volume of incoming water, is positioned so that it is located between the shut-off valves.

To protect the meter from reverse flow of liquid, it is necessary to install a check valve.

If the tap into the water supply involves passing the input through the wall, then during installation a gap should be provided in the structure - a space of 0.2 meters in size. After installation is completed, this space is sealed with waterproof seals or resin strands. To disguise the formed seals, they are covered with a cement finish.

Step #5 - adjusting and testing the system

The correct alignment and connection of all system elements is checked by testing. To do this, pressure is applied to the new pipeline line, and the air accumulated in the system is released through a tap located at the other end of the pipe.

Having made sure that the water supply is tight, all that remains is to bury a trench laid from the point of connection to the house.

Conclusions and useful video on the topic

Video #1. Tips from a pressure tapping specialist:

Video #2. Operating principle of the tapping device:

Video #3. Consequences of poor installation:

Pressure tapping operations must be carried out taking into account all the listed recommendations and rules. If the conditions are not met, there is a high probability of violating the integrity of the system, which will reduce all efforts to “no” and lead to disastrous consequences.

Would you like to share useful information about tapping into an existing water pipeline? Do you have any questions about the topic of the article, or have you found controversial issues in the material? Please leave comments in the block below.

I have a problem - in the kitchen of an old house, a section of pipe rotted away due to rust, and a leak formed, which I eventually plugged. In this article I wanted to find the answer to the question - how to cut into an old, rusty water pipe, but only in a different place, and restore the water supply to the house? How to ensure the tightness of the tie-in on a rusty section of an old iron pipe, and what clamps can be used to do this?

Hello. In your case, there is no point in cutting into an old pipe, since it is very dilapidated, as you yourself wrote about. You cannot do without turning off the water; you will need to replace the damaged section of the water supply.

Here you can see for yourself what will be easier for you:

- cut off the dilapidated section with a hacksaw or gas torch, then cut the thread and connect;

- cut off the damaged area using the same methods and connect it by welding.

After this, the insertion is very simple. In your case, with a pipe that is damaged by corrosion, tapping will be dangerous and leaks may occur in the future.

The article describes insertion methods in detail.If the question is about the very poor condition of the pipes, then it is better to replace them initially. No amount of patches will help such wear and tear.

Although this does not happen often, when tapping without shutting off, in any case, you cannot do without a saddle clamp. Otherwise, you can arrange such a breakthrough! The water utility itself made a similar connection for us (it was impossible to turn off the main system). Well, but everything is according to the rules and officially: they made a tap with a tap, and you can handle the pipe supply to the house yourself before connecting to the centralized network.