Choosing a high-quality plug for a profile pipe - main characteristics

Profile pipes that are hollow inside require protection from corrosion, dust, dirt, and debris. Plastic plugs are used for this.In addition, you cannot do without them when repairing or replacing sewer, gas, and water pipes. Therefore, those who are planning repair work or laying a highway should know what kinds Such devices exist, how to choose them correctly.

The content of the article:

Where is it used?

A profile pipe is a hollow structure. To increase its service life and decorativeness, plastic plugs are used. The scope of their application is large.

This is where a plastic plug for a profile pipe is used:

- Blocking the ends of pipelines during repairs or for the entire period of operation.

- For the production of industrial products exposed to high pressure - tanks, pneumatic, hydraulic tanks, etc.

- In furniture production to improve the appearance of objects, as well as protect the floor and other surfaces from damage by the sharp edges of profile pipes.

- Protection of profile structures from penetration of water, dirt, dust during production, leading to their damage.

- Sealing posts used to construct a fence.

The restrictive plug gives the product a finished look. Often the cut of a profile pipe has uneven edges, nicks, and other defects. A special protective cap hides them underneath, increasing their aesthetic appeal.

Characteristics

Plastic plugs have the following properties:

- frost resistance;

- heat resistance;

- resistance to pressure, chemicals;

- moisture resistance;

- tightness.

Such qualities allow them to be used in different conditions - indoors and outdoors, as decoration, in industrial, chemical and other industries. Such devices are often equipped with stiffening ribs that securely fix them inside the profile pipe and prevent them from falling out.

Depending on the shape of the pipe, restrictive plugs can have different sizes, appearance, shape, and color, which makes selection easier and eliminates the need for painting. However, with inept and careless handling, the plastic fails, bursts, and is scratched, so it must be handled carefully. In addition, it is worth choosing products from high-quality polymers.

Types of stubs

Plastic plugs are divided according to purpose:

- Oil and petrol resistant. They are used in the automotive industry and mechanical engineering. They are required for additional Kevlar reinforcement.

- Multi-size, high-temperature, and also having a standard diameter. All these characteristics are demonstrated by pneumatic plugs. They are installed in large-diameter profile pipes, as well as where the working and ambient temperatures are high.

- Bypass. They are used for leak testing in profile pipes, and they can also be used to change the system sewer and drains, bypassing the defective area and redirecting the flow of liquid.

- Mechanical. They can be not only plastic, but steel and aluminum.

- Installed remotely. Often such devices are installed in the sewer system in order to block its use by debtors who ignore payment for housing and communal services.

- With standard and non-standard sections.

- Plug fittings used in profile pipes with pressure from 10 to 25 atmospheres.

- Having increased chemical and other resistance.

Types of plastic plugs for profile pipes depending on the design:

- Threaded. This device is screwed into a profile pipe.

- Pneumatic. This type of plastic cap is installed under pressure through application.

- Elliptical plugs. They are mainly made of metal and installed using a welding machine.

- Cap-shaped. The simplest, easy to put on/take off.

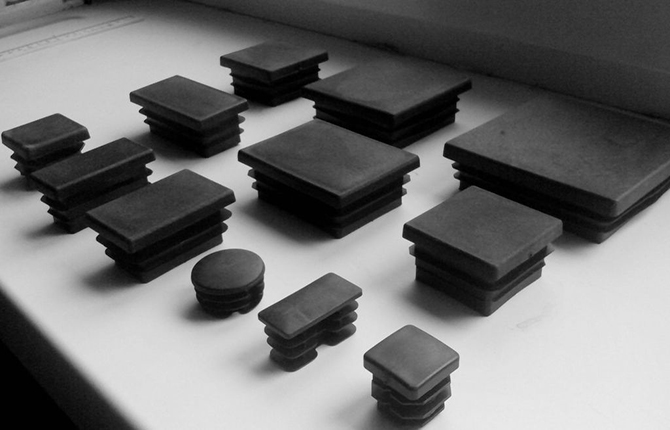

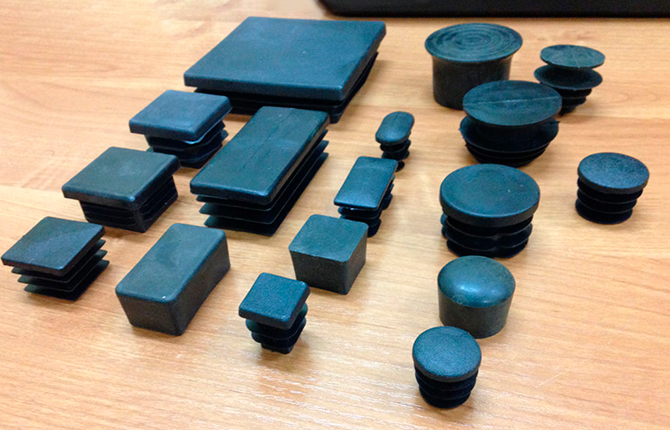

Plastic locking elements are distinguished by shape - square, round, oval, trapezoidal. Depending on the type of installation, they can be external or internal. The size depends on the cross-section of the profile pipe and may also differ.

On sale you can find products with stiffeners. They can be different in shape: straight, converging into a cone, etc. The depth of insertion is a parameter that is different for each plastic cap. The quality of the material determines the service life. Temporary end caps are made of flexible plastic, while permanent ones are more hard and durable.

Choosing a quality plug

What you should rely on when you need to buy a high-quality plug for a corrugated pipe:

- Material. All polymers are different. Thin and elastic ones are used to make temporary plugs, and strong, hard ones are used for permanent ones.

- Availability of thread. If the profile pipe has a thread, then it is necessary to choose similar plastic stops.

- Installation method. For some devices, the hands of a master are enough, while others are mounted using a pump, for example, pneumatic ones. Such varieties reliably block the passage of gas or liquid, allowing repair and replacement of the pipeline.

- Presence of holes for bolts.They are usually equipped with flange stops for casing pipes. They can be easily installed and then dismantled at the right time.

- Lifetime. Corrugated pipes are equipped with shipping or temporary plugs during transportation to protect and preserve them, prevent contamination and debris from getting inside.

- Purpose. Of course, furniture table caps are not used in industry, and vice versa.

- Matching the design and color of the pipe. It matters when the device is decorative.

- Size and shape.

- Compliance with the dimensions of the professional pipe.

How to install

Depending on the purpose, the plastic limiter can be installed on the corrugated pipe independently or using tools. In furniture production, it will not cost a person anything to insert the device into the hole and snap it all the way with your hands. At industrial enterprises, when working with gas, water supply or sewerage systems, it is first necessary to temporarily stop operating the system, ensure the safety of the work, and only then proceed with installation.

Complex types of caps may require the use of additional devices:

- When installing threaded plugs, a sealing material is used, for example, FUM tape.

- To increase the tightness of non-threaded types, gaskets are used.

- Pneumatic ones require the use of a pump, while flanged ones use bolts.

Plastic plugs for profile pipes are not only a decorative element. With their help, you can protect the corrugated pipe from debris, and also, if necessary, block a certain section of the highway for repair work.

Have you ever purchased similar products? Share your tips in the comments. Perhaps they will help someone in their work.Save the article to bookmarks and share it on social networks with your friends.

We also recommend watching a selection of videos on the topic.

What is a plastic pipe plug - review, advantages of PVC plugs.

Plastic plugs for profile pipes.

Links to sources:

- https://santehstandart.com/poleznye-materialy/zaglushka-plastikovaya-na-profilnuyu-trubu

- https://tpspribor.ru/truby/kak-podobrat-zaglushki-dlya-profil-noy-truby.html