Water pumps "Typhoon": overview of the model range, design and operating rules

The Bosna LG company produces the Typhoon water pump, which differs from its analogues in its maximum immersion depth and high performance. The unit is used to supply water to a private home from a well, a well or an open water source.

Let's consider the characteristics of modifications of the Typhoon pump, describe the device, operating principle, features of installation and operation of the equipment. This information will be useful to those who are already using the unit or to those who are just thinking about purchasing pumping equipment.

The content of the article:

Model range and technical characteristics

The Bosna LG company (Ukraine) produces three brands of submersible electric pumps for clean cold water “Typhoon” in a cast iron body. All water pumps in this series are designed to operate from an electrical network with a voltage of 220 V. The water intake is bottom, which requires hanging these pumps at a certain distance from the bottom.

The small diameter of 10 cm makes it possible to use all models in wells as small as 12 cm. All Bosna LG equipment comes with a 12-month warranty. The pump is supplied with a coupling for connecting to a hose or pipe.

"Typhoon-1": maximum pressure - 16 m

Electric pump "Typhoon-1" modifications BV-0.5-16-U5-M - a high-performance household unit with an immersion depth of up to 16 m. The performance of this pump at a maximum immersion depth is 35 l/min, at a depth of 3 m - 50 l/min. The pumping apparatus is capable of pumping water from a depth of up to 8 m.

The equipment is equipped with a built-in overheating protection system and a two-channel water intake system for additional cooling of the housing during operation.

"Typhoon-2": maximum pressure - 90 m

Modification pump BV-0.25-40-U5M is capable of transporting water over a distance of 90 m, which includes pumping from the wellbore, moving along horizontal and vertical sections of the water pipeline to the consumer. Only very expensive imported pumps can do this.

The performance of the electric pump depends on the distance between it and the generation:

- 90-80 m — 8 l/min;

- 40 m — 15 l/min;

- 10 m — 30 l/min;

- 5 m — 40l/min.

The pump is equipped with built-in thermal protection and a two-channel water intake system for the best cooling. This pump is the basis for the Typhoon domestic pumping station, manufactured by Bosna LG.

"Typhoon-3": automation unit and maximum pressure - 90 m

Electric pump BV-0.25-40-U5M with UZN (noise protection device) - unique equipment for domestic use in conditions of unstable power supply. The unit is equipped with an UZN automation unit built into the power cord. UZN equalizes voltage drops in the network in the range of 190-250 V to the operating level.

Voltage drops do not affect the performance of the pump in any way, do not lead to its overheating and failure, which is especially important for summer residents with an unstable power supply system.

The pump starts up smoothly, this is of great importance, because...starting currents for pumps of this type are quite large. The maximum immersion depth is 90 m, while the pump capacity is 8 l/min.

All Typhoon pumps are designed for long-term operation without stopping and have moisture protection indicators IPx8 level.

Design and principle of operation

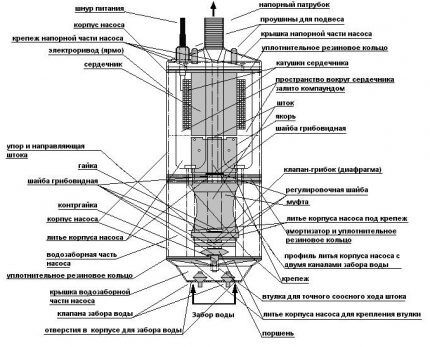

All modifications of the Typhoon water vibration pump include three main components:

- Vibration part. Consists of a shock absorber, diaphragm, coupling, rod. At one end of the rod there is an anchor, and at the other there is a piston. There is a certain distance between the shock absorber and the diaphragm; both elements guide the rod during operation of the electric pump and ensure its tightness, preventing water from entering the part of the housing where the electric drive is located.

- Water intake part. It is a cavity, at the top of which there is a glass with holes for collecting pumped water and check valve, preventing backflow even in cases when the pump is turned off.

- Electric drive part. Consists of a core, two coils and a suction pressure pipe. These parts are located in the body and filled with a compound containing fractions of quartz sand.

The compound fixes the electromagnet and insulates the windings of the coils, protecting them from water penetration. Quartz sand increases heat dissipation from the electric drive part.

The core is a U-shaped figure made of plates made of transformer steel.An enamel wire with a certain number of turns is wound around the core, insulated with a special varnish coating.

The operating principle is based on alternating current, which, with the help of a shock absorber, is converted into mechanical vibrations transmitted to the piston and armature. Water enters the pump through the water intake holes and ends up in the chamber where the piston and valves are located.

The piston, under the influence of vibrations, begins to perform reciprocating movements, creating a hydraulic shock in the glass with holes. The valves close the holes, and the water ends up in the chamber, from where it is released under pressure through a two-channel system into the outlet pressure pipe.

Preparing the pump for operation

To put Typhoon electric pumps into operation, you must:

- Connect the hose to the outlet pressure pipe using the coupling included in the kit. To do this, you need to tightly screw the coupling half onto the thread of the pipe, and then install a piece of tube inside the hose. Place the half coupling, bushing and rubber ring on the end of the hose, and then insert the hose until it stops. Instead of a hose, you can use 3/4″ plastic pipes.

- The Typhoon pump is connected to the water supply system only through a flexible reinforced hose. The diameter of the hose must match the size of the pipes. It is not allowed to use a reinforced hose of a smaller diameter to increase the pressure, because this will create a significant load on the running pump.

- It is necessary to thread a nylon cord into the existing eyes (mounts) of the pump to suspend the unit. It is best to place the knot that will secure the cord at a distance of at least 10-15 cm from the holes in the suction cup to prevent the cord from getting into the pump.

- The length of the power cable for Typhoon pumps is a maximum of 10 m. If this length is not enough, you must use a waterproof extension cord. It is forbidden to extend the electrical cable yourself!

- Fasten the electrical cable, hose and nylon cord together using clamps or regular electrical tape every 1-1.5 m.

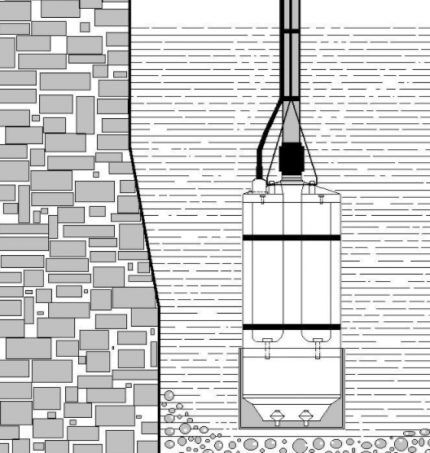

- Lower the pump into the water so that the electrical cable does not become too tight, and secure it to a holding device, such as a well bar. When installing equipment into a well, before lowering it is necessary to put rubber rings on the unit.

When attaching the pump, it is advisable to melt the ends of the cord. Steel cable must not be used for hanging vibration modifications with the Typhoon logo in mine workings and sources. From constant vibration it will collapse.

The Typhoon pump must be suspended so that during operation it does not touch the walls or bottom. The distance from the water intake glass to the bottom must be at least 40 cm.

Pump installation and operation

The Typhoon electric pump can be installed in a well with a diameter of more than 12 m, in an open reservoir or in a well.

Features of operation of electric pumps "Typhoon":

- The equipment does not require lubrication or pre-filling; it begins pumping liquid immediately after startup. It is not allowed to connect the Typhoon series pumps to the network without first immersing them in water!

- Electric pumps are designed for long-term continuous operation, including in winter. Raising equipment to the surface is only necessary for maintenance or routine inspection.

- The pump can only be turned on/off using a plug or a two-pole switch. When the protection system is triggered, there is no need to restart the pump; when the parameters are normalized, the unit will start working in automatic mode.

- During operation, the electric pump housing should not hit the walls of the well or well. If this happens, the pump must be lifted and reinstalled to avoid shock.

- When operating an electric pump in winter, it should be remembered that its immersion depth should be lower than the depth of soil freezing in the region. Considering that the optimal level for Typhoon units is 3 m from the water surface, this pump can be used without hindrance all year round.

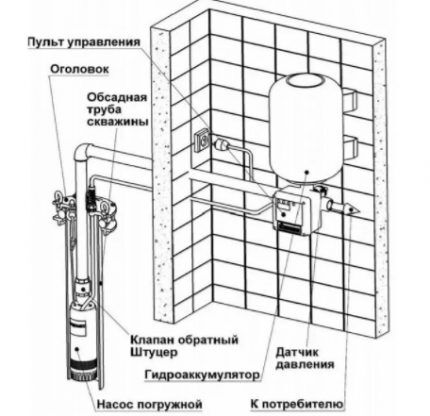

"Typhoon-2" can operate as part of domestic pumping station, which is very convenient to use for irrigation and water supply of a private home.

Typhoon pumping stations

Unlike conventional pumping stations, which consist of hydraulic accumulator, pressure switch, pressure gauge and various connecting fittings, the Typhoon station consists of a high-performance electric pump Typhoon-2 and an electronic control unit that allows you to control the pump in automatic mode.

The Typhoon-2 water pump is connected via a controller, resulting in a full-fledged pumping station capable of providing water supply for a private house.

The Typhoon pumping station maintains constant pressure in the water supply system, without changing pressure and performance. The controller also ensures a smooth start of the pump, which reduces the risk of water hammer and pump overload.

The device allows you to turn the pump on/off multiple times without reducing its service life.

The pump, which is part of the pumping station, is reliably protected from dry running if the water in the water source runs out. The controller will automatically turn off the unit, and when the normal water level is restored, it will automatically turn on.

When the voltage in the electrical network increases above 250 V, the pump also automatically turns off.

Connecting the controller is very simple: you need to connect the plug of the power cable of the Typhoon-2 pump to the socket of the electric pump control unit and the tube transmitting pressure to the pressure pipe from the pump to the water consumer. You can connect the controller yourself without involving a specialist.

Adjustment of Typhoon units

Like other vibration-type electric pumps, “Typhoons” need adjustment in order for the equipment to operate with the required parameters. Adjustment is the selection of the optimal distance between the armature and the core, as well as between the valves and the working piston.

To set the working gap between the core and the armature, it is necessary that the voltage in the electrical network be exactly 220 V. This can be achieved using a power network stabilizer. Low voltage reduces the performance and pressure characteristics of the vibration pump, and increased voltage leads to excessive load.

On average, the gap between the core and the armature for normal operation of the unit is 4.3-5 mm. If you have special tools, you can adjust this indicator yourself, but given the complexity of disassembling and reassembling the electric drive part of the pump, it is better to entrust this adjustment to service center specialists.

You can independently adjust the position of the washers on the rod, located between the armature and the shock absorber. The washers are responsible for the performance characteristics of the electric pump, as well as its efficiency.

By adding washers you will get better performance. It is important here not to fix the washers too close to each other, because... this will lead to a collision between the armature and the core.

The washers, which are located under the piston, are responsible for the overall pressure of the pump by influencing the working piston. If you add washers here, the piston will fit more tightly and the pressure will increase, reducing the washers will reduce the pressure.

By adjusting, you can achieve optimal performance of the Typhoon electric pump, for example, reduce the pressure, while increasing productivity and efficiency.

Maintenance and safety rules

Maintenance of the Typhoon electric pump includes periodic inspection, which is carried out every 100 hours of operation. While the equipment is under warranty service, it is prohibited to disassemble the pump yourself.

During the post-warranty period, you can replace worn parts yourself. The most common parts that need this are the piston and valves. To replace them, it is necessary to disassemble the pump in accordance with the manufacturer's instructions.

Also often, owners of Typhoon series pumps are faced with clogged inlet holes on the glass. You can remove the blockage by clearing the holes with a thin, blunt instrument. This must be done carefully so as not to damage the check valve.

Do not repair the power supply cable yourself!

For safe operation and uninterrupted operation of the pump, the following rules must be observed:

- do not allow the pump to operate without immersion in water;

- Do not raise/lower or inspect a running pump;

- the power supply voltage should be as close as possible to 220 V;

- the temperature of the pumped water should not be higher than +35 C°;

- The plug and service socket must be located in a place protected from moisture.

Before putting Typhoon pumps into operation, carefully read the manufacturer’s instructions and follow their recommendations.

Alternative pumping equipment options and tips for choosing units are presented in this article.

Conclusions and useful video on the topic

Review of the electric pump "Typhoon-2":

Review of the Typhoon-3 electric pump with UZN:

Ukrainian-made electric pumps “Typhoon” are distinguished by high performance and have no analogues in terms of immersion depth. The cost/quality ratio of these pumps is the most optimal.

The equipment is perfect for those owners who are looking for an electric pump for year-round water supply to a private home from deep artesian wells or open water sources.

Do you have personal experience installing and operating the Typhoon pump? Would you like to share your impressions of using it or ask questions on the topic? Please leave comments - the feedback form is located below.

Of course, the owner is a gentleman, but I think that for autonomous water supply in an individual residential building, home pumping stations are best suited. In addition to the pump, they are equipped with a hydraulic accumulator - a tank of a certain capacity that maintains pressure in the water supply network; metering and control devices are provided. But again, the disadvantage is that they are very noisy. Your pump will be quieter.

Dear Stepan, the hydraulic accumulator in no way maintains pressure in the water supply network. It is supported by a pump

The operating principle of Typhoon vibration pumps is based on vibrations of the working body (piston) under the influence of an electromagnet (220 V AC mains). The piston stroke is limited to a few millimeters, which determines their low performance. Typhoon units of this type are used for pumping water from small wells, mainly from wells up to 10 m deep, with a protective device in the form of a mesh on the suction pipe for collecting water from open reservoirs. With low water consumption on the farm, it will be the best budget solution.

I have a well on my property that is 14 m deep. But the distance from the bottom to the water’s edge is not very large. The pumping station is good because it automatically turns on/off the water supply according to the settings of the pressure switch. The only thing I’m interested in is how long the device can be used (maximum). So that you don't waste your money. And also - maintenance once every hundred days. If the influx of water into the mine is insignificant, i.e. the static level is restored slowly, is it necessary to focus on the pump’s performance? I would appreciate your answer.

The pump works well, but makes a lot of noise. What is the reason?

For all submersible pumps, the causes of humming are similar. If there are no complaints about the operation of the pump, then the problem is in the power line. The voltage is likely above the limit allowed for operating the pump. Don't turn it on until you figure out the network.

It may still buzz if the rubber piston is leaking. But in this case, the volume of pumped water should be reduced. The piston can be changed, usually a spare one is included in the package.

When you turn on the Typhoon 3 pump directly through the outlet, the water pressure is much greater than if you turn it on through the control unit. What could be the reason?

Hello. Press control provides automatic, stable regulation of water pressure, which is not carried out with direct activation.

Pump Typhoon 3m, with remote control.

There is a factory problem!!!

The pump turns on by itself from time to time.

The first time it was during a thunderstorm, and I thought that it was to blame. The service center said that the case was not covered by warranty; I had to replace the control unit and remote control together at my own expense.

After the replacement, there was no thunderstorm, the pump has already turned on five times in half a year!

The service (manufacturer) promised to figure out the reason and solve something. Then they fed me breakfast for a long time, saying that they would talk to the chief engineer, and later they stopped picking up the phone altogether.

This company is NOT SERIOUS!!!