Hand pump for a well: types of equipment, characteristics, their pros and cons

A well on the site helps solve the issue of autonomous water supply.But without special equipment it is impossible to raise the liquid to the surface. But you don’t really want to buy expensive automatic devices if you visit your dacha occasionally, do you?

A hand pump for a well of domestic or foreign production will cost much less. It is not difficult to install, and it can work even if there is no central electrical supply on the site.

But which option is better to choose? We will help you sort out these issues - our publication discusses the design features of the most popular types of manual pumps, their capabilities, and the main pros and cons. We have also provided recommendations for choosing the appropriate equipment option.

The content of the article:

Features of manual equipment

A hand pump allows you to pump liquid from wells installed on the site, to the selection point with little effort. The water flow rate here is much lower than in automatic devices. But manually pumping a bucket of water is not difficult - even a teenager can cope with this task.

However, lever mechanisms have a number of significant advantages.

Key positions include:

- autonomy – the device can be used where there is no electrical network, or the cost of electricity is too high, and connecting powerful equipment is not economically profitable;

- low material costs for acquisition – a manual unit costs much less than an automatic one and there is not always a real need to pay a significant amount of money for equipment that will not be used constantly;

- versatility – hand pumps on the market are presented in a wide range; you can choose a suitable device for both deep and shallow wells;

- maintainability – if any components of lever models fail, they are very easily and quickly replaced;

- easy installation – installation does not require specialized knowledge and is carried out without the use of specific, expensive tools:

- basic use – for the pump to start supplying water, you only need to raise and lower the handle several times; even a child, woman or pensioner can easily cope with this task.

The equipment has only two disadvantages. The first is the physical effort required to obtain liquid for drinking or irrigation. In this plan automatic pumpsthose pumping water from a well without direct human intervention win.

The second is low productivity compared to automatic units.

However, this cannot be considered a full-fledged disadvantage. After all, such models are intended for installation in places where there is no need for constantly flowing water from the tap or an uninterrupted supply is simply physically impossible to organize.

Typically, hand pumps are used in summer cottages, visited only in the summer, and in places where there are problems with a constant supply of electricity.

Manual models are also used as an accompanying water supply option. So, it will be quite difficult to provide the required amount of water to vegetable beds every day. A hand pump will help you cope with this task, and without extra costs for electricity.

Types of hand pumps

Manual water pumping equipment on the market is presented in a wide variety of options.

Well owners are offered the following types of products:

- winged;

- piston;

- rod;

- membrane

Each type has features that determine the area of maximum effective use. Regardless of the design and operating principle, all devices demonstrate approximately the same performance.

In one full cycle of reciprocating motion, about a liter of liquid will be obtained from the well. In a minute, you can collect from 20 to 40 liters of water in this way. A more accurate figure depends on how often the user can raise/lower the handle lever.

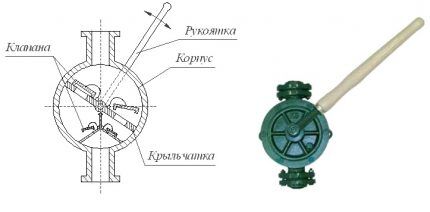

Type #1 - wing units

A manual vane pump is a compact device for pumping water from underground sources depth 5-7 meters. Its small dimensions make it possible to use the device for technical purposes in factories, warehouses, bases and other areas where it is not possible to install more powerful and larger equipment.

Structurally, the product consists of a housing with pressure and suction pipes. The impeller with blades is fixed on a shaft firmly connected to the handle of the device. The upper compartment of the device maintains a constant volume even if the position of the impeller changes.

The lower part of the pump working chamber is divided into two parts by special jumpers. Two valves are located on the pump blades, and two more, working in opposition to them, are located at the entrance to the lower chamber.

When the user acts on the handle, the impeller begins to rotate. Alternating zones of high pressure and discharge are formed in the working chamber. The liquid is sucked in through the inlet pipe and vigorously pushed out through the pressure pipe. Pump valves ensure that water moves along communication lines in only one direction.

Vane-type hand pumps cope with pumping fairly viscous liquids, but do not tolerate contaminated liquids well. Not suitable for transporting water containing fragments of liquid fuel, alcohols, paraffin, edible oils and any abrasive materials. Work well with clean, shallow wells.

They can often be used in basements where it is not possible to place more powerful and bulky equipment.At a budget price they are sold in an anodized metal case.

Among models from foreign manufacturers, they are popular German K1 and K2 with brass valves and blades. Russian analogue of RK2 is sold at a higher price, but is equipped with a wing mechanism made of metal that is prone to corrosion.

Advantages of vane pumps: compact dimensions, ability to pump viscous liquids.

Disadvantages: low productivity, high demands on water purity, work in shallow wells.

Type #2 - piston type pumps

Piston devices are widely popular. Structurally, they consist of a cylindrical body made of food grade stainless steel. A piston moves inside, secured by a rod to a rocker arm.

Elastic fluoroplastic seals ensure a tight fit of the piston disc to the walls. Spherical check valves are located on top.

These types of pumps create inlet pressure. Placed 1 meter above ground level. They are mounted on the upper part of the casing communications in such a way that the check valve of the system is located at the outlet of the water-lifting pipe immersed in the hole.

Used where the water surface is high. Water is obtained from wells up to 10 meters deep. They cannot bring liquid to the surface from deeper sources. Great physical effort is not required to press the lever mechanism.

As the piston moves forward, the valve lowers and prevents fluid from flowing in the opposite direction. Water under pressure opens the built-in valves and rises above the surface of the piston disc.

During the reciprocating movement of the piston, the valve lowers and prevents the outflow of liquid in the opposite direction. Water under pressure opens the built-in valves and rises above the surface of the piston disc. During the return stroke, the disc valves close, preventing water from flowing down.

The air pumped into the system pushes the liquid under pressure upward and, as a result, it pours out through the pump outlet pipe.

In the ranking of the best-selling piston models, the top positions are occupied by steel devices with galvanized bolts from Russian manufacturer Watergood. Products of foreign brands are less popular.

Advantages of piston pumps: pumping both clean and muddy water with sand, suitability for working with light petroleum products, acids, solvents, alcohols.

Another advantage is the simplicity of the design - for example, a piston-type pump can be make at home.

Main disadvantages: some models require insulation for the winter, as they cannot be used if the ambient temperature drops below +1 °C. Typically, this information is indicated on the manufacturer’s website and in the accompanying technical documentation of the device.

Type #3 - rod (rod) devices

Rod hand pumps are sometimes called rod pumps. They are used where water lies at a depth of 12-30 meters. For all other manual models, this is an impossible task.

The design of the devices is somewhat similar to piston units. The main working unit here is a cylinder and a piston with an elongated end. The pump part of the device is located in the aquifer.

Rod-type equipment is mounted directly into the well. The rod part is immersed in water to a depth of about 1 meter.

Pumping of water begins when a person operates a lever device. The piston moves down and the bottom valve closes. The resulting pressure opens the upper valve and the liquid moves into the space above the cylinder.

During the process of lifting the piston element, water closes the upper valve, and the vacuum created under the piston opens the lower valve to suck in water.

It is most important to use rod pumps in conditions where the water is too deep to install an external electrical appliance, the diameter of the well does not allow the installation of an automatic pump, or there is no possibility of connecting to the electrical network. In all other situations, spending money on equipment is not practical.

The main advantage of sucker rod pumps is lifting liquid from great depths. A compact rod-type pump for a well up to 15 m deep can be made at home. We recommend that you read the detailed manufacturing instructions homemade pumps from scrap materials.

The disadvantages of purchased models are the complexity of installation, cumbersome design, large efforts required for pumping, the inability to use the unit in wells located on slopes or with internal curvature, and a high risk of rod breakage.

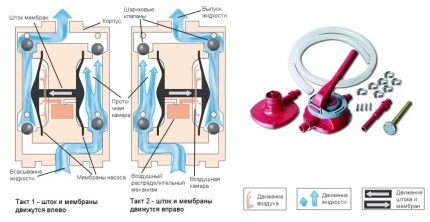

Type #4 - membrane equipment

Manual diaphragm or diaphragm pumps are very durable. They can pump clean/contaminated household water and diesel fuel containing impurities with equal success. Even if there are a large number of small particles of sand and abrasive elements in the liquid, all components work flawlessly.

Ball valves do not occupy a fixed place, do not rub against each other, but constantly roll. This promotes self-cleaning and reduces the risk of jamming to zero.

The round body of the devices is made of durable plastic or cast from high-quality cast iron. Diaphragms and valves are made from oil and petrol resistant rubber. The equipment lasts for years and does not fail. Suitable for use only in shallow wells.

The device can be used not only for pumping water of any quality, but also for draining waste or rainwater from cellars, basements, trenches and other areas subject to flooding.

Models from Danish concern Grundfos And Taiwanese Ampika pumps. They are sold at the best price.

Among the advantages are wear resistance, undemanding quality of pumped water, optimal weight, reasonable cost, durability.

The main disadvantage is the ability to work in shallow wells (up to 6 meters).

Recommendations for choosing a hand pump

When choosing a hand pump, you must first focus on the depth of the well. If it is from 5 to 7 meters, all types of portable pump-action devices will cope with the task. For sources where the water surface is at a height of up to 10 meters, any lever equipment is suitable, except for vane ones.

Only a hand-held rod device can lift liquid to the surface from a depth of up to 30 meters. But for this, the well should not have bevels or bends.

The weight of lever equipment ranges from 4 to 130 kg. This parameter is important at the time of transportation. Light products up to 15 kg can be delivered to the installation site yourself. Heavier models will have to be transported by car and hired workers will be used for loading/unloading.

Problems often arise when installing heavy hand pumps. Typically, the owner requires outside assistance when carrying and installing the device.It is advisable to think about this in advance and invite a master or use the services of one of your relatives, friends or acquaintances.

Another important element when choosing a model is water quality. Vane units are very demanding in this regard and cannot cope with pumping liquids containing sand and impurities.

If there is a problem with water purity at the site, you should prefer piston, rod or diaphragm type pumps. They will perform the task normally and will not fail after small abrasive particles pass through the system.

Do you need a functional pump to pump out dirty water, but a manual option is not suitable? We recommend that you read the best automatic modelspresented on the market and selection rules.

If the equipment is needed only for operation in the summer, it is worth considering pumps with a plastic body. They are sold at a lower price, weigh little and are considered a budget option. But they cannot withstand serious workloads and often fail without working even for one season.

Products made from thin-walled food grade steel are considered more durable than plastic ones. Cast iron and bronze appliances have the longest service life. Their high price is compensated by a long operating period, reliability and resistance to environmental influences. All metal units are suitable for year-round use.

The appearance of the pump also matters. It is desirable that it be harmoniously combined with all other elements on the site and not spoil the surrounding landscape. Some manufacturers produce hand pumps with attractive handles and stylish taps.Such products are more expensive, but fully justify the cost, turning from a familiar element into a decorative object.

In order for the pump to always work correctly and not break down, you need to take care of it, clean the individual components and lubricate them with special products. Some models have a self-cleaning system. Such devices do not require additional maintenance.

If you plan to spend a lot of time at the dacha, then you cannot do without automation of the water supply system. In this case, we recommend that you read rating of pumping stations, which are in demand among buyers, and the rules for choosing the best.

Conclusions and useful video on the topic

Technical characteristics and features of a piston hand pump with a cast iron body.

The operating principle of a piston-type hand pump mechanism.

How does a rod pump work? A real user demonstrates the process of extracting water from a well.

Using a hand pump is a good solution for owners of summer cottages or country houses for temporary residence. The equipment is inexpensive, easy to install, does not require connection to the electrical network, and supplies water from sources with a depth of 5 to 30 meters.

The lever pump operates in all weather conditions and withstands intensive use. It can be used to organize an additional water distribution point in areas where the main water supply is located far from irrigation sites.

Do you use a manual pump at your dacha? Show your pump model in the comments and share your impressions of using it. Or are you just looking at this option of pumping equipment, assessing its pros and cons? If you have any questions about choosing the right type of hand pump, don't hesitate to ask our experts and other site visitors for advice. The feedback form is located below this post.

Are there combination pumps that pump both manually and automatically? Our electricity is often cut off, then manual mode would come in handy.

It all depends on the type of pump you are using (surface, submersible, well), so it is impossible to give a definite answer. In any case, today such combinations are produced less and less often. Therefore, it would be more advisable to install a hand pump for the well separately. This way you will always have a running pump, even when there is no power supply. Another option to solve this problem is to purchase a gasoline or diesel generator, from which you will supply power to the well pump.

But the best option is to simultaneously install a hand pump in parallel with an electric one, as well as purchase a generator. In this case, you will be prepared for any unforeseen situations. In addition, the generator can power any equipment and appliances in the house.

Good day!

The article is very useful, but unfortunately the question regarding deep wells is not addressed.

I have a well 73m deep.The casing pipe is 110mm stainless steel, a borehole pump is installed, and a HDPE pipe rises from it to the head. Like the person in the comment above, my electricity is often cut off. I want to replace it with a mechanical (manual) pump or do something so that I can quickly install a mechanical one in this well if necessary. Please tell me which mechanical pump can be used in this case?

I'm going to the comment above!

So what kind of hand pump can handle lifting water from 70-80 meters.

Generator - ok, accepted.

If there is no gasoline, but you need water, what model can lift water from such a depth?

I cannot lift pumps that operate on rarefied air to a height of more than 10 meters.

But you can’t always install an auger in a working well, and the price tag on them at great depths will be prohibitive