How to make a sand filter for a pool with your own hands: step-by-step instructions

Does your pool, in addition to the joy of bathing and swimming, cause you trouble in the form of quickly polluted water? Did the cost of filters for cleaning it, which are offered in specialized stores, shock you? Agree, it would be nice to get a filter device for a reasonable price.

You don't have to buy expensive devices for this. You can make an effective sand filter for your pool with your own hands, which will adequately purify the water from foreign matter. We will help you cope with this task - the article provides step-by-step instructions on how to make such a filter on your own.

We provided the construction process with visual photographs and videos on how to independently create simple and effective filter devices.

The content of the article:

- Does the pool need to be equipped with a filter?

- Advantages of sand filtration device

- Making a sand filter

- Stage #1 - getting acquainted with the operation of the sand filter

- Stage #2 - select a connection option

- Stage #3 - we prepare the body

- Stage #4 - cutting in fittings and internal elements

- Stage #5 - prepare the filter element

- Stage #6 - install devices for filter operation

- Stage #7 - piping the filter system

- Stage #8 - connect the system to the pool

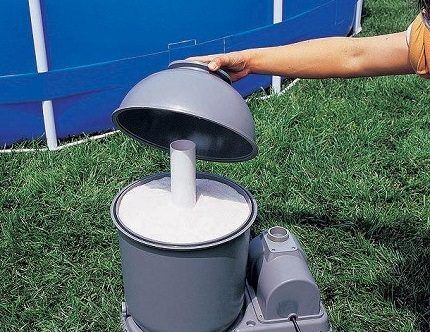

- Stage #9 - fill the filter with sand and start

- Nuances of operation and maintenance

- Conclusions and useful video on the topic

Does the pool need to be equipped with a filter?

Owners of small inflatables and stationary swimming poolsPeople often don’t think about water purification. After bathing, it is simply used for household needs and watering the garden.

If necessary, fill the container again with clean water. However, this method is justified only for very small inflatable pools.

But even with them there is enough hassle - the water becomes polluted after the first bath. After draining the liquid, the surface must be washed and filled with clean water, which must still warm up. But in hot weather you want to swim more than once - children, for example, splash there all the time.

In addition to the pollution caused by humans, various natural pollutants also constantly enter stagnant water, these are:

- leaves and grass;

- dust;

- bird droppings;

- plant pollen.

Large and light debris is removed from the surface of the pool with nets, and particles settled to the bottom are removed with a water vacuum cleaner.

However, many substances dissolve or remain suspended in water. Under the influence of sunlight and atmospheric oxygen, bacteria and microorganisms begin to actively multiply in such a liquid. It begins to emit an unpleasant odor, bloom and can cause poisoning and serious illnesses.

Therefore, it is necessary to clean not only the surface and sedimentary formations, but also the water column itself. An effective way to maintain water in normal condition at all times is to turn on effective filter into the water supply system.

Advantages of sand filtration device

Three types of filters are used to purify pool water:

- diatoms;

- cartridge;

- sand.

Diatomaceous. The best quality of cleaning and reliability of operation is ensured by the diatomaceous earth (also called diatomite) type of filter device. However, such a unit is expensive due to the use of an expensive product that performs ultra-fine filtration and adsorption, in addition to eliminating a number of bacteria.

The filter elements of the cartridge variety are the devices on which the name of this group of filters is based. This is the most convenient, but not very popular type of water purification device due to the price. True, they are more affordable than the previous ones.

Cartridge devices They have a simple design and can be easily disassembled for cleaning and replacing the main element. The cleaning component is a cylindrical cartridge consisting of polypropylene membranes.

Such filters have low performance, so they are suitable only for small pools. The cartridges themselves have to be washed frequently (once a day) and replaced.

Sand filters capable of efficiently servicing fairly large tanks. The filter layer is quartz sand. The units have a simple design and can be assembled on your own. At the same time, the cost of the finished cleaning system will be approximately 2 times lower than the purchased one.

In addition to mechanical methods for purifying pool water, they also use chemicals, promoting the precipitation of contaminants, after which they are simply collected with a net or similar device.

Making a sand filter

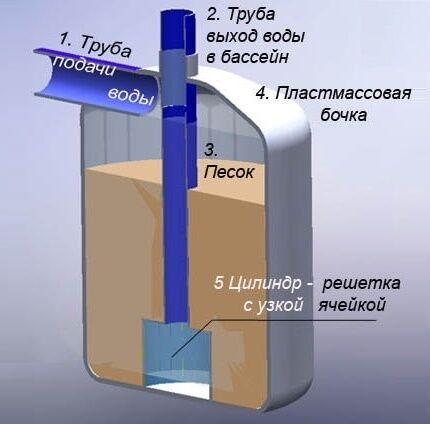

The sand filter for the pool has a simple and reliable device. Main components of the design:

- airtight container with a wide neck;

- supply pipe;

- sand;

- intake device;

- outlet pipe.

The sand reservoir is made of a material that is not subject to aggressive influences. Most often, plastic barrels are used for this. At the bottom there is a device for collecting purified water.

This is a small drainage chamber to which an outlet pipe is connected. Its walls are made of fine mesh, the cell sizes of which are smaller than the particles of sand used. The filter element is purified sand with fractions of 0.4-0.8 mm - quartz or glass. The first is a democratic option and needs to be replaced every 2-3 years.

The second one is more expensive, but it lasts for 5 years. There are multilayer models. The filler in this case consists of layers with different fraction sizes - from larger to smaller, or from several types of filter elements - sand, anthracite, gravel.

Stage #1 - getting acquainted with the operation of the sand filter

The principle of operation of the filter is to mechanically sift out particles suspended in the water column (mineral and organic origin) by passing it through sand in a vertical direction - from top to bottom.

The reservoir is not completely filled with the filter element. When the container is closed, a sealed receiving chamber is formed above the surface of the filler, into which water from the pool flows.

Seeping through the layer of the filter element, the water is purified. Contaminants settle on sand particles, so it must be fairly fine. Clean water accumulates in a bottom drainage chamber, from which it flows back into the pool through the outlet pipe.

The liquid is pumped through the filter by a pump that is installed in close proximity to the tank. It can be installed on the supply line (before the filter) or on the outlet line (between the filter and the pool).

In the first case, a slight pressure is created in the receiving chamber of the filter, which forces water through the filler. In the second, the suction of liquid from the drainage chamber creates a slight vacuum in the upper part, due to which water from the pool is sucked into the system.

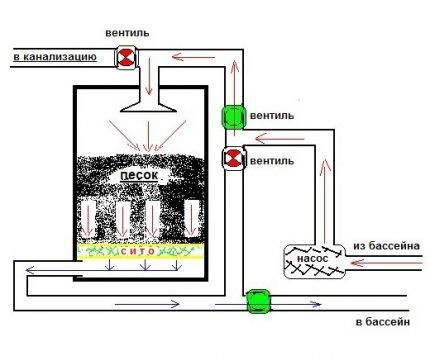

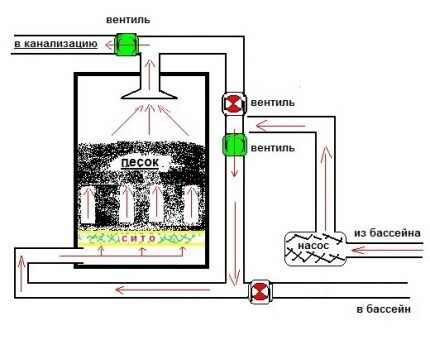

As the product is used, the filter element gradually becomes dirty. The quality of cleaning decreases. To resume normal operation of the unit, the sand is washed.

To do this, clean water from the pool is passed through the filter in the opposite direction - from bottom to top. The washing liquid filled with suspensions is removed from the upper part of the filter into the sewer.

Building a sand filter for a pool with your own hands will save almost half the cost of a similar purchased unit. This is subject to the use of new components. If you already have some individual elements and suitable available means, then the savings will be significant.

Stage #2 - select a connection option

There are three filter connection schemes regarding pool pump:

- The pump is installed in front of the sand tank. In this case, water is pushed through the sand under pressure, which is created by a pump installed on the supply in a hermetically sealed filter container.

- The pump is installed after the filter. This creates suction and vacuum in a hermetically sealed container with sand. Due to this, liquid is sucked from the pool into the tank.

- Purified water is pumped by a pump installed after the filter. Water from the pool flows into the sand reservoir by gravity.

Industrially manufactured sand filters perform cleaning according to the first scheme. They are equipped with pressure gauges and a safety group to relieve excess pressure.

When designing with your own hands, the choice of connection option largely depends on the components already available on the farm, on the type of pool and on how the drains are organized in it.

Stage #3 - we prepare the body

If you have a sealed container of sufficient volume that can operate under pressure, then you can safely build a filtration system according to the first scheme.

The filter chamber can be a housing from a membrane-type expansion tank.In this case, it must be freed from the “pear” (membrane) and treated from the inside with paint that protects against rust formation.

You can also use a polypropylene barrel with a volume of at least 60 liters. These are often found at dachas. This material is resistant to aggressive influences and is not subject to corrosion. But not all of them will be able to withstand the pressure. Most often, in such homemade designs, the lid is torn out, but the body itself can also burst - in a thin place.

Ideal for organizing water filtration according to the second or third scheme plastic containers. However, if water is pumped by suction, then the lid is installed with additional sealing. Even a small air leak affects the operation of the system.

Stage #4 - cutting in fittings and internal elements

It is necessary to ensure that dirty water enters the filter and purified water is pumped out. To do this, fittings are cut into the walls of the housing or into the lid. The insertion areas are carefully treated on both sides with a sealing compound.

Attached to the supply fitting coarse filter, protecting against the entry of large debris. This can be a ready-made cartridge, or a home-made device - for example, the conical part of a plastic bottle covered with a nylon stocking.

In addition to its main function, such a part will play the role of a diffuser so that the stream of water entering the filter splashes and does not “dig” the sand.Prepare a water intake, which can be any perforated container with an additional covering of fine mesh, the cells of which are smaller than sand granules.

To make the simplest water intake drainage device, you can use a piece of plastic pipe with soldered holes, which is covered with covering garden material on top. Or use a ready-made, commercially available cylindrical cartridge, which is used for filtering drinking water.

On one side the cylinder is plugged tightly, and on the other, an angle fitting is cut into the plug, ensuring the tightness of the connection. A pipe is attached to the device for connection to the fitting. Place it horizontally on the bottom of the filter.

Stage #5 - prepare the filter element

It is most advisable to use ready-made quartz sand, specifically designed for the pool. Its granules have an optimal size of 0.4-0.8 mm.

The filler is clean, disinfected and does not require any preparation before use. The standard weight of packages is 25 kg. For a medium-sized pool - from 15 to 40 cubic meters - you will need two of these bags.

It is better not to use ordinary sand. Its small version is prone to clumping and the formation of straight vertical channels in the filter layer, while the large version will not provide adequate cleaning. This can lead to a decrease in the quality of the treated water or to the complete failure of the filter to fulfill its main function.

Perhaps the owners have quartz sand at their disposal, but not prepared. Then pre-treatment should be carried out before use.

The filler is sifted through a sieve that does not allow particles larger than 1-1.5 mm to pass through. Then it is washed. This operation can be carried out already in the filter - turn on the backwash mode and pass clean water through the sand until it becomes clear.

Stage #6 - install devices for filter operation

When implementing a pressure circuit, it is imperative to install pressure gauge. It can be in the line between the pump and the filter or attached to a fitting embedded in the tank lid.

Instead of a pressure gauge, you can use the device - security team. This is a small manifold to which a pressure gauge, safety valve and air vent are attached.

By setting the devices to the required parameters, you can avoid such troubles as tearing off the lid when making a filter from a polypropylene barrel. If the pressure is exceeded, the safety valve will simply drain the excess liquid, and the structure will remain intact and operational.

Air vent in the system will also not be superfluous, since air-saturated water circulates in the system. Gradually released, the gas can accumulate under the filter cover. For an installation that operates on the principle of “sucking out” water, it is advisable to embed an air vent into the filter cover - a small-diameter pipe with a tap.

In case of accidental airing of the system or air leakage, it will be enough to open the air vent valve and wait until water comes out of it. Then the tap should be closed tightly.

Stage #7 - piping the filter system

In industrially manufactured sand filters, a six-position valve is used to switch modes.

In the case of self-installation, a pipeline is laid out with appropriately located shut-off valves and fittings. The design must provide at least two operating modes of the system - filtration and sand washing.

The pump for the filtration system does not need to be very powerful. 150-300 W is enough. Productivity is selected taking into account the fact that a complete replacement of the contents of the pool should occur in no more than 6 hours.

So for an artificial reservoir of 20 cubic meters, you need to choose a pump with a capacity of at least 4 m3/hour. You should not choose a more powerful pump, since the unit is used in conjunction with a filter. Their performance should be equal.

A powerful pump will pump liquid through the filler too quickly, as a result of which the quality of cleaning will decrease and the filler will fail earlier.

Stage #8 - connect the system to the pool

Using clamps, we connect the supply and discharge hoses to the outlet fittings of the filter system. If the pool has ready-made nozzles in the walls, then the hoses are connected to them. You can simply throw the hoses over the side.

The intake of liquid from the pool and the discharge of clean water should be located as far apart as possible. This is necessary to ensure good circulation and eliminate the formation of dead zones in the reservoir.

In front of the pump, wherever it is located, it is necessary to install a coarse filter. This will avoid internal damage to the unit.

For a gravity-filled system, the top surface of the barrel should be located below the water surface in the pool. In this case, approximately equal flows should be ensured - that is, the amount of incoming liquid should be commensurate with the amount of fluid being sucked out.

To do this, taps should be installed at the points where the hoses connect to the pool, which will help regulate the pumping.

Stage #9 - fill the filter with sand and start

The container is filled with a filter element, leaving space at the top for water to enter. As the sand is backfilled, water is poured over it so that it is compacted tightly enough. Water is allowed into the filter line, since the pumps cannot be turned on without liquid.

Perform a test run of the filter and check all connections for leaks. If they are detected, the pump is turned off, the water is drained and the system is sealed. After all design defects have been eliminated, the filter line is put into operation.

Nuances of operation and maintenance

Those wishing to build private pool in the country house methods of its maintenance should be thought out in advance and provided for. Water must be filtered constantly, especially if it is initially dirty (for example, rusty) or has turned green after forced downtime.

If the water is clean, then in order to save electricity, you can turn it on twice a day for 5-6 hours or once for 10-12 hours. During this time, the entire volume of water in an average reservoir is 15-20 cubic meters. m will change twice.

As the filter element is used, it becomes covered with a layer of contaminants, which interferes with the further operation of the unit. Therefore, the sand should be washed.

Procedure #1 - washing the filler

The frequency of cleaning sand from contaminants depends on the intensity of use of the pool, the degree of contamination of the contents, the composition and amount of chemicals used. You can use the recommendation to wash the filler once every 7-10 days. However, for a pressure-type filtration system, you should monitor the pressure gauge readings.

The normal pressure in the system is 0.8 bar. If the indicator reaches 1.3 bar, then the sand needs to be washed.

For the cleaning process, it is necessary to ensure the flow of water under pressure into the lower chamber of the filter - into the intake device. To do this, arrange the appropriate wiring in advance, so you can change the direction of flow by simply switching the taps.

If the wiring is not installed, you can rearrange the hoses. For the injection system, the hose is removed from the upper fitting and attached to the lower one (to the fitting connected to the water intake). If the pump is on suction, then transfer the hoses from the pump.

The suction is disconnected from the fitting of the intake device and connected to a source of clean water or lowered into the pool. Pressure - connect to the outlet of the water intake. A hose is attached to the upper fitting to drain the flushing liquid into the sewer or into a separate container.

The pump is turned on, and the water under pressure loosens and washes away the accumulated layer of dirt. The sand should be washed until the drained washing liquid becomes clear.

Procedure #2 - replacing sand in the filter

Gradually, the filter element becomes heavily clogged with fatty and organic substances, skin particles and hair. Such sand is no longer able to provide proper water purification. Therefore, it needs to be completely replaced.

The filler is replaced as follows:

- Close the water supply tap.

- Pump out the remaining water as much as possible - if the pump is on supply, then quite a lot of liquid will remain in the filter.

- Turn off the power supply to the pump.

- Scoop out all the filler. Contaminated sand is simply teeming with bacteria, so this should be done carefully and with gloves, avoiding it coming into contact with mucous membranes and eyes.

- Pour some water into the filter reservoir - about 1/3 full. The liquid will soften the mechanical impact of falling sand on structural elements.

- Add the required amount of filter element.

- Open the water supply.

- Perform backwash. If the hose for purified water is simply thrown over the side of the pool, then you can skip this step and drain a certain amount of liquid into the ground when putting the system into operation.

- Enable filtering mode.

When using quartz sand as a filler, it will need to be completely replaced every three years.

Conclusions and useful video on the topic

Filtration system with supply pump. It works by pumping liquid into a reservoir of sand:

Gravity filter filling system. An example of a good wiring for this type of connection:

An option for a quick homemade filter. Gravity filling of the filter system. This option is suitable if urgent cleaning of the pool contents is required.

For permanent use, wiring should be installed to enable switching to the flushing mode:

The correct design of the filtration system and timely maintenance allows you to comfortably enjoy the best summer entertainment for the whole family - swimming in the pool.

You shouldn’t rush and just immerse the hoses in the sand - it’s better to think about a convenient layout, thanks to which caring for an artificial reservoir will take a minimum of time and will not create any hassle.

Would you like to share an interesting sand filter design or talk about your experience of connecting the device to the pool water supply system? Please write comments in the block below. Here you can ask questions.

When I had to clean the pool twice in a week, I immediately began to think that something needed to be done to purify the water. It is too expensive and unwise to constantly change it by pumping it from a well. I myself couldn’t make a filter like this one. I made the connection incorrectly (I already realized this now). I bought it ready-made in the store and use it.And you could save a lot of money.

To be honest, I don’t believe that a sand filter alone will work well. We have a purchased one, one of the cheapest. We watched a video on how to do it ourselves, but in the end we thought it would be expensive, because... There are no tools (or even the necessary knowledge). We have a small summer pool with a filter. But I also buy additional tablets in the water itself. And still, after a week the water turns green ((

Perhydrol helps a lot.

Try hydrogen peroxide 38%.

It doesn’t matter perhydrol or bleach, the main thing is to control the chlorine content and PH (most importantly, not with Chinese home tests) and correct them. Otherwise, stupidly stuffing chlorine and perhydrol will not bring you happiness.

Here in Krasnodar we decided to buy sand for a pool filter https://krasnodar.pesok-quartz.ru/catalog/dlya-filtrov-basseyna/ We didn’t expect that we would be able to find what we needed so quickly. As a rule, the search usually takes much longer, but we managed to find sand for the filter literally in a couple of days. At the moment the pool is completely ready for use.