How to bend a profile pipe with your own hands without special tools

Profile pipes are indispensable in the process of assembling frames for building structures.Greenhouses, various greenhouses, gazebos and other objects are built with their help quickly and efficiently. However, everything is not so simple.

To bend such a pipe, you have to use expensive special equipment, which is not always acceptable for a home craftsman. Let's talk about how to bend a profile pipe at home.

The content of the article:

Profile pipe - what is it?

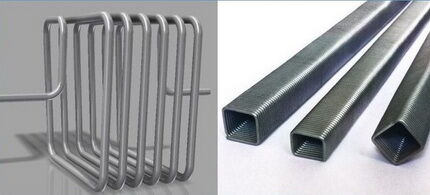

A profile pipe is considered to be a pipe that has a cross-section different from circular. It can be rectangular, oval, hexagonal or square. The pipe has increased strength, because its edges take on the role of stiffeners.

Profile products cope with significant bending loads, making them a good choice for the construction of metal frames for buildings for a wide variety of purposes.

The raw material for the production of profile pipes is most often high or low alloy steel. Depending on the manufacturing method, electric-welded, cold-rolled, hot-rolled, and seamless pipes are distinguished.

Products vary in wall thickness and profile height. Such pipes can be used to make various parts in the form of frames, stairs and railings. Most often, profile pipes are used in construction for the construction of arched structures and as a replacement for iron beams in the construction of frames.

Skills in bending profile pipes will be useful to home craftsmen who want to independently equip a suburban area:

Useful: How to make a gazebo from a profile pipe with your own hands.

Possible complications during work

The actual bending of such a pipe is the process of giving the element a curved-smooth configuration. This can only be done under pressure, since the part has high strength. To reduce the pressure force required for bending, you can use heating of the bent fragment.

Despite the apparent simplicity of the operation, bending does not always result in elements of the desired configuration. Problems arise quite often. The most common complications include three.

The first is that the inner side of the profile folds in peculiar folds that resemble corrugation. In the correct version, it contracts evenly.

The second difficulty is the rupture of the outer wall of the profile pipe. During bending it stretches. Sometimes the metal cannot withstand the force and bursts. The third problem is that the pipe, changing its shape, can lose the alignment of the elements.

This means that its fragments in a bent state will lie in different planes. And this is unacceptable. Practice shows that all difficulties occur due to the wrong choice of bending method.

To choose it correctly, you need to take into account the plastic capabilities of the profile pipe. They are determined by the size and shape of the section, as well as the thickness of the walls of the product. Based on these values, you can calculate the minimum possible radius of curvature. Trying to make a round with a smaller radius is strongly discouraged.

To determine the minimum radius, we need the height of the section. It is calculated as follows.The height of the profile is measured, and twice the wall thickness of the product is subtracted from it.

The resulting number will be the desired height, let's denote it h. For pipes with a cross-section in the shape of a rectangle and square, the following rule applies. If the profile height is above 20 mm, the part can withstand bending in a section whose minimum length is hx3.5.

Products with a profile below 20 mm can be bent over a length of hx2.5 or more. This rule applies to all pipes. However, the wall thickness of the part also affects bending limitations.

The thinner it is, the higher the likelihood of a rupture or crushing of the part. Experts strongly do not recommend trying to bend wide products with wall thickness less than 2 mm. In this case, it is optimal to use a welding machine.

One more thing to be aware of. Pipes made of low-alloy and carbon alloys are very elastic and, after bending, can seem to “spring”, trying to take their previous shape.

This involves additional work with the product, since it will have to be adjusted again according to a pre-made template. Therefore, it is recommended to find out the value of the plastic moment of resistance of a given profile pipe and carry out bending taking this indicator into account. The smaller it is, the less the part will “spring”.

Features of different profile bending methods

There are two main methods of bending profile pipes: cold and hot. The first assumes that the bending process is carried out without preliminary temperature exposure to the part.

While the second is carried out only with a preheated pipe. It must be admitted that heating the part significantly increases its ductility and facilitates the bending process.

There are no standards strictly regulating the use of cold and hot bending methods for profile products. They are only available for pipes with a round cross-section. According to these standards, hot bending is used for parts whose diameter is 100 mm or more. For rectangular and square pipes, slightly different rules apply.

If you have a one-time job of bending a pipe, you can buy, but it is better to rent a hydraulic pipe bender with a manual drive:

Plumbers recommend cold bending only all pipes with a profile height of less than 10 mm. Products with a profile height of 40 mm and above are hot bent.

How to bend parts with a profile height from 10 to 40 mm is up to the performer to decide.To avoid mistakes, you can perform a trial bending. In general, if available pipe bender, with its help you can bend the pipe without any heating.

If there is no special tool, it is worth performing a trial bending of the profile pipe. To do this, one edge of the part is firmly clamped in a vice. A pipe with a diameter larger than that of the product being bent is put on the other end.

The resulting “shoulder” should be pulled strongly, bending the product. If the part bends, you can use the cold bending method. If not, bending with preheating is used.

Subtleties of hot bending

Bending of a fragment of a profile pipe occurs after it is heated. It is advisable to perform the operation in one approach, since repeated heating of the metal is undesirable. A product that has cooled to a light cherry color may rupture.

Therefore, this method is ideal for performing a single corner bend. To bend a profile into a rounded arch, it must be used with caution, since repeated heating in this case is inevitable.

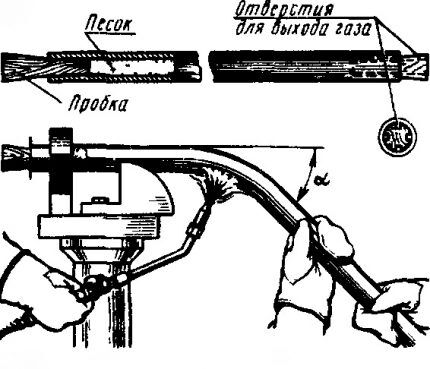

To correctly bend a profile pipe using a hot method, you should use a filler. This will prevent possible crushing of the part. Sand is usually used as a filler.

The best option is medium-grained construction sand. If this is not available, material from a children's sandbox will do. First, you need to clean it of unnecessary impurities.

To do this, sand is sifted through a sieve with cells measuring 2-2.5 mm. This will help you get rid of large pebbles and debris.If during the bending process such an inclusion ends up directly next to the pipe wall, it will form a relief that is completely unnecessary.

Too small grains of sand are also not needed. During the heating process, they can sinter, which is undesirable. Therefore, the sand will have to be sifted again, this time through a fine sieve. Its cell size should be about 0.7 mm. We calcinate the sifted sand.

The filler is ready. Now you can work on the detail. First you need to anneal the pipe in the area where bending will be performed. Then you can start making the plugs.

You will need two parts of the same size that will cover both ends of the profile pipe so that the sand in it does not spill out. The plugs are made only from wood; no other material can be used.

Let's decide on the size and shape of the parts. These must be pyramids, each ten times longer than the width of the base. The dimensions of the base itself should be almost twice the size of the hole that will be closed with this plug. The prepared products need to be tried on the pipe.

If everything is fine, we make a longitudinal groove on each side of one of the plugs. The gas accumulated during heating will escape from the workpiece through these grooves. You can start filling the pipe.

To do this, take a plug without grooves and install it in place. A regular funnel is inserted into the opposite end of the part. If the pipe is long, it is placed at an angle to the ground, if it is short, it is placed perpendicularly.

Sand is poured in small portions through the funnel.After each portion, take a rubber or wooden mallet and thoroughly tap the part from below, helping the sand to be distributed as evenly as possible and compacted. Once a dull sound is heard when tapping along the entire length of the pipe, work must be stopped. This means that the part is completely filled with sand.

The sand-filled workpiece is closed with a second plug. Now you need to chalk out the boundaries of the area that will be heated. Its length must be equal to at least six workpiece diameters.

The part is securely fastened in a clamp or vice. If the pipe is welded, it must be secured so that the seam is outside the bend. If it is inside, the part may burst.

Now you should heat the pipe fragment to a red-cherry color. This can be done with a blowtorch or gas soldering torch. Important point. The entire area should be heated evenly.

Do not allow individual fragments to overheat. If this does happen, such areas should be cooled. An indicator of a sufficiently heated pipe will be scale bouncing off it.

After the workpiece is heated, a piece of pipe with a larger cross-section is put on its end. So that the edge of the part does not reach the future bend a little. After which the pipe is carefully bent to the desired shape.

This must be done in one step with a smooth translational movement in a vertical or horizontal plane. The resulting bend is checked against the template.

The bent pipe must cool, after which it should be compared again with the template and make sure that the given shape is correct. If so, the plugs are knocked out. This is often difficult to do, then you can simply burn out the wooden plugs and pour out the sand.

To ensure a clear bend, without folds or tears, you need to pack sand into the pipe as tightly as possible and heat the part evenly.

Features of cold bending

You can bend a profile without heating in different ways. The easiest way to do this is to use a special tool, namely a roll forming machine. You can buy it or make it yourself, which is quite difficult.

However, buying a tool is not worth it if you only need to bend a few parts. Therefore, many are interested in how to bend a profile pipe by hand and whether it is even possible.

Such an operation is quite possible. To carry it out, you will need the simplest devices in the form of a mandrel or bending plate. They can be easily assembled from scrap materials. Before bending, you need to decide on the filler for the pipe.

If the height of its profile is less than 10 mm, there is no need to fill the part; for products with a larger height, filler is required. This can be sand prepared as described above, or a spring.

In the latter case, a part made of steel with dense winding is selected. Its diameter should be such that it fits tightly into the cavity of the profile pipe. Only in this way can it effectively prevent too sudden changes in the cross-section of the pipe at the bend site.

So that at the end of the work the spring can be removed without problems, a piece of wire is securely attached to its edge before installation.

Now you need to decide on the type bending equipment. This can be done by knowing the height of the product profile. For a thin pipe, with a profile height of less than 10 mm, use a bending plate with pins that act as stops. They are located in accordance with the bending radius of the part. The pipe is laid between the stops, giving it the required shape.

They start laying the part from the middle, this makes it easier to complete the operation. Then they gradually move towards the edges of the product. A significant disadvantage of this bending method is the need to apply significant effort.

In addition, it is quite difficult to bend exactly according to the template; it is very likely that there will be some deviations from the given shape.

Pipes with a profile height of more than 10 but less than 25 mm are bent using special equipment equipped with a roller. It operates on the principle of the so-called Volnov machine.

This happens as follows. The part is securely fastened in a vice. A significant force is applied to it through the roller, which bends the element. This method allows bending to be carried out more accurately and efficiently.

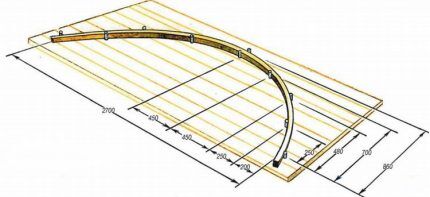

But even in this case, you will have to make very significant physical efforts to get the desired result.If you need to get a part with a large bending radius, for example, an arch for a frame structure, plane-parallel plates or a mandrel are used.

The device is a stationary round-shaped template on which clamps are located for fixing the part.

The profile pipe is inserted with force into a groove, the size of which exactly matches the profile of the product. Retaining clamps hold the piece pieces in place until the entire piece is placed in the fixture. This way the pipe is given the desired shape.

If you have basic electric welding skills, then you can make a simple machine for bending profile pipes with your own hands:

We also recommend that you look at the article in which we talked about how to bend pipes from various metals - read more Further.

The simplest devices for cold bending

Let's look at how to make two very simple devices yourself that will help you bend a profile pipe.

Profile mandrel

The basis for the device will be a workbench. It is important that not only the work area, but also the space around it is free. To secure the mandrel, you will have to make several closely spaced holes in one edge of the workbench tabletop.

The actual mandrel or template is made of plywood. However, this option is only acceptable if several parts are to be completed.

If you need to bend a large number of pipes according to this template, it is best to make the mandrel from a steel angle. In some cases, the profile product must be bent at different angles.

For such work you will need several templates, which should be prepared in advance. Before starting work, the mandrel is firmly attached to the base using clamps.

The pipe to be bent is securely fixed to its edge. After which bending is carried out. The operation is performed smoothly, without sudden jerks. The force applied to the pipe should increase gradually. During the bending process, the part takes the shape of a mandrel. This will require significant effort.

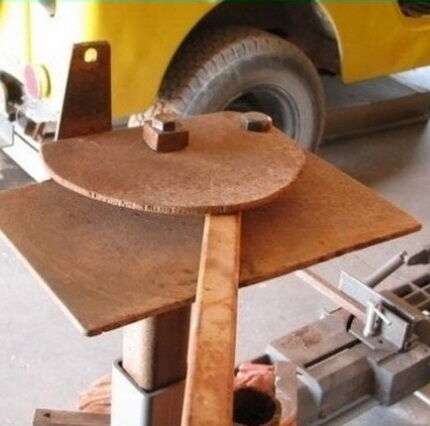

Advanced bending plate

This is a convenient multifunctional device that allows for high-quality profile bending. The device is a durable metal base plate mounted on a pedestal. The latter is fixed to the workshop floor using fastening bolts.

You can make a simple-to-make and affordable bending plate with a mandrel with your own hands:

As an option, you can consider a similar device mounted on a workbench. After work, the bending plate can be easily dismantled and put away, or you can use it as a stand for other metalworking operations.

To make such a device you will need a thick metal plate. It is welded onto a telescopic stand. For bending stops, two holes are made on the base plate.

Stop bolts are installed in them. Nozzles of various radii are put on and fixed on them, which allows you to bend the pipes as needed. A pressure plate is cut from thick sheet steel.

Its use is mandatory so that the alignment of the part being bent is not disturbed, since bending a profile pipe without a pipe bender can accidentally deform it in two different directions. The plate is secured above the nozzles with stop bolts.

The actual bending process is as follows. The pipe section is fixed in the device, after which the opposite edge is pulled with force. The part should begin to bend. If this does not happen due to insufficient force, you can try to increase the shoulder by placing a pipe of a larger diameter on the part.

Conclusions and useful video on the topic

We bend the pipe using a mandrel made of steel angles:

How to make a homemade pipe bender easily and quickly:

The simplest way to bend a profile pipe:

There are quite a few ways to manually bend profiled pipes. And they all have a common drawback: a very large force is required to bend them. A physically unprepared master may not be able to cope with such work. Bending parts using specialized devices is much simpler, more accurate and does not require much physical effort.

The problem is that the cost of such equipment is quite high. Therefore, buying a device just to perform a one-time job is certainly unprofitable. The best option is to rent specialized equipment, which will allow you to get profile products bent exactly according to the template for a small fee.

If you have the necessary skills, please share your experience with our readers. The feedback form is located below the article. There you can ask a question about the topic of the article, and we will try to answer it promptly.

I tried to use heat to bend two profile pipes the same way:

1) They turned out different!

2) The inner side wrinkled (but it was lucky that the outer one stretched well and smoothly).

3) I won’t take on this on my own anymore.

It’s strange that no one at the trading places could tell me where to go for this work. I also corrected my mistakes myself, tolerably. Not perfect, but I did it.