Materials for waterproofing swimming pools: a comparative review

Many people consider swimming pools to be attributes of a “beautiful” life and associate them with expensive multi-storey cottages and mansions. In reality, everything is not quite like that. Any owner of a country house or house can pamper his family with a swimming pool.

You just need to carry out the construction work correctly. Particular attention should be paid to protecting the structure from water. It is important to choose the right materials for waterproofing swimming pools, and we are ready to provide effective assistance.

The article presented for consideration describes in detail all options for systems for protecting the bowls of swimming structures from the effects of water. We have described in detail the main characteristics and methods of applying compounds and waterproofing coatings. Taking into account our recommendations, you will not go wrong with your purchase.

The content of the article:

Why is waterproofing needed?

Waterproofing in construction means a set of works aimed at providing effective protection against moisture. Swimming pools are no exception. They must be protected from the destructive effects of water.

You need to understand that the bowl is a complex structure, inside of which there is a fairly large mass of water. It puts pressure on the walls of the pool, and when filling or lowering, additional forces are applied to them.

The slightest cracks or any other defects will become a serious threat to the entire structure. When exposed to moisture, even microscopic flaws quickly turn into serious problems.

Therefore, it is very important to prevent contact of water and the walls of the structure. Pools are often built from concrete. This is a porous material that instantly absorbs moisture. The very bad thing is that water inside concrete structures quickly destroys them.

But it’s not just concrete that is threatened by excess moisture. The inside of the bowl walls are usually reinforced with metal rods. The porous material allows water to pass freely to the fittings.

As a result, it corrodes and disintegrates quite quickly. Thus, without proper waterproofing, a bowl undergoing serious stress will literally crumble in the shortest possible time.

High-quality waterproofing of a swimming pool must meet the following requirements:

- Durability and long service life;

- High resistance to adverse external influences;

- Good adhesion.

- High elasticity.

Ideally, the insulating layer should have all the properties listed above and form a seamless monolithic coating covering the entire surface of the bowl.

About methods of conducting waterproofing the pool bowl, available for doing with your own hands, is written in detail in this article. It also provides the materials needed to form a perfect protection.

Types of pool waterproofing

The structure is protected from water from the outside and inside, and therefore the waterproofing materials used are divided into two groups.

External moisture protection of the bowl

External waterproofing is used to protect the structure from flood and groundwater. It is relevant for street structures buried in the ground. The requirements for external waterproofing are similar to those for moisture protection of foundations.

The main difference lies in the shrinkage rates and changes in the geometry of the bowl structure that occur under the influence of a significant mass of water. Before building a bowl, it is necessary to carefully study the soil structure in the selected area, find out the level of soil freezing, as well as the depth of groundwater.

It is very important that the level of the bottom plate of the bowl is not lowered below the depth of groundwater. If this is the case, waterproofing alone will not be enough. In this case, groundwater must be drained away from the structure using a drainage system.

The most proven and affordable method of arranging external waterproofing is considered to be a clay castle, which is installed directly during the construction period. After the soil is removed from the pit prepared for the pool, clay is poured into it and compacted thoroughly.

This is a clay castle. The best results can be achieved when it is used in combination with other insulating materials: pasting, coating or penetrating materials.

You need to choose the option of an external water barrier for the bowl at the design stage. After pool construction it is more expensive and more difficult to eliminate defects and apply material to the walls. And it will be completely impossible to protect the bottom.

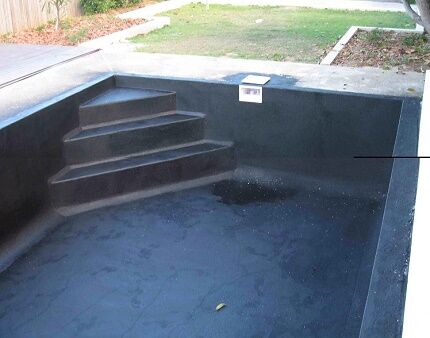

Internal waterproofing of the pool

Internal insulation of the bowl is mandatory for any type of pool. The insulating layer protects the material from which the structure is made from the destructive effects of moisture and chemical compounds.

Most often, the composition includes protection against disinfectants, which will certainly be present in the water. The latter are relatively safe for humans, but are an aggressive environment for building materials.

Waterproofing not only protects the pool from moisture, but also from possible leaks and corrosion. Internal insulation will be considered high quality if it is resistant to opening holes and cracks up to 3 mm wide.

It is desirable that the waterproofing layer be low, but at the same time elastic. The material must have good adhesion to the base and maximum water resistance.

In addition, the insulating coating must resist hydrostatic and dynamic loads and fully comply with environmental standards. It would be nice if the waterproofing suppressed the activity of microorganisms.Another important nuance is full compliance with the type of finish chosen, otherwise it will be impossible to fully cladding the bowl.

All of the above requirements are met by the one-component composition “AKTERM Gidrodef Pool”, which can be used on different surfaces. The material has good adhesion and is resistant to destructive environmental influences. The coating is easy to apply with your own hands.

The internal waterproofing of the bowl is applied in the final stages pool construction. You can choose a material for it after all the work on the construction of the bowl has been completed, but always before cladding.

Materials for insulation work

A variety of materials can be used to waterproof bowls. Each of them has certain advantages and disadvantages. To make an informed choice, you should carefully study the different types of insulation.

Bitumen-based coatings

Appeared on the construction market more than half a century ago. They are produced in the form of built-up roll materials, roofing felt, and bitumen mastics.

Bitumen coatings have a number of advantages:

- High elasticity, which virtually eliminates damage to the insulation during operation and during further finishing work.

- Effective protection against moisture.

- Long service life.

- Possibility of carrying out work on laying the material and subsequent finishing at any time of the year.

- Resistant to almost any aggressive influences, including chemicals.

- Most materials are affordable.

Despite a fairly large number of advantages, bitumen coatings for waterproofing swimming pools are used quite rarely. This applies to a greater extent to welded roll materials, which are difficult to apply.

Hot solutions are also difficult to install. The main obstacle to the use of bituminous materials for insulating swimming pools is poor adhesion to adhesives used to decorate bowls.

Cement based solutions

Such mixtures usually contain three components. The first is astringent. This is a high-quality cement that provides the material with strength and partially repels water.

The second is filler: fine quartz sand. The third is polymer additives. Various substances that increase the hydrophobic properties of the mixture, adhesion and elasticity. These can be synthetic resins or vinyl acetate.

Cement-based waterproofing has many advantages:

- Good adhesion. The material adheres well to wood, brick, concrete, metal, etc. The adhesion of cement insulation is much higher than that of bitumen-polymer or bitumen.

- High abrasion resistance and mechanical strength.

- Water permeability. The insulation does not allow water to penetrate into the base, but at the same time allows the moisture inside to evaporate. This ensures that there are no possible peelings.

- Possibility of application, if necessary, not only on a dry, but also on a wet base.

- Environmental Safety.

- Fast drying. After 10-14 days, the surface treated with cement compounds is ready for further finishing. No additional preparation is required - finishing materials adhere well to this base.

- Long service life.

Practice shows that throughout the entire period of operation, repairs of cement waterproofing are not required. It is quite easy to apply and can be placed on surfaces of various configurations.

The cost of coverage is relatively low. The main disadvantage of cement waterproofing is its high rigidity. It is not elastic, so if a crack appears in the bowl, the insulating layer will inevitably be destroyed.

This problem can be solved. On sale you can find special two-component cement-based compositions with a high content of the polymer component. Such mixtures are laid in several layers. A reinforcing fiberglass mesh is mounted between them.

Rubber-polymer elastic bands are additionally applied to all internal corners. The result is an insulating coating that is superior in its characteristics to bitumen. However, its cost is quite high.

Penetrating waterproofing

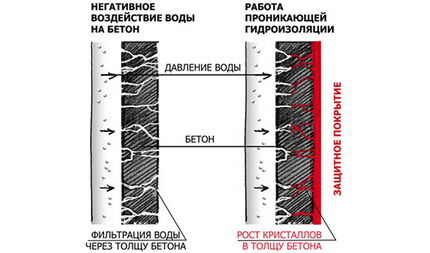

Penetrating insulation is produced in the form of a mixture containing high-quality Portland cement, filler and active chemical additives.

Additives are alkaline earth and alkali metal salts or polymers. After dissolving in water, a liquid working solution is obtained, which is applied to the base, forming an external protective coating.

Its main difference from analogues is that the composition penetrates into the base through pores, structural capillaries and microcracks. Here the mixture is converted into water-insoluble waterproofing crystals.

The base material becomes impervious to moisture and at the same time strengthens, which significantly extends its service life. This effect is not achieved by any of the known types of waterproofing.

In addition, when applied, coating and roll materials form a non-breathable dense film on the surface. If there was moisture in the pores of the base, and this happens very often, it will remain inside, which over time can lead to mold.

Penetrating compounds work differently. When they enter the pores of the base, they crystallize and at the same time displace moisture and vapors out.

Only after all moisture has been removed from the base does the crystallization process stop and a protective layer forms on the surface. Penetrating mixtures can fill the thickness of the concrete base 35-40 cm deep.

At the same time, penetrating compounds completely seal cracks and other defects up to 0.4 cm wide. The service life of the material is 70-100 years, while rolled and coating analogues last 25-30 years.

In addition, the advantages of penetrating waterproofing include the following:

- Forms a sealed seamless coating that is highly resistant to mechanical damage and aggressive chemical influences. It does not crack or peel.

- Easy to prepare the mixture and further installation. The composition can be applied to a damp base.There is no need to pre-dry it.

- Ability to process both new and old structures. The latter is relevant when carrying out repair work.

- Complete environmental safety for both people and the environment.

- When applied to a reinforced concrete structure, the composition protects the metal component from corrosion, which extends the service life by approximately three times.

- The composition can be applied in any weather. Temperatures for using the solution are from +75 to -30C. Compositions have been developed that can be used on hot surfaces.

- After the mixture dries, it becomes a good basis for further finishing. No preparatory work is required.

The disadvantages of penetrating materials include selectivity of application. They are not placed on very porous materials such as expanded clay concrete, shale ash concrete and the like.

A large number of pores will require significant consumption of expensive insulation, which is very unprofitable. In addition, the material cannot be applied to areas connecting elements of water supply equipment with a concrete base.

Waterproofing film coating

It is a polyvinyl chloride or polyester film that is placed in a bowl. Several varieties of this coating are produced. Non-reinforced fabric has the least strength.

This is a single-layer material with low performance characteristics and a budget price. This film is most often used to insulate prefabricated swimming pool models.

Reinforced films are characterized by greater reliability and durability.They are a multilayer coating, where reinforcing polyester threads are laid between the film panels.

This material can easily withstand fairly large loads without any signs of deformation. The outer coating of the films also varies. The most practical option is with an anti-slip layer.

On sale you can find a film with an acrylic coating, which prevents the active proliferation of microorganisms, which greatly facilitates the maintenance of the pool.

The advantages of waterproofing film include:

- Attractive appearance. This coating is not only waterproofing, but also a decoration for the bowl. The material is available in a variety of colors and textures. Imitations of mosaic tiles, stone and sand are especially good.

- High resistance to various aggressive environments, frost resistance.

- Easy to care for. The coating is easy to clean with the most common soap solution.

- Possibility of laying during construction on a new bowl or during repairs on a prepared old base. In this case, the panel can be applied over the old finish, for example, laid on ceramic tiles.

- Low cost of material.

Among the disadvantages, the main one is considered to be the rather short service life of such a coating. It lasts about 5-10 years, after which the panel must be changed.

This is due to the fact that during operation the film inevitably loses its color saturation and becomes covered with scratches. This happens especially quickly with intensive use of the pool; for home structures the process usually proceeds more slowly.

Installation of a new coating is quite complicated and is most often performed by experienced craftsmen. During its implementation, special technologies are used. Including hot air welding of panel joints. Even a small mistake can lead to water getting under the waterproofing carpet, which is unacceptable.

Liquid rubber for waterproofing

The coating is a modified latex-bitumen emulsion. It includes two mutually insoluble components - water and bitumen.At its core, it is a bitumen emulsion, the performance characteristics of which are improved with the help of latex.

The name liquid rubber is somewhat unjustified, because the basis of the material is not rubber at all, like classic rubber. However, it stuck. There are two main types of coating available: one-component and two-component. The latter has a more complex composition and better characteristics. In addition, the material differs in the method of application to the base.

This can be spraying, painting or pouring. It must be admitted that the first option gives the best result. True, its implementation requires special, expensive equipment, which only trained workers can handle.

Liquid waterproofing has many advantages:

- Forms a monolithic, completely sealed coating, which does not have the slightest joints.

- High adhesion to any substrate.

- Fills microcracks and small defects in the base.

- Good elasticity, which implies the ability to return to its original position after a short-term increase in size. Therefore, the coating is especially resistant to temperature changes and high humidity.

- Short installation time. The process of applying liquid rubber is mechanized, which makes it possible to lay it several times faster than, for example, pasting materials.

- Environmental safety of waterproofing material.

- Good repairability of the coating. Defects can be easily eliminated by applying a new portion of the mixture.

- Finishing coatings can be applied over liquid rubber. It can also be used without additional decoration.The material is available in various colors, which improves its decorative properties.

The disadvantages of liquid rubber include high sensitivity to ultraviolet radiation. You cannot leave such a coating without applying a special protective layer if the pool is located in direct sunlight.

Another disadvantage is the fairly high cost of the coating, especially if it is applied by spraying. In this case, the cost of applying it is added to the price of the material.

Insulating coating “liquid glass”

Under this name, a composition based on water mixed with natural potassium or sodium silicates is known. It has a special viscosity and does an excellent job of waterproofing.

Small crystals that are visible in the material, after being applied to the base, increase in size and fill all cracks and small defects. Liquid glass is absolutely impenetrable to water and air.

In addition, the insulating coating also has antiseptic properties - microorganisms do not live on it. It is antistatic, that is, it does not accumulate static electricity. Liquid glass acts as a hardener for the base. It significantly strengthens the structure of the material it is applied to.

In addition, the advantages of liquid waterproofing include:

- High degree of adhesion. The material fits perfectly on almost any base, penetrating into the smallest cracks and thereby holding them together.

- The resulting insulating coating has no seams or joints and is completely sealed.

- High water repellency.The insulating layer is completely impermeable to water.

- The cost of the finished coating is relatively low compared to other waterproofing materials.

- Economical consumption of liquid glass when laying the insulating layer.

- Environmental Safety. The waterproofing material does not contain toxic substances.

- The ability to lay the coating in conditions of high humidity, which is impossible for other materials.

Liquid glass has a lot of disadvantages. First of all, it has a short service life. It is only 5 years. After this time, the material begins to self-destruct.

True, if you cover it with a protective layer of paint, it will last much longer. It is not recommended to use liquid glass on brick surfaces, otherwise the base may be destroyed. Another disadvantage is the difficulty in applying the material, since it dries very quickly.

Conclusions and useful video on the topic

Video #1. How to use liquid rubber to waterproof a swimming pool:

Video #2. Waterproofing a swimming pool with polyvinyl chloride roll material:

Video #3. Features of using liquid glass:

We are convinced that the range of waterproofing materials that can be used in the construction of swimming pools is quite large.

When choosing the best option, you should take into account the material from which the bowl will be made, the operating conditions of the structure and other features of the specific design. Only in this case can you expect that the new pool will serve for a long time and without problems.

Please comment on the material proposed for consideration in the block located below the text of the article.We are interested in your opinion, stories about your experience of installing a private pool and a country plot. We are waiting for useful tips, suggestions and photographs on the topic.

We used special mastic from a German manufacturer for waterproofing. It's very expensive, really. Apply with a brush like paint, in several layers (2-3 layers) with short technological intervals required for drying and polymerization. This mastic is used for waterproofing underground and underwater tunnels, so it is designed for high water pressure. Any final finishing can be done on top.

Good afternoon What kind of mastic did you use? Thank you

I used liquid rubber as waterproofing for my pool at the dacha; it penetrates well into all cracks, even the smallest ones. I used gray color.

The first time I didn’t quite manage to distribute it evenly around the entire perimeter of the pool, so I had to additionally go through the “unfinished” places.

Then I applied decor on top of it.

The pool has been serving us for three seasons now. So far there are no complaints.

GOST recommends the use of primary waterproofing, which makes the structure itself waterproof. In this sense, penetrating waterproofing is preferable to all others. The cost is 300 rubles/m2 for the entire service life, I think it’s very inexpensive.

Tell me where I can buy or order penetrating waterproofing