Design and operation of a bag filter: pros and cons + features of replacing a filter bag

Of course, compliance with environmental standards is an important condition for the successful and safe operation of any production.Purification of air contaminated with processed products is the main requirement for enterprises in the mining, cement, chemical, flour milling, metallurgical and other industries, during the activities of which a large amount of dust, soot and other microscopic pollutants are formed.

But modern cleaning designs make it possible to effectively solve the problem of excessive dust in the air: the design and operation of a bag filter is aimed specifically at removing the smallest particles of harmful suspended particles. After installing this unit, all dust and dirt settle on the walls of the filter, and lighter air, free of impurities, is released into the atmosphere.

In this material we will look at the structure and principles of operation of a bag filter, learn about methods of self-regeneration and replacement, and also reveal the advantages and disadvantages of this cleaning design.

The content of the article:

The need for air purification in production

The environmental crisis on the planet is getting worse every day. Manufacturing enterprises play an important role in this: leakage of chemicals, pollution of water bodies with wastewater and dust emissions have an extremely negative impact on both the state of nature and human health.

In addition to direct harm to workers and residents living near production, dust also causes damage to the enterprise itself.Dust deposits have a detrimental effect on the operation of equipment and worsen the condition of ventilation system and heat exchangers. These factors can lead to a decrease in the quality of manufactured products and even increase their cost due to breakdowns and faster wear of the equipment used.

That is why high-quality dust collection and neutralization is an integral stage of the entire technological process in production. The bag filter effectively copes with the assigned tasks and protects not only nature and people, but also the equipment of the enterprise.

How does a bag filter work?

Purification equipment with a bag filter can be used as part of internal ventilation, which provides for the return of purified air back into the room, and as a system for completely purifying the air before releasing it into the environment.

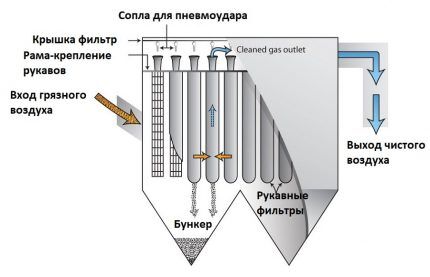

The bag filter is a fairly simple design, which consists of the following basic elements:

- housings for filter units;

- chambers for clean and dirty air;

- bunkers and supports;

- an intake valve through which the air mixture passes;

- a cleaning sleeve or a set of sleeves that are located in the air path;

- an outlet valve with a pressure regulator that allows the purified flow to pass through;

- filter regeneration system, which allows you to periodically clean the bag from dust.

The design of the device is designed to allow a sufficiently large amount of air or gas to pass through.The flows entrained by the inlet valve pass through the system, leaving particles of dust or soot contaminants on the surface of the filter on a woven or non-woven basis.

The filter can be single, but complexes with a battery of hoses, which purify the air more effectively, remain more effective. After the hose, the recycled air is released through an outlet valve equipped with automatic pressure control.

In fact, the design performs three main tasks:

- qualitatively cleans the gas-air mixture from pollutants;

- ensures uniformity of dust load;

- regulates the amount of air supplied for filtration.

Separation of small particles in the exhaust air makes it possible to ensure proper purity of the exhaust stream. Unwanted suspended matter is securely contained within the hose, which is self-cleaned during the regeneration phase.

Main types of filter bags

The choice of a suitable bag filter is based on the specifics of the production and the nature of the dust produced in the process. The main criteria that you should rely on when selecting this equipment are the performance of the installation and the depth of purification of the incoming air. The remaining parameters are individual: the degree of their importance depends on the production conditions.

For example, the choice of material from which the filter is made depends entirely on the characteristics of dust pollutants that arise during production.

No. 1: Difference in hardware performance

Bag filters are divided into two main types: round And flat. The first type is designed for operation in enterprises with a large dust load and is capable of passing and purifying quite significant volumes of air: more than 100 thousand m3 at one o'clock.

Flat hoses have a more modest performance, but also have a more compact design. Such cleaning systems are suitable for workshops with a small dust load.

No. 2: Classification by type of hose installation

According to the type of installation, systems with bag filters can be vertical or horizontal. The latter remain more efficient as they allow more air or gas to pass through.

The flow path through the hose itself is quite long, so the pores of the filter material trap more pollutants.

Sleeves are also distinguished by shape: ellipsoidal, cylindrical, rectangular.

No. 3: Varieties based on material of manufacture

The classification and operating principle of a bag filter is also influenced by the material from which the filter element is made. It is often made from fabric.

It can be either natural cotton or wool, or synthetic materials:

- polyester;

- fiberglass;

- polyamide;

- meta-aramid;

- polytetrafluoroethylene;

- polyacrylonitrile, etc.

The choice of hose material is based on the type of production, characteristics of the filtered mixture, dispersion and properties of dust, and aggressiveness of the environment.

Recently, non-woven filters with a more uniform and finely porous structure, which, due to their fibrous surface, retain more pollutants, have become particularly popular.

No. 4: Classification by regeneration method

The filter restoration method can be considered another category in the classification of these devices. Regeneration of the hose assembly is an important stage in the operation of the structure, so it should be given special attention.

In fact, regeneration is the process of cleaning the hose from accumulated dirt.

The procedure can be carried out using several methods, the choice of which depends on the nature of the dust:

- Vibration cleaning, during which the hose or battery of hoses is vigorously shaken, after which the contaminant particles fall into a special hopper for subsequent removal. Dust is removed from it using a dust transport system: a screw or pneumatic conveyor, a rotary vestibule, a scraper chain, a slide or valve gate.

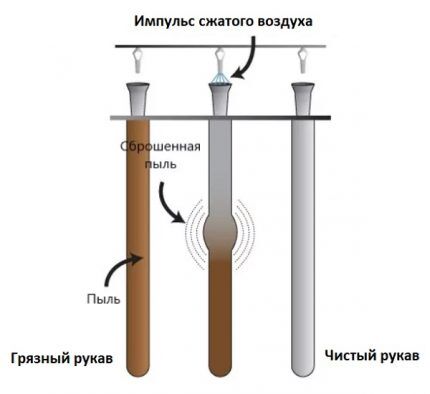

- Pulse purge or pneumatic cleaning. The filter is subjected to pulse blowing or pneumatic cleaning using a reverse air flow, which knocks microparticles out of the pores.

- Combined cleaning. A battery or a single hose is subjected to a combined cleaning process, during which the filter is shaken and sprayed with streams of clean air.

Vibration cleaning can occur not only automatically: the regeneration process is sometimes carried out manually thanks to a special handle and is called mechanical cleaning of the sleeve.

But most often, the regeneration process is carried out automatically thanks to the operation of pollution sensors, which react to the amount of collected debris and determine the pressure and throughput of the hose. If the pressure at the outlet of the structure drops, the sensor triggers a purge process or a shaking mechanism.

With a low dust load in a non-aggressive environment in a small production area, the full functioning of a bag filter can reach five years, after which its scheduled replacement will be required.

Features of replacing a bag filter

Like installation, replacement of worn-out filters is carried out on the basis of design documentation and the conditions in which the cleaning device operates.

Many key factors are taken into account:

- dust load;

- dust dispersion and its quality;

- characteristics of the work environment;

- the performance of the filter itself;

- installation location;

- depth of mixture purification, etc.

If only one sleeve in the battery fails, you can cut off its operation without replacing it. To do this, the filter is clogged at the level of the tube sheet. There is no need to remove the purge pipe or frame.

If the unit requires complete replacement, you must perform the following steps:

- Close the dampers at the entrance and exit to the compartment, if this is provided for by the design features of the system.

- Through the inspection window, remove the purge pipe leading to the hose or battery to be replaced.

- Remove the sleeve frame.

- Remove the sleeve from the structure. It can be lifted up the tube sheet or dropped into a dust bin. In the latter case, the filter will need to be removed from the compartment through the viewing window.

- Install the new sleeve in reverse order. After connecting, secure the frame and install the purge pipe.

After replacement activities, it is necessary to conduct a test run of the equipment to ensure its functionality.

It is better to trust the replacement to a specialized company whose employees have the skills and experience in removing and installing bag filters.

We also have an article on our website with detailed instructions on replacing the filter in the supply ventilation.

Advantages and disadvantages of devices

Like any other cleaning equipment and systems, for example, aspiration, the bag filter has its own operating characteristics, during which the characteristic advantages and disadvantages of the system are revealed.

The advantages of such a complex outweigh the disadvantages, which is why bag filters are widely used in various areas of production.

The undeniable advantages of bag filters include the following features:

- The design is universal, so it can be easily integrated into the ventilation and cleaning systems of various industrial sectors.

- The complex with a bag filter can be easily integrated into a technological line and is undemanding in terms of the amount of space required for its installation.

- The degree of purification of the gas-air mixture reaches 90-99%, which is an extremely high indicator for a dry cleaning system.

- Filtration occurs equally effectively both at extremely low air temperatures and in a heated room.

- Control of the complex is very simple and can be fully automated.

- Planned replacement of spent bag filters is carried out every two to three years.

In addition to the advantages, the bag filter also has minor disadvantages. The main one is the need for a compressed air supply in conditions of filtration of air volumes of more than 150 m3 at one o'clock.

Certain types of production or aggressive operating conditions may require filters made from expensive materials, such as fiberglass or meta-aramid, which are more resistant to wear.

Other types of filters are also used in the ventilation system. We talked more about air and carbon filtration systems in the next article.

Conclusions and useful video on the topic

The structure and operating principle of a cleaning system with a bag filter is clearly shown in the video below:

The hose testing process and the filter cleaning mechanism are demonstrated by the manufacturer of the cleaning equipment:

A bag filter is one of the simplest and most effective ways of dry air purification from dust of various origins. The universal system can be successfully integrated into almost any technological process during which large volumes of filtration medium are formed, requiring maximum removal of unwanted suspended matter. The hoses are quite easy to replace and do not require complex or expensive maintenance.Therefore, owners of production facilities should definitely take a closer look at this type of exhaust air purification.

Would you like to supplement the above material with useful information or talk about the features of using filters based on personal experience? Write your comments and additions, ask questions to our experts - the feedback block is located below.