Is it possible to insulate a wooden house from the outside with penoplex: requirements and nuances of technology compliance

Most private developers are trying to find simple, reliable and extremely inexpensive construction technologies that make it possible to construct buildings that are relatively cheap to install and operate. For our climate, the most expensive item of operating costs remains heating in the cold season, don’t you agree? So the search for optimal insulation has always remained a pressing problem.

Nowadays, penoplex is very popular, which has proven itself well in insulating foundations, plinths and concrete structures. Experienced developers have been convinced of the excellent characteristics of this material, but owners of wooden houses doubt whether it is possible to insulate a wooden house from the outside with penoplex, and if so, what is the optimal technology for this process.

To understand, you should, first of all, understand in what cases such an undertaking is necessary, what criteria insulation must meet, and what is the mechanism for such a costly and troublesome event. It is these questions that we will consider in detail in our article.

The content of the article:

When is insulation of wooden houses required?

Wood itself is an excellent heat insulator. And a high-quality wooden house, if we talk about traditional log technology, does not require additional insulation. But this is in an ideal world.

In practice, a wooden building may turn out to be uncomfortable or completely unsuitable for habitation due to technological errors, for example:

- a triangular longitudinal groove in the log instead of a semicircular one, which cuts off part of the caulking over time and is therefore easily blown through;

- insufficient thickness of lumber used in construction;

- repurposing non-residential premises into residential ones;

- An attempt to stop age-related changes in the structure of a house is a little costly - sooner or later the tree is subject to biological damage and its heat-insulating properties drop sharply.

That’s when the owners think about additional insulation of the walls.

Of course, the ideal is not to insulate a wooden house, but to correct flaws in its design. But for a variety of reasons, this path is not always possible. Therefore, the developer still decides to carry out insulation.

Requirements for the thermal insulation circuit

Let's break the big picture down into a few basic points. Firstly, wood is a material susceptible to biological damage (fungus, mold, woodworm, etc.). The problem can be partially mitigated by using chemical bioprotection methods. But this path is not always effective, and it can only be considered as part of an overall complex, and not as a self-sufficient means.

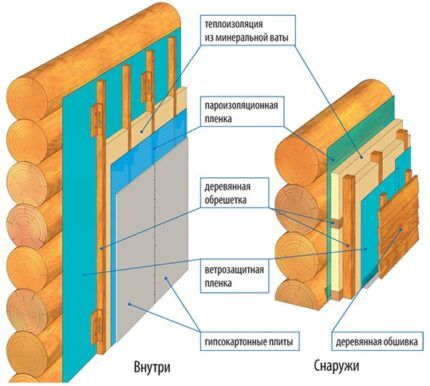

The main protection of wooden structures is moisture protection and natural ventilation. Consequently, the additional heat-insulating circuit should not in any way interfere with the normal ventilation of the walls and should not interfere with the removal of moisture from the wall mass.

Second important point - flammability of wood. Impregnation with fire retardants (substances that protect wood from fire), as in the case of chemical bioprotection, is only part of the solution to the general problem. It is also important to minimize the possibility of fire spreading. What should also be taken into account when installing insulation is that if ventilation gaps are formed, then they should be designed accordingly, which will be discussed below.

Thirdly, it is important follow the general installation rules heat insulator. But everything is simple here: no internal insulation wooden house. Any competent builder will tell you that the heat-insulating circuit is always mounted outside the structure being protected. There is a simple explanation for this - Dew point.

In simple terms, moisture can condense directly from the air when temperatures change. And therefore, condensation at the border of warm and cold is inevitable - physics. Accordingly, the dew point must be artificially shifted either to the outer surface or moved deeper heat insulator – if it is dense and not hygroscopic. And you can’t allow condensation to form in the room itself or in an area that can hold moisture. And the tree is just one of them.

Fourthly, façade cladding will be required. Since we are talking about external insulation of a wooden house, we should think about an affordable way to improve the facade after insulation measures are carried out - after all, existing insulation materials are in no way classified as decorative materials. And here the properties of the insulation must correspond to the design of the facade.

How to comply with the requirements in practice?

The ideal insulation for wood should be considered one that approximately corresponds to it in terms of vapor permeability and hygroscopicity. This can be considered ecowool made from recycled waste paper or (with some stretch) mineral mats based on basalt fibers.

Subtleties of using penoplex

But here considerations of the overall cost of the project and the ease of installation of the structure often come to the fore, and that’s when many people remember penoplex – slabs made of extruded polystyrene foam. A material with unique heat-insulating properties, almost zero water absorption and a host of other useful qualities. Moreover, the Internet is full of tips and recommendations for its use. Unfortunately, even the manufacturer does not always correctly indicate the areas of application of this material.

Penoplex is sometimes used in frame construction, since the material is vapor-proof and retains heat well. However, it should only be used in combination with kiln-dried wood. EPS does not combine well with damp wood or naturally dried wood.

In order for penoplex, or more precisely, a shell made of it, built around the walls, to meet all the above requirements, it is necessary to provide for a lot of nuances. So that there is no threat of biological damage, normal ventilation must be ensured.

If an array of penoplex is permeable to steam, then a separate slab is not (there are simply gaps between the slabs, which even when filled with mounting compounds do not provide the necessary tightness). So, areas with high vapor conduction voltage will be created in the insulation array, that is, all the steam that is formed in one way or another in the room will begin to pass through the walls, not through the entire surface, but only in some point areas, which is why condensation will form in these areas . And, as a consequence, there are problems of focal accumulation of moisture - in places where steam can pass through the walls.

The problem can be partially solved by creating a ventilation gap between the wooden wall and the EPS layer. But this option is not possible for fire safety reasons. Yes, the manufacturer assures that extruded polystyrene foam is safe in terms of fire, since it does not catch fire, but in the vicinity of flammable material it supports combustion well, so they are not good neighbors with wood. More details technical characteristics of EPS we covered in this article.

In general, the construction of ventilation gaps using flammable materials with wooden walls is strictly prohibited - such a gap plays the role of a chimney with excellent draft and therefore contributes to the immediate spread of fire in the event of a fire.

Since the option of maintaining a gap is eliminated, you have to think about the tight fit of the EPS to the walls of the house.What is possible only in timber or frame construction. A log house made of round logs cannot be protected in this way.

But at the same time, additional measures will have to be taken to improve the ventilation of the interior of the house - in order to get rid of the effect of a thermos (although here the comparison with a greenhouse is more correct). And an increase in the power of supply and exhaust ventilation can affect a decrease in the efficiency of the heating system.

To remove such negativity, you will have to think about recovery schemes - we are mainly talking about preheating the air coming from the street due to the air that is removed from the room) in the ventilation system. And this will lead to additional costs, so the primary visible savings on insulating a house in this way can reduce all budget bonuses to zero.

Thin sheets EPPS cannot be used for façade insulation in principle. Due to the same dew point. It should be located in the thickness of the polystyrene itself or on its outer surface. Shifting it to the middle of the general massif is unacceptable - the tree should be protected in every possible way from the ingress of water.

In factory-made frame structures, this problem is solved by almost completely sealing the solid wall and using chamber-dried wood, but in artisanal conditions this is simply impossible. Therefore, only enhanced ventilation.

Exterior finish over insulation

Expanded polystyrene has a fairly high coefficient of thermal expansion. Accordingly, the linear expansion of its massif with daily and seasonal temperature fluctuations will reach serious values.Therefore, the use of a wet facade, the creation of which uses technologies that use hydraulic binders, in other words, putties and plasters, is excluded.

In theory, it is possible to create around polystyrene foam the shell of a certain base reinforcing layer that will become load-bearing. But this solution is by no means optimal. Therefore, only the frame cladding method remains.

Tips for facade insulation EPPS

If the skeptics are not convinced by our arguments and they continue to insist on insulating a wooden house with the help of slabs penoplex, we will give some tips that will allow you to at least somehow level out the shortcomings of such a solution.

So, install the slabs on the walls without a gap. It is best to use mounting adhesive based on polyurethane foam. Additionally, the plates are fixed with plastic “fungi” or self-tapping screws with reinforced mounting washers.

When choosing a material, preference should be given to slabs with a quarter edge - for greater joint density. And still, after installation, the joints of the slabs should be carefully filled with polyurethane foam. The thickness of the slabs is ideally from cm - with a smaller layer of protection, problems with the same notorious dew point may begin.

Particular attention should be paid to window and door slopes. They should be made as tight as possible.

It is better to carry out work in winter, as paradoxical as it may sound.Since installation in cold weather will eliminate fragmentation (separation of monolithic insulating shell of the house into separate slabs) protective layer due to the large KTR (coefficient of thermal expansion).

Conclusions and useful video on the topic

We recommend watching a video where a specialist with a construction education explains in detail the disadvantages of insulating a residential building with slabs EPPS:

This video discusses the issues of compliance with technology during installation. penoplex:

EPPS cannot be considered the optimal insulation for the external walls of a wooden house. Yes, it has excellent heat-insulating properties, is distinguished by its low specific gravity and relatively low price. And yet, for external walls, in addition to the ability to retain heat well, other equally important requirements are put forward. Which, unfortunately, penoplex cannot provide.

Do you still have questions about the intricacies of insulating external walls with penoplex? Or would you like to share your own experience in installing XPS and give recommendations to our readers? Ask questions to our experts, participate in the discussion - the feedback form is located below.

Hello! Tell me, please, that is, Penoplex 20 mm thick is not suitable at all? It’s just that the design of the sheathing does not allow the use of thicker sheets. Thank you

“The thickness of the slabs is ideally from cm - with a smaller layer of protection”

from how many cm?

Hello. I insulated my log cabin like this: Lathing, fiber cement boards. And between them is a mixture of sawdust and clay mixed in a concrete mixer. The ratio was approximately 1:5. It turns out when it dries something like Soviet cardboard. It takes a long time to dry.I didn't add lime. I painted the slabs white and put noodles painted brown along the joints. It seems to me that this is better than mineral wool and even more so than EPS. And it’s easier for a couple to leave the house through this mixture.

A question! I put the house (log house) on the plinth, backfilled it to the top brick 10 cm, spilled the screed 10 cm, it was even with the plinth! The log house lies on a 150:200 beam, I want to put a 5 cm penoplex water-heated floor, but when pouring concrete I want to cut off the tree, that is, a 150:200 beam, I lined it with 2 cm penoplex. The question is, is it possible to do this, I was told that it is possible, but now you need to cut off the tree itself from the penoplex inside and then screw 2 penoplex and otherwise the timber will rot