Grounding the ventilation system: rules and subtleties of constructing a protective circuit

Have you ever experienced electric shocks when touching the metal casings of home appliances? One of the reasons for the threat of electric shock is the absence or improper grounding of the ventilation system in a private home. Its device is required for the safe use of electrical equipment.

Agree that even weak impulses do not evoke positive emotions. And for people with pacemakers, the consequences of such touches can be especially sad.

Checking the correctness and integrity of grounding is not difficult. You shouldn’t invite electricians very often for this. We will help you deeply understand all the intricacies of monitoring the electrical safety of your home ventilation system.

The content of the article:

- The physical essence of the grounding process

- What does grounding consist of?

- Classification and types of ground electrodes

- Differences between the protective and working systems

- How to ground air ducts?

- Installation of protective circuit grounding conductors

- Typical mistakes made by DIYers

- System check by technical services

- Why do you need to ground air ducts?

- Conclusions and useful video on the topic

The physical essence of the grounding process

Beautifully mounted electrical wiring hidden in walls or ducts, as well as the complete absence of electrical devices in the ventilation system, do not guarantee against injury when contacting its metal parts. Only reliable connection of conductive external structures of ventilation equipment with grounding will provide you with confidence in safety.

Parts of air ducts, fan casings made of metal and other electrically conductive materials that are not energized during operation must be grounded. Such requirements are specified in the Electrical Installation Rules (PUE).

An electric charge on elements accessible to touch may appear from damage to the insulation of nearby wires, devices, or from the accumulation of static electricity. Grounding means that if an accidental electrical charge occurs, it will flow from the duct into the ground.

We all know from school physics that electric current follows the path of least resistance. If we compare, for example, with the free flow of accidentally spilled water, then the analogy is this: the water will not flow upward or sideways, but according to the force of gravity, it will rush downward. So with an electric charge, if it accidentally hits a grounded air duct, it will flow deep into the ground to the grounding conductors of the house circuit.

Human electrical conductivity can be reduced by additional insulation from the ground and other electrical conductors. For this purpose, special protective clothing and shoes are used. Or you can increase it by using a moist, unprotected area of skin.

A person with a built-in metal medical device is at greater risk. Or hung with various metal decorations. Current resistance also decreases in people under the influence of alcohol.

What does grounding consist of?

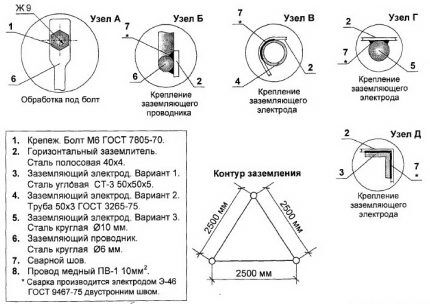

The grounding loop is a simple circuit of two elements - conductors and grounding electrodes.

Throughout the entire length of air ducts located indoors and outside the house, their external electrically conductive parts, which are not energized during normal operation, must be connected into a single electrical circuit.At at least two points this bundle is firmly connected to the ground loop.

Ventilation air ducts must be grounded in accordance with the PUE standards. The rules require the use of steel strips, copper wires or direct connection to grounded pipelines and other structural elements. It is common practice to combine the grounding of air ducts with the general grounding system of the house.

Classification and types of ground electrodes

These elements ground loop of any type are located directly in the ground. Grounding ensures that electrical charge flows into the ground from housings and other non-working conductive parts of ventilation equipment.

There are two types of grounding electrodes - natural and artificial. According to PUE standards, it is preferable to use natural grounding conductors.

In a private home these include:

- metal pipelines, armor of power cables;

- buried reinforced concrete columns, foundations;

- metal street structures, for example, a fence.

It is prohibited to use water and sewer pipes as natural grounding conductors.

Before connecting to permitted types of natural grounding conductors, their conductivity should be determined. The provisions of the PUE regulate the maximum value of the resistance to spreading of grounding conductors. For three-phase/single-phase current sources with a voltage of 380/220V, its value should be no more than 4 Ohms.

To order measurements, you need to contact any certified electrical laboratory. You should be given a protocol with the measurement results and copies of certified documents certifying the admission of specialists and the compliance of the devices with metrological requirements.

Differences between the protective and working systems

Grounding conductors from air ducts can be connected to the main grounding bus (GZB) or to the protective grounding bus in electrical panels. Provided that this equipment is available in a house where, if necessary, a ground loop has already been installed.

If you have already decided which air ducts in the house, according to the rules, must be grounded, then do not confuse the connection points. The fact is that electrical panels have a working grounding bus. It is intended for a working function, not a protective one.

The working neutral conductor (N) is the fourth conductor of the supply power cable, where there are three phase wires (L). It is connected to the neutral of the power supply. In the electrical panel, this neutral conductor is connected to the panel body and the working ground bus.

There are cables with a special insulated conductive braid, armor, which can serve as a natural grounding conductor. Or with a protective earth conductor (PE).

It is also connected to the body of the shield and to another grounding bus, but not a working one, but a protective one. It is not a fact that in your home such a reinforced, expensive cable is used in the power supply circuit.

Using a working neutral conductor, all 220 V devices are connected to the power supply. That is, the socket has two contacts “phase” and “zero”. All home craftsmen are aware of this.

Euro samples of sockets also have a grounding contact. You should never confuse these two completely different concepts - grounding and grounding. The consequences can be sad for both the victim and the owner of a private home. After all, it is the homeowner who is responsible for the safe operation of all equipment.

How to ground air ducts?

Flexible copper shunt bridges must be installed between the flanges if the air ducts do not have factory-made ones. A bolted connection, even one made without insulating spacers, is unlikely to comply with the rules.

Since the contact resistance must be less than 0.1 Ohm. It is allowed to connect the joints of metal structures by welding steel brackets.

Grounding conductors are connected:

- through adapter bars to flange bolts or other detachable connections;

- a crimp clamp, cleaned and treated with conductive lubricant;

- using welding or reliable detachable connections to the supporting frame.

Visible grounding must be done at the beginning and end of the duct. Copper lugs can be used as adapter bars.

The cross-section of steel grounding conductors must be at least 75 mm2. For a copper conductor, the cross-sectional thickness is allowed from 10 mm2.

The current-conducting parts of fan housings with a circuit should be grounded using separate conductors.Series connection of fans with grounding of air ducts is not allowed; there must be only a parallel circuit.

Installation of protective circuit grounding conductors

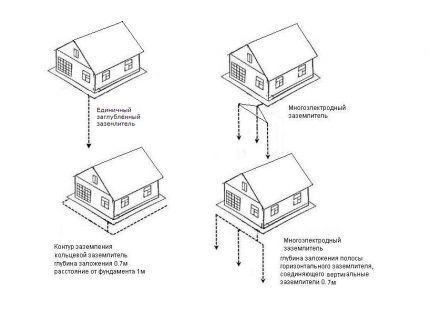

When reconstructing or building a private house, the missing grounding device can also be done with your own hands. The efficiency of the circuit depends on the selected connection scheme, the type and resistivity of the soil.

The resistance of a grounding device used solely to protect a person from static electricity from the air duct can be increased to 100 ohms. Introduce methods for measuring resistance next article, which we recommend reading.

It is advisable to photograph all stages of hidden work when installing a grounding loop. Keep printed paper photographs, hand-drawn diagrams with exact dimensions and specified materials along with test reports.

These are serious documents called a grounding device passport. With their help, you can monitor contour changes, plan repairs, and even reduce insurance company rates when taking out a home insurance policy.

Typical mistakes made by DIYers

Do-it-yourself grounding can be done flawlessly. But sometimes inattention, haste, and poor practical skills lead to errors in installation.

The most common common shortcomings and flaws:

- Poor contact due to protective coating of detachable connections;

- Non-compliance with the size standards of grounding conductors;

- Rapidly deteriorating material of grounding system elements;

- Connection of neutral working and protective conductors.

For some reason, many people advise placing ground electrodes away from home, choosing distance numbers from the depths of their consciousness. All installation data is advisory, but not mandatory. The contour does not pose any danger to humans; there are no distance restrictions in the rules.

Some “experts” advise pouring salt into the ground near the ground electrodes for better conductivity. No need to listen to amateurs, consult with professionals.

Indeed, at the beginning, due to an increase in humidity, a slight decrease in the spreading resistance of the ground loop is possible. But metal elements in such an environment will quickly collapse due to the acceleration of corrosion processes of grounding conductors.

System check by technical services

It is recommended to inspect the grounding of home ventilation equipment 2 times a year in spring and autumn. Detected breaks, corrosion, and other defects in visible external connections must be eliminated as quickly as possible.

It is better to carry out measurements with the assistance of electricians in dry summer weather or in winter frosts. Under these conditions, the soil resistivity increases. This means that the resistance to spreading of the ground loop will be maximum. This will ensure its reliability and compliance with the standard in all other seasons.

Why do you need to ground air ducts?

Ignoring proper design and installation of grounding ventilation systems owners of private houses most often explain it by their reluctance to spend extra money. For some reason, people who do not have special knowledge in this area believe that electrical safety can be neglected here.

In Russia, electrical injuries are the cause of death in 2.7% of accidents. These dry numbers hide specific human losses. The point is that electric current strikes unexpectedly. It has no smell, no color, you cannot see or feel it until you touch it or determine it using instruments.

The process of connecting metal parts of ventilation equipment to grounding devices requires special care. Observe safety precautions when working at heights, with welding equipment, and with electrical appliances.

Conclusions and useful video on the topic

Installation of a ground loop in a private house:

Composition of the building exhaust ventilation system:

The fan housing, air ducts and other elements that may contain an electrical charge must be safe from accidental human touch.

All grounding conductors, electrodes, and natural grounding conductors have electrical characteristics standardized by the rules. A well-designed circuit and properly installed protective elements will serve you for many years. It is only important to periodically carry out maintenance and measure the electrical parameters of the grounding parts.

What do you think: is it worth doing the grounding yourself or is it better to invite specialists? In the comment form below, share your opinion, ask our expert questions, and leave a review.