Ground Resistance Measurement: Review of Practical Measurement Methods

Grounding is used in various electrical system projects.The very concept of “grounding” is schematically considered by connecting a section of an electrical circuit to the ground potential.

The ground loop contains a conductor and an electrode embedded deep in the ground. A traditional action in electrical engineering practice is to measure the grounding resistance of networks that are still being launched and are already in operation. We will tell you how and how this important action is performed.

The content of the article:

Why are measurements needed?

A brilliant solution to the problems listed below is achieved by an ideal zero resistance in the ground circuit:

- Prevent stress from appearing on the body of technological machines.

- Achieve effective reference potential of electrical equipment.

- Completely eliminate static currents.

True, electrical engineering experience shows: it is impossible to obtain a result at an ideal zero.

In any case, a grounded electrode produces some kind of resistance.

The specific value of resistance is determined:

- resistance of the electrode at the point of contact with the conductive busbar;

- contact area between the earth electrode and the ground;

- soil structure that gives different resistance.

The practice of measuring ground loop resistance notes that the first two factors can be completely neglected, but subject to logical conditions:

- The grounding electrode is made of a metal with high electrical conductivity.

- The body of the electrode pin is carefully cleaned and firmly planted in the ground.

The third factor remains - the resistive surface of the soil. It is seen as the main design part for measuring the resistance of the ground loop.

It is calculated using the formula:

R = pL/A,

where: p – soil resistivity, L – conditional depth, A – working area.

To protect the owners of the house/apartment, all types of powerful home electrical equipment must be equipped with grounding:

When testing resistance, each of the ground lines is tested separately. The resistance between the grounding element and each non-conducting part of electrical equipment that may come under voltage must be less than 0.1 Ohm.

Overview of measuring methods

There are several options for measuring resistance ground loop, each of which allows one to quite accurately determine the required value.

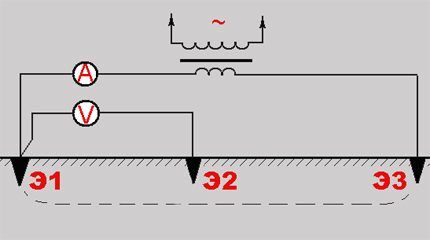

3-point detection system

For example, the 3-point circuit technique, based on the effect of potential drop, is often used.

Measurements are performed in three main steps:

- Measurement of voltage on electrode E1 and probe E2.

- Measurement of current strength on electrode E1 and probe E3.

- Calculation (formula R = E / I) of the resistance of the grounding electrode.

For this technique, the accuracy of measurements is logically dependent on the installation location of the E3 probe. It is recommended to introduce it into the soil at a distance - optimally beyond the so-called ESE (effective electrode resistance) area E1 and E2.

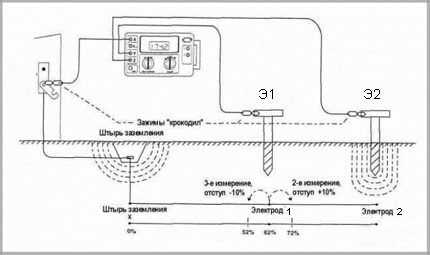

Measurements using “62%” technology

If the structure of the soil for placement of the grounding electrode is homogeneous, the “62%” method for determining the resistance of grounding loops promises good results.

The method is applicable to circuits with a single grounding electrode. The accuracy of the readings here is due to the possibility of placing the working probes on a straight section relative to the grounding electrode.

Installation points for control probes

| Electrode depth, m | Distance to probe E1, m | Distance to probe E2, m |

| 1,8 | 13,7 | 21,9 |

| 2,4 | 15,25 | 24,4 |

| 3,0 | 16,75 | 26,8 |

| 3,6 | 18,3 | 29,25 |

| 5,5 | 21,6 | 35,0 |

| 6,0 | 22,5 | 36,6 |

| 9,0 | 26,2 | 42,65 |

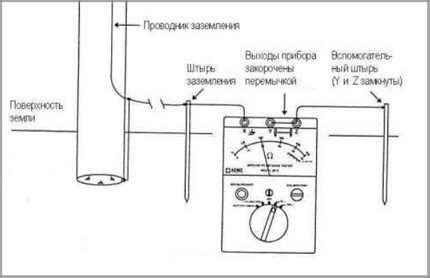

Simplified two-point method

The use of this measurement method requires the presence of another high-quality grounding in addition to the one that will be examined. The technique is relevant for densely populated areas, where it is often not possible to widely operate with auxiliary working electrodes.

The two-point measurement method differs in that it simultaneously shows the result for two grounding devices connected in series.This explains the requirements for high quality performance of the second grounding, so as not to take into account its resistance.

To perform calculations, the resistance of the ground bus is also measured. The result obtained is subtracted from the results of general measurements.

The accuracy of this method leaves much to be desired compared to the two above. Here, the distance between the grounding electrode, the resistance of which is measured, and the second grounding plays a significant role. This technique is not used standardly. This is a kind of alternative when other measurement methods cannot be used.

Accurate four-point measurements

For most resistance measurement options, the most optimal method, in addition to 2- and 3-point, is considered to be 4-point technology. Devices like the 4500 series tester are equipped with this measurement technology. Judging by the name of the method, four working electrodes are placed on the working platform in one line and at equal distances.

The current generator of the device is connected to the outer electrodes, as a result of which a current flows between them, the value of which is known. Two internal working electrodes are connected to other terminals of the device.

There is a voltage drop value present at these terminals. The final result of the measurements is the grounding resistance (in Ohms), the value of which is shown by the device on the display.

Instruments from the 4500 series are often used to measure touch voltage.Using a special module, the device generates a small voltage in the ground - simulating cable damage.

At the same time, the instrument scale indicates the current flowing through the grounding circuit. The readings on the screen are taken as a basis and multiplied by the estimated current in the ground. In this way the touch voltage is calculated.

For example, the maximum value of the expected current at the fault site is 4000A. The value of 0.100 is marked on the device screen. Then the value of the touch voltage will be equal to 400V (4000 * 0.100).

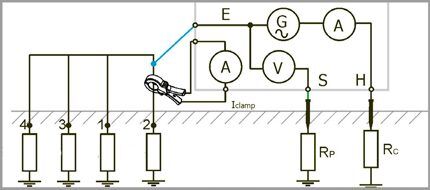

Measurement with device S.A6415 (6410, 6412, 6415)

The uniqueness of this method is the ability to carry out measurements without disconnecting the grounding circuit. Also here it is necessary to highlight the advantageous side when it is permissible to measure the total resistance of the grounding device by including the resistive component of all connections in the grounding circuit.

The operating principle is approximately the following:

- A special transformer creates current in the circuit.

- Current flows in the formed circuit.

- The measured signal is recorded using a synchronous detector.

- The received signal is converted by an ADC.

- The result is displayed on the LCD display.

The device is equipped with a module (selective amplifier), thanks to which the useful signal is effectively cleared of various types of interference - low frequency. and v.ch. noise The paws of the pliers in their articulated state form an excited circuit that encircles the grounding conductor.

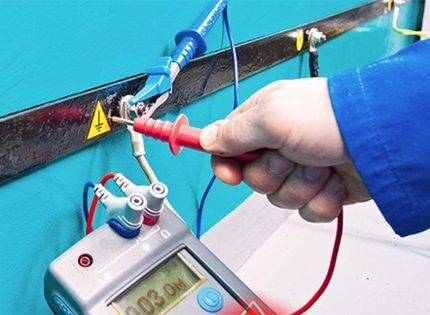

Instructions for measuring with the S.A6415 device

The sequence of actions when working with the device of the S.A6415 series is clearly described in the instructions supplied with this unique device.

For example, there is a need to measure the grounding resistance of an electrical module (transformer, electric meter, etc.).

Sequencing:

- Open access to the grounding bus by removing the protective casing.

- Grab the grounding conductor (busbar or direct electrode) with pliers.

- Select measurement mode “A” (current measurement).

The maximum current value of the device is 30A, so if this figure is exceeded, measurements cannot be performed. You should remove the device and try to measure again at another point.

When the current value obtained on the scale falls within the permissible range, you can continue working by switching the device to measure resistance “?”.

The displayed result will show the total resistance value, including:

- electrode and grounding bus;

- neutral contact with ground electrode;

- contact connections on the line between the neutral and the ground electrode.

When working with clamps, you should keep in mind: overestimated grounding resistance readings from the device are usually due to poor contact of the grounding electrode with the ground.

Also, the cause of high resistance may be a broken current-carrying bus.High resistance numbers at the points of connection (splicing) of conductors can also affect the readings of the device.

General recommendations for measuring USG

Before construct a grounding circuit, for example, for a gas boiler, you should obtain accurate information about the area in which soil the grounding electrode will be laid. It is often suggested to refer to existing tables to determine the “p” values of soil.

However, this option with tables provides purely indicative data. Therefore, you should not rely on them. The true values of soil resistance can differ significantly.

Option #1: single-layer primer

If the soil has a homogeneous component, its resistivity is measured using the “test electrode” technique.

The method involves performing a certain procedure in two stages:

- Take a rod control probe with a length slightly greater than the depth of the design backfill.

- The probe is immersed into the ground strictly vertically to the depth of the design laying.

- The end remaining above the ground is used to measure the spreading resistance (Rr).

- The USG is determined by the formula p = Rr * Ψ.

It is advisable to perform the procedure several times at different points on the work site. Alternative measurements help achieve accurate soil resistance measurements.

Option #2: multi-layer soil

For such a situation, USG measurement is performed using the step probing method. That is, the control probe is immersed to the working depth in steps and resistivity measurements are taken at the position of each step. Calculations of the average USG are made using formulas for each individual measurement.

Then, based on the climatic characteristics of the area, values for seasonal changes are found. In this way (quite complicated) the calculated values of the upper layers are obtained. The underlying layers are considered not subject to seasonal changes and therefore the calculation for them is limited to somewhat simplified measurement and calculation.

Requirements for the execution of work

Work of this kind, of course, is carried out by qualified personnel representing specialized organizations. Thus, utility services are usually responsible for the operation of power panels in residential buildings. It is permitted to make any measurements at these points only by accessing these services.

Electrical circuits are classified as dangerous systems. Despite the fact that communications in the household sector are designed for voltages less than 1000V, this voltage is fatal to humans. All necessary safety precautions must be observed when handling electrical equipment. Such measures are often simply unknown to the average person.

He will introduce you to the features of grounding construction for a bathtub in a city apartment. next article, containing rules and guidelines for carrying out work.

Conclusions and useful video on the topic

Performing measurements in practice using the device:

Carrying out work related to checking grounding resistance is required, regardless of the complexity of the electrical circuit and the category of the facility where the electrical equipment is installed or installed and operated. Many specialized organizations are ready to provide such services.

Please leave comments in the block below. It is possible that you know a simple and effective way to measure the resistance of ground loops, which is not given in the article. Ask questions, share useful information and photos on the topic.

At one time I did grounding using the two-point method due to the impossibility of using other methods. From my own experience, I will say that it is not worth constructing it yourself without proper experience, because... Without measuring instruments there will be no accuracy of measurements. It is very difficult to calculate even for some professionals. In general, the most common and at the same time reliable option is measuring a linear contour at four points.

I completely agree with Victor, the author of the previous comment. Regardless of the type of grounding, it is better to have this work performed by an experienced electrician, and the performer must not only have permission to perform such work, but also the appropriate education and certificate. It is important. It is better that everything is arranged as reliably as possible, since, for example, thunderstorms are not uncommon in our country, and lightning striking a building is very, very likely!

Grigory, probably lightning protection and grounding have different purposes, although in the ground the lightning protection and grounding contours can be combined.