Do-it-yourself ventilation in the workshop: options and principles for arranging an air exchange system

Work associated with the formation of dust, the release of toxic gases, and fumes requires the installation of an exhaust system in the workplace and room. In most cases, do-it-yourself ventilation in the workshop is the most affordable way to solve the problem.

There are various options for constructing air exchange systems. We will help you navigate their diversity and consider the features of building ventilation for each type of workshop. Let's look at the most effective and affordable options for self-installation.

The content of the article:

Types of ventilation systems in the workshop

Based on the method of air circulation in the room, there are two main types of ventilation:

- natural;

- forced.

In the first case, air movement occurs due to the temperature difference between indoors and outdoors.

And in the second, circulation is provided by fans that create excess pressure or vacuum in the workshop. This type of ventilation is also called mechanical.

In turn, forced is of the following types:

- exhaust;

- supply;

- combined.

Exhaust ventilation ensures the removal of harmful gases and vapors, while clean air enters the workshop naturally. Supply, on the contrary, creates excess pressure inside the room due to the intake of street air, and the exhaust air is squeezed out of the workshop through natural openings and cracks. If necessary, the input stream can be heated, cleaned, or humidified.

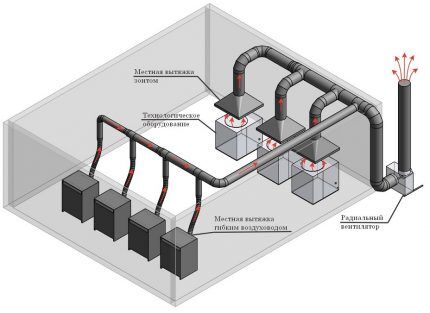

Combined The workshop ventilation system is called supply and exhaust. Depending on the relative position of the air supply and removal channels, circulation can occur by displacement or mixing.

If the supply fans are located at the bottom, then the cold air rises and displaces warmer air. When the inlet channel is located at the top, the cold flow is distributed throughout the room, going down and mixing with the warmer one. The exhaust air is then removed through an exhaust duct.

Depending on the method of organization, ventilation in the workshop is divided into two types:

- local;

- centralized.

The first is used to remove harmful substances directly from the workplace. It is advantageous to use it to localize contamination when pieces of equipment are located far from each other throughout the entire area of the room.

For small workshops with a more compact arrangement of machines, it is advisable to install a centralized hood.

Also applicable hybrid ventilation options, when some of the machines are connected to a common system, and some have local filtering. In some cases, in principle, preference is given only to local systems to prevent the spread of fine dust and other toxic substances throughout the workshop.

Features of ventilation in the workshop

Working in a workshop is associated with the presence of toxic and harmful substances in the air. The design and construction of ventilation in such premises depends on the type of work and the nature of the harmful factors.

Let's consider the main features that affect the configuration and parameters of ventilation systems for different types of workshops.

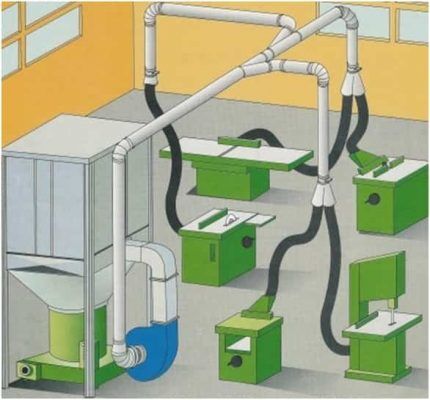

#1. Dust removal in a carpentry workshop

Fine dust is the main problem in woodworking workshops. Such a suspension of particles can remain in the air for 24 hours, although it is not noticeable to the eye, but is inhaled by the lungs. In addition, it settles on all surfaces. Whenever there is a draft or the engines of machines or tools are started, it ends up in the air again.

Organization of a dust removal system (aspiration) is complicated by the presence of a large number of sources of dust and different fractions of chips. For this reason, it is necessary to connect suction hoses with individual filtration to each machine.

But, in addition to the harmful effects on breathing, wood dust also has fire and explosive properties.Which places increased demands on ventilation systems in terms of eliminating electrostatics and grounding structures.

#2. Air purification in a car service center

A car service workshop belongs to premises with increased air pollution. The constant presence of exhaust gases, carbon and nitrogen monoxide, aerosols, gasoline vapors, paint and other technical fluids places special demands on the performance of the ventilation system. The power of the supply and exhaust unit is selected with a reserve to ensure pumping of the entire volume of the room with the recommended multiplicity of 20 - 30.

In addition, contaminated air must be filtered and discharged through a pipe separate from the general ventilation.

#3. Ventilation of repair and forging workshops

The combustion products of electrodes, smoke, fumes and dust released during welding and metalworking operations when cutting and processing metal require removal using local exhaust hoods. What is regulated GOST 12.3.003, SP 49.13330, POT R M 020-2001 [22], STO 221 NOSTROY 2.10.64-2013 and safety rules during construction, installation, gas welding and electric welding work.

For manual electric welding, their approximate productivity is selected based on ensuring air exchange from 1500 to 4500 thousand m3*h/kg divided by the weight of electrodes burned in 1 hour.

With semi-automatic welding, the volume is increased to 1700 - 2000 thousand m3*h/kg.

The general air circulation is distributed in an inflow to exhaust ratio of 1:3 for the upper tier, and 2:3 for the lower.

A feature of the ventilation of a forge workshop is the need to remove excess heat and toxic gases. For this purpose, local suction above the furnaces and natural ventilation are used.

When calculating the performance of ventilation systems for all types of workshops according to the recommended multiplicity, it is necessary to take into account heat losses during the cold season. Choosing the maximum parameters will guarantee the rapid removal of harmful substances, but at the same time, will require costs for heating the supply air. If heat recovery is not provided, it is better to stop the choice at the lower permissible limits of the multiplicity.

Options for building ventilation in the workshop

In searching for the best ways to build ventilation for your own workshop, you have to review many possible options before finding the most suitable one.

To facilitate this search, let us consider, as an example, the most successful, in our opinion, solutions for independently arranging ventilation in the workshop.

Option #1 - exhaust ventilation from plastic pipes

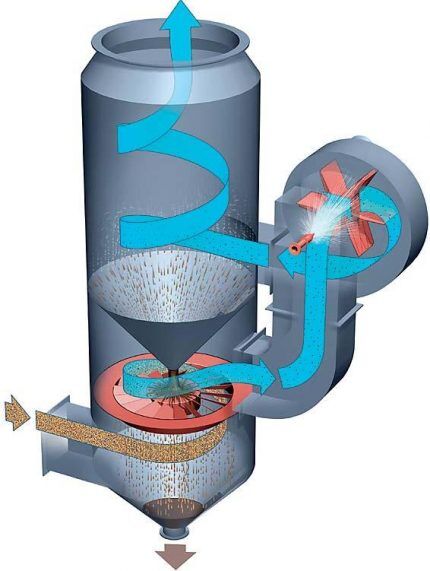

To implement this project, the following were used: a used centrifugal fan “snail” with a 2.2 kW electric motor, a 40-50 liter barrel with a neck corresponding to the inlet hole of the “snail”, sewer plastic pipes 110 mm.

A few words about the material of the air ducts.The use of plastic sewer pipes for ventilation is a fairly popular option, primarily due to the price. They are several times cheaper than plastic and steel air ducts for ventilation.

But sewer pipes also have their disadvantages:

- they cannot be used in places where the temperature may exceed +60 degrees;

- they do not have an antistatic coating, so it is not advisable to use them for chip and dust removal systems;

- their diameters do not meet the standards of ventilation systems, which makes it difficult to interface with other equipment.

Despite these disadvantages, in most cases, sewer pipes successfully used as air ducts. The considered option for constructing a ventilation system from scrap materials was no exception.

In this project, all the main components of the hood for the locksmith workshop were made by hand. Let us briefly describe the stages of the work done.

So, first a major overhaul and modification of the centrifugal fan was carried out. The modification concerned the inlet pipe. More precisely, due to its absence, it was necessary to make a new one from a small sealed barrel, the volume of which would allow the fan to reach the required speed of the vortex flow.

A side hole was made in the barrel and a piece of plastic pipe was glued in, taking into account aerodynamics, so that the inlet flow would go along the inner circumference of the barrel. Then an air duct made of plastic pipes was installed under the ceiling along the center along the entire workshop.

A centrifugal fan creates a powerful vortex flow in the barrel, ensuring rapid pumping of air throughout the entire system. Its strength is so great that it holds the saw blade of the angle grinder at the most distant inlet.

The parameters of the exhaust system were as follows:

- engine power 2.2 kW;

- fan speed 2800 rpm;

- productivity 1000 m3/h – 1500 m3/h;

- The time required to extract the entire volume of air from the workshop is 5 – 10 minutes.

The entire system has 6 supply holes closed with homemade adjustable plugs. They are made of standard plastic with cut-out slots in the lid, and the same slots in a movable metal plate, fixed on one axis. When they rotate mutually, the air flow is adjusted.

Option #2 - dust collector from a KAMAZ filter

Since factory dust removal systems are quite expensive, homemade dust collectors based on air filters from large trucks such as KamAZ, tractors or combines have become widespread.

By adding a fan to such a filter, you get a good air purifier that takes up minimal space and can be easily transported to any part of the workshop.

The performance of such a system is regulated by selecting the fan power. Such filters are capable of purifying air volumes from 500 to 1000 m3 per hour, depending on type. They can be connected to fans with a capacity of up to 300 – 400 m3/h.

Assembling the air purifier is quite simple.To do this, you need to cut out the flange and attach a pin to the axis for the length of the filter. Next, glue the fan to the flange and screw the entire structure to the filter.

Due to their ease of manufacture and low cost, several of these filters can be made and significantly improve the air in the entire workshop.

Option #3 - aspiration system in a carpentry workshop

The main role in the proposed dust removal system is played by a factory chip ejector from JET. The cost of such equipment, depending on the parameters, is 15 – 40 thousand rubles. Most models have a fabric dust collector and a chip bag.

For this option, the best model JET DC-1200CK with a paper filter element in the form of a removable drum was chosen. It is equipped with a manual internal cleaning tool that allows you to remove major dust without removing the filter.

Ventilation pipes were selected to provide maximum protection against electrostatics and the least resistance to air flow. These requirements are best met by twisted pipes made of galvanized steel.

During their installation, the reliability of the electrical contact at the connection nodes was checked with a multimeter. If necessary, the contact was strengthened with two self-tapping screws on opposite sides. The entire pipeline was grounded. In addition, the joints were wrapped with aluminum tape for tightness.

To reduce noise and dust, the exhaust unit was moved outside the workshop to the adjacent boiler room. The supply pipeline is laid through a hole in the wall under the ceiling. The inlet pipe is fixed to the ceiling in the middle part of the workshop. A two-meter corrugated pipe made of transparent plastic is put on it.

In addition to aspiration, air exchange in the carpentry workshop is ensured by supply and exhaust ventilation.

Conclusions and useful video on the topic

One of the hood options in the workshop:

Where is the best place to place the chip pump? More about this in the next video:

Option for arranging a mobile hood for a workshop:

The options discussed above do not cover the entire variety of ways to independently build ventilation in the workshop. But, at a minimum, they will help you choose the right direction for implementing your own project and avoid a long path of trial and error. Practice shows that it is quite possible to design and install a ventilation system of sufficient performance for a workshop with your own hands.

Do you still have questions about the ventilation system in the workshop? Or do you want to tell other users about how you organized an effective air exchange and dust removal system on your own, using scrap materials? Share your experience, ask questions to our experts - the comment block is located below this publication.