How to insulate ventilation in a cold attic: specifics of thermal insulation of air ducts

Proper design of the ventilation system involves insulating the air ducts.Otherwise, they are doomed to constantly become covered with condensation, causing irreparable harm. Based on this, the question of how to insulate ventilation in a cold attic is very important, because that is where all the prerequisites for the accumulation of moisture inside the pipes are.

We will tell you everything about the purpose and specifics of the thermal insulation device for the ventilation duct system. We will analyze all the options for insulating air ducts using materials of different structure and purpose. Home craftsmen who want to carry out the work themselves will find detailed instructions here.

The content of the article:

- Arguments in favor of ventilation insulation

- Where to insulate the ventilation pipe?

- Thermal insulation materials for pipes

- Key selection criteria

- Glass wool for ventilation insulation

- Features of the use of basalt wool

- Polyethylene foam for ventilation insulation

- Application of foamed synthetic rubber

- Polystyrene foam as insulation for ventilation pipes

- Extruded polystyrene foam - many protection features

- PirroVentiDuct thermal insulation for ventilation

- The procedure for insulating ventilation in a cold attic

- Conclusions and useful video on the topic

Arguments in favor of ventilation insulation

The process of condensation accumulation inside an uninsulated ventilation pipe is inevitable. This is a consequence of the collision of warm and cold air flows. To a large extent, condensation is caused by failures in the system and deviations from the rules for operating premises.

Both the moisture that has settled on the structures and the condensation that has fallen on the walls of the air ducts flow down the pipes.Through any leaks at the joints they will get onto the floors and walls. Because of them, the floor insulation becomes wet, as a result of which its insulating qualities are reduced by at least half.

At negative temperatures, frost appears and the internal diameter of the pipe will decrease. Not only the material is destroyed, but also good conditions are created for the life of mold fungi. Residents of the house are at risk of frequent respiratory diseases and allergic reactions.

Ventilation in an unheated attic especially needs insulation. Here the difference between the air temperature inside the system and the pipe walls is significant.

Only the fabric air distribution system does not require additional insulation. Condensation does not form on the vapor-permeable surface of textile pipes, and since the channels are dry, microorganisms do not settle in them.

The saturation of air with steam is directly proportional to temperature. The higher it is, the more steam there is in the air masses. Even a minimal change in temperature reduces the ability of air to retain water in the form of steam. For this reason, condensation accumulates at the outlet of the ventilation duct when the air is cooled.

Where to insulate the ventilation pipe?

Mandatory insulation is necessary in places where temperature changes occur. In areas where warm and cold air come into contact, condensation appears most abundantly. Here is the dew point. When designing the insulation of exhaust ducts, the position of this point is calculated first of all.

The goal is to move it as close to the outlet as possible ventilation pipe. The ideal option is when the mixing zone of cold and warm air flows is moved outside the house.

Since this rarely occurs, on a ventilation pipe that crosses a cold attic and then goes out onto the roof, the area that passes through the ceiling of the upper floor or attic must be insulated. The pipe itself is insulated along its entire length until it reaches the roof.

In the case of supply ventilation, the amount of condensate that falls on the outer walls of the ventilation duct is directly proportional to its length. This phenomenon is also influenced by the installation feature. In large areas, in addition to pipes, valves are also insulated.

The insulated valve looks like an adjustable blind. The latter limit the passage and slightly increase the temperature of the air supplied from outside, because The design contains tubular heaters.

The speed of air supplied through the valve is controlled using levers or an electrically driven system. Warming up the valve blades with heating elements is necessary to prevent them from icing. This changes the temperature of the supply air masses slightly.

Thermal insulation materials for pipes

After determining the dew point and carrying out the necessary calculations, the question remains of how to insulate the ventilation in the attic, and by what criteria to evaluate the material.High-quality thermal insulation is possible provided the correct choice of insulation, its thickness, taking into account the air humidity inside and outside, and temperature differences.

Key selection criteria

There are three main criteria by which insulation material is selected:

- level of thermal conductivity;

- fire safety level;

- material price.

Let's consider the most popular heat-insulating materials, their inherent advantages and disadvantages. The most popular are insulation based on mineral fibers. This group combines wool made from slag, fiberglass, and basalt threads thinly drawn during the melting period.

Basalt, also known as stone, wool stands out both in terms of characteristics and cost. Slag is harmful to health, and it is better not to use it.

Glass wool for ventilation insulation

The greatest demand among materials based on mineral fibers is glass wool.

Thermal insulation coefficient is from 0.03 to 0.052 W/m⁰. The heat insulator has long fibers intertwined in such a way that a shell is formed that resembles a cocoon that retains air.

The positive technical characteristics of the material are as follows:

- Fiber thickness is 3-15 micrometers, length is from 15 to 50 mm.

- Good absorption of noise vibrations and acoustic interference due to uniform distribution of fibers. This indicator for insulated structures ranges from 35-40 dB.

- Fire resistance ranges from NG to G1. Although the material contains binding resins, it is not spontaneously combustible.Without changes in the structure, glass wool can withstand temperatures up to 250⁰.

- Resistance to mechanical stress. Early analogues of this insulation did not have good resistance to mechanical stress. Modern samples have sufficient strength and good elasticity.

- The vapor permeability index of glass wool is 0.6 mh/Pa, which is almost 2 times higher than that of basalt wool.

- Daily sorption moistening is less than 1.7%.

- The material has good biological stability. Rodents do not settle in it, and mold fungi do not multiply.

- Without loss of quality characteristics, glass wool can be compressed 6 times. After straightening, the elastic fibers return to their original position.

- The average density is 11-25 kg/mᶾ, but the figure may vary among different manufacturers.

If you do not allow it to get wet, high-quality insulation will not shrink during prolonged use.

The negative is the increased fragility of the fibers. It is permissible to work with glass wool only with the use of protective equipment. To prevent the thinnest sharp fragments of fibers from getting into the surrounding space, reliable insulation of the insulating layer is necessary. Protection is also necessary in order to neutralize the destructive effect of sunlight on glass wool.

In addition, glass wool has a relatively short service life - about 10 years. When choosing insulation for ventilation pipes in a cold attic, you should definitely ask whether the product has a conclusion on compliance with its hygienic and sanitary epidemiological requirements.

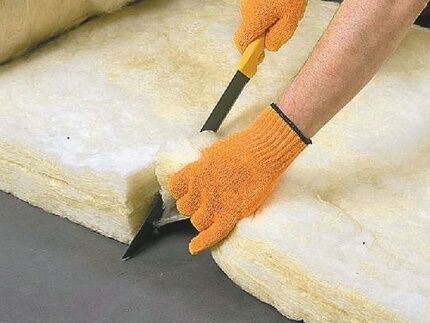

Round ventilation sleeves are insulated with rolled mineral wool. Ventilation pipes with a square cross-section - material in the form of plates. The ventilation duct is wrapped first and secured with metal wire or synthetic tape. The second ones are glued.

Features of the use of basalt wool

This material is an improved mineral insulation. It consists of molten basalt fibers. It is produced in the form of slabs and mats. For round ventilation ducts, ready-to-use insulation is produced in the form of cylinders covered with insulation - foil. There are products without an insulating layer.

The thermal insulation coefficient of the material is 0.034-0.038 W/m⁰. Cheap brands that contain formaldehyde resins can be hazardous to human health. In more expensive insulation, completely harmless biopolymers are used as binders. The price of basalt wool is higher than its glass wool counterpart.

Polyethylene foam for ventilation insulation

Applying polyethylene foam to round and square ducts within the attic is a simple and inexpensive insulation option.

There are several varieties of this material:

- Ordinary. This category includes penolon (cross-linked polyethylene foam), isolon, and others. Its use is extremely simple - pieces of material are wrapped around the air duct and secured with tape.

- Foiled. This insulation is covered on one side with a layer of foil designed to reflect heat and repel moisture.It goes on sale under different names: tepofol type A and B, penofol, mosfol, faralon, ultraflex. This insulator is connected with special glue or aluminum tape.

The insulation is supplied in roll format with measured lengths. Among the offers there are self-adhesive options. Their back side is covered with an adhesive composition, which greatly simplifies and speeds up installation.

For pipes, they produce insulation made in the form of a shell; these are items called thermoflex, energyflex, etc. It is a ready-made shell in the shape of a cylinder covering communications.

The thermal conductivity coefficient of foamed polyethylene depends on its brand and is in the range of 0.031-0.051 W/m⁰.

This material is durable, elastic, resistant to aggressive chemicals, lightweight, easy to install, moderately flammable (class G2). In terms of smoke-forming ability, it belongs to class D3, i.e. produces a large amount of smoke when burning. Doesn't apply to environmentally friendly materials in any way, because... the period of its decomposition is two hundred years.

Depending on the production method, there are 2 types of polyethylene foam:

- PPE or cross-linked;

- NPE or non-crosslinked (gas foam).

The first is superior to the second in all respects, but its price is also higher. NPE is characterized by the smell of gas. By this feature it can be distinguished from non-crosslinked polyethylene. Among the disadvantages inherent in polyethylene foam are its high flammability, low mechanical strength and resistance to UV radiation.

Application of foamed synthetic rubber

This insulation, consisting mainly of closed cells, is similar in appearance to cross-linked polyethylene foam. Unlike the latter, it has increased flexibility. The installation technology is the same as for PPE. The release form is the same - mats, sheets, rolls, cylinders, but the service life is three times longer.

Rubber cylinders have an internal diameter of 5-300 mm and a wall thickness of 5-150 mm. For easier installation, pipes of large and medium diameters have a longitudinal section.

In the area to be isolated, the joint is sealed with an adhesive. The thermal conductivity coefficient is 0.024-0.038 t/m⁰. Does not change its characteristics in the operating temperature range -200/+175⁰.

It is possible to use the material in premises subject to increased sanitary and hygienic requirements. Foamed rubber is moisture-resistant, mold-resistant, and is a self-extinguishing material.

The combustion temperature is above 300⁰. In terms of thermal conductivity, vapor permeability, thermal conductivity, and tightness of joints, rubber exceeds its analogues from polyethylene foam and polyurethane foam.

Polystyrene foam as insulation for ventilation pipes

Polystyrene foam is a foamed mass of plastic containing a large volume of gas. This is a rigid material in the form of pipes, consisting of 2-3 parts and connected by means of a tongue-and-groove lock or plates. Only square pipes are insulated with slabs.

The advantages of polystyrene foam include light weight, resistance to rotting, ease of use, low price, and service life of up to 25 years. The thermal conductivity coefficient ranges from 0.032-0.05 W/m⁰.Over 30 days, water absorption is 4%. When bending, the tensile strength is in the range of 0.07-0.2 kgf/m². Operating temperatures - -50/+75⁰.

Polystyrene foam is ordinary polystyrene foam. It is attractive to rodents, highly flammable, and releases toxins when burned. For installation, a special glue is required; any other glue may cause the material to melt.

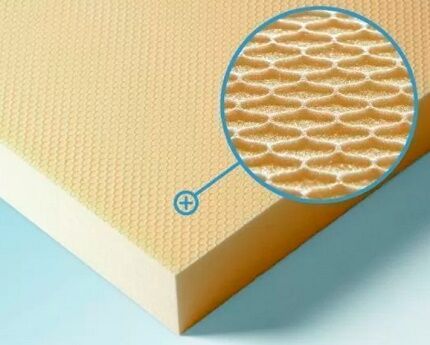

Extruded polystyrene foam - many protection features

In the production of extruded polystyrene foam, the same raw materials are used as in the production of polystyrene foam. However, it is precisely thanks to this specific technology that a material is obtained that does not have pores and channels in its structure into which moisture can penetrate.

For the same reasons, it retains heat better. It is produced in the form of rigid tubes or slabs and is sold as Penoplex, EPPS, Technoplex, equipped with tongue-and-groove locks. It has a long service life - up to 50 years.

The thermal conductivity coefficient of polystyrene foam obtained during extrusion is in the range of 0.028-0.034 W m⁰. 30-day water absorption is 0.4%. Operating temperatures range from -50⁰-+75⁰. It has sufficient bending strength - 0.4-1 kgf/m².

PirroVentiDuct thermal insulation for ventilation

PIR boards are a new generation of insulation with a rigid cellular structure. It is made from polyisocyanurate foam. The two sides of the PIR board are covered with layers of foil.The service life declared by the manufacturers is 50 years. The material is resistant to rotting, moderately flammable, but when it burns it releases toxic substances.

Straight and shaped air duct elements based on PIR boards are obtained by cutting the latter, followed by gluing the blanks with a special contact adhesive.

The thermal conductivity coefficient of the material is 0.021 W/m⁰. The water absorption rate is within 1%. The compressive strength of the slabs is 120 kPa.

The procedure for insulating ventilation in a cold attic

All thermal insulation measures are carried out according to the standards regulated by SNiP 2.04.14-88. Clear instructions are given here on where and how to organize ventilation insulation.

When installing the insulating layer, the main rule should be observed: the insulation should be fastened as tightly as possible so that there are no gaps left between the ventilation duct and the insulation. The installation of each material has its own characteristics.

Features of mineral wool insulation

When insulating with mineral wool, we must not forget that it is hygroscopic.

This fact leaves an imprint on the order of work:

- The pipework in the cold attic is wrapped with a waterproofing membrane, leaving no gaps or cracks.

- The mineral wool is wound overlapping, overlapping the previous strips. The thickness of the layer must comply with SNiP.

- A layer of waterproofing is wound over the insulation.

- The entire structure is tightened with special bandages.

A rectangular pipe can be insulated with mineral wool in mats.First, blanks of the required size are cut out, and, covering the pipe with them, they are tied together with knitting wire, a clamp or tape.

In the outer corners of air ducts, certain difficulties arise with the installation of insulation; it will not be possible to immediately achieve the required tightness. Therefore, upon completion of the installation of the main thermal insulation coating, the remaining gaps are filled with pieces of material.

Insulation of ventilation in a cold attic with polystyrene foam

If the material is in the form of slabs, therefore, rectangular air ducts can be insulated with it. The technology for insulation work is the same as when laying mineral wool. The only difference is the optional waterproofing device. The decision is made based on the density of the thermal insulation material.

So, in the case of using PPS-40, waterproofing is necessary, and if PPS-60 is used, waterproofing is optional. The plates must be joined tightly, cracks and gaps must be filled with foam.

Thermal insulation using cylinders

Special shells for ventilation insulation are made from many insulation materials:

- mineral wool;

- polyurethane foam;

- expanded polystyrene;

- polyethylene.

They are used when used for ventilation of round pipes. There are several types of such thermal insulation:

- solid with a longitudinal section;

- two, three, four-section.

The cylinders are selected according to the diameter of the air duct. The larger the cross-section of the pipe, the greater the number of parts the shell consists of. If it is a solid cylinder, it is opened along the cut and put on the air duct.

The cylinder is useful as insulation for straight sections. In places where the air duct turns, it will not be possible to put it on. Mats are used in these areas. Among insulating materials of this type, cylinders made of mineral wool, polystyrene and polyethylene have the lowest cost. The most expensive option is a foam rubber shell.

A very convenient option for insulating ventilation with your own hands is self-adhesive insulation, i.e. penofol grade "C". On one side there is foil, on the other there is a plastic film with an adhesive composition applied to it. The adhesive side is protected by an additional layer of film. It is removed before installation.

The material is cut to a size corresponding to the perimeter of the air duct. At the next stage, the pipe is covered with insulation, folding the edges overlapping 50 mm. The joint is sealed with foil tape.

Conclusions and useful video on the topic

How to make insulation of ventilation pipes with your own hands:

Insulation of ventilation pipes with mineral wool and the achieved effect:

In a cold attic, pipes must be insulated. When choosing a material for this purpose, you should be guided by the design features of the house and your financial capabilities. If you properly insulate the ventilation system, it will be extremely functional and will last a very long time.

Would you like to share your own experience insulating the ductwork running through the cold attic of your home? Do you have information on the topic of the article that is worth sharing with site visitors? Please write comments in the block form below, ask questions, post pictures.