Installing a split system: step-by-step instructions for self-installation

By controlling the microclimate of personal space, we create conditions that are optimal for rest, work, and activities.Installing a split system will allow you to set a favorable level of temperature and humidity in the simplest way. Agree, in the summer there are many days that require regulation of climatic parameters.

After reading the article we have proposed, you will learn all the details and subtleties of the installation of air conditioning equipment. Carefully selected and systematized information will be useful to both independent home craftsmen and customers of installer services to verify proper performance.

We describe the installation process in detail, listing the nuances of the location and fastening of the blocks. The materials required for installation and connection of the units are listed. Photo and video attachments are a valuable addition to the text, making it easier to perceive information.

The content of the article:

Choosing a location to install the system

When studying information on how to properly install a split system in a private house or apartment, you first need to choose the location of its parts.

To do this, it is necessary to take into account the direction of distribution of the flow of cold/hot air in the room, taking into account the basic technical requirements specified by the equipment manufacturer in the instructions.

There are certain rules that must be taken into account when choosing a block placement point:

- the distance between the unit and the ceiling should be at least 15-20 cm, although some manufacturers indicate 20-30 cm in the instructions;

- from the side to the wall - at least 30 cm;

- to an obstacle that will impede the flow of outgoing air or disperse it - at least 150 cm.

For the external part of the split system, the location is chosen based on the load-bearing capacity of the walls. Installation is possible near a window, on slabs enclosing a loggia, or on a wall next to a balcony.

For those who live on the lower floors, the unit is installed above the window - as far as possible from passers-by.

For a multi-storey building, especially if the apartment is on the top floor, you will need to involve high-rise specialists or determine the installation point very close to the window, which will provide easy access during installation.

Determining the distance between blocks

Often the choice of location for equipment is regulated by the minimum and maximum distance between its parts. These indicators are mainly indicated by the manufacturer and depend on the model range and characteristics split systems.

Sometimes companies do not indicate the minimum length of the circuit between two units, so installation can be carried out arbitrarily.

It is a little easier to figure out the maximum possible distance between two units. The standard indicator is 5 m. It is also possible to increase the length of the route, but in this case it is necessary to count on additional costs due to the need to refuel with freon.

Preparation for work

The decision to install a split system yourself usually comes after asking the specialists for prices. Incredibly high amounts for completing a job that takes 3 hours are justified by the presence of expensive tools and their wear and tear during operation. This is what makes up the bulk of the fee for the master’s services.

If you look at the recommendations of equipment manufacturers, the instructions often indicate that the preparatory work can be done on your own, but for the installation of pipelines, connecting to the electrical network, and carrying out the vacuum process, it is advisable to invite specialists with the appropriate tools.

Hardware Installation Tools

You can install the cooling unit yourself, because... Most of the tools are in the handyman's suitcase.An exception may be a vacuum pump, but it is not necessary to buy one - it will be possible to make such a unit from old parts.

Some teams of craftsmen do not even use this equipment when laying a route up to 6 m long.

During the installation process, an important aspect is maintaining the horizontal position of the block systems. In connection with these requirements, each stage of work must be accompanied by a control check at the construction level.

If a tool is not available, you can rent it at a hardware store.

You will need to prepare the following equipment in advance:

- Hammer. It is used to make holes in the façade through which a route will be laid, connecting the external and internal blocks.

- Drill with a set of drills. Used for mounting fasteners.

- Pipe cutter for cutting copper pipes.

- A device for removing burrs after cutting pipes. You can use a reamer, a file and sandpaper.

- Copper pipe roller.

Some people believe that using a reamer is not worthwhile, especially if pipe cutter new and does not leave burrs or dents, but in vain.

Only after manipulations with the chamfer remover can the edge of the flared tube be pressed as tightly as possible with the nut, and accordingly, freon leakage is unlikely.

According to the technical installation rules, a vacuum pump is required - the sealing of the air conditioning system is carried out with this equipment. After filling the route with refrigerant, the evacuation process is carried out.

Purchasing the necessary materials

You will need quite a lot of components, but all of them are easily available in any specialized store. Do not forget that the materials must be of the highest quality and selected exclusively for the device, functionally aimed at cold.

It is necessary to purchase a wire to supply power and connect the units. The required parameters are always indicated in the passport or equipment installation instructions.

Standard is a four-core power cable with a cross-sectional area of 2 mm2 or 2.5 mm2. The length is selected based on the distance of the route, taking into account a small margin.

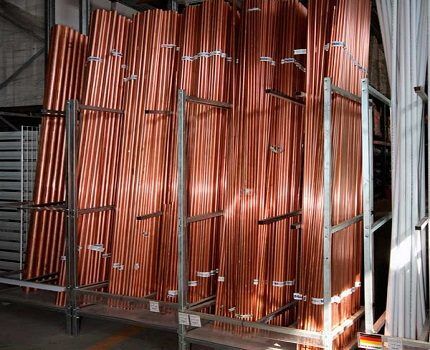

You will also need to prepare thick-walled seamless pipes made of soft copper intended for cooling devices. Pipes are selected with smaller and larger diameters. More specific specifications are listed in the user manual.

The length is equal to the length of the route plus an additional margin of up to 30 cm. During the transportation of tubes, their edges must be sealed to protect from dust settling inside the product.

Foamed rubber insulation is used to insulate pipes. They sell it in 2 m lengths. To implement thermal insulation measures, you will need a length equal to the length of the route.Synthetic insulation is used on two pipe diameters.

As a drainage tube, experts recommend installing a corrugated hose equipped with a plastic spiral inside. You can also use an alternative part - a polypropylene tube. Its length is equal to the length of the track with an additional 80 cm.

You will also need two L-shaped brackets to secure the unit from the outside. The suitable size of the parts is determined by its dimensions, and the safety margin for the load-bearing load should exceed its weight by 5 times. This increase in the maximum permissible stress of the part is required to compensate for wind and snow loads.

It is better to buy these components from a company that sells spare parts for household split systems.

The following fastening parts are used: anchors, dowels and bolts. Their number, type and parameters are selected based on the type of brackets and mounting plate intended for the indoor unit.

The type of walls where the outer part of the system is to be installed also matters. To camouflage the laid communication line, you will need a plastic box of standard dimensions 60*80 cm.

Installation procedure for split system

Installing an air conditioning system yourself is a very real task, however, there are many nuances in the work and they relate to certain models, so the installation process may have some differences. To study all the requirements, you must first read the instructions for the purchased equipment model.

Stage #1 - installation of outdoor and indoor units

The indoor unit must be installed first. Having decided on its location, the area for the mounting card is marked on the wall. After drilling out the gaps, plastic plugs for the dowels are inserted, the card is hung and secured with dowels.

After installing the cassette, using a building level, the strict horizontal positioning of the future block is measured. In case of any discrepancy, all completed work will need to be redone.

At this stage, preparatory work for laying the routes will take place. First, the lines of its location are calculated. Then a hole is drilled in the facade wall, taking into account the required slope of more than 1/100.

A hole with a diameter of 5 cm is also drilled with a slope, and the angle of inclination can be increased in comparison with the route. Thus, the condensate formed will better leave the system.

When choosing a back-to-back installation of units, you need to check the hole intended to accommodate the power cable. To do this, you need to check the location of the power ports on the units.

And now it’s time to install the outdoor unit. If we are talking about a multi-story building, then you will need special equipment for high-altitude work.

As in the first case, the block must be strictly horizontal, so a level is also used at the marking stage.

When installing the fasteners, each existing hole must be filled with anchor bolts (standard diameter 10*100 mm), regardless of their number. Afterwards, the outdoor block is installed and also fixed with fasteners.

Stage #2 - laying a communication line

Using an electrical wire and two copper tubes, the outdoor and indoor units are connected. Additionally, a drainage system will be laid through the wall, which is responsible for removing condensate. These elements must be correctly selected, connected, laid and secured.

First, you should prepare the copper tubes by cutting them to the required length using a pipe cutter and treating the edges with a reamer to remove burrs and dents after the cutting procedure.

It is not recommended to use other tools, such as a file. After its use, metal shavings get inside the tube, which will circulate throughout the system and ultimately lead to failure of the compressor.

Thermal insulation of tubes is carried out by putting polyurethane foam on them

Now it’s time to lay the drainage and cable. Each wire must be equipped with a special tip. They are installed on conductors cleared of insulating material and crimped with pliers.

The finished cable is connected to the air conditioner according to the diagram given in the manual for the device.

The drainage tube is connected to a special outlet on the unit indoors and is discharged through a hole in the wall. The tube must be long enough and end at least 60 cm from the wall.

According to the rules, its installation is carried out at an angle towards the exit. Fixation with clamps is required every meter of length to eliminate sagging and prevent condensation accumulation.

Stage #3 - connecting system units

Communications carried out through the wall are connected to the corresponding ports. It is important to remember that the total length of the drainage pipeline cannot be more than 20 m. Copper pipes are laid in a loop to catch oil, which is contained in small quantities in freon.

Drainage can be diverted in two ways: take it to the sewer or to the street. The first method is technically correct, but due to the complexity of reproduction it is not widely used.

At the bottom of the internal block of the system there is a tube with a plastic tip. A corrugated hose is put on it and tightened at the connection with a clamp.

A similar procedure is performed for the outer part of the device, but many people ignore it. If a polymer pipe is used instead of a hose, an appropriate adapter is selected.It is used to connect the output of the unit and the tube.

To connect copper pipes, you first need to lay them along the wall using a pipe bender. If such a tool is not available, then we suggest that you read the article, which describes in detail how to bend a pipe without special equipment. Read more - read Further.

The tubes must be given the necessary slope without kinks or sharp creases. First of all, they are connected to the unit indoors. To do this, loosen the nuts on the corresponding ports.

When unwinding, a characteristic hissing sound of escaping nitrogen will be heard. It is pumped in at the time of production to eliminate oxidation of parts. After lowering it, you need to remove the plugs and completely unscrew the nut. Next, the rolling procedure is performed.

The edges of the pipes in a 5 cm area are leveled. Then flaring is carried out to ensure the connection between the inlet and outlet of the blocks. This will create a closed circulation system. Correct installation plays an important role in achieving maximum tightness during the movement of freon.

The flared edge of the pipe is connected to the required outlet and secured with a nut. It is prohibited to use any additional devices - sealants, gaskets, etc. The copper tubes used provide the necessary sealing.

Similar actions are performed with all four ports.After the connection, the final stage of installing the air conditioning system follows - eliminating air and moisture, as well as possible argon residues that may have accumulated during the installation process.

Stage #4 - vacuuming the system

During installation work, air enters the air conditioner pipes and if it is not removed, it will end up in the air conditioning system. The result is increased load on the compressor and, accordingly, its rapid heating.

Also, water particles negatively affect all parts. Freon contains a proportion of lubricating oil; its hygroscopic consistency becomes less effective when in contact with water. As a result, component wear will accelerate.

To remove air, two methods can be used: a vacuum pump or a small amount of freon liquid, which is drained from a unit located outside. When manufacturing an outdoor unit, manufacturers fill it with freon with a slight excess.

An alternative to an expensive vacuum pump is to release excess freon from the outdoor unit system. To do this, unscrew the plugs on its valves. It is necessary to work with a lower port of larger diameter. Under its cover there is a hexagonal connector. Based on its parameters, the appropriate key is selected.

Using a suitable key, turn the valve 90° and after a second return it to its previous position. Thus, a small amount of freon enters the system and increased pressure is created.By pressing your finger for a second on the spool located on the same port, excess freon and gases are released from the system.

After complete removal of air, the spool outlet is tightened with a plug, and the valves are fully opened and freon enters the split system. To check the tightness of the connections, they are coated with soap foam.

At this point, the installation process of the air conditioning system is complete, you can proceed to direct operation.

Conclusions and useful video on the topic

How to lay an air conditioner route:

Rolling a pipe for a split system:

Installation and installation of air conditioners, subtleties and secrets:

It is worth remembering that with independent installing an air conditioner, there are no insignificant factors. And everything that was done incorrectly, for example, rolling pipes without cleaning the edges, or an insufficiently fixed connection, ultimately leads to rapid wear of the cooling system components. Therefore, during the installation process you need to be extremely careful with all the details.

If you have the necessary experience or knowledge in the installation of split systems, please share it with our readers. Perhaps you know some subtleties that we did not mention in this material? Leave your comments and ask questions in the block below.

It is a fact that stores selling split systems parasitize the installation, and in any case you need to invite specialists for a banal but logical connection to the electrical network. And often these unfortunate installers from online stores only know how to screw self-tapping screws into the wall and hang the block on them, and that’s all.And they ask for fabulous sums, although you can handle this kind of work yourself just once or twice.

If you order from a normal company, then the installers will be normal. In the end, they have significantly more experience in installation, compared to the average person, provide a guarantee and are responsible. Personally, I thought about installing it myself, but I thought about it and changed my mind.

I’ve also been thinking about installing a split-split system myself... because... there are a lot of negative reviews about the quality of installation and installation prices in stores are 4500-9000 rubles, I think that it is expensive, for 3-4 hours of work (you can find it a little cheaper) ... So, I read several articles and come to the conclusion: that I probably changed my mind): Vacuum pump + not a cheap hammer drill and drill, all sorts of flaring, etc. they cost a pretty penny and for even 3-4 installations for yourself it’s a dubious idea. Equipment for rent will be cheaper, but here too: pay for rent + for materials + waste of personal time + risk of messing up, although you will try for yourself... how much cheaper is it and what is the gain x.z. It’s probably easier to read and look about the installation of splits so that you know how to control and check the installation and try to find conscientious installers who give a written guarantee.

I have been working as an installer of climate control equipment and ventilation systems for more than ten years, and here is my advice: entrust this work to a good specialist. Believe me, it will work out much cheaper for you. No matter how smooth your hands are the first time, and even the third time, you will not install the split system correctly. Theory is theory, but in practice it won’t turn out very well, to put it mildly.

How do you like to pay 3000 for 15 minutes of “picking” a master key in a keyhole with an important look, the so-called defect-free opening of a lock? Do not make a hole in the wall with an SDS-Max hammer drill from a stepladder, mm 40-55 (by the way, perf is available for rent for a day for 2000 and WITHOUT DRILL, the drill made in China is the cheapest at 40 mm from 2500.) Bring, lift and lower a bunch of suitcases. Hanging up the asshole, excuse me, on the windowsill, rolling out new bullshit copper “foil” on which the “skirt” (whoever understands the topic) is once “bursting at the seams” (and they stopped selling normal, thick-walled tubes) And a block weighing at least 30 kg (this while health due to age allows) on straight arms, hunched over the window sill on the brackets. How do you like this? It’s not the installer who makes money. It’s the OFFICE. excuse me. The FSB is in control, the police are in control. And so is the split installer. There are grabbers, of course, God be their judge, and they’ll rip off the money and do the job in a clumsy way. It’s fashionable these days to say that, “Cheap and cheerful.” You gave it away cheaply, and then you get angry? But on who?

Air conditioning, like many other businesses, has its dark sides and much of it is from the evil one, starting from the very top, so to speak, from the manufacturers and founders.From Carrier and BuPont. All this is not unfounded, but taken from primary sources, from literature for those who do this, who have this profession, or, as it is now fashionable to say, do it professionally. And no one (with perhaps rare exceptions) will enlighten You won’t even tell you what and how is actually happening. Air conditioning is becoming, perhaps in meaning, similar to the word “AVENTURE”, “MAGIC”, starting from supplies and purchases and ending with the end consumer (Customer). Money is made from everything. Everything is confusing it’s impossible. Prices are “plastic”, as coaches like to repeat at seminars. Yes, yes, personal growth seminars on “SKILLFUL STEAMING”. The manager-air conditioner is like a sorcerer, a magician. There’s a top hat, a rabbit and a fifth ace in the hole. This is not bad and not good. Today it is ORDINARY. The profession is interesting, not an easy one, you need good health, a strong back, legs, arms, eyesight. And the most important thing is that the head can think, however, as in most other professions. Everyone I wish managers and installers to find themselves. Take care of your health, both physical and mental. It is given only once. Good luck to everyone.

The advantage of installers from the company is that they do not purchase consumables at retail, because the tool pays for them, and the experience is not 2-3 installations. So, it’s probably better to contact a company with good reviews. But if the price of the services offered is three times higher than the cost of a ready-made (such are sold) installation kit, you can think about installing it yourself.