How a washing machine engine works: operating principle + how to replace it if it breaks

When choosing a home assistant, we are usually guided not only by appearance, but also by technical characteristics.And the engine of a washing machine is one of the important parameters that deserves close attention, don’t you agree?

We suggest you understand the performance characteristics, specifics of the design and functioning of different types of motors - for an objective assessment, we conducted a comparative analysis of the operating parameters of the engines.

In addition, they told us how to diagnose the engine, and also outlined the rules for connecting and operating the washing machine, compliance with which will extend the life of the home assistant.

The content of the article:

Types and features of engines

Washing machines use 3 main types of motors: commutator, inverter, and asynchronous. They differ from each other technically and functionally, and have their pros and cons. Let's look at each type in detail.

Type #1 - small and budget collector

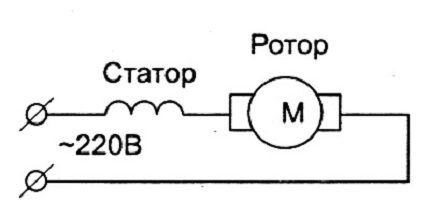

Most washing machines on the market are equipped with a commutator motor. Its design is an aluminum case, inside of which there is a rotor, stator, tachometer and two brushes.

The latter are placed in the device to ensure contact between the motor and the rotor. Through them, current is supplied to the armature, a magnetic field is formed, which starts rotation.The network voltage significantly affects the speed of this rotation.

The commutator motor is located at the bottom of the machine structure and is connected to the drum pulley by a belt. Brushes and belt are considered design flaws. Brushes wear out over time belt needs replacing, as over time it wears out and stretches.

Advantages of the mechanism:

- operates on direct and alternating current;

- small in size;

- easy to repair if a breakdown occurs;

- simple electrical control circuit.

To overcome the frictional force of the belt, the entire mechanism expends more energy. This leads to low efficiency due to increased electricity consumption.

But the statement is quite controversial, because the main consumption comes from the heating element, and not from the engine. Real savings compared to the next type are 2-5%.

Type #2 - innovative and compact inverter

Washing machines began to be equipped with inverter motors in 2005. The development of this variety belongs to the company LG, For a long time, innovation provided the manufacturer with leadership in the market.

Later, inverter motors began to be used Samsung, Bosch, AEG, Whirlpool, Haier.

What is special about the design? In the absence of a commutator-brush assembly and direct drive. Such an engine is installed directly on the drum and operates without a transmission belt.

The armature in it is assembled on magnets, the voltage is supplied to the stator windings in a form converted by an inverter, so the speed of revolutions can be adjusted and controlled.

Inverter advantages:

- simple and compact design;

- efficiency due to the absence of the need to waste electricity to overcome the friction force in the commutator-brush assembly;

- almost silent;

- there are no quickly wearing elements (brush, belt), so the service life is long;

- low vibration level during spinning;

- the ability to set a higher spin speed.

In some models of machines with an inverter, it is possible to configure the drum rotation modes. This is an advantage for the manufacturer LG technology provides 6 Motion. But such washing machines are more expensive, and repairs are expensive due to the price of components.

Type #3 - quiet and simple asynchronous

Such motors are available in two- and three-phase types. The first model is classified as obsolete and in the 21st century it has been discontinued almost everywhere.

The second can be found in early washing machines Bosch, Candy, Miele, Ardo. The rotor of the asynchronous motor is located at the bottom of the washing machine and is connected to the drum by a belt, so they work simultaneously.

Pros of the model:

- easy to maintain;

- works quietly;

- relatively cheap;

- simple design - easy repair.

The asynchronous motor is unpretentious in maintenance - the user’s main task is to timely replace the bearings and lubricate the motor.

But there are also disadvantages to it. Due to its operating principle, you will not find much power in its characteristics.The torque can be weakened at any time, the drum will stop making full revolutions, and the quality of the wash will deteriorate greatly.

And one more feature - electrical circuits are difficult to manage. With all its advantages, the asynchronous motor has sunk into oblivion; the main competition in the market is between inverters and collectors.

Comparative analysis of models

Data on the type of engine and drive can be found in the machine’s passport. The sales consultant must also have this information. Beforehand, you can compare which engine is best for each list of consumer requirements. But first, let's look at the fraudulent maneuvers of manufacturers of this or that type of engine.

Parameter No. 1. No rubbing parts in the inverter. This is not true, the mechanisms have the same number of bearings, but there are no brushes.

But how long do the brushes that frighten collector buyers so much last? 10-15 thousand hours or up to 15 years of daily work for 2-3 hours a day. At the same time, the guaranteed service life of the machine itself is 7-10 years. And the brushes cost about 5 dollars. In an inverter washing machine, as in a collector washing machine, it may be necessary bearing replacement.

Parameter No. 2. Noise. Yes, the “brush” motor is noisier, but the inverter also makes a characteristic squeak. The main sound is produced not by the motor, but by the pump paired with the drum. During the spin cycle, the inverter squeaks, reminiscent of a mosquito.

Parameter No. 3. Energy Saving. The inverter consumes up to 20% less electricity than the collector.This occurs due to more precise adjustment of the speed and load on the engine itself.

What does this look like in practice? You are loading an incomplete drum. The collector will spin it up as much as possible, and the inverter will stabilize the speed. But we considered earlier that the savings as a result are insignificant, because the heating element will still spend the full amount of energy on heating.

Conclusion: if noise is not so important and you are ready to constantly care for your washing machine, choose a collector. This type of engine allows you to save a lot on your purchase. If the priority is performance characteristics in terms of power, noiselessness, and durability, it is worth taking a closer look at inverter models.

The manufacturer guarantees it for at least 10 years. But it only applies to the inverter; other parts of the machine may not be very wear-resistant.

Checking the functionality of the mechanism

There are machines on sale only with inverter and commutator motors, so we will consider these two varieties, leaving out the asynchronous one.

We are looking for a breakdown of the direct drive motor

The inverter is not intended for home repair. The best option is to try system testing, if your machine model is capable of this.

Self-diagnosis will display a fault code, its decoding and will help you understand where the problem is and whether the services of a specialist are needed.

If you still want to remove the inverter, follow the correct algorithm:

- Disconnect the device from the power supply. It is recommended to wait a few minutes until all elements are completely de-energized.

- Unscrew the bolts and remove the back panel.

- We find the screws under the rotor that secure the wiring and unscrew them.

- Before disconnecting the wires, we take photographs or sketch them, so that later we can correctly connect all power sources.

- Remove the central bolt that holds the rotor. During the process, you need to hold the rotor to prevent rotation.

- We remove the rotor assembly, and behind it the stator.

- Disconnect all wire connectors.

Now you can inspect the engine. It is unlikely that it will be possible to thoroughly test the operation of the inverter. What can be done? Check the integrity of the rotor winding.

The Hall sensor often breaks down in such engines. Whether it is operational can only be determined in a workshop if the part is replaced with a new one.

We carry out diagnostics of the belt drive

To check the collector, you must first remove it from the housing. To do this, remove the back panel, disconnect the wires and unscrew the bolts. It is permissible to pry with a screwdriver in the places where the bolts are attached, where dirt often accumulates and sticking occurs.

Now let's start diagnostics. We connect the wires of the stator and rotor windings according to the diagram. We connect it all to electricity. There is nothing wrong with the device if the rotor starts rotating.

To avoid a short circuit, you can connect a ballast in the form of a heating element to this circuit. We connect the ballast from the rotor side. It will begin to heat up, thereby protecting the engine from combustion.

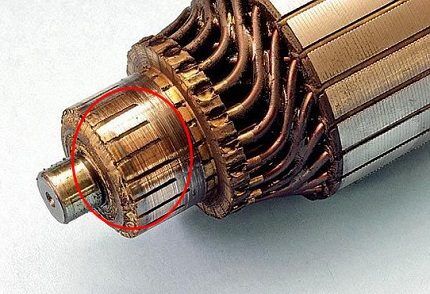

The collector is a structure of several parts and they all require inspection. First in line are the notorious brushes. They are located on the sides of the body. We take them out and inspect them.

If they are worn out, they need to be replaced.A clear sign of such a need is that the engine sparks when rotating. To buy new brushes, take your old ones with you and write down information about the model of the washer.

The next element is the slats. They serve as current transmitter conductors to the rotor. These parts are glued to the shaft and if the motor jams, their detachment is possible.

If you have access to a lathe, it can be used to remove minor flaking. Don't forget to clean off the shavings with fine sandpaper.

Now let's move on to the stator and rotor windings. If a short circuit occurs in them, the collector heats up, which causes the thermistor to operate. The result is that power is lost or the mechanism stops working altogether. We test the windings with a multimeter in resistance mode.

The stator is checked in buzzer mode. The ends of the wiring are tested one by one with probes. If there is no signal, the part is fine. You can determine the location of the short circuit by connecting one probe to the wiring and the second to the housing.

If the device is silent, this is normal. If a breakdown is detected, you will need to create a new winding to repair it yourself, and this is difficult for a non-specialist.

If you still need to replace the engine, it is usually enough to simply install a new part in place of the old one. After all the manipulations, do not forget to turn on the machine and check its operation.

How to extend the life of the washing machine motor?

Maintaining electrical safety will not only protect you from accidents, but will also extend the life of any type of motor. The performance of the washing machine is also affected by proper operation by the owner.

Step #1 - properly connect to the power supply

To properly connect the machine to the network, you need to meet only 6 criteria.

The first thing we will pay attention to is power, cross-section and wire brand. The power of most models ranges from 2000-2500 W. By power we determine the cross-section of the supply wires. Tables with the necessary parameters can be found in GOST 31946-2012.

A two-core aluminum cable is not suitable for powering the washing machine socket; you need to lay a copper and three-core cable. Most often, we have copper cables installed in our apartments with cross-sectional parameters of 2.5 square meters. mm.

You can protect this line using circuit breaker, whose rated current is indicated at 16 A.

Now you need to determine the brand of the supply wire, based on the power and cross-section. The PUNP wire cannot be used.

The next point is grounding. If there is no grounding in the house, you need to take care of this yourself. You can separate the PEN conductor so as not to have problems with this.

More will be needed grounded socket. The ideal option is with ceramic fittings and a higher protection class for rooms with high humidity (if the outlet is in the bathroom).

It is better not to use a tee, adapter, or extension cord for connection.And if there are frequent power surges in your home, connect the machine through a converter.

Recommended purchase an RCD - an automatic device that turns off the power in case of problems in the network. Its parameters should not exceed 30 mA. Ideally, if you can organize power supply for the washing machine from a separate group in the electrical panel.

It is strictly forbidden to make grounding by connecting the machine body and heating or water pipes. And the second taboo is installing a jumper in the socket where there is a zero and a ground contact.

Step #2 - operate the equipment carefully

There are also certain operating rules that affect the operation of the engine. Children should not be allowed to play with software buttons. Do not open the detergent compartment while washing.

Prohibitions also include sudden program changes. If you have a manual machine, do not turn the program dial counterclockwise.

Conclusions and useful video on the topic

You can learn how to repair a broken engine with your own hands from a useful video collection.

Repairing a washing machine if the inverter does not rotate:

How to check the collector with an ohmmeter:

Select the wire cross-section to connect the washing machine:

Each type of engine has its own advantages and disadvantages. Choose a variety to suit your requirements.If you prefer the most modern designs with excellent technical performance and the budget does not matter, choose an inverter.

If you need reliable equipment at a relatively low price and you are ready to make repairs in case of breakdown, buy a manifold. And do not forget to properly connect the machine to the electrical network.

Have you ever had to repair a washing machine motor? Please tell us what the specifics were in disassembling the unit, and whether you were able to repair the equipment. We are waiting for your comments, questions and advice on repairs - the contact form is located below.

In fact, with a good manual on how to replace a washing machine motor, even a novice can perform the repair. Yes, the problem lies elsewhere. How to find an identical engine, or even better, exactly the same one that was standing and burned out. I visited all the markets in my city, scoured the Internet, online and offline stores with spare parts. I found this engine and it cost almost as much as I would have paid for a rebuilt engine. So, it is not always profitable to repair it yourself.

I don’t quite agree; after all, replacing a washing machine motor is not like pulling a button out of a drum. It’s better not to try it without skills, because in my opinion it’s difficult to do it using only manuals and videos. And often not all the necessary tools are available at home. I’d rather pay a normal master to do everything right the first time. They are still more valuable than their nerves.

Repairing is profitable when you know what you are doing. If a person who has little understanding of repairs gets involved, then he risks giving away even more money later.

Thank you very much for a good lesson. My Indesit car recently began to fill and drain water, while the lights on the panel were blinking. The master came and didn’t even turn on the machine, he began to disassemble it, changed the brushes, took the engine to rewind, saying that it would soon break too, the shock absorbers had turned on, but when he turned on the machine, it showed exactly the same breakdown, I told the foreman that it might be the case in the “brains” of the machine, to which he agreed, unscrewed and took away the control panel. The car is 13 years old, I calculated 8000t for repairs. I’m wondering whether it’s worth repairing or buying a new one; based on your recommendations, I would choose an inverter. Not a repair, but a scam for money.

Tatyana, you were simply scammed out of money. According to your description of the malfunction of the manostat. It costs a lot less than 8 thousand.