How to remove an air conditioner yourself without losing freon: a detailed guide to dismantling the system

Air conditioning units for domestic and office purposes, as well as those used in the industrial sector, as a rule, operate on a specialized refrigerant - freon. This chemical substance is capable of taking on different states - liquid or gaseous, depending on parameters such as pressure and temperature.

The practice of operating air conditioners does not exclude the need for dismantling, for example, for repairs. In such cases, the owner begins to study information on how to remove the air conditioner on his own without losing freon, so that he can try to fix the breakdown without involving specialists. We will talk about how you can do this with your own hands in our material.

The content of the article:

What you need to know about air conditioner refrigerant?

Unfortunately, breakdowns of air conditioners, like other equipment, are not uncommon. Therefore, a potential technician, even a “home” one, will need theoretical and basic information regarding the same freon if he plans to install, dismantle or repair an air conditioner.

Modern air conditioning devices, household or office, use refrigerant for operation, the brand of which is indicated in the air conditioner passport, as well as directly on the equipment body.

Therefore, the first thing a home mechanic needs to know is, of course, the brand of refrigerant used in the system.The brand of freon is determined by reading the information on the technical plate of the device, which is always present on the housing of the outdoor module.

What is this information for? For the correct execution of installation (dismantling) and commissioning work.

Freon is a very fluid substance. That is, if there is even a slight violation of the tightness of the system, this refrigerant completely escapes. This class of substances refers to chemicals that can destroy the ozone layer of the atmosphere. Accordingly, the release of freon into the atmosphere is unacceptable in principle, even in small volumes.

When installing a new air conditioner, the risk of refrigerant leakage is minimal, but the process requires a certain technological approach. However, the situation is completely different when dismantling the system. We will talk further about how to remove the air conditioner so that freon does not leak out of it.

Removing the air conditioner while saving freon

Let's consider two options for dismantling a household split system with full preservation of freon, which potential users of air conditioners have to deal with:

- Dismantling of the working installation.

- Dismantling a faulty installation.

Both options are the reality of the current practice of operating household and other air conditioners.

By the way, the second option, when you have to dismantle a faulty machine, is even more common than the first.Working air conditioners are dismantled quite rarely, allowing the machines to work out the entire period stated by the manufacturer.

Option #1 - dismantling working equipment

This case of dismantling is usually associated with the user moving to another place of residence (work, etc.). True, sometimes equipment is going to be dismantled in connection with replacement with a more advanced (modern) model.

Let's consider the main stages of dismantling the system while preserving the refrigerant.

Stage #1 - pumping freon out of the system

Whatever the purpose of dismantling the working equipment, the air conditioner must first be “mothballed”.

This term implies:

- disassembling the system into individual modules;

- disconnection linear pipelines;

- disconnecting electrical connections;

- maintaining freon in the system.

With a working (fully functional) air conditioner, completing the items noted in the list is relatively easy. It is enough just to first pump out the freon present in the evaporator (a part of the indoor module) and in the copper tubes connecting the indoor module to the outdoor unit.

It should be noted: in this option, the refrigerant is pumped out entirely by local means - in other words, directly by the air conditioning compressor.

User actions are as follows:

- Close the freon supply valve to the evaporator (on the smaller diameter tube).

- Leave the valve open on the vapor exhaust line (on the larger diameter tube).

- Turn on the air conditioner at "cooling" mode.

- Wait until the system switches off automatically (due to low pressure).

- Close the valve on the vapor exhaust line.

This is, in general terms, what the technology looks like, demonstrating how to properly remove a household air conditioner while preserving freon in one of the system modules (outdoor module).

After completing this procedure, all that remains is to disassemble the air conditioning unit into separate modules for transportation to another installation site.

Stage #2 - disassembly into modules of a household split system

Next, we will consider the sequence of actions for dividing the air conditioner into modules. But this is subject to the procedure described above for pumping out freon with a compressor.

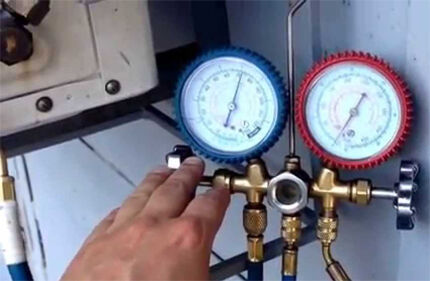

Thus, it is recommended to connect the pressure gauge station to a fitting specifically designed for filling/removing freon. This service port (standard specification name) is part of the gas line shut-off valve design (larger line). The fitting is closed with a brass screw plug, which must first be removed.

The connection of the pressure gauge station to the service port is carried out through a pressure gauge (pressure-vacuum gauge), designed to control the low pressure side. On branded devices, this part of the equipment (including the adapter hose) is usually blue. In this case, the shut-off valve of the blue station pressure gauge must remain in the “closed” position.

The service port (fitting) of the low pressure line has a built-in check valve. When a hose equipped with a special threaded head is connected to the fitting, the check valve opens by pressing the head crossbar onto the valve stem.Therefore, connecting/disconnecting to the service port (screwing on the head) must be done quickly but carefully.

After connection, the pressure gauge will show the presence/absence of pressure in the line. If there is no pressure, you can safely disconnect the pipelines connected to the outdoor unit by unscrewing the union nuts. Otherwise, the procedure for pumping out the refrigerant with the compressor should be repeated.

Then the electricity supplied to the outdoor and indoor units is turned off, as well as the electrical supply to the module terminals. It is recommended to number the electrical conductors if you intend to use old wires for new installation.

Stage #3 - removing blocks from installation sites

The next stage of the operation of dismantling a working household split system is purely physical. It will be necessary to remove the air conditioner modules (external and internal) directly from the installation sites.

The external module of low weight (up to 50 kg) located at a low height can be removed manually - by two people and using ladders if necessary. At a height, if the external module is located next to a window, manual removal of the device is also quite possible. Although in this case it should be remembered that this is a rather risky and dangerous undertaking.

Of course, dismantling options from a great height, when there are no so-called “cargo” terminals nearby - windows, doors, etc., should be considered a more complicated procedure for removing the outdoor module.

For such cases of removal, as a rule, they use additional equipment and also resort to the services of after-sales services:

- climbers;

- mechanical towers;

- taps, etc.

The internal module of a split system usually does not cause any special problems when performing dismantling work. Although, if during the installation of the air conditioning system the passage of pipelines through the wall was carefully sealed, you will have to carefully open this area of the wall in order to pull out part of the linear pipes brought outside. First, before working with copper linear tubes, the pipeline connection is disconnected directly on the internal module, and the module itself is removed from its mounts.

True, sometimes it makes sense not to disconnect the copper tubes from the internal module, dismantling this block of the system together with the pipelines. However, this option is acceptable provided there is a short (no more than 1.5-2 meters) line connecting the system modules.

Since the internal module of a household split system is hung on the upper edges of the mounting plate attached to the wall, to remove it you need to slightly pull down the lower edge of the housing adjacent to the wall, and then pull the lower part of the housing towards you. As a result of these manipulations, it will be possible to tear off the lower area of the body from the clamps.

Then, if you lift the housing up a little, the internal module of the split system can be easily removed.

If you encounter difficulties during the dismantling process and a freon leak occurs, do not worry. After the new installation of the air conditioner, you will have to take care of the correct refrigerant charging.

Option #2 - dismantling a non-working air conditioner

The situation with pumping freon out of the system, when the compressor of a household air conditioner does not work for one reason or another, is much worse compared to the first option.

At inoperative compressor of the air conditioner, it will no longer be possible to implement the freon pumping function at the local level. What to do in such cases? How to properly remove and disassemble the air conditioner without freon leaking out?

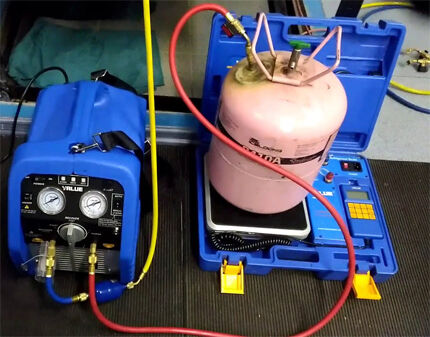

This pumping option usually involves the involvement of service services, since it is impossible to do without the use of special equipment - a freon elimination station.

The use of a freon pumping station allows you to completely free the air conditioning system from the presence of refrigerant. Plus, if necessary, the elimination station allows you to additionally create a vacuum inside the circuit of the outdoor module of the dismantled air conditioning system.

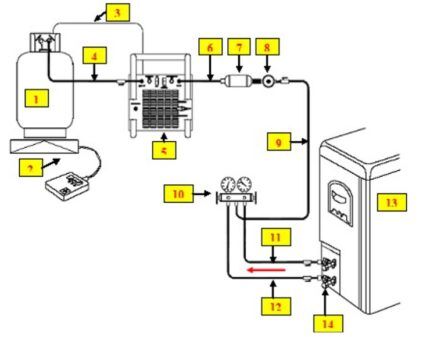

A non-working air conditioner is freed from freon by sequentially using two methods of eliminating the refrigerant:

- Elimination of liquid substance.

- Elimination of gaseous substances.

The process of pumping out freon from a non-working air conditioning system is accompanied at the first stage by actions to collect the liquid phase. The shut-off valves on the linear pipelines of the air conditioner are opened completely.

In addition to the shut-off valves, it is also necessary to open the control solenoid valves provided by the outdoor module circuit.

To move to the open position, a temporary appropriate supply voltage is supplied to the valve coils (usually indicated on the valve body or in the air conditioner documentation).

Next, install a container (freon container) on the scales, equipped with a two-way (gas and liquid) terminal. The cylinder must correspond to the brand of refrigerant - suitable, for example, specifically for storing freon R22, if this is the refrigerant that is being pumped out.

Connect the service tubes to the cylinder and open the corresponding valves (liquid or gas) on the cylinder.

At the next stage of work, the freon elimination station is turned on and the valves of the pressure gauge station, previously connected to the circuit for eliminating refrigerant from an inoperative air conditioner, are opened. The pumping of freon is controlled by the glass of the manometric station.

In a similar way, gaseous freon is pumped out, with the only difference being that in this case the gas valve on the assembly cylinder is open.

It should be noted that the refrigerant pumping system provides for filling the collection container - the cylinder - to no more than 80%. As a rule, the operating algorithm of the refrigerant elimination station is adjusted to this volume parameter. The design of the liquidation station itself is equipped with special sensors for monitoring the collected volume.

When the elimination of freon is completed, you can begin dismantling the air conditioner.

Conclusions and useful video on the topic

Features of freon evacuation are clearly shown in the following video:

Dismantling a household air conditioner must always be carried out taking into account the complete pumping out of the refrigerant in order to avoid loss of freon. Meanwhile, quite often in practice the opposite situation occurs when freon is simply dumped into the atmosphere. This approach is unacceptable, as it violates the natural environment of human existence. Simply put, people poison themselves by resorting to methods of banal freon drainage without rules.

Would you like to share your own experience of pumping out freon and give useful recommendations for repairs? Or do you still have questions that we have not addressed in this material? Ask them to our experts and other site visitors in the comments block located below this article.