How to make a mirror screen for a bath: step-by-step instructions

Arranging a small bathroom, where every centimeter of space counts, is not an easy task.A win-win option in this situation would be to install a mirror screen. It will visually expand the space and allow you to organize storage space for accessories. But you need to know how to build it, don’t you agree?

We will tell you how to make a mirror screen for a bathtub so that the result of the work will please you with its appearance and impeccable service. The article we have proposed describes in detail the assembly and fastening technology of a not at all simple design. Taking into account our recommendations guarantees high final quality of the product.

The content of the article:

What are mirror screens made of?

A mirror screen is a structure consisting of a frame frame, inside of which rigid curtains with a mirror surface are fixed. Depending on the design solution, panels can be solid or consist of several parts.

The main requirement for the material used to make the screen is moisture resistance and the ability to easily withstand temperature fluctuations. Mirror surfaces meet both of these criteria. They do not absorb moisture, are resistant to mold, and also do not deform under the influence of temperature changes.

When arranging bathrooms, it is recommended to use acrylic mirrors. They are most suitable for specific premises and are highly resistant to chemical influences.

In addition, acrylic surfaces are famous for their high impact resistance. They are five times stronger than glass mirrors. In fact, breaking an acrylic reflective panel requires a lot of effort. Therefore, you should not worry that children or animals will accidentally break the fragile material and be injured by its fragments.

It is better to choose silver amalgam as a reflective material. Compared to its aluminum counterpart, silver amalgam is characterized by increased resistance and durability.

To cover the panels, you can use tinted and colored mirrors. To create them, a colored layer of amalgam is applied to the glass: gold, bronze, blue...

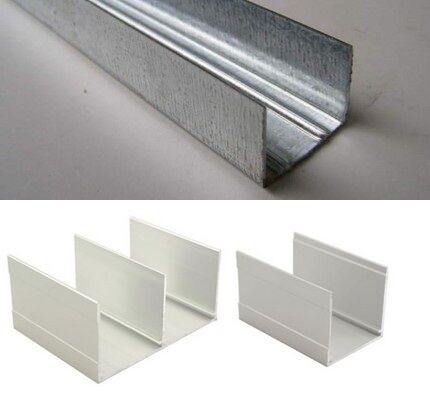

The frame of the structure is assembled from aluminum profiles.They are inexpensive, light in weight and easy to install. In addition, aluminum profiles do not rust, and they do not wear out so quickly. Profiles for the frame can also be made of dense plastic.

The combinations of materials look interesting. For example: the bottom of the panel is made of metal, and the top is decorated with a mirror or glass.

To enhance the decorative qualities of reflective surfaces, lighting can be installed around the perimeter of the panels or along their upper edge.

The only drawback of mirror surfaces is that residues of splashes and dried drops are always visible on them. Therefore, in order to maintain a presentable appearance, they should be regularly wiped with a cloth moistened with detergent.

Design options

Depending on the design, mirror screens for baths are divided into two main types: stationary solid structures and sliding systems. The screen configuration depends only on your technical skill and economic capabilities.

You will become familiar with all existing types of screens used in bathtub design. next article, which we recommend reading.

Tightly closing walls

Fixed screens are tightly closed structures that perform a decorative function and hide communications laid under the bottom of the bathroom from prying eyes.

Solid, mirror-lined walls have a presentable appearance. But such structures should be installed only if you know for sure that the pipework under the bathroom is in perfect order.

To enable preventive inspection, structures are equipped with inspection holes. But if it is necessary to carry out repair work involving partial replacement of communications, the structure will still have to be completely dismantled.

Swing and sliding systems

Movable screens are more functional designs because they can provide access to pipes in a matter of seconds.

They may have:

- Doors that open on hinges. Hinged doors open according to the book principle - to the sides or forward.

- Systems sliding along special grooves. In them, the doors move along guides to the sides.

Screens with hinged doors are easy to use. The number of doors depends on the dimensions of the bowl itself. But when choosing hinged structures for arranging your bathtub, keep in mind that in order to fully open the sashes by 90°, additional space must be allocated.

When arranging a small bathroom, preference should be given to sliding models, our recommended article will introduce you to the specifics of their assembly.

A convenient sliding system makes it possible to save extra centimeters of space in a small room, while providing free access to the farthest corners under the bottom of the bowl.

Additional design possibilities

If we consider additional “options” in the form of internal content, then the screens can be equipped with spacious internal shelves or a retractable unit. The choice is simple or functional design depends on what shape the bowl has and how much space is allocated for the room.

Due to the fact that the bowl has a concave shape, the space under the bath can be conveniently used as a kind of pantry for storing bags of powders and bottles of cleaning products.

The shelves hidden behind the doors can be made horizontally or vertically.

On narrow shelves located along the front side of the bowl, it is convenient to place:

- household chemicals (bottles with air fresheners and detergents, containers with gels and rinses);

- household items (sponges, brushes and napkins used for cleaning premises).

The design of such improvised lockers comes in two types: retractable and sliding. To increase functionality, built-in cabinets are complemented with pull-out trays.

Mirror screen manufacturing technology

There is nothing difficult about making a mirror for a bathtub. The main thing is to decide whether you need cabinets with doors for storing household items or whether you can limit yourself to a conventional design without doors. In essence, the manufacturing process is not much different from assembling a regular screen, the only difference is in the design of the mirror surface.

Selection of required materials

The size of the structure being built depends on the dimensions of the bath. They can have a length from 1.5 to 1.7 meters and a height of 50-65 cm.

For the manufacture of the frame, a reinforced metal profile of the PN 27*28 brand or a wooden beam with a section of 40x40 mm is suitable.

When planning to use wooden beams, take care to extend the life of the frame. To do this, treat the surface of the wooden blanks in 2-3 layers with a special primer, which contains antiseptic, moisture-repellent components.

The tools you will need to carry out the work are:

- building level;

- plumb line;

- Bulgarian;

- perforator;

- construction knife;

- screws and self-tapping screws;

- polyurethane foam;

- sealant;

- "liquid Nails".

The size of the screws must correspond to the thickness of the profile used to construct the frame. Compliance with this condition will prevent damage to the bowl during installation.

As noted above, it is better to use acrylic mirrors to decorate the panels. They are two times lighter than their glass counterparts. Standard cutting tools can be used to process them.

Acrylic sheets can be mounted with or without a base. In the first case, the glass is glued using “liquid nails” onto blanks cut from chipboard or MDF. And in the second, acrylic sheets are simply fixed to the frame with their back side or inserted into the grooves of the guide profiles.

When planning to install fittings, such as door handles, pay attention to the quality of the material. It must be resistant to corrosion.Otherwise, after a short period of time, the doors on the handles will take on an unsightly appearance. The best option is galvanized steel fittings.

Assembling the structure frame

The first thing you need to do when building a frame is to correctly calculate the dimensions of the structure.

Failure to comply with this condition may result in the frame simply deforming during operation under the gravity of a bathtub filled with water.

The frame installation process consists of the following steps:

- Marking the installation of fasteners. Along the contour of the bath along the entire length of the bowl, using a building level and a plumb line, mark the location of the profile. The markings should be flush with the edge of the bowl. The top side of the bathtub is taken as the starting point for measurements.

- Construction of the front and side framing frames. Blanks of the appropriate size are cut out of the metal profile, and then they are fixed to the floor covering, guided by the marked lines.

- Installation of corner and intermediate slats. Vertical profiles are attached to the corners of the framing frame to connect it to the floor using dowels. Intermediate slats are placed at a distance of 60 cm from each other.

- Fastening panels to the frame. The finished panels are carefully inserted into the guide profile.

When marking strips for the starting profile, it is necessary to leave a gap between the bath for inserting the future material. The width of the gap depends on the thickness of the cladding.To facilitate the assembly of the structure, marks are applied not only to the floor, but also to the wall plane.

The joining of frame elements is carried out using self-tapping screws. And the slats adjacent to the wall are screwed onto mounting bolts. To increase the rigidity of the structure in the area of the side supports and in the places where it is planned to install shelves or place a drawer, additional racks are made from metal profiles.

To ensure a tight connection between the guide profile and the floor covering, thereby preventing the penetration of moisture into the space under the bottom of the bathroom during operation, the lower edge of the frame is sealed with sealant. It is better to blow out the upper profile with polyurethane foam.

Screen panel cladding

When planning to install sliding doors, an W-shaped guide profile is installed along the bottom side of the frame. The upper guide is installed after the mirror panel is inserted.

To regulate the level of deviation of the screen from the vertical position, loops are installed on the sides of the profiles. When fixing the profile, it is important to ensure that there is no gap between the side walls and the rail.

To make cladding panels from chipboard, one or two blanks of appropriate sizes are cut out.

If you intend to make a blank screen, cut the blank to the full size of the front panel. When planning to build a structure with sliding doors, prepare two identical pieces of such a size that when the screen is closed they overlap each other by several centimeters.

In the place where the technological window is provided, use a knife to carefully cut a hole measuring 30x50 cm. Later it can be equipped with a ready-made plumbing hatch with a removable panel. They come in rotary or folding versions.

The cutting of facing panels is carried out using a construction knife and a grinder. Mirror panels are attached to blanks cut from MDF or chipboard using “liquid nails.”

The processed blanks are attached to a wooden frame, mounted on “liquid nails”. Gluing the canvas allows you to create the effect that the mirror screen is made without a frame.

When creating a blind screen, dowels are used to fix the panels to the metal profile, maintaining a distance between the fastening points of 15-20 cm. To decorate the fastening points, plastic sides are installed around the perimeter of the structure.

Do you want to install handles? Use suction cup models. This way you can protect yourself from the problems that arise when curious little household members start climbing through the cabinets. Using removable suction cup handles, you can remove them at any time and be sure that your child will not harm himself by accidentally removing cleaning chemicals from under the bathtub.

At the final stage, in order to improve the aesthetic qualities and ensure the tightness of the structure, the technological gaps are filled with a silicone-based composition.

If as a cladding bath screen If you use tiles with a mirror surface, the effect will be similar. The method of constructing such a design is described in detail in the article we recommend.

Conclusions and useful video on the topic

Video #1. A selection of mirror screen design options:

Video #2. Construction frame installation technology:

There is nothing difficult about making a mirror screen on your own. The main thing is to be extremely attentive and careful. After all, if there is an error of even 5-10 millimeters, the slightest flaws will immediately become noticeable on the mirror surface.

Do you have experience in constructing mirror screens for arranging a bath? Perhaps you know technological subtleties that will be useful to site visitors? Please write comments in the block below, share information and photos on the topic of the article, and ask questions.

A mirror screen for the bathtub is, in my opinion, too much, although... if you walk around the bathroom in “slippers made of pillows or wrap them with foam rubber,” this is probably an excellent, very beautiful option. The issue of safety must come first. And if there are also children in the family..? I would recommend a frame made of plastic panels. The choice is huge in thickness, color and width, so you can choose any option. Well, if you really want to, there are also mirror ones. What the frame is made of is up to the master. If you have hands, any option is possible. There is a huge field of activity for “homemade” people, especially for beginners.

Danila, what are you talking about? Or didn’t you read the article except for the word “mirror”? We are not talking about a mirror on glass, but about an acrylic mirror. And no need for foam slippers.

Yes, apparently the person read the article diagonally and did not want to delve into the technical details, but nevertheless there is a portion of criticism. Perhaps there really is no understanding of what we are talking about.

A mirror screen under a bathroom is a kind of false panel behind which the interior space of the bathroom itself is hidden. That is, you can equip a place to store something (for example, household chemicals) and hide it behind a mirror screen.

If you are concerned about safety, especially for children, then the article suggests installing mirror screens made of acrylic. This is a fairly durable material that will not break from mechanical impact, as can happen with a regular mirror. In addition, acrylic is resistant to chemical exposure associated with the use of detergents and high humidity in the bathroom. Therefore, I advise you to read the material carefully so as not to mislead anyone.