Machine for bending profile pipes: how to build a pipe bending machine with your own hands

In households, a machine for bending profile pipes is not used so often that it is necessary to buy expensive factory-made equipment.

If such a need arises, a simple pipe bender can be made privately, having previously decided on what type of this structure is suitable for completing the task.

This article examines in detail the types of pipe bending machines, describes the principles of their operation and construction methods.

The content of the article:

Types of machines for bending profile pipes

There are many equipment modifications for changing the configuration of profile pipes. This is due to the minimum bending radius. If we neglect this important parameter, the strength characteristics of the material will change for the worse at the bending point. You also need to know some technological subtleties metal pipe bending and take them into account while working.

When choosing a design, take into account the workpiece material, diameter, and wall thickness.

Classification of bending machines by drive type

Depending on the type of drive, machines designed for bending any pipes are manual, electromechanical and hydraulic.

Manual. These are extremely simple mechanisms that can be manufactured independently even by a person not versed in the intricacies of working with metal.

Electromechanical. Such a machine has a drive in the form of an electric motor - stepper or conventional, connected through a lower gearbox. The latter solution ensures high-quality bending due to correct stress distribution.

The structure of the mechanism is not simple; in order to make it, you need special knowledge and at least a little professionalism.

Hydraulic. The drive in this model is manual. Unlike the simple manual design, here a hydraulic cylinder is included in the design, which significantly reduces the muscular effort applied during bending.

Rollers make it possible to bend a profile pipe in any desired direction. A manual profile bender with hydraulics, with its light weight, can bend pipe assortments up to 10 cm wide.

Types of pipe benders by installation method

There is a division of profile benders depending on the installation method. There are stationary, portable and wearable equipment. Stationary machines can take the form of a simple concrete slab with rods or solid equipment.

Compact portable pipe benders have a support stand, but the portable model does not have a support; it is selected each time the equipment is used.

Classification of machines by bending method

The design of the profile bender and its performance will depend on the bending method. There are 3 main bending methods. The first is extrusion, when the geometry of the profile pipe is changed using a deforming roller that acts as a punch. In this case there is no matrix.

To perform the operation, 2 strong supports are required on opposite sides of the bend, which act as a matrix. Rotary shoes or rollers are used as such supports.

Since the force increases gradually and is constantly perpendicular to the pipe, the method makes it possible to obtain a good final result. We apply the method only for small-scale work.

The second is pressing. To obtain a bend, the principle of a bench vice is used - a piece of pipe is placed between the matrix and the punch.

To obtain a high-quality bend, the profiles of the latter must exactly repeat the geometry of the part. And also in the calculation it is necessary to take into account the residual deformation of the metal. At home, this method is applicable when great accuracy is not required.

The third is rolling - a universal method used for bending both thin- and thick-walled pipes. The bend is produced by pulling the workpiece between rollers - one rotating and two supporting.

In addition to those mentioned above, pipe bending can also be carried out using the following methods:

Regardless of the chosen design, when independently manufacturing a pipe bending machine, it is necessary to take into account the recommendations of specialists. When choosing a material for the frame, you need to proceed from the fact that the thickness of the metal should be at least 1/6 of the width of the profiled pipe.

So, if you have to bend a pipe with a rectangle in cross-section with parameters of 50 x 25 mm, then in order to avoid deformation of the frame during the bending process, you need to take a channel or angle with a thickness of at least 10 mm. The base plate and punch with the matrix must be 2 times thicker.

The optimal diameter of the rollers is at least triple the cross-sectional dimensions.The shelf of the channel and angle taken to make the frame should be 2 and 3 times the width of the pipe, respectively. If you have to bend profile pipes with a rectangular section of 50 x 25 mm, you need a 100 x 10 channel or a 150 x 10 angle.

We make a hydraulic pipe bender

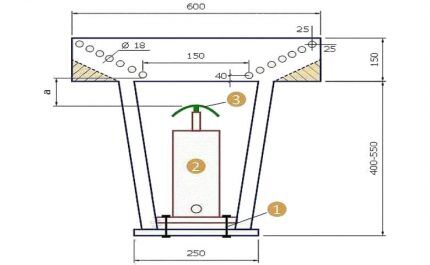

Let's consider the diagram of a machine with a hydraulic drive, where bending occurs due to pressing a profile pipe in the center with a punch fixed on a rising rod. As a result of close contact of the workpiece, supported by two stationary rollers, with the movable punch, the latter takes on its outline.

To mark the working surface, lay a vertical axis and, at the distance indicated in the drawing from the edge and axis, mark the location of the lower holes. Then mark the location of the upper holes, retreating the required distance from the edge. Connect the center of these holes with a straight line and lay equal segments on it.

The axes of the intermediate holes will be located at the intersection of the marks made with the inclined axis. Holes on the working surface are needed to be able to adjust the bending radius of the profile workpiece. Since the working surface consists of two mirror-like parts, the second one is marked in the same way.

The height of the machine is determined by the parameters of the jack and the distance indicated in the drawing by the symbol “a”. To bend a profile pipe 15 mm wide, this gap when the jack is not in use should be approximately 20 mm.

In this design, the force transmitted by the punch is concentrated in its upper part. As a result of this effect, the outer radius of the pipe is subject to tension, which can cause thinning of the wall, and in some cases, rupture. Therefore, this machine is not recommended for deforming thin-walled workpieces.

DIY rolling pipe bender

On such equipment, the workpiece acquires a given shape by rolling. In a home workshop, it is easier to make a 3-roller design with a manual drive. Let's consider two options for such machines.

Machine version with rotary platform

The design principle of such a machine for bending pipes with a cross-section other than round is as follows:

- The main frame is connected through a swivel joint to a rotating platform, which sets the bending angle.

- The platform is set in motion by a jack resting against it with a working rod.

- The profile is drawn by rotating the handle located on the intermediate shaft.

To make the base of the machine and the stands, you will need a channel with a wall height of 150 to 200 mm in an amount of about 3 m. A steel pipe with an internal diameter equal to the external diameter of the bearings, which is divided into 6 short sections, is suitable as a cage for the bearings, the basis of the rollers.

The base and two platforms are made from the channel.Having retreated about 0.5 m from one of the sides, weld a vertical stand from the same channel. To do this, two sections are paired to make the stand strong.

Strictly observing horizontality, a stationary platform is mounted, and the rear pillar is welded to it. Next, they take a section of a profile pipe and increase the limiters with a height no less than the thickness of the profile pipe, the deformation of which is supposed to be carried out on the machine being manufactured.

The guide platform is connected to the main frame via door hinges. Bearings are mounted on the extended stops and edges of both platforms by welding and the structure is reinforced with corners. The shafts are inserted into bearings, and a handle is attached to the middle one.

A jack is installed under the edge of the guide platform and secured to the base using a bolted connection.

The assembly of a pipe bender with a rotating platform is carried out in the following sequence:

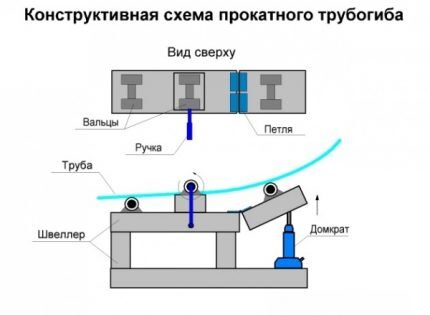

Rolling machine with three rollers

On this machine, the pipe is laid on rollers located on the sides. The upper movable roller is lowered onto the product from above and in this way it is fixed. Next, they rotate the handle and transmit movement to the shafts through the chain. The pipe stretches and changes its geometry.

Gradually increasing the pressure by tightening the clamping bolt and pulling the workpiece, the pipe is bent at the required angle.

To make a machine that operates according to this scheme, it is necessary to prepare a shelf and rolled metal profile for the frame, shafts, 4 strong springs, a chain, bearings, fasteners, and other parts. To attach the bearings, you will need 3 shafts with parameters corresponding to the sprockets and bearings.

Two shafts are designed for lateral placement, and the third (pressure) is for hanging on springs. These elements will most likely have to be ordered from a workshop, but the rest can be done by hand.

The pressure shaft includes bearings, gears and rings.Threads are cut into the rings for clamping bolts and grooves are made. In the shelves made of channel bars, seats are made for the pressure shaft. At the final stage, the structure is assembled, starting with the installation of the frame.

Afterwards, the pressure shaft on springs, connected to the shelf by means of a key connection, is suspended. The support shafts are installed on the sides and the chain is pulled between them, using a magnetic corner as a holder.

Attach a handle with a rotating tube to one of them, then carry out the work of installing the jack. It is attached to the platform with bolts and welding.

When installing the suspension shaft, a certain sequence is followed: first, install it on a shelf, weld nuts for the springs to it, turn the platform over and connect it to the springs. It should be noted that as the distance between the rollers increases, the forces applied for bending decrease.

To assemble a rolling pipe bender you will need:

There are several more articles on our website that describe in detail the options for homemade devices for bending profile pipes, we recommend that you read:

- How to build a profile pipe bender with your own hands: a review of the best homemade products

- How to make a pipe bender with your own hands: examples of the best homemade products

How to bend a profile pipe in a simple way?

The most primitive device for changing the shape of a profile pipe is the use of a wooden template. It can be used in the case of bending thin-walled pipes made of steel or aluminum. To make such an improvised machine, take boards, fasten them together in any way and cut out a template.

At the point of contact with the pipe, the thickness of the template should be several centimeters greater than the cross-sectional height of the profile pipe. The edge of the template is inclined, otherwise the pipe may slip.

The structure is supported and secured to some stable base.The pipe is placed between the template plane and the stop and the material begins to bend, starting from the edge of the tube. If you start the bending process from the center, the thin-walled pipe may flatten.

You can insert a metal rod into the pipe with a diameter equal to the flow area of the pipe, or you can simply take a piece of pipe and put it on the end of the workpiece. In any case, it will be more convenient.

For more information on how to bend a profile pipe without special equipment, read this material.

More powerful machines are made using the same principle. In this case, the force is created using a winch, and the pipe is secured more firmly so that it does not fall off.

Conclusions and useful video on the topic

Basic rules for manufacturing a machine for processing profile pipes:

Pipe bending machine, similar in design to the factory one:

Of all the options for roll forming machines, you should choose the design that best suits the purpose of its use.Sometimes the simplest mechanism is enough to provide yourself with the required amount of bent profile without any special financial costs.

Do you have personal experience building a pipe bending machine? Perhaps you can provide useful information on the topic of the article and post a photo of the device you made? Please leave comments, share your experience, and ask questions in the block below.