How to make a pipe bender with your own hands: examples of the best homemade products

The desire to equip a country house and plot dictates the need for a maximum of tools.When installing water pipes, building a greenhouse, or installing arched structures, you cannot do without a good pipe bender. Its cost in stores is measured in hundreds of dollars, so it is better to make this tool yourself.

We will tell you how to make a pipe bender with your own hands. The article we presented describes in detail the designs tested in practice and provides step-by-step instructions for assembly. Taking into account our tips, you can build an excellent tool for your own household.

The content of the article:

Types of pipe benders on the market

Pipe benders are mechanical or hydraulic structures that help bend metal pipes, angles, rods, and profiled steel without disturbing the internal structure of the product. Hand tools are mainly used to form a bend in one place, while large machines can change the shape of pipes along the entire length at once.

Based on the principle of operation, the following types of pipe benders can be distinguished:

- Mechanical with direct manual force. They are used when working with pipes of small diameters, the deformation of which requires the strength of one person.

- With hydraulic drive. Mostly such tools are made according to the crossbow type, and they are designed to form a local bend.

- With ratchet mechanism.Pipe benders of this type use manual force, but allow you to record the achieved level of deformation after each press of the tool handle.

- Electrically driven machines. The electric motor greatly facilitates the process of pipe deformation, but also significantly increases the cost of the tool.

Features of working with some types are discussed below:

Structurally, pipe benders can be divided into 2 types:

- radius;

- crossbow

In the first case, the pipe is bent around a template segment of a given diameter, and in the second, it is squeezed out with a shoe between two support posts.

When making a pipe bender on their own, craftsmen usually rely on existing tool models that have proven their simplicity and effectiveness. When assembling a pipe bender at home, its design is greatly influenced by the available materials from which the tool will be made.

The presence of a pipe bender among the home craftsman’s tools will allow you to make many useful structures and garden furnishings with your own hands:

Required tools for assembly

You won’t be able to make a good pipe bender with a hammer, screwdriver and screws.

At a minimum, when making this tool you will need:

- welding machine;

- Bulgarian;

- lathe;

- drill.

But the main part of assembling a pipe bender remains an accurate drawing, without which you should not even start assembly work. When making a pipe bender, you cannot do without general household tools.

Naturally, it is not necessary to purchase a lathe and welding machine. To turn several parts from blanks and weld them, you can contact your friends or a workshop that produces forged products. For a small fee, they will quickly help you do everything you need.

How to make a snail pipe bender?

Making your own volute pipe bender may seem difficult.In fact, this device is no more difficult to assemble than a roller pipe bender. The process differs only in the parts used and assembly time.

A volute pipe bender allows you to bend a profile along its entire length at once, and not just in one place. For this property, it gained popularity among installers.

Required materials and tools

Since the described roller pipe bender does not have a specific working diameter and can be made from any available materials, the proposed materials will not contain specific part sizes. The thickness of all metal structural elements should be 4, or preferably 5 mm.

To make a pipe bender you will need:

- Channel – 1 meter.

- Sheet iron.

- Three shafts.

- Two stars.

- Metal chain.

- Six bearings.

- Metal 0.5-inch pipe for making gates - 2 meters.

- Bushing with internal thread.

- Pressure screw.

Particular attention is paid to the dimensions of sprockets, shafts and bearings, which must match each other. Sprockets can be taken from old bicycles, but they must be absolutely the same in size.

Before selecting and purchasing all materials, you need to draw a drawing with a schematic representation of all structural elements, so as not to purchase them additionally during the manufacturing process of the pipe bender.

Scroll pipe bender assembly process

The assembly of any equipment begins with drawing up a drawing diagram.

After this, you can proceed to the main work processes, which are demonstrated in the photo instructions:

- Weld the base of the tool from two parallel channels. If desired, you can simply use a 5 mm thick metal plate or one wide channel.

- Place bearings on the shafts and weld two such structures to the base. It is advisable to limit the shafts with metal strips or place them in the internal cavity of the channels.

- Put on the sprockets and weld them, first stretching the chain between them.

- Cut and weld the side guides of the clamping mechanism to the base.

- Place the bearings on the pressure shaft and assemble the press structure with side stops from strips or channels.

- Make a base for the bushing and weld it to the plate. Screw in the clamping screw.

- Weld to the top edge of the clamping screw and to the drive shaft of the pipe gate.

- Lubricate the bearings with machine oil.

Some useful tips:

After pipe bender assemblies and its tests, you can paint the structure with anti-corrosion paint for better preservation of welding seams. To increase ease of use, a spring is additionally attached to the guides to return the press to the upper position.

Making a manual roller model

Making a manual pipe bender with your own hands is made from steel parts alone without the use of special mechanical devices. This device is designed for local pipe bending. Direct manual force is used to deform the profile, so the pipe bender must be equipped with a long and strong lever.

Next, we will consider the process of manufacturing a two-roller pipe bender attached to a support frame. Tool sizes may differ from those suggested, depending on needs and materials.

Required materials and tools

Pipe deformation is a labor-intensive process that requires good and durable materials, otherwise, instead of the profile, the working tool itself can be bent.

To make a mechanical manual radial pipe bender you will need:

- Welding machine.

- Two rollers made of durable steel (eg 1045 grade) that have been pre-turned. The diameter of the larger one is 100 mm, and the smaller one is 60 mm. Both are 35 mm thick and have a 0.5 inch outer cavity radius.

- Steel pipe with a diameter of at least 1.5 inches with a thick wall (minimum 3 mm).It will serve as a lever, so its minimum length is 1.5 meters.

- Four steel strips measuring 15 x 6 cm and 4-5 mm thick for fixing the base of the pipe bender in a vice, supporting the pipe and making a handle. You will also need 20-25 cm of steel plate with a width of 60 mm and a thickness of 3 mm.

- Two bolts: the first is 0.75" in diameter and 60mm long for the large roller, and the second is 0.5" in diameter and 40mm long for the small roller.

- Steel plate 300 x 300 mm and a minimum thickness of 3 mm.

- Vise.

During the work process, you may also need other general household tools: a hammer, files, sandpaper, a ruler, etc. The above rollers are designed exclusively for pipes with a diameter of 1 inch, but by eliminating the circumferential recess from them, you can get a universal tool for bending a metal profile.

Pipe bender manufacturing process

When all the necessary parts and tools are collected in one place, you can proceed directly to the manufacture of a pipe bender:

- Prepare a drawing marking the location of the main elements.

- Check the compatibility of the holes in the rollers with the diameter of the bolts.

- Drill two holes in two metal strips with a diameter of 0.5 and 0.75 inches. The distance between the axes of the holes should be exactly 80 mm (the sum of the radii of both rollers).

- Make a 0.75-inch hole in the center of the support frame. Insert the corresponding bolt into it without protruding it from the reverse side. Weld the bolt to the metal plate.

- Take drilled metal plates measuring 15x6 cm, a 0.5-inch bolt, a smaller roller, a strip of steel 35 x 60 mm and weld them into a structure in the shape of the letter “P”, after inserting the bolt with the roller on into the corresponding holes.

- Weld the ends of the bolt to the metal strips. You should get a kind of spear with a hole of a larger diameter closer to the open edge.

- A pipe-handle needs to be welded to the base of the resulting spear.

- Weld the support strip for the pipe onto the metal frame. The distance from the strip line to the center bolt axis should be equal to the radius of the large roller plus 0.5 inches.

- Weld a 15 x 6 cm strip at the bottom of the frame for fixing in a vice.

- Insert a large roller into the slingshot, place the structure on the central bolt and screw the nut on top.

- Clamp the pipe bender in a vice and carry out the first tests.

Important manufacturing nuances:

The weak point in the entire resulting structure is the welding seams, so special attention is paid to them during the manufacturing process of the pipe bender.

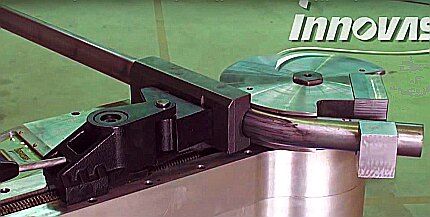

Roller pipe bender from car hubs

Another unique pipe bender from folk craftsmen is a tool assembled from a metal profile and car hubs. Its design is massive and simple, which allows you not to worry about breakdowns during operation.

The manufacturing process of such a pipe bender is as follows. Two automobile hubs with a steering knuckle or machined shafts are screwed or welded to the frame so that they can rotate around their axis.

Between the hubs there is a fixed guide channel, which can be welded from two corners. Inside the guide structure there is a smaller channel, to one edge of which a third hub with a rotary axis is welded, and to the second - a nut or threaded bushing for the clamping bolt.

Along the edges of the guide channel, strips or corners are welded to limit the vertical movements of the moving part of the structure. The edge of the main groove is covered with a sheet of metal with a hole for the clamping screw. On the other side of the plate, a gate handle is welded to the screw.

The result is a roller pipe bender with local clamping force. If you screw a rotation handle to the top of the movable hub, then with the help of such a tool it becomes possible to bend the profile along its entire length.

The considered pipe bender is a powerful and versatile tool that can be assembled with a minimum of cost, because old hubs can be purchased from car repair shops for the price of scrap metal.

Manufacturing a pipe jack bender

A pipe jack bender is the most basic tool for deforming metal profiles and pipes, which you can build yourself.

To make it you will need the following products:

- car jack;

- two channels 100 mm wide and 60 cm long;

- four corners with sides 50 mm and length 40 cm;

- base-bed;

- two hourglass-shaped rollers with through central holes;

- 2 bolts for fastening the rollers;

- semicircular attachment for a jack with an internal recess.

If the procurement of raw materials and the assembly process seem to you to be unnecessarily labor-intensive, then hydraulic pipe bender It is better to purchase it ready-made. Our recommended article will introduce you to the rules for choosing equipment.

To make a pipe jack bender you need:

- Weld four corners in a vertical position to the frame.

- In the channels, from the center to the edge, drill holes in both directions for the bolts that will hold the rollers.

- Place a channel on each two corners and weld it. Both channels should be turned towards each other with their bases, and the distance between them should be equal to the length of the rollers.

- Insert rollers between the channels in symmetrical places and secure them with bolts.

- Place a semicircular attachment on the jack screw and place the hydraulic tool in the center of the frame between the channels.

After assembling the structure, you can place the pipe at the bottom of the rollers and press it in the center with a semicircular nozzle using a jack.

The disadvantage of this device is that it is static, because it will not be possible to rotate the entire length of the profile through a pipe bender.

The advantages of a pipe jack bender include low cost, simplicity of design and no need for hard physical labor.

Those who want to make a machine for working with profile pipes will find a lot of useful information in the next article, the contents of which we advise you to familiarize yourself with.

Conclusions and useful video on the topic

The presented video materials will help you see the above-described recommendations for making homemade pipe benders in dynamics, and will also introduce you to additional options for assembling these tools from scrap materials.

Video #1. Rolling type pipe jack bender:

Video #2. Manufacturing a pipe jack bender:

Video #3. Assembling a pipe bender from hubs:

Video #4. Making a volute pipe bender:

The types of home-grown tools for bending a metal profile are not limited to the proposed options, because you can make a pipe bender with your own hands from any parts available on the farm.

The main thing is to build a clamping mechanism that will push the pipe between two posts or a roller system to deform the entire profile at once.

Would you like to tell us how you made a pipe bender with your own hands? Do you have a tool option in your arsenal that is not described in the article? Please write comments in the block below, share useful information, photos on the topic of the article, and ask questions.

We need some working and simple pipe bender that can be assembled without a lathe (I don’t have one).Of the ones proposed, I liked the option of car hubs. Let's see if he is able to make identical arcs or if the run-up will be significant.