Which pipe to choose for water supply: we figure out which pipes are better and why

The range of pipes for communication devices is extensive.Manufactured products differ significantly in their characteristics: material, flexibility, strength, durability. It is often difficult for the user to determine which pipe to choose for water supply to a house or apartment.

The type of pipeline and transported medium, the number of plumbing points in the network - all these are factors that tip the balance in favor of choosing one type or another.

In our material we will try to understand the subtleties of choice, and also tell you how to determine the optimal diameter of the pipeline.

The content of the article:

Selection of pipes taking into account operating conditions

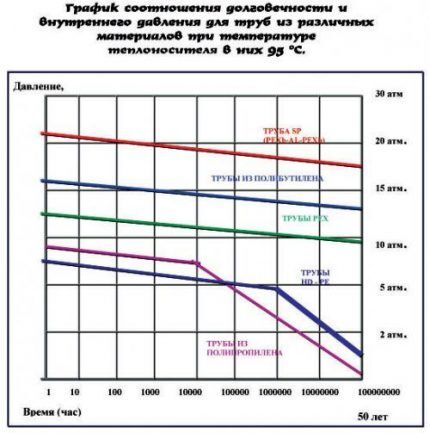

TO internal water supply refers to the piping system (distribution) that transports water to plumbing fixtures and equipment. Pipes and connecting elements made of polyethylene, polyvinyl chloride, polypropylene, polybutylene, metal polymers may not be used for all networks. Each of them has its own operating conditions and they can vary greatly.

Can be used without restrictions copper pipes, brass, bronze - for high-pressure systems, for transporting drinking and technical, cold and hot water. Steel products with external and internal anti-corrosion coating can also be used for any purpose.

For each type of pipe and its standard size, the value of the maximum pressure in the network that they can withstand is determined. It is better that it be higher than the maximum possible pressure in the water supply network.

For example, in a house with centralized water supply water pressure can fluctuate between 2.5-7.5 bar with a norm of 4 bar. In this case, peak readings can sometimes reach 10 bar, and system testing is carried out at values of 12 bar. To prevent the pipeline from bursting, when choosing pipes, a “safety margin” is provided with a focus on maximum performance.

When choosing pipes for the construction of external underground systems, pay attention to the ring stiffness indicator. When laying a polymer pipeline without ducts in soil where damage is possible, products with a protective coating are used.

One of the determining factors for the choice is operating conditions:

How to determine the required pipe size?

To conveniently determine the diameter of pipes and fittings and link them to all elements of the system, use the value of the internal diameter (Dy - conditional diameter of pipes). Focus on typical sizes of steel pipes - they are produced with Dy - 15 mm, 20 mm, 25 mm, 32 mm.

Length supplied steel pipes can be different, mostly these are lengths from 4 to 12 m. Metal-plastic pipes can have a diameter (Dy) 16-30 mm and wall thickness 2-2.5 mm.

The choice of the diameter of the future pipeline depends on the following factors:

- Water pressure in the network. The lower it is, the larger the diameter should be. A thin pipe with insufficient pressure will produce only a thin stream of water.

- Pipeline lengths. The greater its length, the lower the pressure in the network and, accordingly, it is necessary to use a larger diameter.

- Number of turns and joints. Each such element reduces pressure. By choosing pipes with a large diameter, it is possible to increase the flow of water into the house.

These factors are related to the properties of the pipeline itself. In addition to them, the water temperature, parameters of pumping equipment and much more are taken into account.

There are special formulas for accurately calculating the diameter, but the general rule when purchasing is not to incline your choice in favor of saving by reducing the diameter of the pipe.

In a narrow pipeline, more hydraulic losses occur, which will have to be compensated for by a more powerful pump and more electricity required to operate it, and this is an additional expense.

At installation of pipeline in the apartment most often there is no need for calculations - there is already wiring at the input. Its dimensions are known, they are designed for the required water flow. Usually, before entering the apartment, the common pipeline is installed from pipes Dy which is 20-32 mm, for apartment wiring they use pipes with Dy 15-20 mm.

Characteristics of pipes made of various materials

When choosing pipes for water supply from a certain material, physical and mechanical characteristics are taken into account, as well as operating conditions - maximum temperature, operating pressure, service life. All parameters are prescribed in regulations and must meet state standards.

Option #1 - steel pipes

The main thing for which a metal pipeline is valued is its strength, resistance to high temperatures, excess pressure in the network and external mechanical damaging influences.

But the few shortcomings that such products have sometimes remove them from the list of products that are accessible and easy to install.

Firstly, this is low corrosion resistance, if these are not pipes made of copper or brass, it significantly reduces the service life and worsens the quality of the water supply system as a whole.

Secondly, it is heavy, which creates additional difficulties during installation. And thirdly, problems that arise when connecting different parts of the water supply system - the need for threading and the inaccessibility of shaped products made of expensive metals.

The products are used for installation of external and internal water supply networks, hot and cold mains. Can be galvanized or non-galvanized. The former last a little longer and clog less.But over time, they also lose their protective layer and, like non-galvanized ones, begin to rust. On average, steel pipelines last about 40 years.

Steel pipes are produced with different wall thicknesses; according to these parameters they are divided into light, ordinary, and reinforced. The thicker the wall, the longer the product lasts and vice versa. Reinforced pipes are harder to cut and require more bending effort.

Pipes can easily be gas welded, but, nevertheless, their installation is more difficult than installing a pipeline made of other materials. In addition, welding cannot always be used in all rooms.

Steel components and parts are ordered from specialized workshops and stores. To connect the pipes, threads are cut on them:

- half an inch, If Dy=15 mm;

- three quarters of an inch at Dy=20 mm;

- one inch, If Dy=25 mm.

They are called half-inch, three-quarter-inch and inch pipes, respectively.

The main disadvantages of a steel pipeline are weak anti-corrosion properties and a high degree of clogging. It must be periodically cleaned of accumulated plaque, otherwise it loses its throughput. In this case, you cannot use alkaline products, which corrode the metal and the pipes begin to leak over time.

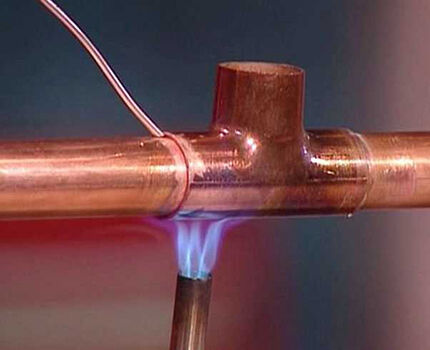

Option #2 - copper pipes

Copper pipelines are least susceptible to negative factors that affect strength and service life. It does not corrode, does not form plaque, and does not deform due to changes in temperature.

When interacting with chlorine compounds contained in water from centralized water supply systems, it does not form harmful compounds.

If we compare copper pipeline with other types of pipes for water supply, we can note its extremely high cost. This is perhaps its biggest drawback.

But it has served for more than 70 years. It is often used if it is impossible to install a hidden water supply system, but the aesthetics of the room must be preserved.

Option #3 - plastic pipes

The choice of plastic pipes is made taking into account their purpose, operating conditions - the temperature of the water used, the maximum operating pressure, etc. Despite the similarity of the material for production, the properties of different types of products can differ greatly.

Due to many positive characteristics, plastic pipes are often used in the design and construction of pipelines. They are characterized primarily by high corrosion resistance.

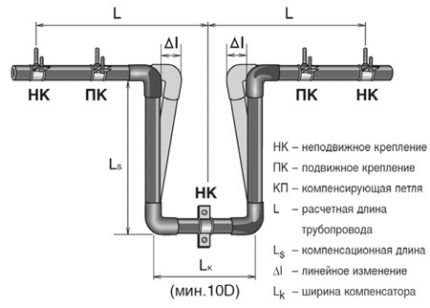

Unlike metal products, they do not require a special protective coating and have less weight, which simplifies and facilitates the installation process and transportation. Their inherent flexibility makes it possible to reduce the number of bent inserts and connecting elements.

Plastic pipes have a flat, smooth surface and, due to this, have low hydraulic resistance and increased throughput (they do not become clogged).They are not subject to corrosion and have low thermal conductivity, which eliminates the formation of condensation.

The disadvantages are that they are easily damaged and are exposed to negative temperatures, becoming fragile. Installation at sub-zero temperatures is strictly not recommended. They cannot be used when installing wiring sections located near open sources of fire and in places of direct solar radiation.

The temperature of the water transported through the pipeline, which differs from the standard indicators, also has a negative impact on the service life of the products. Besides, plastic pipes During storage, transportation and operation, it must be protected from sunlight and mechanical damage.

Plastic piping is a general characteristic of products made from plastic. This includes products made of polyethylene, polypropylene, and unplasticized polyvinyl chloride.

A polyethylene (PE) pipeline is used to supply cold water for domestic and drinking purposes at temperatures from 0 °C to 40 °C, with a maximum operating pressure not exceeding 25 bar (the exact value depends on the size of the pipe). Installation of elements is carried out using welding.

Polypropylene pipes (PP) include several types of products, which may differ slightly in the composition of raw materials for production and are designated as PPH, PPR and PPB. Used for transporting domestic and drinking water (except for those used for fire safety networks).

They can withstand temperatures of 70–80 °C and have reduced resistance to bending and impact loads. These properties are especially pronounced at sub-zero temperatures.

Pipes, depending on the class of operating conditions, can withstand pressures of 4, 6, 8 or 10 bar. Their connection is carried out by welding, with a special soldering iron butt or socket, as well as by thermistor welding.

Unplasticized polyvinyl chloride (UPVC) pipes are suitable for transporting water for any purpose with temperatures ranging from 0 °C to 45 °C.It is unacceptable to use this type of product for hot water.

Can be used for external above-ground and internal cold water supply networks, provided they are protected from sunlight and mechanical damage. The parts are connected into a socket using glue.

Units and parts for installing a plastic pipeline are produced in the factory. A wide selection of configurations and sizes makes it easy to assemble the most complex plumbing systems.

During purchase, unwinding of coils or installation, make sure that there are no flattened areas, fractures or strong bends on the pipes. If such a section is nevertheless found, it must be removed - it is not suitable for installation.

When purchasing products, they are inspected for cracks, burrs, and signs of peeling. Often these defects appear due to improper storage or transportation.

Wall thickness and outer diameter are selectively measured. Check the functionality of valves and taps. Shaped elements must be free of breaks, sharp edges, and burrs. Rubber gaskets and cuffs should not have tears or holes.

Each manufacturer of plumbing products must provide data on the properties of water that can be transported through this type of pipe, the features of its use, including how to resist the penetration of air into the system.The material used to make the pipes should not affect the composition and quality of the water.

Option #4 - metal-plastic pipes

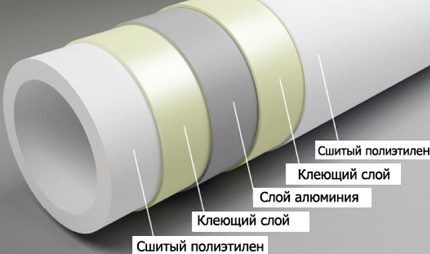

Pipes made of metal-plastic combine the characteristic properties of metal and plastic - strength, flexibility, non-corrosion, no plaque.

They are made from several layers of durable polyethylene, welded together “overlapping”, and an aluminum layer that serves as a frame. The metal layer can be solid, perforated or spiral-shaped.

The basis of the pipe is the inner polyethylene layer. It performs a load-bearing function, imparts strength, and, thanks to its smooth surface, eliminates the formation of scale and deposits.

The inner aluminum foil layer prevents the penetration of oxygen into the water supply and stabilizes linear expansion. The outer polyethylene layer serves as protection for the inner layers.

This type of product is intended for installation of plumbing and heating systems. Withstands pressure up to 16 bar and temperature up to +90 °C. They can be used to transport both hot and cold water suitable for cooking and household needs. The service life of a metal-plastic water supply system is 20-50 years; the actual lifespan depends on the quality of installation and operating conditions.

Supplied metal-plastic pipes in coils, complete with special fittings designed for their type. Unlike steel pipes, there is no need for thread cutting for metal-plastic pipes; connections are made using special detachable and permanent fittings.

Installation of the pipeline can be carried out without the use of welding equipment, which means it can be installed where welding work is prohibited

The areas where the sections and reinforcement are connected are the weak link of the metal-plastic system. Connections must be tightened periodically, at least once every two years. But in general, experts speak well about the properties of metal-plastic pipes and call them one of the most acceptable options in a relatively inexpensive price segment.

Conclusions and useful video on the topic

Differences between plastic pipes - polypropylene, polyethylene, metal-plastic:

How to choose pipes for water supply.Pro Tips:

When buying a pipe for water supply, the user most often has to choose the optimal balance between an affordable price and acceptable quality. Often the choice leans towards the cost-effectiveness of the project. But even among cheaper offers, you need to carefully study the properties of the product and weigh all the arguments.

If doubts remain, the advice of an experienced specialist will help determine which pipes are best to choose for the water supply and how to avoid common mistakes.

Have you already had to deal with replacing the water supply in an apartment or private house? Or maybe there is valuable information that you can share with our readers? Please leave your comments in the block below.

No matter how much steel or plastic pipes are praised for their comparative cheapness, I want to say that the most optimal material is copper. Only copper pipes for water supply guarantee the greatest durability during operation. I work in the housing and communal services sector, and I can say with confidence that they are the only ones that break down less often than others and do not cause as many problems as, say, steel pipes.

Hello. “they break less often than others” - pipes can leak, burst, but break? The cost of copper pipes, fittings and soldering is not something everyone can afford. Even wealthy people install them in prominent places, and combine them in a hidden system with more affordable ones.

Correctly noted - copper pipes are good in all respects. But they are too expensive, so for interior work I choose plastic pipes.They are easier to install than galvanized ones, and they look quite aesthetically pleasing. For outdoor work, I use metal-plastic ones - here the frosts are 30-40 and ordinary plastic quickly breaks down. And I’ve had these for about 15 years now.

I wonder if anyone else uses steel pipes for internal wiring in a house or apartment? The question here is not even the cost of the material itself, or its sanitary qualities, you just need to compare the process of installing steel and plastic pipelines. Steel involves welding, pipe benders, and subsequent painting.

Polypropylene is installed using white gloves, without smoke and dust. A soldering iron costs from 700 rubles, and you don’t need any other tool. If you don’t have pipe scissors and special stripping, then all this can be done with improvised means - a hacksaw and sandpaper. Well, the aesthetics after the work is completed are incomparable.

Of course they use it, why not. True, in most cases, these are pipes from Soviet times. They rarely replace them with steel ones anymore.