Features of the production of polypropylene pipes and fittings - a review of the best manufacturers

In recent years, the business in the production of polypropylene pipes has become one of the most popular in terms of financial stability. Such stability could be the envy of such industries as the production of food and medicine. The demand for polypropylene pipes will only grow; the situation clearly will not change for at least another 20 years.

The content of the article:

General information

The attractiveness of the production of polypropylene pipes is based on two factors:

- superiority of polypropylene communications in technological, production, and operational criteria over steel pipelines;

- the costs of production, installation of equipment, and maintenance of the technical process are much lower than those of traditional steel.

Another important advantage is the simple assembly of communications based on polypropylene blanks. There is no need to train a worker, improve, or maintain his qualifications, like, for example, a welder or electrician, spending a lot of money on him. The docking technology is so simple that you can master it yourself in a few hours of practical training.

The production of products itself does not require significant capital investments; even a small company that has purchased the line and raw materials can produce polypropylene blanks.

Positive properties of polypropylene products

Main advantages of polypropylene pipes – durability, strength and environmental friendliness of the material. Subject to operating conditions, polypropylene does not react with alkaline or acidic solutions and does not emit chlorine-containing volatile substances upon strong heating, as is the case with polyvinyl chloride. Another plus is that the material does not emit fine dust, like polystyrene foam or polyurethane foam.

Production is often focused on four main areas of application:

- water supply, gas supply and heating systems;

- supply of compressed air or inert gases;

- pipelines for pumping water, liquids, technological solutions, drainage sewer lines for wastewater, both in production and in everyday life;

- use of blanks as a protective sheath when laying electrical cables in the ground.

The polypropylene pipeline can withstand heating up to 90 OC for 1-2 minutes without losing its original shape. Typically, heating under internal water pressure is limited to 75 OC at 5-6 At. Under such conditions, a polypropylene pipeline will last for several decades.

Sewer pipes are less resistant to mechanical stress and thermal shock. But if you do not pour boiling liquids into the sewer and choose the right depth, then polypropylene pipes will easily last at least twice as long as the famous cast iron waste systems.

In addition to pipes made from copolymers and homopolymers of polypropylene, the production of products with mineral and fiberglass fillers has been established. For example, adding molten talc or calcium carbonate 20-55% by weight makes it possible to obtain pipes fittings, couplings with high decorative qualities and increased mechanical strength.

The addition of fiberglass 20-45% of the volume is used in the production of blanks for the construction of pressure water supply lines. Plasticizers and elastomers provide polypropylene with high resistance to low temperatures. Such products are suitable, for example, for laying external sewer lines.

According to the production scheme, salts of heavy metals and fire retardants can be added to the polypropylene mass. Accordingly, the polymer becomes self-extinguishing. Such pipes are not used for water supply, but they are perfect as a protective polypropylene sheath for electrical wiring.

Production Features

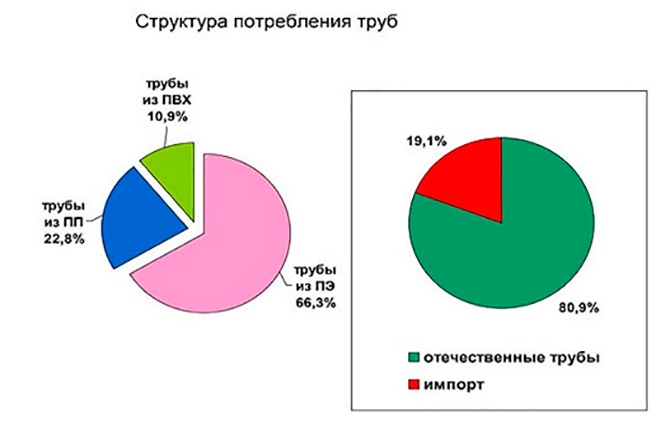

The polypropylene pipe market accounts for approximately 1/5 of the volume of cross-linked polyethylene pipe blanks sold. This does not mean that polypropylene is inferior to PE in a number of criteria. On the contrary, polypropylene pipes are of much higher quality than their counterparts made from cross-linked x-polyethylene.

The only negative is that raw materials and equipment for production are more expensive and require more advanced technologies and trained personnel.

Today, almost the entire market of polymer pipes is flooded with cheap polyethylene blanks made in China, partly in Europe. As the production of polypropylene materials increases, the demand for PE will be predicted to fall, even “collapse.” The price of communications made of polypropylene, as production volumes increase, will come close to the level of products made of PE.

The business in the production of polypropylene pipe blanks is interesting because it is focused on the overhaul of existing communications, water supply, gas, heating, and hot water supply systems. This part of the market is only growing as the housing stock ages.

Learn more about installation of polypropylene pipes possible on our website.

Pipe production

The technology for manufacturing pipe blanks is based on the process of extruding a superheated molten mass under high pressure through a special die nozzle. In theory, the production of polypropylene pipes can be established even in a garage, which is what Chinese enterprises did throughout the 90s of the last century.

The quality of polypropylene products was extremely low, so they abandoned it in favor of modern lines that provide multi-stage control, calibration, and correction pipe sizes.

The modern technological process for manufacturing polypropylene pipe blanks is as follows:

- The granulated semi-finished product with additives is heated to a temperature of 240-250 ℃. Polypropylene granules melt and turn into a semi-liquid state. The melt is constantly stirred to improve fluidity.

- Using an extruder, the mass is pressed through the holes of the die. The output is a pipe blank, but in an unhardened form. To maintain its shape, water is applied to the walls of the workpiece. The outer layer of polypropylene hardens, but the material still retains its plasticity.

- A slightly cooled pipe blank is calibrated by crimping or vacuum. At this stage of production, the polyethylene pipe cools and takes on its final dimensions.

One line produces about 200 kg of pipe blanks per hour.The pipe is inspected visually, marked, cut into blanks and stored. In general, the production process looks simple, but the real situation always has nuances.

Quality directly depends on the equipment and level of personnel training

The durability and performance characteristics of the pipe are 60% determined by the quality of polypropylene granules. Any attempts to speed up the production process, change the recipe to increase the share of Chinese polypropylene, or replace original equipment with a cheaper analogue lead to a sharp deterioration in the quality of the pipe billet.

What equipment is used to produce products?

The minimum configuration line consists of the following units:

- heating chamber with raw material receiving hopper. Usually this is a container made of corrosion-resistant steel with thermal insulation of the walls, with a gas or electric heater;

- extruder with replaceable die block. A screw is used to create pressure. If several components are used in the recipe, then a disk blower is used;

- a device for transporting unhardened pipe blanks to the cooling and calibration zone. Several Teflon-coated conical rollers rotate to push the hot workpiece into the cooling zone;

- closed-type water baths - most often these are horizontal cylindrical containers with inlet and outlet openings closed with insulating glands;

- automatic pipe cutting into standard lengths - high-speed carbide-tipped disk with cooling of the cutting line;

- vacuum calibration container or roller calibrator;

- marking apparatus - a shaft coaxial to the pipe with a replaceable stamp and a disk that applies longitudinal stripes of a certain color;

- blank packer – forms packages from pipes;

- conveyor for loading;

- stock.

Typically, one thread of a polypropylene blank is rolled into a spool weighing no more than 1200 kg. The holes are closed with plugs, and the material itself is covered with PVC film.

Large-diameter blanks are cut into 5 m pieces and placed in bundles. The total shelf life of products in the warehouse is no more than a year, with a shelf life of 2 years. Information about the date of manufacture and batch must be placed on the pipe along with the markings.

Polypropylene, both in granules and in the form of finished products, decomposes under the influence of ultraviolet radiation, so the storage location of the material must be protected from sunlight, direct rays of halogen or mercury lamps.

The second production problem is air humidity. The production of polypropylene pipes is adjusted to a certain water vapor content. Any deviation from the norm leads to the appearance of cavities, fistulas, and streaks. Therefore, the premises for the production of polypropylene blanks are equipped with a ventilation system.

Raw materials for making pipes

As raw material manufacturers prepared granules of primary polypropylene and cross-linked polyethylene are used.Depending on the nature of the finished product, two types of recipes are used in production:

- for sewer pipes, the initial granulate consists of a polypropylene homopolymer. This is a 100% highly purified polymer;

- For pressure lines, water supply systems, heating, and hot water supply systems, a mixture of polypropylene and cross-linked ethylene is used.

In the first case, raw materials are purchased from domestic manufacturers with a small addition of imported material, most often made in Turkey and China. Secondly, imported ready-made mixtures are used.

Well-known Russian manufacturers of polypropylene pipes

The production of polypropylene pipes often uses foreign equipment, so the quality of the product depends on the correct choice of raw material supplier. The list of the most famous Russian manufacturers of polypropylene-based pipes is as follows:

- Cosmoplast company. It produces polypropylene pipes, fittings, couplings for water supply systems and heating systems. Raw materials and equipment were purchased in the European Union.

- "YarInterPlast" Produces polypropylene pipes for water supply and sewerage. Uses equipment from Cincinnati Extrusion;

- "Polytron". A large manufacturer of polypropylene non-flammable pipes, fittings for sewerage, non-pressure water communications. Uses imported equipment from leading European manufacturers ZWICK, BINDER, SCITEQ.

Most of the technological lines were purchased more than 10 years ago, so production is carried out using outdated technologies and recipes. The raw materials are predominantly Russian.

Foreign pipe manufacturers

The following are popular among foreign manufacturing companies:

- Ekoplastik, Czech Republic.The company produces PP materials for industrial and domestic pipelines. Pipes are characterized by good weldability and resistance to low temperatures;

- German manufacturing companies - Rehau, Wefatherm, Banninger. The products are distinguished by high quality polypropylene, but clearly overpriced;

- Valtek, Italy. High quality material. Installation is possible using crimp, brass press fittings.

In addition to products from the European Union, polypropylene pipes made in China, but under the British brand Blue Ocean, are popular. The quality is practically the same as in Europe, although the price is lower, plus a 10-year warranty on products.

Conclusion

The production of polypropylene pipes directly depends on the precise operation of the equipment and the technology used. As a rule, the world uses the developments of German chemical companies and manufacturing plants. Therefore, it is best to buy PP pipes produced using original or licensed equipment from Germany, the Czech Republic, and Austria.

What do you think, what type of pipe is better to buy - domestic or European? Write in the comments. Save the article to your bookmarks. Share it on social networks.

If you buy a PP pipe, review and check each piece yourself. At all wholesalers, for every five more or less high-quality ones, there is one with cavities and weakened walls. It works great as a replacement for steel, but you need to know how to do the strapping correctly. I won’t say anything about freezing, it’s more related to the sewer system if it’s shallowly dug in.

I was at one such production, you couldn’t envy the guys, the smell of burnt plastic was everywhere.I advise those who are involved in replacing water pipes to go to the factory and buy from them. You can choose, it turns out cheaper, and they’ll also give you a choice.

This is true with ultraviolet light. My heating return was located next to the flowers, and there they were illuminated with an ultraviolet lamp to make them grow better. Within a year, microcracks appeared and two meters had to be re-soldered.