Advantages of polypropylene pipes for hot water: selection criteria and installation rules

Today, polypropylene pipes for hot water are the main material used in hot water supply and heating systems.They are many times superior in almost all characteristics to their steel counterparts, which have been used for a long time.

The content of the article:

Main advantages

Polypropylene pipes are a universal material. But more often they are used in cold and hot water supply systems. In heating polypropylene steel pipes apply after manufacturers offered a reinforced option. These are products that have a reinforcing frame made of aluminum foil inside them.

And if in private houses non-reinforced models can be installed in heating systems, because the pressure in the network does not exceed 3 Bar (this is 0.3 MPa), then in apartments it is impossible to do without a reinforced frame. It's all about the pressure of hot water supplied from the boiler rooms.

The liquid is supplied using pumps that pump it to certain values, the indicator of which depends on the number of floors of the building.

Eg:

- Five-story buildings of old construction, in which cast iron batteries are installed. Hot water is supplied here under a pressure of 7 bar.

- In the nine-story buildings, which were built during the Soviet Union, hot water is supplied under a pressure of 5 bar. In some houses, water pressure can reach up to 10 bar.

- In new buildings - at a pressure of 15 bar.

An unreinforced polypropylene pipe may not withstand such pressure.

As for temperature, polymer products of this type can easily withstand the load of hot water +95 ℃. Or short-term exposure to liquid with a temperature of +110 ℃.

Advantages polypropylene pipes for hot water:

- Long-term operation – up to 50 years.

- Easy to maintain.There is no need to cover the surface of the highway with other finishing materials. For example, paint, as usually happens with steel analogues.

- They easily tolerate alkaline and slightly acidic environments. Under their influence, the polymer does not change its characteristics. Hence the long-term operation, because in many regions hot and cold water have increased hardness.

- Layers of dirt, rust and other substances never form on the internal surfaces. Therefore, the diameter of polypropylene pipes is always the same, hence the stable operation of water supply and heating networks.

- The thermal conductivity of polypropylene is very low. The hot water flowing inside them practically does not lose heat.

- Almost one hundred percent frost resistance. If for some reason the hot water supply or heating system suddenly freezes, then the water inside the pipes will freeze, but the polymer products themselves will not burst. The utility network will remain in good technical condition. After defrosting, it can be put into operation again.

- Polypropylene has good noise absorption. The sounds of hot water moving inside the network are not heard. Such a system also rarely vibrates.

- The hardness of the material is sufficient to withstand heavy loads. At a water temperature of +140 ℃, the polymer softens, which is why the strength can sharply decrease. It returns to its original value as soon as the indicators begin to decrease.

- Polypropylene pipes used for transporting hot water are an environmentally friendly material. Under the influence of changes in humidity, temperature and other loads, it does not emit substances harmful to the body. This is especially important in the water supply system.

- Easy installation. To do this, you only need a soldering iron and a few more simple tools.The whole process boils down to cutting the pipes to the correct size and connecting them to each other using fittings according to the pipeline layout.

- Polymer is an inexpensive material. Hence the relatively low price of polypropylene pipes.

Polypropylene pipes have one drawback - linear expansion under the influence of hot water. But this problem is solved by installing a reinforcing frame inside the product. It is reinforced pipes that are installed today in hot water supply and heating systems.

Reinforced pipes for hot water

Reinforcement is carried out in different ways:

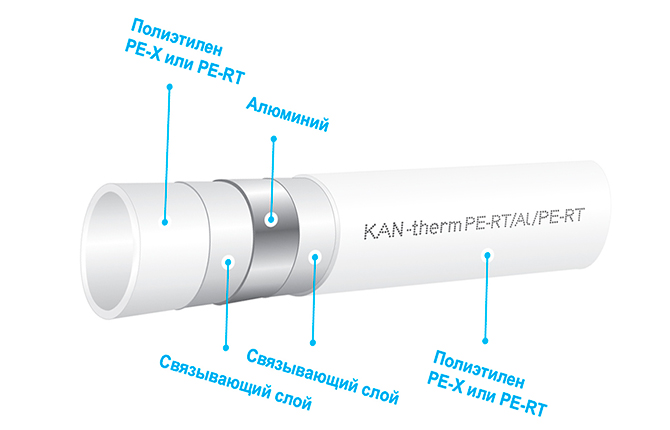

- Using a solid sheet of aluminum. It can be laid on the outside, on the inside or in the middle of the wall of polypropylene pipes.

- A perforated aluminum sheet is used, which is laid only on the outside.

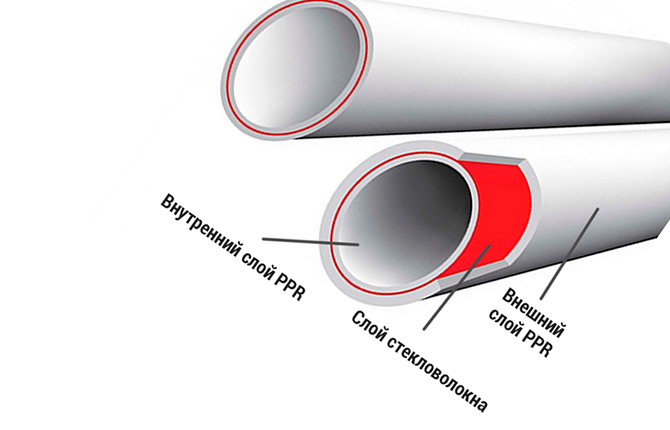

- Fiberglass is used, which is installed in the middle.

- The composite material used is a mixture of polypropylene and fiberglass.

Aluminum reinforcement has disadvantages. Aluminum itself, although it is an anti-corrosion material, begins to oxidize over time under the influence of salts and active substances found in hot water. Therefore, at the ends of the pipes you can often see traces of metal corrosion, which gradually lead to a decrease in the quality of the product and the system as a whole.

In this regard, non-aluminum reinforcement is considered the best option. This relates to the question of which polypropylene pipe is better for hot water.

Distinctive features of products with non-aluminum reinforcement:

- there is no need to clean the ends when soldering two pipe elements, and this requires a special tool;

- the fiberglass reinforced frame is not glued, but welded, so the polypropylene pipe for hot water cannot delaminate;

- Electrochemical processes do not occur because there is no metal in the body of the product.

How to install under hot water

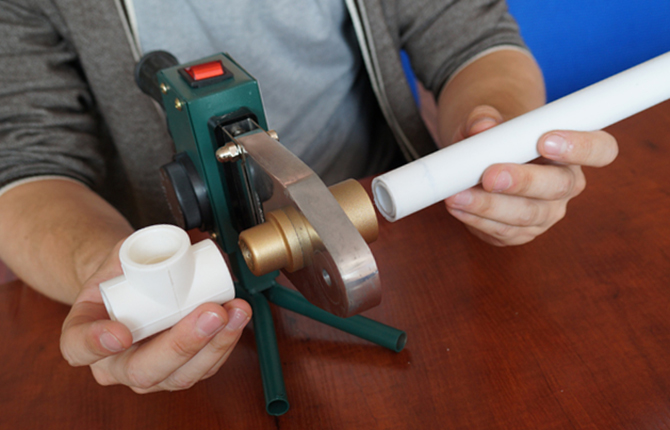

The installation of a plastic hot water pipeline is based on the soldering process, through which polypropylene pipes are connected. This does not happen directly, but through fitting. There is also a direct method, but it requires special equipment.

At home, a hand-held device called a soldering iron is used to make connections. It comes with nozzles for standard pipe sizes. With their help, the polymer material is melted. They are mounted on a soldering iron, which is heated by a heating element. Heating temperature - +260 ℃. It is set on the soldering iron using a thermostat.

Temperature is an important indicator on which the quality of the connection depends. If it is low, the polymer will not soften to the required state. The joint will be leaky. If you overheat, the material, on the contrary, will become too soft, which will lead to deformation of pipes and fittings.

Installation process:

- A preliminary wiring diagram is drawn up water supply or heating.

- Polypropylene pipes are cut into pieces with precise measurements of the areas where they will be installed.

- The edges are cleaned. If aluminum-reinforced products were selected, then the frame must be removed to the length of the connection.

- Plugs into socket soldering iron. It must be heated to the required temperature, which will be indicated by the light on the device. It will go out.

- On one side, a fitting is put on the pin nozzle, on the other hand, a pipe is inserted into a nozzle similar to a sleeve. It warms up for 15-20 seconds.

- The connection elements are removed from the nozzles and inserted into each other until they stop.

- In five seconds, a strong and reliable joint is ready.

In this manner connect between all elements of the pipe structure. After which the hot water supply or heating system must be filled with water and checked for leaks at the connections. If none are found, it means the installation was successful.

Which pipe to choose for hot water

It is necessary to pay attention to the material from which the pipes are made. Polypropylene can be used both in pure form and with additives:

- PRN is a pure polymer. It is called a “homopolymer”. Pipes made from it are durable, but not heat-resistant. Under the influence of hot water, they will begin to swell and deform, because their linear expansion is large. Such products are used only in cold water pipes.

- PPB is a block copolymer. It is a mixture of polypropylene (70%) and polyethylene (30%). This material has higher heat resistance than the previous one. But not enough to use it in hot water supply and radiator heating systems. But they are used in underfloor heating systems because they require hot water with a temperature of no more than +45 ℃.

- PPR is a static copolymer. This is also a mixture with ethylene, but in different proportions. Moreover, both materials are connected at the molecular level, which provides increased strength and heat resistance. The material copes well with high temperatures - up to +70 ℃ and sub-zero - up to -15 ℃.

- PPS is a heat-resistant option with a heating limit of +95 ℃. It is also called flame retardant.

The second criterion for choosing polypropylene pipes is their technical characteristics, such as temperature and pressure of hot water.

Here the classification is:

- PN10. The products can withstand pressure up to 1.0 MPa and temperatures up to +20 ℃. Not suitable for hot water supply and heating.

- PN16. Here the maximum pressure indicator is 1.6 MPa, the temperature is up to +60 ℃.

- PN20. Pressure – 2.0 MPa, temperature – +95 ℃.

- PN25. Temperature is the same as the previous model, pressure is 2.5 MPa.

You can find polypropylene pipes in different colors on the market. Color has nothing to do with choice. The only caveat is that the products are black. They resist ultraviolet radiation well. Otherwise these are standard polypropylene pipes.

For hot water, regardless of the system in which it moves (heating or plumbing), products made from PPR or PPS grade PN20 or 25 are best suited.

Have you ever chosen similar products? What did you pay attention to? Write in the comments. Share the article on social networks and save it in bookmarks so as not to lose it.

Polypropylene pipes for water supply and heating systems. Types and benefits in the video below.

Sources:

- https://santehstandart.com/poleznye-materialy/polipropilenovye-truby-dlya-goryachey-vody/

- https://trubanet.ru/vodoprovodnye-truby/polipropilenovye-truby-dlya-goryachejj-vody-rekomendacii-kak-vybrat.html

- https://sansovet.com/detali/truby/polipropilenovye-dlya-gvs.html

Polypropylene pipe for heating is the best. The others are not worth even looking at.

If you need a material for a heated floor, then cross-linked polyethylene. There is more fuss with propylene.Such a pipe does not bend; all deviations will have to be made through the fittings. For a long time.