Installing an overhead sink: the main stages of installing a do-it-yourself sink

Kitchen sinks differ in material, size, shape, design and installation method.Overlay models are considered outdated against the background of a variety of fashionable mortise products. However, they have a number of advantages for self-installation and are still used in summer cottages and temporary apartments.

In this article, we will look at how to install an overhead sink with your own hands, what needs to be prepared for this, and what installation methods are best to use. To make it easier for you to understand the main stages of installation, we have selected visual photos and useful video recommendations for installation.

The content of the article:

Distinctive features of overhead models

If we do not take into account sinks that are a thing of the past, which are attached directly to the wall on special brackets and do not require a cabinet or countertop as a support, all products for washing kitchen utensils can be divided into 2 categories: overhead and mortise.

The main difference between the two types is the installation method. The first ones, chosen exactly to size, are “put on” the top of the cabinet, and to install the second ones, you need to cut a hole in the tabletop.

From here follow the distinctive features expressed in design, material, and shape.

Products that do not require additional processing of the base are preferable for self-installation, and they are on average cheaper.

However, design features rarely allow the use of “overlays” in modern kitchen sets with a single countertop and built-in appliances. Overhead models are also quite often chosen for installation in the bathroom room, but this plumbing fixture has a more attractive design, material and size than kitchen fixtures.

But there are similarities between the two types of sinks. For example, installation of a tap and siphon, as well as connection to water supply and sewerage, is carried out using the same technology.

Detailed installation instructions

Let’s look at how you can independently install an overhead sink from “A” to “Z” without resorting to the services of hired installers and furniture manufacturing companies.

The instructions will be useful to anyone who is used to doing all the simple housework with their own hands, and the sink itself will find a place in a country house or in an apartment kitchen as a temporary replacement.

Step #1 - selection of materials and tools

To assemble more quickly, the cabinet can be purchased ready-made, but only if it is sized to fit the sink.

The second solution is to order from a furniture company, but this option is only advisable if the cost of the order is low.

To put together a cabinet and attach a sink to it, you will need the following materials:

- thin boards, sheets of chipboard or MDF plywood;

- steel sink;

- kitchen faucet with eyeliners;

- fastenings for washing (screws, corners);

- sealant or polyurethane foam;

- hinges and handle for the door;

- siphon with sewer fittings;

- antiseptic impregnation;

- legs or rollers.

To attach the sink to the cabinet, you only need a screwdriver or a screwdriver to tighten the screws, but to cut out the walls, base and door you will need a hacksaw, circular saw or jigsaw.

To clean the ends, you will need sandpaper, and to drill holes for self-tapping screws, a drill with a thin drill bit.We do not recommend using nails: they are more difficult to hammer into particle board panels, and besides, the structure fastened with nails becomes inseparable.

It is better to purchase all materials in advance so as not to waste time searching for the necessary parts during the assembly process. The listed tools are usually found in the home workshops of amateur craftsmen, especially if they are in charge of a dacha farm.

Step #2 - making a kitchen cabinet

The sink cabinet has a design that differs from conventional kitchen cabinets. It does not have two elements: a back wall - for free connection to communications, as well as a countertop, since it is completely replaced by an overlay sink.

Sheets of chipboard, thick plywood or moisture-resistant plasterboard - sometimes it’s easier to take some materials left over after repairs - we take in such a volume that there is enough material for two full walls, a bottom and parts for the connecting “belt”.

Procedure:

- first we cut out the large elements - two identical side walls and the base, then - the horizontal connecting parts;

- We carefully cut and, if necessary, clean and process the edges;

- if we use planed boards or plywood, before assembly we cover all elements with antiseptic impregnation, varnish or paint;

- we connect the elements according to the drawing using self-tapping screws and metal corners;

- Attach legs or rollers to the bottom side of the base.

If possible, we adjust the legs. If desired, the space under the cabinet can be covered with a plank.Lastly, we hang the door. This is best done after installing the sink.

It is recommended to place drawers (transverse stiffeners) directly under the sink and at the very bottom. You can also make additional crossbars in the middle if the structure is voluminous.

Having assembled the structure, we check its strength. We install it at the chosen location - it is desirable that it is as close as possible to communications.

Step #3 - choosing a suitable sink

Metal overhead sinks are sold in plumbing stores and can also be found in garden departments. They are similar to each other, but may differ in design and size.

In addition to single sinks, which are a traditional rectangular or square product with rounded corners of the bowls, there are models with drying shelves on which it is convenient to stack washed dishes, vegetables or fruits.

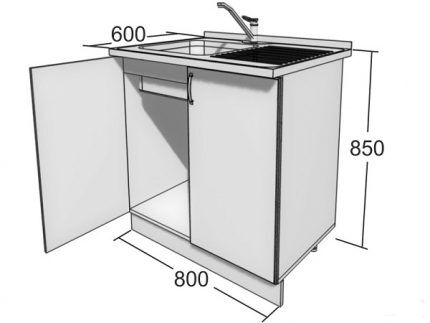

When choosing the size, you need to take into account the dimensions of the cabinet, if it is already ready. Otherwise, the sink is chosen according to needs: single or double, with or without a drainer.

The metal from which the sink is made can be shiny (traditionally “steel”) or matte.In terms of technical characteristics, both options are the same.

Next, we’ll look at how best to attach an overhead sink to a kitchen cabinet.

Step #4 - installation of faucet and siphon

Once the cabinet is assembled and adjusted, the hardest part of the job is over. All that remains is to fix the sink, having previously fixed the mixer and siphon to it.

First you can install a mixerusing the fasteners and gaskets included in the kit.

If only cold water supply is available at the dacha, then instead of a mixer, install a simpler device - a single tap for cold water.

Next comes install a siphon. It is necessary to prevent odors from the sewer pipe from spreading throughout the living quarters.

It is also advisable to attach it to the bottom of the sink before installation, but it is also possible after - there is enough space under the sink to manipulate the plastic fittings.

Thanks to the prefabricated design, plastic siphons are installed quickly - according to the scheme proposed by the manufacturer.

Step #5 - installing the sink on the cabinet

Often, to install metal sinks, plastic “corners” are used - L-shaped pads, which are fixed to the upper ends of the side walls.

If the sink and cabinet fit perfectly in size, linings, screws or other fasteners do not need to be used.

Before installation, sealant is applied to the edges of the cabinet, after which the edges of the sink are pressed tightly against the walls and partitions.

When using any adhesive, you should remember that a permanent connection is created, although with a certain force it will still be possible to tear the sink away from the cabinet.

When planning the installation of the door, you need to make sure that it opens freely without touching the front edge of the sink, which will be lowered by several centimeters.

The process of installing a sink is simple and takes a minimum of time if it matches the size of the cabinet.

Step #6 - connecting to communications

Without a connection to the water supply and sewerage system, the sink is unusable, so the final stage is connecting the plumbing fixtures.

First we connect to the water supply network. The mixer has already been installed - all that remains is to connect two flexible hoses. They lead from it to tees embedded in water pipes.

Next, it remains to connect to the drainage system by connecting the outlet pipe - a pipe connected to the outlet of the siphon - with a sewer pipe.

Most often, corrugation is used for assembly, but it traps debris and sags over time.

After installing and connecting the mixer and siphon, turn on both taps and check the functionality of all devices.

Upon successful completion of the work, the door is hung at the very end - this completes the installation of the sink.

Conclusions and useful video on the topic

Video instructions for installation on a kitchen sink:

An overhead sink is not the best solution for improving the kitchen. But when a suitable cabinet is idle at the dacha and you need to quickly create comfortable living conditions, it is considered one of the most successful options. It is also attractive that installation work does not require special skills, time and effort - everything can be done with your own hands.

Would you like to supplement the step-by-step instructions outlined above with useful tips or point out nuances that we did not mention? Please write your comments and recommendations under this article.

Or maybe you want to share your personal experience of installing a sink in your dacha? Tell us how difficult this work was for you and how much time it took you to assemble the structure.

We have a countertop sink in our dacha, but not as a separate cabinet, but as a cabinet as part of the kitchen “wall”. To this day I see such sink options in furniture stores. Naturally, these are the cheapest kitchen sets, but they are quite popular among buyers. There are a lot of situations in life when people need just this, and not a cool designer option.I think cabinets with sinks will be in demand for a long time.

I like the option of a sink with two bowls and a “beach”. It’s convenient that you can wash dishes and, for example, thaw fish at the same time. Or wash dishes in one bowl and rinse in another. The problem is that this option takes up a lot of space.

The overhead sink may not be in fashion, but it is the most common, simple and reliable option. I am sure that most Russians have exactly these in their kitchens. It is easy for any man to install it, because the cabinet has a cutout exactly for the standard sizes of such sinks. All that remains is to secure and connect the siphon and flexible wiring. In my experience, such sinks have the least number of problems, leaks and breakdowns.

“Often, to install metal sinks, plastic “corners” are used - L-shaped pads, which are fixed to the upper ends of the side walls.” - That's all?! There is no detailed description of installing a sink with this kind of lining.

I agree that this type of sink is the most affordable and no less reliable... But... The L-shaped fastening of this sink is extremely inconvenient and unreliable! Please note the new type of fastening. It's really worth it.