Water pump for heating: types, technical characteristics and selection rules

Gravitational natural phenomena are not always able to provide a sufficient level of coolant circulation, especially in complex systems with several rings. A water pump for space heating will help stimulate the movement of coolant. What is this equipment? We will consider this issue in our article.

In addition to the design and technical characteristics of the water pump, we will analyze the types and marking features. We will also consider in detail the advantages of circulation equipment and important parameters that must be taken into account when choosing.

The content of the article:

General structure of a water pump

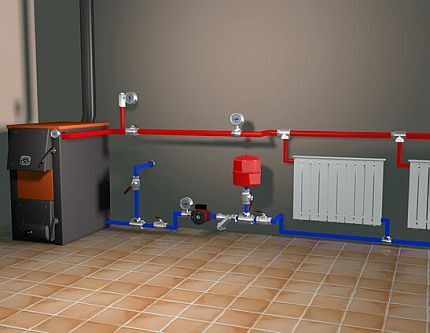

The water pump is built into the heating circuit to ensure the movement of the coolant. Therefore, such systems are called heating with forced circulation.

It consists of the following basic elements:

- housing with a working chamber;

- engine;

- impeller;

- air bleed screw;

- terminal box.

The terminal box can be equipped with additional mechanical and electronic equipment designed to regulate the operating mode of the engine.

The simplicity of the device ensures high reliability of the pumps, thanks to which they can operate effectively for about 5-10 years.

Types of pumps for heating systems

Modern circulation pumps are divided into two main types: “dry” and “wet”. They differ somewhat in their internal structure and operating scheme, but the movement of liquid in them is still ensured by circulation processes in the system. Some models are equipped with devices to automatically regulate their operation.

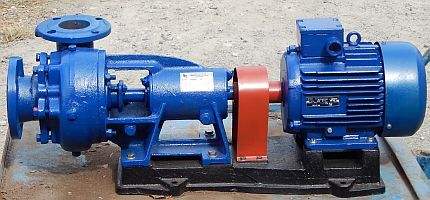

Option #1 - “dry” type devices

The design of a dry circulation pump does not imply contact of the coolant with the rotor. Its working area is separated from the electric motor parts by special rings.

They are made from the following types of material:

- graphite;

- ceramics;

- tungsten carbide;

- of stainless steel;

- aluminum oxide.

The principle of operation of a “dry” pump is to rotate a wheel in a coolant environment. The water supply hole is located in the center of the main chamber, and the outlet channel system is located on the periphery.

The rotation of the impeller of the functional wheel leads to the emergence of centrifugal forces that move the coolant from the center of the housing to its edges. This principle of operation of the circulation pump ensures constant movement of water through its internal chamber.

The positive features of dry type heating equipment are:

- high level of efficiency – 70-80%;

- minimum water hammer at startup;

- possibility of horizontal and vertical engine arrangement;

- pumping large volumes of coolant due to high power.

Due to the combination of efficiency and noise, dry pumps are used primarily in heating systems of industrial, administrative buildings and large residential buildings.

Therefore, devices of this kind can have the following negative aspects:

- High noise level, which does not allow their use in apartments.

- The need to replace sealing discs every 2-3 years.

- There is a high probability of coolant leaking out if the seal of the working chamber is broken.

- The need for external engine cooling.

Due to their heavy weight, such equipment is installed on the floor or hung on brackets.

There are two design options for dry pumps:

- Monoblock. The engine and the metal body of the device are combined into one structure with specific fastenings.

- Cantilevered. A motor of any power can be attached to the equipment body using universal mounts.

“Dry” circulation devices for heating systems, with proper maintenance, are more durable, so they are gradually replacing models with a wet rotor from the market.

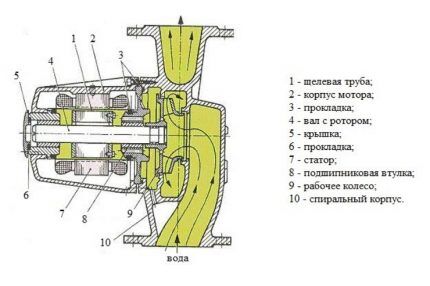

Option #2 - pumps with a wet rotor

The principle of operation of a circulation device with a wet-type rotor is similar to its counterpart in the “dry” version: when the impeller rotates, the coolant supplied to the center moves to the periphery of the working chamber, from where it is collected into outlet channels.

The rotor of the “wet” pump is in contact with the coolant, which also provides engine cooling. Such devices should not be operated in dry mode, because they quickly overheat and burn out.

The components of the equipment are usually located in one housing and form a single structure, so if individual elements break down, they are not replaced, but a new pump is purchased.

Advantages of a unit with a “wet” type of rotor:

- quiet operation;

- compact dimensions;

- low power consumption (30-50 W);

- duration of operation without maintenance;

- relatively low cost;

- ease of installation.

The devices are often built directly into the design of household boilers, making it easier for the consumer to select equipment when installing a heating system.

Heating devices of this type also have disadvantages:

- design restrictions on maximum power;

- low maintainability;

- low efficiency (40-60%);

- the need for a strictly horizontal location of the engine axis.

Due to their low power, the “wet” type of pumping machines is used mainly in heating systems of apartments and one-story houses.

Advantages of circulation devices

Until 1990, heating systems in private buildings were designed and built primarily without pumps.The coolant moved through the pipes by gravity, and its circulation was ensured by convection flows of liquid when it was heated in the boiler. Currently, systems with natural circulation, although not so often.

Nowadays, coolant movement is carried out forcibly using water pumps, which have a number of advantages:

- Reduced load on the boiler by reducing the temperature difference in the incoming and outgoing pipes.

- Uniform distribution of heat throughout the rooms due to the same temperature of the coolant along the entire length of the heating rings.

- The ability to quickly regulate the temperature of the coolant.

- Quick heating of the heating system when starting a cold boiler.

- There is no need to install pipelines with a slope towards the boiler, ensuring spontaneous movement of the coolant.

- Possibility of using thin pipes that take up little internal space in the apartment.

- The power of the pump allows you to build up pressure in the heating circuit sufficient to supply coolant several floors up.

- Use of shut-off valves on individual loops of heating networks.

- Possibility of integrating the pump into the automatic control system of the boiler.

With a lot of advantages, circulation devices also have two disadvantages - dependence on power supply and additional costs for electricity.

But the disadvantages are easily compensated for - installing a water pump allows you to save 10-20% of fuel, and the share of the cost of electricity in total heating costs is only 3-5%. In addition, if there is a frequent lack of electricity, you can install a UPS, which will ensure autonomous operation of the boiler and pump for a certain period.

Features of equipment marking

Unfortunately, there are no standardized requirements for the labeling of circulation pumps. Manufacturers independently choose a list of technical characteristics that are indicated on the device body.

The front panel typically displays the following information:

- direction of coolant movement;

- diameter of connected pipes;

- maximum permissible pressure;

- manufacturer and model;

- maximum operating temperature;

- degree of protection;

- operating parameters of the electrical network;

- marks of compliance with national technical regulations.

Manufacturers may provide other information at their discretion. Detailed technical characteristics of the devices are indicated in the operating instructions.

Units of measurement vary from country to country, so the numbers on the case can be deceiving. It is better to once again open the instructions, where, along with the characteristics, their units of measurement are also indicated.

What to look for when choosing a pump?

The selection of a separate pump for the heating circuit must take into account many parameters.

Equipment technical parameters

Circulation equipment has a number of characteristics that are especially important to consider when purchasing.

These include:

- Efficiency – the ratio of the volume of electricity consumed to the useful work performed on pumping the coolant.

- Pressure – pressure difference between the outlet and inlet ports of the pump.

- Water supply – the maximum volume of coolant pumped through the working chamber with minimum resistance of the heating circuit.

- Power electricity consumption.

- Pipe diameter – nominal value of the connected equipment.

- Maximum nominal pressure (designated PN) in an operating circuit at 20 °C, at which long-term operation of the device is still guaranteed within the warranty period.

This data is usually sufficient to confirm that the technical characteristics of the pump meet the parameters of the heating system.

We examined the selection criteria in more detail In this article.

Sufficient power of the device

The choice of a specific model of circulation equipment is influenced by technical characteristics, as well as the financial capabilities of the buyer and the properties of the heating system. If you want to save money, it is important that the pump power is sufficient for normal operation of the boiler. After all, the water supply level indicated in the instructions is always significantly higher than the actual one.

To independently determine the adequacy of the device’s power, three stages of calculations must be carried out.

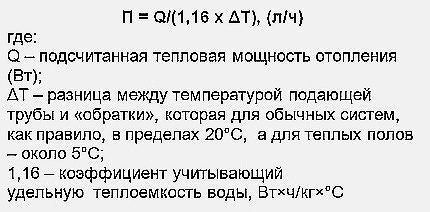

Stage #1 - determine the pump performance

Determining the required pump performance using the formula.

For apartments in multi-storey buildings, the heating thermal power is assumed to be 75-80 W/sq. m., for houses - 100-120 W/sq. m.The temperature difference between the boiler inlet and outlet is usually 10 °C.

It turns out that for an apartment of 60 square meters. m. the actual pump performance of (80*60)/(1.16*10)=414 (l/hour) will be sufficient.

Stage #2 - calculate the pressure value

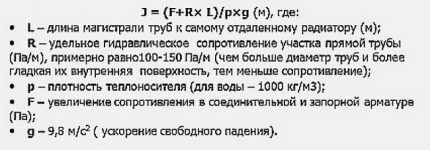

Determining the amount of pressure to overcome the total hydraulic resistance of the system using the formula.

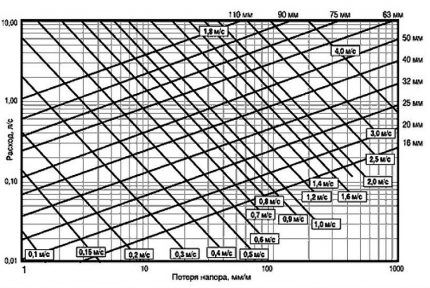

This formula requires complex calculations using reference data, so for home and apartment heating systems you can use a simplified schedule.

According to the schedule, the pressure loss in an apartment with a pipe diameter of 20 mm will be 70 mm/m, and taking into account the pipeline length of 50 m - 3.5 meters. This figure should be multiplied by a factor of 1.3-2.2, which takes into account the resistance of the water pressure fittings.

Stage #3 — determine the pump power

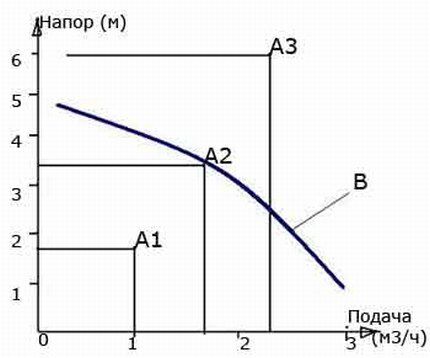

Determining the sufficiency of pump power according to the graph of pressure-flow characteristics.

This schedule is indicated in the operating instructions, and it is unique for each pump model. If the intersection point of the parameters calculated above is below curve B, then the device is suitable for the heating system, but if above, then not.

We have provided detailed recommendations for calculating a circulation pump with specific examples. in the next article.

Additional functions of the device

If constant fluid movement is critical for the heating system, then you can install a pair of pumps located in series in the circuit. The second motor in such a system can be turned on if there is insufficient power or failure of the first motor.

To automate the operation of a boiler with heating from a heating circuit, you can use pumps with a thermostat and timer. The built-in mechanism ensures that the engine is turned on and off depending on the coolant temperature and time of day.

In branched heating networks, circulation pumps with a thermostat and continuously adjustable impeller speed can be used. With their help, the speed of the coolant is independently regulated in different loops, depending on its temperature. Pumps with automation are many times more expensive and are rarely used in apartments and small residential buildings.

The market offers both models with standard and non-standard structures that provide additional functionality. Rating of the best heating pumps, based on reviews from real users, we brought here.

Other nuances of choosing a pump

It is important that the equipment not only performs its function, but also works for a long time, without causing inconvenience to the residents of the house or apartment.

Therefore, when choosing a device, you should adhere to the following rules:

- Choose well-known pump manufacturers: Calpeda, Grundfos, WILO. The price of their equipment is 20-40% more, but the likelihood of breakdown is much less.

- Take a device with characteristics that are 20-30% higher than calculated. This reserve will reduce the operational load and increase the service life of the equipment.

- Pay attention to the dimensions so that the pump fits in the space provided for it.

- The operation of the device should be as silent as possible so as not to disturb residents at night.

- There is no need to strive to buy a model with a power that greatly exceeds the calculated parameters. This will only lead to excessive energy consumption, but also to unnecessary noise.

- Choose a pump specifically for heating systems, because they are designed for operating temperatures up to 130-150 °C.

- It is desirable that the device have a built-in mesh to filter solid particles suspended in the coolant.

The performance characteristics of the equipment must necessarily correspond to the parameters of the heating system; it is impossible to save on this. Additionally, you will only have to pay for a reliable manufacturer, increased security of the housing and an automatic control system.

Most household heating circulation devices do not require adjustment. To start them, it is enough to connect the pipes to the pipeline and connect the device to the electrical network. We looked at how to properly install the pump in step by step instructions.

Conclusions and useful video on the topic

How to choose a good circulation pump for heating:

DAB circulation equipment:

Comparison of two Grundfos devices: UPS and Alpha2 models:

It is better to coordinate the choice of a circulation pump with specialists.If the power of equipment for a standard apartment can be suggested by salespeople in a store, then before buying a heating device for a country house you will have to turn to professionals for complex calculations.

It should be remembered that you cannot exchange it in the store after you start using it, so it is better to immediately buy a suitable model.

Would you like to supplement our article with useful recommendations for choosing a heating pump? Or have you noticed a discrepancy in the data presented? Write your comments in the comments block - we will definitely take your opinion into account.

Or maybe you still have questions after reading the article? Ask our experts, ask for advice - we will try to help you.

I am one of those who learn from my mistakes. Although, I must admit that limited funds forced me to buy a simpler, cheaper circulation pump, not from a well-known reliable brand, but from a Chinese no-name.

It looks good, inexpensive, worked well for six months, no complaints, a little noisy.

And then - bam, and stopped disconnecting. I took it off, took it to the craftsmen, they said: “Uncle, we’ll clean it, but it’s better to buy a normal one, it’s the metal, it oxidizes when it comes into contact with water and the duct and sensor get clogged.”

In general, I had to buy Grünfos, it has been working for six years, I don’t even look into it, it doesn’t make any noise at all.