Why does the boiler generate electric current from the tap through the water and from the body - all the reasons and troubleshooting methods

The hot water boiler has recently become an indispensable type of household appliance.It is installed not only in dachas and private homes. The unit can often be seen in city apartments.

This device is good for everyone, but intensive use of the device often leads to its rapid breakdown. Some defects can be easily eliminated. Others, related to the electrical part, require an understanding of the operation of the device. And when the boiler electrocutes, you must first understand the reasons, and then move on to repairs.

The content of the article:

Possible reasons

You can usually feel that some electrical device is giving you an electric shock if you touch it with your hand. In the case of a boiler, electric shock will occur not only through the body, but also through the water that flows through the mixer or tap.

There are two reasons here:

- The insulation of the wiring that is connected to the heating element is broken.

- Destruction of the protective metal tube of the heating element.

Heating element malfunction

Inside the tubular heater there is a nichrome spiral, which heats up when an electric current is applied to it. If any, even the smallest, defect forms in the tube, water will penetrate through it. There will be contact with the spiral. The electric potential will again close on both the water and the boiler body, because both elements are in close contact.

Defects in the tubular heating element occur for various reasons:

- manufacturing defects;

- long intensive operation, which leads to thinning of the walls of the heating element due to metal corrosion;

- scale formation on the surface of the tube.

In the latter case, it depends on the quality of the water, its hardness. The harder it is, the faster plaque forms. The reason may also be the heating temperature. If the boiler often overheats, then scale will form quickly and in a thick layer.

Poor grounding

Grounding system simply necessary in the house. It's all about electrical appliances, the group of which includes the boiler. This device has a body made of stainless steel. It is an electrical conductor.

Therefore, if the boiler is not grounded, then the so-called stray currents, if not removed, will leave micropores on the stainless steel. This will lead to depressurization and reduced service life.

But the grounding system also has another function. It removes electric current if the heating element fails or the wiring is exposed. In case of contact with the housing, the latter will not receive an electric shock when the boiler is on.

Electrical wiring problems

Exposed wires touch the metal body of the boiler. Upon contact with a person, the electrical circuit is closed - the phase is on the device body, the zero is closed to the ground.

Electric shocks through water

Modern electrical household appliances are manufactured with high operational safety. Even if the body or the water inside is exposed to the potential of an electric current, the boiler will not hit much. The impact will not be felt as such. Tingling fingers, unpleasant sensations - this is what is meant in this case by the concept of electric shock.

These sensations are a signal to turn off the power to the boiler, not to use it, and to invite a technician to troubleshoot the problem.

Destruction of the heating element shell

The technical condition of the tubular electric heater must be constantly monitored.Because this element is the main source of electric current, the potential of which enters the water.

It’s easier to open the top cover of the boiler and inspect the heating element with your own eyes. Scale and other defects are a reason to carry out prevention.

You can use a multimeter. To do this, the device is configured to measure resistance. Its wires with terminals are connected to the power terminals of the tubular heating element. The multimeter turns on. If the display shows numbers from 0 to 1, then the heating element needs to be changed. There is very little time left for it to depressurize and for the nichrome thread to come into contact with water. The latter will give you an electric shock.

The heating element itself is a device of simple design. In addition, replacing it with a new one is easy. You can carry out the entire process yourself:

- The boiler is de-energized - the plug is pulled out of the socket or the machine is turned off.

- Water is drained from the boiler. Any nearby consumer opens: mixer, tap, etc.

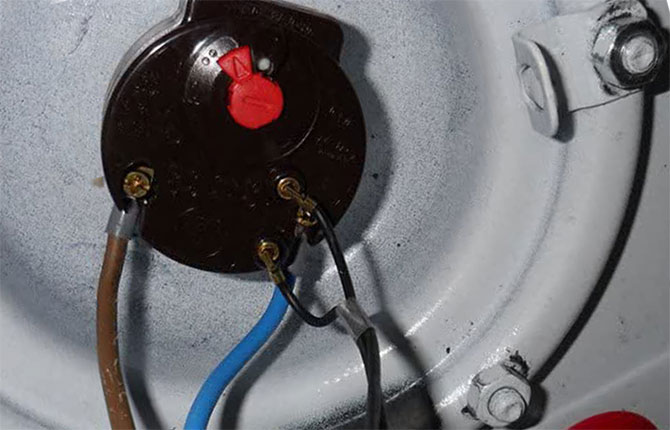

- The cover on the side of the case is removed, under which the heating element contacts are hidden.

- The contacts are disconnected.

- The union nut is unscrewed.

- The heating element is pulled out of the boiler. A new one is inserted in the same way. From the outside it is attached to the body with a union nut.

- Power connection.

- The device is filled with water and connected to the electrical network.

Incorrect network connection

Connecting a boiler so that it gives an electric shock just because it was connected to the power supply incorrectly is nonsense. Household appliances operate on a single-phase 220 volt network. You won't be able to connect it incorrectly.

It may be that the power supply wiring was laid in the wall (hidden wiring was organized).If wires of a smaller cross-section or poor quality were purchased, the insulating braid of the cable will burn out under the current power. This can lead to a short circuit, causing the boiler to fail. But the device will not shock.

Another thing is the wires that are inside the device. If their insulating layer burns through, a bare core is exposed, which is in contact with the body, then an electric shock will occur.

Troubleshooting Methods

A summary of the problems that cause the boiler to shock:

- Destruction of the heating element. This is the most frequently occurring reason. Just replace it with a new one.

- Exposed wires that touch the body of household appliances. If this concerns wiring located inside the boiler structure, then it must be examined for damaged insulation. There are 2 ways out of the situation. The first is to replace the old burnt wires with new ones. The second is to isolate the exposed areas with electrical tape yourself.

- The boiler is not connected to the grounding system or the contact between the grounding wire and the device body is loose. In the photo below you can see the yellow-green wiring. This is the ground wire. It is connected to the boiler body using a nut. She may also weaken. She needs to be tightened up.

Body punches

When a boiler shocks through water, it is not as noticeable as if it strikes through the body. It is important to immediately turn off the power to the heating device.

In this case, each cause may be present. But if the case is electrocuted, then the first thing that can be said for sure is that the grounding system is not working. It needs to be checked or carried out if there is no network.

RCD installation instructions

RCD (residual current device) is a necessary element that must be installed in the supply circuit of any household appliance with a power of more than 1 kW. Its task is to turn off the power supply if there is a problem inside the boiler. There is no current supply, which means the device will not shock.

RCD installed in the distribution board. Therefore, it is better to connect the boiler to a separate circuit drawn from the device to the panel. Here you will have to take into account the power of the water heater and calculate the cable cross-section.

The RCD is inexpensive, installation is simple and short. But it’s better to have it carried out by a specialist.

Everything related to electric current should not be carried out under the motto of saving. Especially when it comes to installing a boiler, where in addition to metal there is also water. Current can always flow through these two elements.

Boiler repair video:

I would like to hear in the comments who and how they dealt with the problem when the boiler began to give an electric shock. Maybe someone will share some useful tips or recommendations. Save the article as a bookmark so you can return to it at any time.

And we called the repairman immediately as soon as current flowed from the tap. They opened it, and not only was the heating element covered in scale, there was a thick layer of dirt in which the heater had sunk. I had to remove the boiler from the wall and take it to the workshop. They changed the heating element and cleaned the dirt. In general, complete prevention. It would be better to buy a new one. The masters took an incredibly large amount.

My boiler did not generate much current. But it felt like current. I immediately turned off the machine. Then he opened the top cover and examined the heating element. He was covered in scum. The layer was thick stone. It is clear that it was necessary to change, which I did myself. I didn't call the mechanic.