Gas heater repair: common breakdowns and methods for eliminating them

It is convenient to heat household objects such as a garage, greenhouse, basement using portable and compact gas heaters. They are used as an additional and safety heat source.Over time, any equipment wears out and requires maintenance. You can repair a gas heater yourself.

In the article we presented, we examined in detail options for restoring the performance of popular models in everyday life. We will tell you how to determine the cause of the malfunction. We'll show you how to prevent breakdowns and extend the service life of heaters.

The content of the article:

The feasibility of self-repair

There are many reasons why a heater malfunctions. The main ones include improper operation of devices, supply of unsuitable fuel to the equipment, placement of the heating unit in a room with an aggressive climate and high moisture, and neglect of preventive maintenance.

Initially, the owner of the device needs to decide which parts can be replaced. It is important in the first stages to figure out which breakdowns are easy to fix on your own, and which ones are best addressed to a repair shop employee.

The main danger that the user will face is a possible gas leak. Therefore, the first and main task when identifying a heater failure is to turn off the gas tap.

If you find that the burner of a gas heater is not burning, but fuel is being supplied, then in addition to shutting off the pipe or cylinder valve, you must urgently open a window to ventilate the room.

If you detect a leak with a characteristic gas odor, do not use anything that can generate a spark: matches, lighter. You should also not turn on the light, it can cause an explosion.

Manufacturers of portable heaters in the instructions for the devices recommend that if the equipment breaks down, take it to a workshop where they repair the corresponding equipment. This requirement is in accordance with safety regulations.

However, not every user wants to spend serious money on repairs. By following simple instructions, most problems can be easily fixed on your own using available materials and tools. The home craftsman will have to acquire some parts and components. In any case, it will cost less than repairing the heater in a workshop.

Before we look at the principles of repairing outdoor gas heaters and garage heating devices you need to determine what types of these devices are produced.

There are three types in total:

- Infrared gas heaters. Such devices are used for heating rooms and open areas: sports fields, verandas, terraces, restaurants. The operating principle is to emit infrared waves.Warming occurs not due to the acceleration of warm air, but due to the heating of objects, which then radiate heat.

- Convectors without combustion product outlets. They are devices that distribute warm air throughout the treated space. They are installed only in open areas, as they release decomposition products during operation.

- Thermal gas guns. The principle of operation is to create heat in the structural unit of the gun and supply warm air to the heated elements due to a very powerful air flow. They are used both for targeted heating of construction sites and for processing large commercial facilities.

A variety of infrared outdoor devices and portable heating burners are catalytic heaters. Like the listed varieties, they are capable of distributing both thermal waves and luminous flux, although not sufficient for full illumination. Their difference lies in the principle of operation - flameless combustion is carried out due to oxidation processes.

Among the common malfunctions of heaters are the following: the burner does not ignite, the device does not turn on, the device turns off a few minutes after switching on, the burner flame changes color, the heater emits an unpleasant odor.

Anyone who wants to repair a gas heater for their dacha should first read the operating instructions for their device.Each type of heater has its own set of typical faults. In addition, to maintain the device in working condition, it must be cared for in accordance with the instructions for use.

To determine the cause of the problem and how to fix it, you need to visually inspect country gas heater and diagnose it. For repairs at home, it is advisable to prepare in advance and acquire the appropriate tools and parts: screwdriver, screwdriver, wrenches, suitable components.

If large-scale breakdowns occur, in some cases it is advisable to contact a specialist from GorGaz or RemBytTekhnika who has experience in restoring the operation of gas equipment.

Subtleties of problem definition

Situations arise in which it is not clear to the user what exactly is broken in the gas heater. In such situations, the first thing you need to do is turn off the device and turn off the gas supply.

Then it needs to be inspected and the problem visually identified. If the initial inspection does not reveal the cause of the malfunction, then it is necessary to proceed to the second stage - diagnostics.

Before turning on the gas heater next time, you need to find out the cause of the problem. Otherwise, it is better not to do this, as there is a high risk of gas leakage. Some heaters are equipped with a security system. The mechanisms of this system avoid leaks, turn off the device if dropped, and allow you to control power.

Diagnostics are usually carried out in accordance with the instructions for the device. However, there are also complex emergency situations that require detailed disassembly of the device and checking the functionality of various components of the device.

Malfunctions of infrared heaters

Quite often, users encounter the following problem: the heater has stopped working. Sometimes it's just carelessness. It is worth checking the presence of gas in the cylinder. Perhaps a simple replacement of the cylinder will help solve this problem.

Before replacing it, you should allow the unit to cool completely to avoid burns. It is strictly forbidden to disable gas reducerwhile the heater consumes gas from the cylinder. After turning off the heater, you need to disconnect the gas reducer from the cylinder and remove it from the holder on the body. Make a replacement.

Common startup problems

When starting the infrared heater, the following problems may occur:

- The heater refuses to turn on;

- The device turns off automatically some time after successful switching on.

Let's look at each situation in more detail.

The heater may not ignite due to a malfunction of the piezoelectric igniter. It is necessary to check the functionality of the device. When starting, a characteristic sound and crackling sound should be heard, and a spark should be visible.

Before starting, it is also worth checking that the tank is filled with gas. The pressure reducer with a pressure gauge must indicate the current pressure in the cylinder.You can also shake the container to make sure it contains liquefied gas. The cylinder must be correctly connected to the device, and the gas supply valve must be unscrewed.

If after installing a new gas cylinder If the device does not light up, you need to check its temperature. Maybe it's too cold. In this case, you need to wait until the temperature of the cylinder reaches room temperature.

Sometimes when the device is first started there is air in its pipes. For this reason, the device may not start. It is necessary to turn on the gas supply and wait until the air leaves the system, gas flows and the main burner lights up.

Spontaneous shutdown of the device after prolonged operation is acceptable. This happens due to the burner going out due to air currents. A special sensor must turn off the gas supply in this situation.

If the device turns on again, then there is no problem. If the device turns off immediately after starting, then a possible reason is the lack of sufficient gas in the cylinder.

Infrared heaters are equipped with sensors that detect the presence of oxygen in the room. If there is not enough oxygen, the device turns off. To solve this problem, you need to open the window and ventilate the room or turn on the ventilation system.

Malfunctions and steps to resolve them

If problems arise with the operation of the device, you must turn it off and do not turn it on until repair work is carried out.Among the main malfunctions encountered during the operation of infrared gas heaters are the following.

The automatic ignition of the fuse does not work. This problem in most cases arises due to the lack of a spark at the interelectrode gap of the piezoelectric device.

To solve this problem, it is necessary to diagnose the operation of the piezoelectric switch. If a visual inspection reveals a defect in this part, then it is necessary to fix it.

Problems with piezo ignition are of the following nature. The user presses the button and clicks are heard, but arson does not occur. A possible problem is the lack of gas in the cylinder. If clicks are not heard, then you need to check the electrical wiring that leads to the piezo ignition spark gap. Perhaps she was interrupted. In this case, it is necessary to change the wires.

If when you press the button the electrical machine turns off, this indicates a short circuit in the network. In this case, it is necessary to check the heater wires for short circuits.

If, upon inspection, it is found that the wiring is fine and the piezoelectric switch is working properly, then the user should try to light the fuse using a match. If ignition is successful, the cause of the malfunction is most likely the incorrect location of the spark in relation to the gas stream.

To solve this problem, you need to adjust the location of the ignition electrodes so that they are emitted along the gas stream.

The next common problem is the heater turning off when the control knob is released. This happens due to the fact that the solenoid valve closes while the device is turned on. The cause of this problem is the displacement of the thermocouple sensor from the fuse fire zone or its breakdown.

To troubleshoot a misalignment, the thermocouple must be properly connected to the valve. If a valve or thermocouple breaks down, these parts must be inspected, the breakdown identified, and the entire part repaired or replaced.

A common problem when using a device for a long period is a decrease in the burning power of the burners. If the user selects the maximum power mode, then all burner igniters turn on, but it becomes noticeable that one or more of them burn with insufficient strength.

This problem occurs for three main reasons:

- The pipes delivering gas to the burners are clogged;

- The pipes supplying the gas heater are dirty and clogged;

- There is a gas leak.

It is not difficult to solve this problem yourself. To do this, you need to carefully remove the pipes and check them for blockages. If a blockage is detected, it must be carefully removed using a small brush or a homemade cleaning device. It is important not to damage the pipe when cleaning.Before reconnecting, remove any remaining water.

The supply pipes are cleaned in the same way. It is not advisable to compress these parts with pliers, since they are made of easily bendable material. After cleaning, it is necessary to return the supply pipes to their place in the same position.

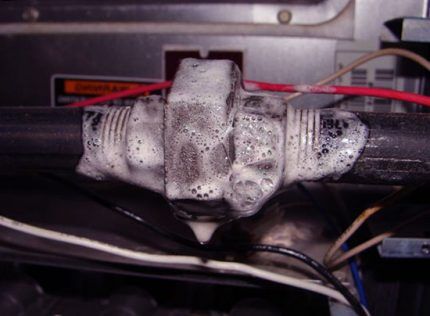

A strong gas odor is a clear sign of a leak. gas hose or pipe connections. To determine a leak, apply a soap solution to the gas pipe connections. Instead of soapy water, you can use foaming dishwashing liquid.

A sign of a leak is the appearance of soap bubbles. If they appear, you need to turn off the gas and restore the tightness of the connection.

When using some models of infrared gas heaters, the problem arises of switching the position of the knob that adjusts the power of the device from low heat to higher heat.

Usually the cause is the location of the heater, when the air flow blows against the direction of the burner flame radiation. There is also a situation when the fuse shifts.

The problem in the first case can be resolved by simply changing the location of the heater. It needs to be moved to a place where drafts will not blow on it. In the second case, you need to open the cover of the device and adjust the igniter. The flame should be located closer to the lower corners of the gas supply pipes.

If an unpleasant burning smell occurs from the device, you must disconnect it from the electrical network. Then you need to check the presence and integrity of the ceramic plates. Often a burning smell is a sign that part of the plate is missing. The check should only be carried out after the device has cooled down.

It is necessary to inspect the perimeter of each of the plates, determine the place where the part is missing. Repair of plates is carried out using a solution of refractory cement. After stirring the solution, it must be carefully applied to the damaged plate without staining the internal elements of the heater. In this way, the missing or damaged part of the plate is repaired.

You can turn on the device 24 hours after applying the solution.

If upon inspection of the fuse it is discovered that it burns bright red, then do not be alarmed. The reason for this is the presence of dirt in the gas pipe. The problem is solved by blowing and washing the pipe with compressed air.

Sometimes users find stains or burn marks on ceramic plates. The cause of stains is usually dirt in the gas outlets, as well as soot accumulated on the ceramic plate, within which flameless combustion occurs. The problem can be easily fixed using a can of compressed air.

The presence of soot on the walls of the device and on the burner usually indicates that low-quality gas is used as a resource for the unit.During operation, only high-quality gas should be used.

Heater Maintenance

Maintenance of an infrared gas heater, like any other equipment, must be carried out at certain intervals. This will help avoid malfunctions during operation of the device.

A large layer of dirt increases thermal insulation, which significantly reduces the effect of heat waves transmitted by the heater into the space being treated. As a result, operating efficiency decreases, which negatively affects the functioning of the unit.

Manufacturers indicate the need and regularity of cleaning in the instructions for the device. This usually needs to be done once a year or as needed. In this case, be sure to turn off the device and wait until it cools down.

Cleaning is carried out using a damp cloth, which must be soaked in soapy water. This way you can wash the heater body and the location of the cylinder with gas mixture. Difficult stains can be removed using chemicals and brushes.

Compressed air is usually used to clean the inside of the heater whenever possible. A stream of air should be passed over the surfaces of the burner and ceramic plates until completely clean. The procedure must be carried out carefully so as not to damage the fragile structure of the ceramic parts.

The spark gap and burner openings are also cleaned using compressed air.

After cleaning the device, you need to wipe it dry. The burner and spark gap area must be dry before starting.

Before reusing the heater again, you need to check the equipment connections for leaks. All connections of the pipeline supplying gas to the device and gas hoses are checked using a soap solution.

If a leak is detected, the device must not be started. Before starting, you must ensure that the leak has been repaired.

Carrying out preventive cleaning of the device and its inspection will help to significantly extend its service life.

Conclusions and useful video on the topic

UFO heater repair:

Repair of infrared ceramic panel:

Despite the high quality of manufacturing, gas heaters have a certain shelf life and must be serviced in a timely manner. If the device begins to act up and malfunction, then it must be repaired in order to avoid such negative consequences as expanding the scope of the breakdown and harming the health of users.

Among the most common malfunctions of heaters are the breakdown of the automatic ignition ignition system, gas leakage, and destruction of ceramic tiles. Independent repair work must be carried out strictly in compliance with safety regulations.

Please write comments in the block form below, post photos related to the topic of the article, and ask questions. Tell us how you were able to fix a gas heater problem with your own hands.It is possible that your advice will be very useful to site visitors.

Wasted time on the video In fact, there is an endless repetition of the Operating Instructions. How can you determine if the valve is working properly, and what do all these fall sensors, high CO2 sensors look like, how is this piece of wire involved, which heats up to red? Is this its only purpose or is it somehow connected to the solenoid valve?

Good afternoon, Infrared gas heater is a PRORAB and the following problem has appeared. When you release the suction button and switch to mode 1 or 2, the burner goes out. Tell me what could be the reason?

A diagram of a ceramic heater is required with the designation of each functional element, its purpose and its function.

We can assume that everyone is familiar with the operating principle of gas ceramic tiles.

But the heater is more complex, as it is supplemented with: a thermocouple, piezo ignition, a gas nozzle for the initial ignition of each of several ceramic plates, a gas supply valve and a tube splitter that directs gas to different ceramic plates, etc.

The MASTER gas heater goes out after a few minutes of operation, what could be the problem?

Good afternoon, please tell me if I should buy a gas infrared heater, I noticed at home that there are black dots on the ceramic panel, is this critical or is it fashionable to leave it?

Timberg gas heater burns for 2 hours then goes out, I start it again, the flame comes off and goes out

Hello, it burns for 2-3 hours then goes out, I start it again and the flame comes off

Hello, it burns for 2-3 hours then goes out, I start it again, the flame comes off, it stays for 2 hours then it works again

There is no gas supply to the nozzle. The cylinder was refilled. It's gas. Gas flows after the reducer. The hose is in good condition. When the handle is recessed and held, there is no gas in the nozzle; my son personally sniffed it. At the dacha, I opened the window, remembering that I was checking the supply after the gearbox. The cylinder is new, freshly filled. Ch. D. I can’t find information on the Internet about the gas supply circuit. The instructions are stupid, there are zero malfunctions

Good hour! Please tell me, when starting everything turns on according to the diagram, switching to the second combustion mode, the fire does not go out! It produces soot and the big flame doesn’t turn off! What could be the reason ?