Heating gas convectors: guidelines for choosing the best variety and brand

The heating system of a house can be either centralized or autonomous.One of the types of local heaters is a heating gas convector. In terms of purpose, functions and some technical characteristics, it resembles electric analogues, but runs on a different energy source - liquefied or natural gas.

To find out whether heating equipment is suitable for a particular room, you need to become familiar with its capabilities. We offer useful materials about gas convectors for home heating and recommendations for choosing household appliances.

The content of the article:

What does a gas convector consist of and how does it work?

A gas-powered convector is a ready-made mini-heating system. If you need to heat one room, for example, a large hall in a country house, just install the device and connect it to a power source - a natural gas line or cylinders. There is no need to purchase a boiler, pipes, pump, or radiators separately.

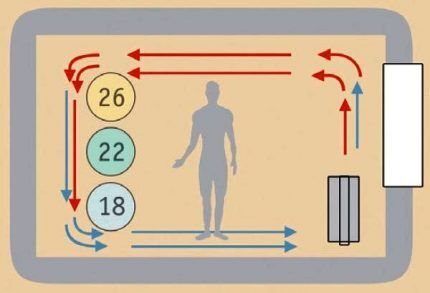

The operating principle is based on a change in the characteristics of the fuel as its temperature increases. The air flow passes through the heat exchanger, heats up and moves up to the ceiling. It is replaced by colder portions of air that follow the same path. This process is called convection, and the units themselves are called convectors.

The traditional and technically sound installation location is the section of the wall under the window: heat loss in this area is considered to be maximum.

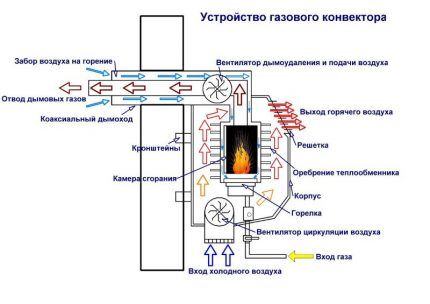

The design of a gas convector is a combination of the following components:

- Housing or casing, performing two functions: protective and decorative. This is a metal box coated with heat-resistant anti-corrosion paint, with holes for air circulation and fittings for installation.

- Gas-burner – element responsible for gas combustion. It is interfaced with a heat exchanger and equipped with an igniter with an electrode, which is used to ignite.

- Heat exchanger performs the main function - heats the air. The larger its surface area, the more efficient the heating will be, which is why the ribbed configuration is common.

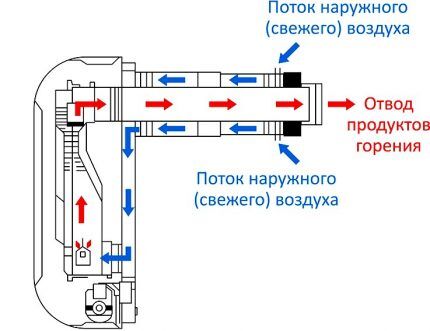

- Smoke exhaust system. The combustion products of gas heating units are removed in two ways: naturally or forcefully, using a built-in fan. In the first case, combustion is supported by air intake from the room, in the second - from the street, through a coaxial pipe.

- Valve, allowing you to regulate the pressure of the fuel entering the combustion chamber. Connected to the thermostat and responds to its signals.

- Thermostat. The combination valve is controlled by a thermostat, which can be adjusted to a comfortable temperature.

- Control system in modern models it is automated.If an emergency situation occurs: a decrease in pressure, a shortage of combustion air, a fan failure, or a flame extinguishment, the convector stops working.

Heaters with tangential fans increase the rate of pumping heated air and warm up the room faster.

All gas models are universal in relation to the type of fuel. They can operate on both natural and bottled gas. Requirements for combustible materials are set out in GOST 5542-2014.

Pros and cons of gas convection heating

The production of heating appliances is developing due to the demand for gas equipment.

Among the main advantages noted by users are the following:

- Economic benefit. The purchase and installation of a gas unit is more expensive than its electric counterpart, but subsequently you will have to pay much less for fuel consumption. Especially if the source is natural gas.

- Versatility. Gas appliances are designed to connect both natural and bottled gas. The ability to run on propane will come in handy for owners whose homes are not supplied with mains fuel.

- Lack of coolant. There is no need to install a pipeline, and in winter, during downtime, there is no risk of liquid freezing. Local convection heating is convenient for garages and small cottages.

- Environmental friendliness. Devices with coaxial pipe and a closed combustion chamber does not burn oxygen from living quarters.

But there are also some disadvantages.For example, not everyone likes the dimensions of heating devices - more compact electric analogues can be found on sale. For residential premises, it is preferable to buy wall-mounted models that take up less usable space.

The steel heat exchanger, typical of inexpensive models, cools quickly, thereby reducing heating efficiency.

Criteria for choosing a heating device

Before purchasing a gas convector using natural or bottled gas it is necessary to analyze the installation conditions, discuss installation details with specialists and select the device that best meets the specific requirements.

Important criteria may include technical characteristics, design or cost. Let's look at what you need to pay attention to when choosing.

Criterion #1 – combustion chamber type

Convectors are equipped with two types of combustion chambers:

- open;

- closed.

In terms of the method of air intake, the first type resembles a furnace: oxygen to support combustion enters the firebox from the room, and exhaust gases are discharged outside through a pipe. Often such devices are installed in place of the stoves, and a pipe for removing combustion products is inserted into an existing chimney.

The main disadvantage of the device is the combustion of oxygen in the house. Requires a well-established ventilation, constantly replenishing the supply of fresh air. The advantage is low cost.

A closed combustion chamber is considered more acceptable from an environmental point of view.

The advantage of devices with a closed combustion chamber is safety, the disadvantage is the need for power supply to operate the fan.

Criterion #2 – type of chimney

Exhaust gases are discharged outside through the chimney. All options for assembling smoke exhaust pipes are divided into two categories:

- vertical;

- horizontal.

Vertical ones, characteristic of open-type devices, are practically not used in residential premises. Although they have a protection system: automatic shutdown when the burner blows out, lack of oxygen or pressure drop, they are considered unsafe. They are mainly used for heating industrial premises, garages, and change houses.

Coaxial chimneys, located horizontally and led out into the street through a through hole in the wall, are used for devices with a closed combustion chamber.

Pipe coaxial chimney has a telescopic structure, so the thickness of the walls does not matter. A protective cap is installed on the outside of the pipe end to protect it from debris.

Criterion #3 – floor or wall installation

According to the installation method, all convectors are divided into:

- floor;

- wall-mounted

Floor-standing ones are distinguished by greater power and heat transfer, so they are installed in spacious rooms - workshops, garages, warehouses. To ensure that heavy units remain stable, a strong and level base is prepared before installation.

Wall-mounted units are household convectors suitable for living rooms, halls, and halls.They take up minimal space, as they are attached directly to the wall, through which the chimney exits.

To reduce the load on the wall, the heat exchanger in modern budget models is made of steel rather than cast iron.

The cost of floor-standing and wall-mounted gas convectors is almost the same; to a greater extent it depends not on the type at the installation location, but on the technical characteristics and materials from which the main parts are made.

Criterion #4 – fuel consumption

The approximate gas consumption of convectors can be calculated in advance by multiplying the volume of gas consumed by one device by the number of devices. Calculations are made based on the type of fuel.

So, for 1 kW of power:

- when natural gas is connected, 0.11 m³/h is consumed;

- when using bottled gas – 0.09 m³/h.

There are several ways to increase heating efficiency and reduce fuel consumption. For example, insulating a room reduces heat loss by about 15-20%.

The second way to reduce gas consumption is to regulate the temperature using a thermostat. You can choose a mode in which the temperature decreases at night and during the day, and increases in the morning and evening, when the family is together.

If you know how much a home gas convector consumes, you can calculate monthly costs.

Criterion #5 – device power

The comfort of those living in a heated room depends on the correct choice of power.On average, approximately 1 kW is required for a volume of 30 m³. Devices with power from 2 kW to 12 kW are intended for domestic use.

[adinserter name=”desktop: insert in text – 6″]There is a large assortment of heating devices with a power of 2-6 kW with a steel heat exchanger on the market. They are attractive with their design and low price, but their service life and efficiency are lower than their analogues with a cast iron heat exchanger.

Considering the likelihood of ventilation, drafts, and insufficient insulation, you need to take a unit with a small power reserve. Let’s assume that a 40 m³ room requires a 2 kW convector.

Criterion #6 – material for manufacturing working units

Heat exchangers and combustion chambers made of steel have two significant advantages: low weight and low cost.

It is estimated that devices with a steel chamber are approximately 12-15 kg lighter than their analogues with a cast iron “filling”. However, there is an important disadvantage - even heat-resistant steel deteriorates faster than cast iron, which means that the cheaper unit will be the first to be repaired. The best types of metal last up to 20 years.

[adinserter name=”desktop: insert in text – 7″]The service life of a cast iron chamber is not limited, it does not rust or burn out, but the metal is sensitive to sudden temperature changes.

Cast iron is recognized as an ideal material for the manufacture of heat exchangers. It heats up quickly, retains heat for a long time and distributes it evenly over the entire surface. The service life of such devices is up to 50 years. But there are also disadvantages - heavy weight and high price.

Criterion #7 – natural or bottled gas

From an economic point of view, it is more profitable to connect convectors to natural gas, so all models are designed to operate on mains fuel. The installation diagram is simple, without additional components.

The disadvantages of using natural gas are considered to be dependence on the fuel supply and control by the gas service, but these are mandatory components of the use of any equipment: stoves, dispensers, boilers.

Using a propane/butane mixture in gas cylinders It is more expensive, but is used wherever there is no possibility of connecting to the highway. Almost all models are adapted for conversion to run on natural gas - for this purpose, the delivery set includes a special adapter.

[adinserter name=”desktop: insert in text – 8″]We recommend connecting the cylinders in the presence of a gas service worker - it is better if a qualified specialist replaces the nozzles or reconfigures the valve.

Popular manufacturers of gas convectors

The first places in the ratings of gas-powered convectors are occupied by models of two Turkish companies - Alpine Air and Hosseven. For heating dachas and cottages, models for installation on the wall are often purchased, so there is a large selection of wall-mounted household series in the catalogs of both brands.

Models Hosseven with a cast iron heat exchanger have proven themselves well in heating private houses. The 3 and 5 series models were replaced by designer HP and HS-8 devices with a glossy surface and heat-resistant glass on the front panel.

The basis for the production of heating devices Alpine Air steel convectors Demrad. Household devices have the same technical characteristics and design. The average power of domestic installations with a cast iron heat exchanger of the NGS series is 2.5-5 kW.

Budget models of the DT series are equipped with a steel heat exchanger. The F in the name indicates the presence of a fan.

Czech convectors Karma Beta functional, reliable, easy to maintain, and have earned popularity due to their low price. Models of 4 series are supplied to Russia: Mechanic, Electronic, Comfort Mechanic, Comfort Electronic.

[adinserter name=”desktop: insert in text – 9″]Mechanic devices are the best option for a summer residence. The absence of complex electronics made them energy independent. Ignition is carried out mechanically, from a piezoelectric element.

Ukrainian brand ATON Vector produces safe, reliable and inexpensive heating equipment. Household models with a power of 2.2-5 kW have long been known in Russia; they are often used to connect to bottled gas.

In addition to convectors of the listed brands, the Russian market includes devices of domestic brands Termotechnik, Vepr, Titan.

Conclusions and useful video on the topic

Visually about the design and functions of devices:

Gas heating technology overview:

To imagine how the installation takes place, here are the installation instructions from the ACOG manufacturer:

Gas convectors are an alternative method of heating premises. They are easy to install and maintain, and when connected to natural gas, they are economical.

The devices help out if you need to quickly heat a room or if the main heating system cannot cope. Convection equipment can be used as a main or backup heat source.

Would you like to share your own experiences in choosing and/or operating gas-fired convective heaters? Do you have useful information on the topic of the article? Please write comments in the form below, ask questions, post photos on the topic of the article.