Manufacturers of polypropylene pipes on the Russian market - how to choose the best

As a rule, the assortment of a construction supermarket is limited to products of two or three main manufacturers of polypropylene pipes, differing in price, color and status. It is difficult to choose due to lack of information. You have to either use the reviews of friends and acquaintances, or trust the master who undertook to do the heating.

The content of the article:

How to choose products from a manufacturer of polypropylene pipes for heating and plumbing

You can only partially trust the opinion of craftsmen or friends who have installed polypropylene water supply systems. Selection criteria may vary greatly. Experts and representatives of trade organizations usually refer to the ratings of polypropylene pipe manufacturers.

Workers or craftsmen involved in assembling or soldering pipe blanks are only interested in technological nuances, how well polypropylene is cut and soldered. They are not interested in price, performance characteristics, or durability of pipelines.

Therefore, you first need to determine the basic criteria, and then use them to determine the best manufacturers of polypropylene pipes.

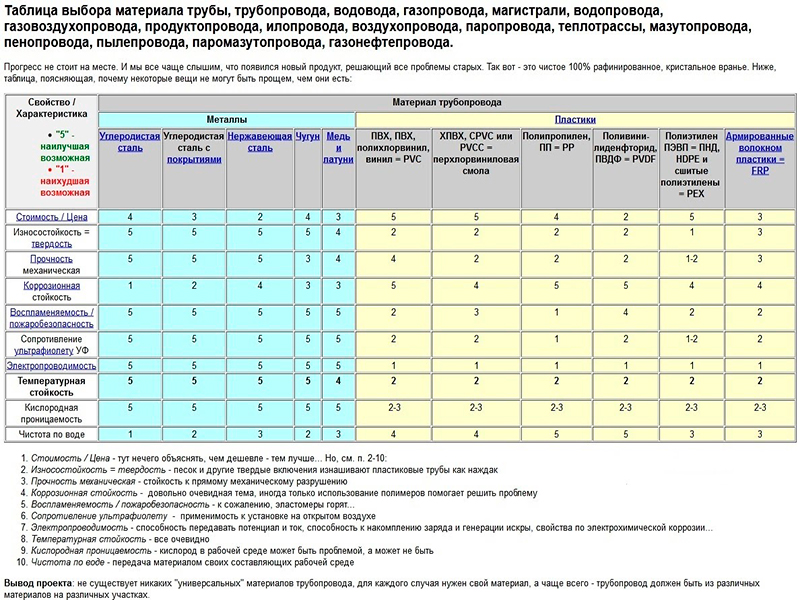

The list of criteria will include:

- performance characteristics;

- acceptable price;

- complexity installation;

- quality, durability of the material.

Not all polypropylene pipes are the same - each manufacturer produces several types of pipe blanks for different operating conditions. Therefore, when comparing products from companies, it is necessary to choose materials with the same characteristics.

Single-layer polypropylene products

More often, for home plumbing, simple polypropylene pipes without reinforcement with an SDR index of 6-7 (this is the ratio of diameter to wall thickness) are purchased. PN 10, PN 20, designed for water pressure 10 bar or 20 bar.

In this case, pipe blanks are formed from two common polymers:

- PPR or random copolymer. Used by the vast majority of manufacturers. The most “advanced” German or Italian companies can use a random copolymer of a deeper modification, including one that is stabilized or subjected to directional crystallization of the melt.

- PPB or block copolymer. It is somewhat inferior to PPR polypropylene in terms of maximum water temperature and strength of the plastic matrix. On the other hand, PPB polypropylene pipes are considered the optimal solution when it comes to installing external water supply systems.

Block copolymer has greater plasticity and easily tolerates freezing with water at temperatures up to 20 ℃. Pipes based on other polypropylene matrices, while possessing even greater strength, often crack when frozen.

Many manufacturers of polypropylene pipe blanks use polypropylene grades PPH and PPS. The first is called homopolypropylene. Used for non-pressure polypropylene pipes with SDR=10-12, ventilation ducts or gutters.

Some manufacturers offer low pressure water pipes made from PPH. For example, for water disposal, sewage.PPS are offered by manufacturers in a limited range, as they are mainly used for pipelines with special characteristics.

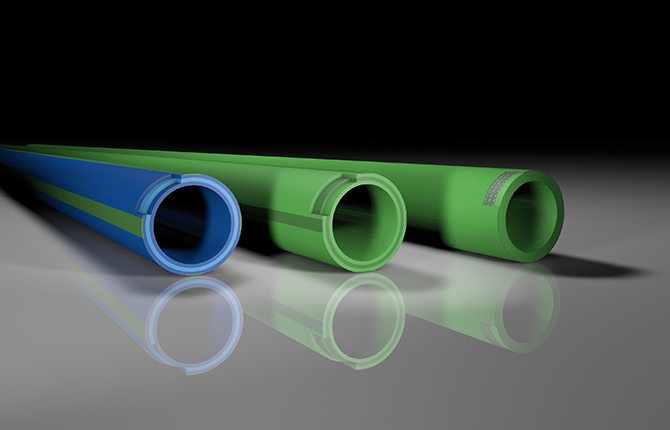

Multilayer reinforced pipes

An ordinary pipe made of PPR or PPV-polypropylene can withstand heating for a long time to a temperature of no more than 70 ℃ at pressures up to 3-4 bar. This is enough for hot water supply. But ordinary polypropylene pipes are unsuitable for heating systems.

Approximately 40% of the volume of pipe blanks produced by leading manufacturers are reinforced pipes. They are more expensive than conventional polypropylene ones, contain a reinforcing layer and are practically not subject to temperature deformation.

The reinforcing component is a glued sublayer of aluminum foil or a composite matrix of 70% PPR polypropylene plus 30% filler - fiberglass or basalt fiber.

Such pipes are less easily soldered and require special preparation before connecting to the fitting. Large manufacturers for multilayer workpieces are developing special formulations for polypropylene mass that improve the fluidity and weldability of the material.

Small, little-known companies make pipe blanks without adjusting the purchased raw materials. As a rule, regular and reinforced grades use the same polypropylene in granules.

What manufacturing technologies do Russian manufacturers use?

In the polypropylene fittings market, fittings, pipe billets are represented by two types of companies. The first include full-fledged manufacturers who have purchased equipment and raw materials and are engaged in the production of products under their own brand.

The second category includes companies that do not have production facilities.Such manufacturers purchase a ready-made single-layer pipe, cut it into blanks 2-6 m long, label it, and sell it as a product of their own making.

Equipment used

The first category of Russian manufacturers is trying to control the market and fight for quality. Equipment for the production of polypropylene pipes is purchased either from China or the European Union.

You can distinguish polypropylene pipes made using European or Chinese equipment by certificates of conformity or quality. Especially when it comes to joint ventures or commercial use of a well-known trademark. This is often required by European equipment suppliers, as they are interested in protecting the reputation of their products.

Chinese suppliers of equipment for the production of polypropylene pipes usually do not require this - their interests are limited to sales with the further launch of production lines.

Raw materials

The standard material for the manufacture of polypropylene pipes is PPR100 grade granules. It is usually purchased in Denmark, the Czech Republic, Germany or France. Türkiye and Italy produce their own version of granulate.

In addition to polypropylene itself, for the production of pipe blanks you need:

- stabilizers that improve the resistance of the polymer to temperatures and ultraviolet radiation from sunlight;

- additives that increase melt fluidity;

- fillers, fiberglass, aluminum foil and basalt fiber;

- dyes.

Raw materials can be purchased from the direct manufacturer of polypropylene granules, but only in case of large quantities. Most Russian pipe manufacturers are focused on Chinese raw materials and domestic production. Granules are bought in Kazakhstan, Croatia, Denmark, and the Czech Republic.

More often, raw materials are purchased from well-known manufacturing companies - “Neftekhimiya”, “Poliom”, “Polimerklab”, “TOTAL PETROCHEMICALS”, “ADOPEN PLASTIK INSAAT SANAYI A.S”.

The best polypropylene pipes are produced from raw materials from the world's leading chemical industries. Therefore, in the product passport or environmental certificate, you need to look for information about the raw materials used, and specifically about the manufacturer of granular PPR.

Most large manufacturing companies buy virgin polypropylene PP-R, PPRCT from Tisza Chemical Group, Public Limited Company, Lyondell Basell Slovnaft, SABIC Innovative.

Which manufacturer of polypropylene pipes to choose

The first thing you need to do is study the quality certificate, the hygiene certificate for the product issued in the country of sale, and examine samples, at least selectively. Often, an inspection reveals shortcomings that the manufacturer’s documents are silent about.

Russian companies

Among the most famous, there are two – “Proaqua” and “Plastic”. The latter produces plastic pipe blanks under the general brand “RVK”.

The Proaqua company is distinguished by a well-thought-out marketing program and tries in every possible way to maintain the image of a Russian manufacturer working according to Western quality standards. Polypropylene pipes are manufactured using European raw materials and equipment. Quality control and product testing are carried out at the stands of Sciteq and Binder.

Among the shortcomings, only the outdated recipe for preparing the melt is noted. Otherwise, the quality of single-layer pipe blanks is stable. Sometimes complaints arise about the reliability of pipes with an aluminum sublayer, but the results of incident investigations showed the fault of the installers, not the raw materials.

Polypropylene pipes of the RVK brand are in stable demand. Moreover, the manufacturer “Plastic” devotes an order of magnitude less effort and money to marketing policy. European raw materials and technologies are used to produce pipe blanks. The quality is consistently high.

Among the shortcomings is the lack of detailed information about product inspections, testing and research carried out by the manufacturer, which is freely available to buyers. In general, there are even fewer complaints about the quality of pipes than our closest competitors.

Italian and Turkish manufacturers

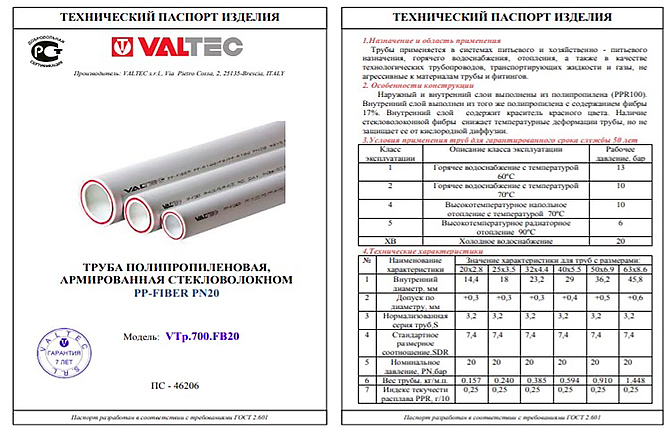

The leader of the CIS domestic market is the Russian-Italian company VALTEC. For the most part, the company is engaged in sales under the Italian brand, but there is also production. Moreover, a sophisticated buyer prefers polypropylene pipes produced in Europe, so when choosing a product, he pays special attention to documents and certificates, and only then to labeling and passports.

The quality of pipe blanks made in Italy is excellent, so the material is welded evenly and holds temperature and pressure well. The only negative is the high price. Italian Valtek PPR pipes may be inferior in quality to German premium brands, but they are cheaper, so the demand for polypropylene fittings and blanks from Italy will always be high.

When purchasing pipe blanks and tools for assembly of the Valtek brand, you can get a significant discount, as well as a guarantee for plastic plumbing or heating systems.

Of the Turkish manufacturers producing accessories, blanks, fittings and pipes, the two most popular are:

- Relatively young company "TEVO". Opened in 2008, the market offers a small selection of offers.Uses modern equipment, raw materials from the Borealis plant. The advantages are low price with good quality of the material, the disadvantages are violation of the geometry of the flow section and a small range of products.

- Concern "KAR GROUP", trademark NOVAPLAST. One of the most powerful and oldest manufacturers of premium polypropylene pipes. High strength and quality polypropylene, certified for transportation of gas and drinking water. Products are exported to the European Union, including Italy and Germany.

Also, fittings and fittings from the Turkish manufacturer “PILSA” periodically appear on the market. The composition of polypropylene is focused on the maximum quality of welds, so water supply and heating systems are reliable. It has a low price, but there are cases of violation of the geometry of the flow section.

Czech and Romanian manufacturing companies

Products from Romania are represented by the SupraTherm plant. PPR pipes and fittings for water supply systems are mostly of average quality, but they are certified and recognized by the European Union regulatory services as one of the safest.

The company is interesting to others - most models of shut-off and bypass valves, ball valves, couplings are highly reliable and have a long service life. Many craftsmen recommend purchasing Romanian fittings, taking into account the fact that many products use components and components made in Italy.

Czech companies producing materials for polypropylene pipelines are slightly inferior to competitors from Germany. One of the best quality brands, WAVIN EKOPLASTIK, is classified as a premium class. The quality of the pipes is high, the price is above average.It makes sense to use it for complex multi-level water supply and heating circuits of multi-storey residential buildings.

For household use, it will be more profitable to use products from the Czech “FV-PLAST”. The company has been producing polypropylene pipes and fittings for more than two decades, so the experience in optimizing production is enormous.

One may come across the opinion that FV-PLAST products are outdated in terms of polypropylene composition and product range. However, the demand for the famous aluminum-reinforced polypropylene pipes of the Stabi or Faser series is only growing, even in competition with products reinforced with basalt fiber.

German manufacturing companies

Polypropylene pipes produced in German factories are considered the best in quality. In practice, it turns out that this is not entirely true. The quality of products from German manufacturers is as high as possible, but if you calculate the price-quality ratio, then materials from Germany will not be in first place.

In addition, manufacturing companies such as Aquatherm, WefaTherm, Banninger invest considerable funds in advertising projects for the installation or replacement of old pipes with their products in the most famous and socially significant buildings in large cities. In addition to replacement with polypropylene pipes, a 50-year warranty and insurance in the amount of tens of millions of euros are issued.

For the common man, German pipe blanks are no better than Italian or Czech ones. All elements of the assembly technology are the same. But if a defect is discovered (and this happens with all manufacturers), it will be difficult to get a replacement or compensation from a large company.If the assembly of the water supply or heating system was carried out with “someone else’s” tools, without certification by a company representative, then you can forget about the warranty.

It is very important to have information about the manufacturers of polypropylene pipes before purchasing the material. This will allow you to optimize costs and get the necessary quality without overpaying for brand popularity.

Share, which manufacturing companies do you prefer when choosing materials for home communications? How justified was the choice? Save the article as a bookmark so you can return to it at any time.

I believe that the brands that are most often counterfeited are the ones you should buy. But only together with an expert or master, so as not to buy a fake yourself.