Heating pump connection diagrams: installation options and step-by-step instructions

The uniform distribution of heat in a house with an autonomous heating system is determined by the model of pumping device used.This equipment ensures the forced movement of a warm medium through pipes and radiators.

To determine which heating pump connection diagram will be optimal for independent implementation, many details must be taken into account. In this article, we will consider in detail possible connection schemes and analyze the connection rules in detail.

We will also pay attention to the subtleties of choosing a location for installation, supplementing the material with thematic photos and diagrams.

The content of the article:

- Pros and cons of using a heating pump

- Selecting the location for inserting the device into the system

- Schemes for different types of systems

- Solid fuel pump and boiler

- Pump installation diagram

- Installation of additional equipment

- Rules for connecting to power supply

- Conclusions and useful video on the topic

Pros and cons of using a heating pump

Just a couple of decades ago, in the private sector, houses were equipped with gravity-type heating. A wood stove or gas boiler was used as a heat source. There was only one area of application left for large circulation devices - centralized heating networks.

Today, manufacturers of heating equipment offer smaller units that have the following advantages:

- The speed of movement of the coolant has increased. The heat generated by the boiler quickly enters the radiators. Due to this, the process of warming up the premises was significantly accelerated.

- The higher the movement speed, the higher the pipe capacity. This means that an identical volume of heat can be delivered to rooms using a pipe with a smaller diameter.

- Water heating schemes have undergone significant changes. The highway can be laid with the slightest slope. Also, the complexity and length of the line can be anything. The basic rule is the rational choice of a heating pump based on the required power.

- With the help of a household circulation device, it became possible to organize heated floors in the house, as well as an efficient closed-type heating system.

- It became possible to hide the entire heating communication line, passing through the rooms, which does not always go well with the design of the room. Options for laying pipes behind suspended ceilings, in walls or under floor coverings are quite common.

The disadvantages of pumping systems include the dependence of operation on the supply of electricity and its consumption by the pumping apparatus during the heating season.

Therefore, if the area is often deprived of power supply, it would be advisable to install a device to provide uninterrupted power. The second drawback is not critical and can be eliminated correct selection power and circulation pump model.

Selecting the location for inserting the device into the system

The installation of the circulation pump is supposed to be in the area immediately after the heat generator, not reaching the first branch line. The chosen pipeline does not matter - it can be either a supply or a return line.

Where can I put the pump?

Modern models of household heating units, made of high-quality materials, can withstand temperatures of a maximum of 100 °C. However, most systems are not designed for higher heating of the coolant.

Its performance will be equally effective on both the supply and return branches.

And that's why:

- The density of water when heated to 50 °C is 987 kg/m3, and at 70 degrees – 977.9 kg/m3;

- The heating unit is capable of generating hydrostatic pressure of 4-6 m of water column and pumping almost 1 ton of coolant per hour.

From this we can conclude: an insignificant difference of 9 kg/m3 between the statistical pressure of the moving coolant and the return does not affect the quality of space heating.

Are there exceptions to the rules?

Inexpensive ones may serve as an exception. solid fuel boilers - with direct combustion type. Their device does not provide automation, so at the moment of overheating, the coolant begins to boil.

Problems begin to arise if the electric pump installed in the supply line begins to fill with hot water and steam.

The coolant penetrates through the housing with the impeller and the following occurs:

- Due to the action of gases on the impeller of the pumping device, the efficiency of the unit decreases. As a result, the coolant circulation rate coefficient is significantly reduced.

- An insufficient amount of cold liquid enters the expansion tank located near the suction pipe. The overheating of the mechanism increases and even more steam is formed.

- A large amount of steam entering the impeller completely stops the movement of warm water along the line. Due to the increase in pressure, the fuse valve. Steam is released directly into the boiler room. An emergency situation is being created.

- If the firewood is not extinguished at this moment, the valve will not be able to cope with the load and an explosion will occur.

In practice, no more than 5 minutes pass from the initial moment of overheating to the activation of the safety valve. If you install the circulation mechanism on the return branch, then the period of time during which steam enters the device increases to 30 minutes. This gap will be enough to eliminate the heat supply.

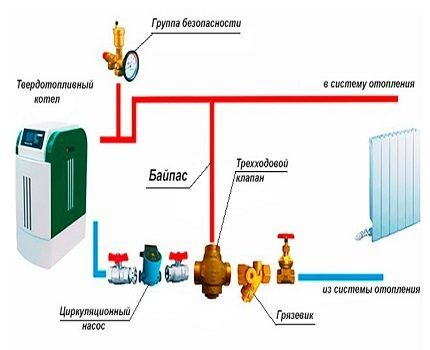

From this we can conclude that it is impractical and even dangerous to install a circulation device on the supply line. Pumps for solid fuel heat generators are best installed in the return pipeline. However, this requirement does not apply to automated systems.

Heating with a group of separate lines

If the heating system is divided into two separate lines, heating the right and left sides of the cottage or several floors, it would be more practical to install an individual pump for each of the branches.

When installing a separate device for the heating line on the second floor, it becomes possible to save money by adjusting the required operating mode.Due to the fact that heat has the property of rising, it will always be warmer on the second floor. This will reduce the coolant circulation rate.

The pump is inserted in the same way - in the area located immediately after the heat generator before the first branch in this heating circuit. Typically, when installing two units in a two-story house, fuel consumption for servicing the upper floor will be significantly less.

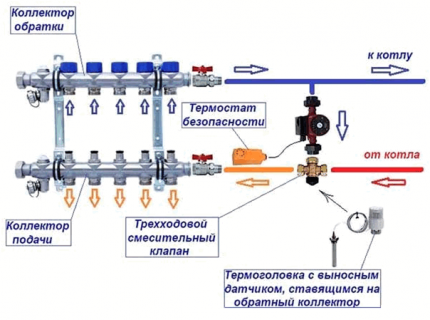

Schemes for different types of systems

Initially, it is necessary to determine the insertion area of the circulation device. With its help, the process of active movement of liquid is carried out - the flow passes through the boiler and is forcibly directed to the heating radiators.

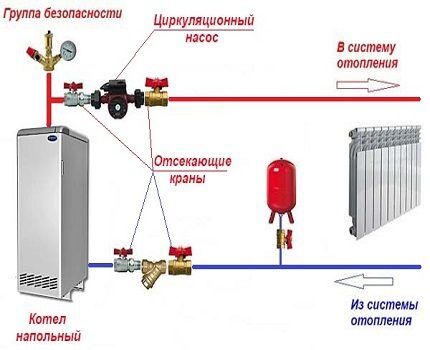

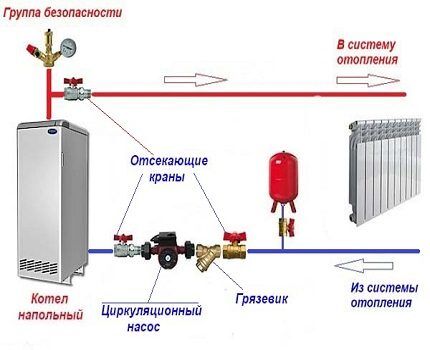

To locate a household pump, it is necessary to determine the most convenient area so that it can be easily serviced. On the feed it is installed after security block and shut-off valves of the boiler.

On the return pipeline, the pump is placed after the expansion tank in front of the heat generator.

Due to the presence of various mechanical impurities in the water, for example, sand, problems may arise in the operation of the pumping mechanism. Particles contribute to jamming of the impeller, and in the worst case, stopping the motor. Therefore, you will need to install a strainer strainer directly in front of the unit.

Separately, it is worth mentioning the issue of an open-type heating system. It is capable of operating in two modes - with forced and gravity coolant circulation.

The second option is more suitable for areas with frequent power outages. This is much more economical than purchasing an uninterruptible power supply or generator. In this case, the unit with shut-off valves must be installed on bypass, and insert a crane into the direct line.

In stores you can find ready-made units with a bypass. In place of the flow tap, there is a spring-loaded non-return valve. This solution is not recommended - the valve produces a resistance force of 0.1 Bar, which is considered a large indicator for a gravity-type circulation system.

It is better to use a reed valve instead. However, its installation is carried out strictly horizontally.

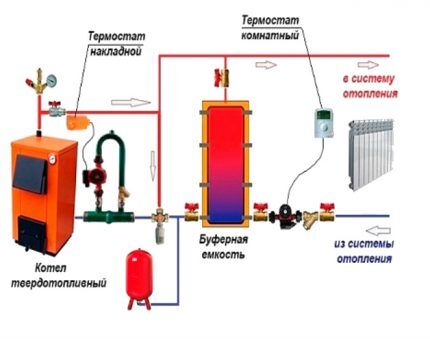

Solid fuel pump and boiler

The pump is connected to the system with a solid fuel unit on the return line. In this case, the pumping device is connected to the boiler circuit with a bypass and a three-way mixing valve. In addition, the latter can be equipped with a servo drive and an overhead temperature sensor.

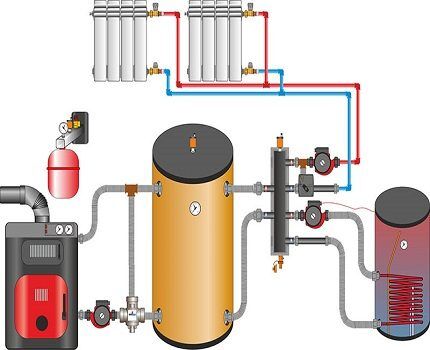

Due to the fact that the maximum performance of heating equipment is used to its fullest extent only during the cold period, it is possible to install a heat accumulator (TA). It is able to absorb excess heat and then, on demand, release it to the heating circuit.

This battery is made in the form of a tank and is lined with thermal insulation material. On one side of the device there are two pipes intended for connecting it, and two on the other - for connecting to the radiator line.

As the liquid passes through the boiler, which operates at maximum, the coolant in the heat accumulator warms up over time to 90-110 degrees. In a large circuit, the insertion of another circulation device is required.

Depending on the degree of cooling of the liquid in the heating system, the required amount of heat from the storage device will enter through the valve.

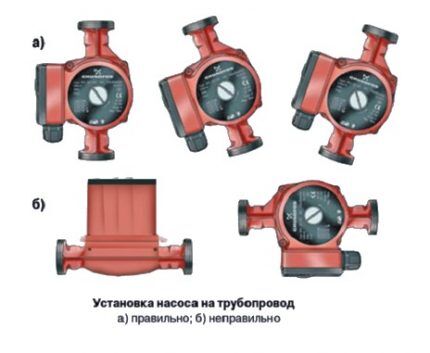

Pump installation diagram

To perform its functions, household circulation equipment, regardless of the manufacturer, must be installed correctly on a pipe or shut-off and control valves.

Fastening is done using union nuts. This fixation option will allow you to remove it if necessary, for example, for inspection or repair.

Correct installation of all elements of the heating system ensures uniform heating of the entire line.

When installing the circulation pump, the following rules must be observed:

- It is allowed to install the device on any section of the pipe. The pipeline can be located horizontally, vertically or inclined. However, the rotor axis must be in a horizontal position.Therefore, installation “head down” or, conversely, up is impossible.

- It is worth paying close attention to the location of the plastic box where the power supply contacts are located - they will be on top of the body. Otherwise, they may be flooded with water in an emergency. To do this, you will need to unscrew the fastening screws on the casing and turn it in the required direction.

- Observe the direction of flow. It is indicated by an arrow on the device body.

With all its weight, the pump presses on the body of the ball valves located nearby. This should be taken into account when choosing fittings. High-quality parts are equipped with a powerful body, which during operation will not become cracked from daily stress.

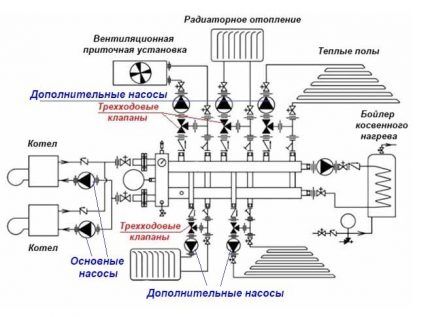

Installation of additional equipment

Regardless of the type of heating circuit used, where one boiler serves as the heat producer, it will be sufficient to install a single pumping device.

If the design of the system is more complex, it is possible to use additional devices that provide forced circulation of liquid.

This becomes necessary in the following cases:

- when heating a house, more than one boiler unit is involved;

- if there is a buffer capacity in the piping scheme;

- the heating system diverges into several branches, for example, servicing an indirect boiler, several floors, etc.;

- when using a hydraulic separator;

- when the pipeline length is more than 80 meters;

- when organizing water movement in floor heating circuits.

To perform the correct piping of several boilers operating on different fuels, there is a need to install backup pumps.

For a circuit with heat accumulator It is also necessary to install an additional circulation pump. In this case, the main line consists of two circuits - heating and boiler.

A more complex heating scheme is implemented in large houses with 2-3 floors. Due to the branching of the system into several lines, 2 or more pumps are used to pump the coolant.

They are responsible for supplying coolant to each floor to various heating devices.

If you plan to install heated floors in the house, then it is advisable to install two circulation pumps.

In the complex, the pumping and mixing unit is responsible for preparing the coolant, i.e. maintaining the temperature at 30-40 °C.

In some cases, the installation of pumping units is not required at all. Many models of wall-mounted electric and gas generators already have built-in circulation devices.

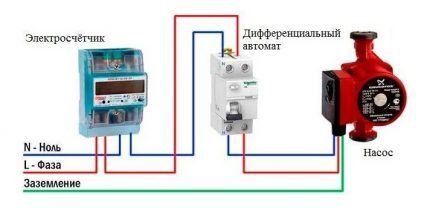

Rules for connecting to power supply

The circulation pump is powered. The connection is standard. It is recommended to install a separate power supply line with a surge protector.

To connect, you need to prepare 3 wires - phase, neutral and ground.

You can choose any of the connection methods:

- via device differential machine;

- connection to the network together with an uninterruptible power supply;

- power supply to the pump from the boiler automation system;

- with thermostat regulation.

Many people wonder why complicate things, because connecting the pump can be done by connecting a plug to a wire. This is how the pumping device is plugged into a regular outlet.

However, experts do not recommend using this method due to the risk of unforeseen situations: there is no grounding and a safety device.

The first option is not difficult to assemble yourself. It is necessary to install an 8 A differential circuit breaker. The wire cross-section is selected based on the device rating.

In the standard scheme, the power supply is carried out to the upper sockets - they are marked with odd numbers, the load - to the lower ones (even numbers). Both phase and neutral will be connected to the machine, so the connectors for the latter are designated by the letter N.

To automate the process of stopping the circulation of the coolant when cooling to a certain temperature, an electrical circuit is used to connect the pump and thermostat. The second is mounted in the supply line.

At the moment when the water temperature drops to the specified value, the device disconnects the electrical supply circuit.

There are no difficulties in supplying electricity through an uninterruptible power supply; it has special connectors for this.A heat generator is also connected to them when there is a need to provide electricity.

If you choose the method of connecting the pump to the boiler control panel or automation, you will need good knowledge of the power supply system or the help of a professional.

Conclusions and useful video on the topic

Rules for installing heating equipment in the video:

The video explains the features of a two-pipe heating system and demonstrates different installation schemes for devices:

Features of connecting a heat accumulator to a heating system in the video:

If you know all the connection rules, there will be no difficulties with installing the circulation pump, as well as when connecting it to the power supply at home.

The most difficult task is inserting a pumping device into a steel pipeline. However, using a set of guides for creating threads on pipes, you can independently arrange the pumping unit.

Would you like to supplement the information presented in the article with recommendations from personal experience? Or maybe you saw inaccuracies or errors in the material reviewed? Please write to us about this in the comments block.

Or have you successfully installed a pump and want to share your success with other users? Tell us about it, add a photo of your pump - your experience will be useful to many readers.

We always have problems with heating in winter, either the pipes were installed incorrectly, or there was simply a weak supply, so we decided to invest and install this pump. We put it in the bathroom instead of one of the batteries, it’s not far from the outlet. The pipes became noticeably hot; at first the pump worked at the highest setting, but then they set it to medium.It doesn’t “eat” a lot of electricity, the main thing is that it’s silent, but it’s forbidden to do that here, and I don’t want to live at 15 degrees either.

I can't find the order to turn on the pump. Does it turn on with the boiler or only after heating the water in the boiler to a certain temperature?