Expansion tank for open type heating: device, purpose, main types + tips for calculating the tank

In today's realities, an open-type expansion tank for heating has long and irrevocably lost the competition of a more modern and efficient closed tank.

Nevertheless, obsolete equipment is actively used. And in a number of situations it even has some advantages over technologically advanced membrane tanks.

In this material we will analyze its purpose and design features, and also get acquainted with the operating principle and rules for calculating this type of tank.

The content of the article:

Purpose of the tank in open systems

This device is used in heating systems to prevent breakdowns when the volume and pressure of the coolant increases, which occurs when heated.

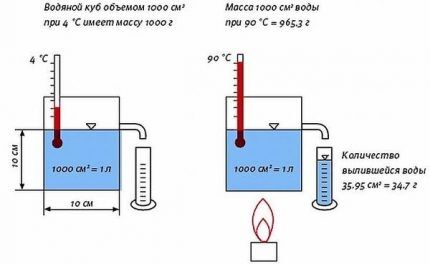

To be precise, when the temperature of the water circulating in the system increases from 5 to 100 °C, its volume becomes 4% larger. And this is a lot, since there is nowhere for it to go in the pipes and radiators - there is no free space there.

As a result, a few hundred grams in a small heating system or several liters in a fairly large one increases the pressure to critical values and leads to the occurrence of powerful water hammer.

Which entails squeezing out gaskets, breaking fittings, radiators and costly repairs - all this at the most inopportune moment.

And after the temperature of the coolant decreases, its excess again becomes necessary for the effective functioning of the system, so it must be returned, and in full. In case of evaporation, liquid reserves must be replenished.

Characteristics of an open tank

Such tanks are extremely simple - an ordinary bucket, a specially made container from scrap materials, a canister, or something similar can always be used as an expansion tank.

Design features of the container

The main design requirements are:

- availability of sufficient volume;

- lack of tightness.

That is, even the absence of a cover is allowed, although it is desirable - it protects against dirt particles getting into the heating system.

The tank, which is planned to be used as an expansion tank, must be equipped with a pipe to which pipe from the heating system. This is the only required device.

But for comfort and to avoid minor troubles, it is advisable to use the following accessories:

- Overflow hose or pipe - such a design element is necessary in case of overflow of the expansion tank. That is, this structural element, by discharging liquid into the sewer or simply outside the building, eliminates the possibility of its flooding.

- Water supply pipe — it is necessary to replenish the heating system with water. It is quite possible to do without it, but you should understand that this procedure will have to be carried out with a bucket in your hands. Although in the latter case the design will be cheaper.

Since expansion tanks are often installed in attics, care should be taken to insulate them. This will prevent the liquid from freezing and causing the entire system to fail.

Only ordinary water can be used as a coolant. Because modern effective antifreezes evaporate quickly in open tanks. This leads to a significant increase in the cost of the entire heating procedure.

In addition, antifreeze fumes are almost always toxic, which affects the health of residents. We talked more about the types of coolants for the heating system and their features in this material.

Shape and material of manufacture

The shape of the tank is not fundamentally important, so it can be anything:

- round;

- rectangular;

- trapezoidal, etc.

The manufacturing material can be any metal or even plastic, but since the coolant can heat up to significant temperatures, it must be heat-resistant.

There are various options for open expansion tanks on sale, among which it is easy to choose the most suitable one. Or make a homemade tank from scrap materials, which will act as an expansion tank.

Operating principle of the device

The expansion tank is part of the simplest heating systems that work according to the laws of physics. When liquid moves through pipes and radiators by gravity, the energy for this is provided by the pressure difference.

In order not to disrupt the natural heat exchange and water circulation, the expansion tank should be installed at the highest point of the entire heating system, while the boiler should be the lowest. We talked in more detail about installing and connecting the tank in this article.

Otherwise, the presence of a tank will not give the desired effect. This will not protect against increased pressure, water hammer and subsequent breakdowns.

When the coolant is cold, the tank itself does not take any part in the operation of the heating system.

Everything changes when the liquid heats up to significant temperatures and creates excess pressure in pipes and radiators, since in such situations its excess is actively created and squeezed into the expansion tank. Where it remains until the coolant cools down, after which it again flows by gravity into the pipes and radiators, the boiler.

The described procedure is performed cyclically, that is, throughout the entire period of operation of the tank.

Due to the fact that the heating system is open, like the tank itself, compensation for the consequences of expansion cannot be carried out without human intervention.

The reason is that the coolant, being in direct contact with the air, evaporates, and the more it heats up, the more active this procedure occurs.

As a result, the user has to regularly monitor the available water level. And top it up as needed.

The specified operation is performed using a bucket or other container with water. This is unpleasant, so the system can be automated by organizing the supply of water from a water supply system, from any one: local or centralized.

In addition, using additional equipment, the described procedure can be made completely autonomous.

But in this case, the most important advantages of all open tanks and heating systems are lost:

- cheapness;

- complete autonomy, that is, independence from the performance, serviceability and presence of any engineering systems in the room.

All processes in an open tank occur according to the natural cycle, without the help of pumps and other equipment.

As a result, in order for the expansion tank to be guaranteed to be useful, the dimensions of the system itself must be moderate, that is, it should not be used for heating cottages and buildings whose area exceeds 100 m².

If this rule is ignored, this can lead to significant financial losses, since a number of alterations will have to be made to ensure the efficiency of the tank and the entire system as a whole.

In addition, height should be limited. Since it is very problematic to achieve the expected result when trying to heat more than a two-story building in this way.

How to make a calculation?

As mentioned above, any expansion tank used for open heating is characterized by simplicity of design and manufacture. And calculating the dimensions of such a product is no more complicated.

For this purpose, you can use formulas or a method that involves approximate calculation of the working volume of the tank.

In reality, to determine the required capacity of the tank, the owners of a small country house use formulas extremely rarely. Most often, the approximate volume of the expansion tank is calculated, to which any number of liters can be added for insurance.

Reason: in the case of open tanks, the extra volume does not significantly affect the cost, and in some cases does not lead to an increase in price at all.

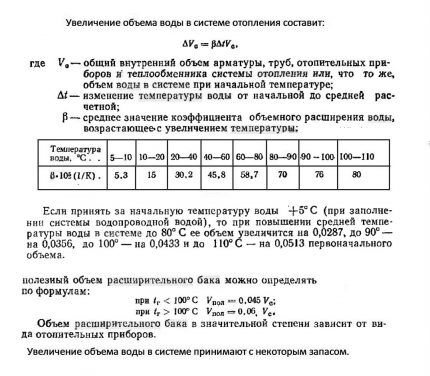

As a result, the entire calculation of capacity comes down to determining 10% of the volume of the entire coolant, which should be its minimum value for the expansion tank.

The easiest way to do this is at the time of designing and creating a heating system, when all the parameters of radiators, pipes and other structural elements are known or can be easily found out by taking measurements. And then simply adding up the volumes of all components.

If the source data is unknown, then the most practical method of calculation is experimental. Why do you need to drain all the water from the system, and then fill it with coolant on a new one.

In this case, measurements must be made, which can be done using a meter or using containers of known volume.After that, all that remains is to find out the required 10% of the coolant volume, which serves as a guideline when making or purchasing a tank.

Conclusions and useful video on the topic

The video below will allow you to better understand what open expansion tanks are, how they are manufactured and installed:

The following video is about homemade tanks for the heating system:

An open expansion tank is considered an obsolete device, as is the entire type of heating system in which it is used. That is, such equipment is ineffective, since its operation is accompanied by significant heat loss, and heating is extremely slow.

Nevertheless, complete autonomy, independence, ease of maintenance, and affordable cost make the open tank in demand far from the stable conditions of large cities - in dachas, villages, etc..

Do you still have questions about calculating the tank or do you want to clarify other points that we did not mention in this article? Ask about the nuances that interest you, ask your questions in the block below - our experts and other site visitors will help you figure it out.

If you have recently been involved in the manufacture or installation of an open-type tank, tell us about it in the comments block - many beginners will find your information useful. Also add unique photos of your expansion tank.

I have an open system, no radiators, just a sloped pipe. I would like to put a bypass with a return pump! Question with the expansion tank, does it need to be replaced with a closed type tank? Can't I keep the old one?

You are a complete idiot, you couldn’t even steal content, because to do this you need to have at least the rudiments of intelligence.