Gas heat generators for air heating: types and specifics of gas equipment

Agree that heating a large room using a mini-boiler room is very problematic and expensive. An excellent solution would be gas heat generators for air heating.These are boilers that use gas burning in a chamber as energy to heat the coolant.

The power of the unit allows you to heat a building with an area of up to 70 sq.m. in 10-15 minutes without wiring and batteries. The equipment does not have the disadvantages inherent in traditional coolants: heat loss during transportation, inertia, difficulties in adjustment, the possibility of leaks, regular repairs.

In this article we will look at the design of gas-fired thermal energy generators. We will analyze their advantages and disadvantages, and also help you choose the best heating device. Taking into account our recommendations, you will easily find a suitable unit.

The content of the article:

Design features of gas heat generators

Air heating is most effective in exhibition halls, production facilities, film studios, car washes, poultry farms, workshops, large private homes, etc.

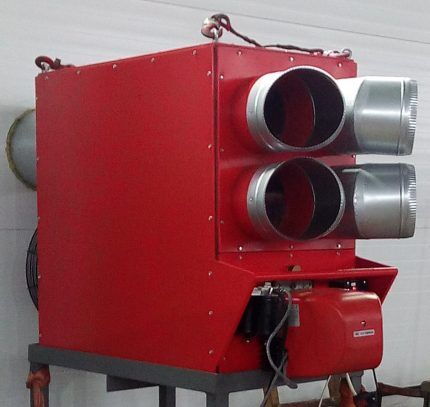

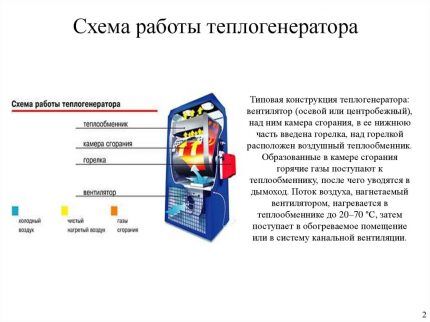

Standard gas heat generator for operation air heating consists of several parts that interact with each other:

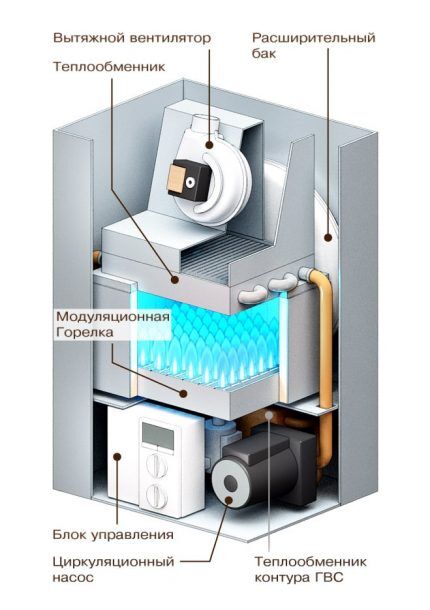

- Frame. All components of the generator are hidden in it. In its lower part there is an inlet opening, and at the top there is a nozzle for already heated air.

- The combustion chamber. This is where fuel is burned, causing the coolant to heat up. It is located above the supply fan.

- Burner. The device supplies compressed oxygen to the combustion chamber.Thanks to this, the combustion process is supported.

- Fan. It distributes heated air throughout the room. It is located behind the inlet grille in the lower part of the housing.

- Metal heat exchanger. A compartment from which heated air is supplied to the outside. It is located above the combustion chamber.

- Hoods and filters. Limit the entry of flammable gases into the room.

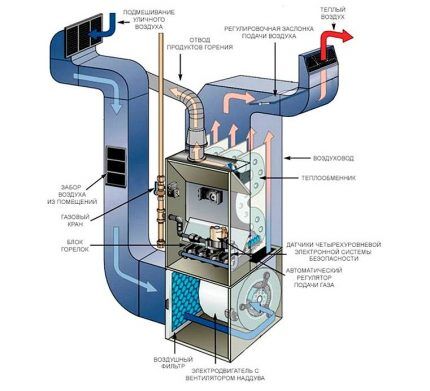

Air is supplied to the housing via a fan. Vacuum is generated in the area of the supply grille.

The pressure is concentrated opposite the combustion chamber. By oxidizing liquefied or natural gas, the burner generates heat.

The energy from the combustion gas is absorbed by a metal heat exchanger. As a result, air circulation in the case becomes more difficult, its speed is lost, but the temperature rises.

Without a heat exchanger, most of the energy from the combustion gas would be wasted and the burner efficiency would be lower.

Such heat exchange heats the air to 40-60°C, after which it is supplied to the room through a nozzle or socket, which is provided in the upper part of the housing.

The environmental friendliness of the equipment, as well as its safety, make it possible to use heat generators in everyday life. Another advantage is that there is no liquid moving through the pipes to convectors (batteries). The heat generated warms the air, not the water.Thanks to this, the efficiency of the device reaches 95%.

How does the heating system work?

The fan blades capture air and direct it to the heat exchanger. The air flow heated by it circulates throughout the building, performing several cycles.

During the operation of the equipment, there is no need to fear that a pipe will burst and you will flood your neighbors, as often happens with water heating systems. However, the heat-generating device itself contains sensors that, in emergency situations (threat of breakdown), stop the fuel supply.

Heated air is supplied to the room in several ways:

- Ductless. Warm air flows freely into the space being processed. During circulation, it replaces the cold one, which allows you to maintain the temperature regime. The use of this type of heating is advisable in small rooms.

- Duct. Through a system of interconnected air ducts, heated air moves through the air ducts, making it possible to heat several rooms at the same time. Used for heating large buildings with separate rooms.

The movement of the air mass is stimulated by a fan or gravity. The heat generator can be installed indoors and outdoors.

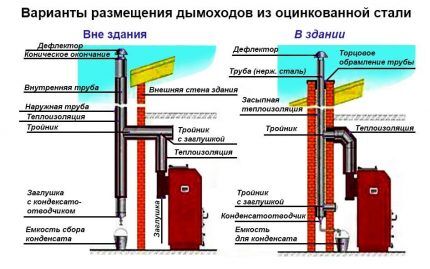

In order for the heating system to function correctly, the chimney must be correctly connected to the gas thermal energy generator.

If the smoke duct is installed incorrectly, it will become more likely to become clogged with soot build-up. A narrowed and clogged chimney will poorly remove toxic substances.

Advantages and disadvantages of equipment

The popularity of gas heat generators is associated with a number of advantages:

- gas is the most accessible and inexpensive type of fuel;

- the device does not heat the coolant, but the air, which makes it economical and safe;

- Efficiency is 95%, which allows you to heat a large room within an hour;

- thanks to the air duct system, you can independently regulate the volume of the heated area;

- ability to move the device;

- all processes are automated, as a result of which any user can control the system and manage its operation;

- the device is also used for ventilation and air conditioning of the building;

- in some models you can change burners for liquefied and natural gas;

- there is no need to install a pipe system and install heating radiators, as a result, the cost of the system is reduced;

- the heat generator can be installed outside the heated building;

- simplicity and speed of installation.

Some consumers are put off by the high cost of the equipment, but the system pays for itself within one year.

Minor disadvantages are also the need to obtain permits for connecting gas equipment and installing a chimney.

Types of gas heat generators

In comparison with diesel, solid fuel and universal heat generators, gas equipment for air heating is the most popular.

Devices are differentiated by size and weight:

- mobile - easy to transport;

- stationary - installed in one place.

Mobile models of gas heat generators are less popular, since their operation requires gas cylinders filled with liquefied mixtures of propane and butane. The most prominent representative of portable heating equipment is heat gun.

Most often, heat guns are used for a one-time increase in temperature at construction sites and in shopping malls. In everyday life it is used in extreme cases (turning off the heating in the house).

Stationary models of gas heat generators can be:

- wall-hung - hung on brackets built into the walls;

- floor - installed on the floor.

Wall-mounted models are used for heating small objects; their power usually does not exceed 35 kW. Floor-standing equipment is recommended for heating small areas. A number of floor-standing units include models that can be installed outside the building, i.e. on the street.

Depending on the distribution of heated oxygen and the method of gas combustion, the equipment is divided into:

- horizontal;

- vertical.

For rooms with high ceilings, vertical devices are used, and for rooms with low ceilings, horizontal devices are used.

How to choose a heat generator?

When choosing heating equipment, you need to take into account a lot of details. First of all, it is important to assess the area of the heated room. The larger the building, the more powerful the heat generator should be.

The heat capacity of a building is calculated using the formula:

р=V·ΔT·k/860

p is the desired heat capacity;

V - heated area (the height, length and width of the room are multiplied);

ΔT is the difference in temperature in the building and outside it;

K - thermal insulation (indicators of the material with which the building is insulated).

Indicators of the most commonly used materials:

- double layer of brick - 1-1.9 W/m°C;

- single layer of brick - 2-2.9 W/m°C;

- wooden panels or corrugated sheets - 3-4 W/m°C;

- modern heat and waterproofing - 0.6-0.9 W/m°C.

The indicator for the number of kilocalories in kilowatts is 860. Generally accepted standards - for 1 kW of heat generator power, 30 cubic meters of forced air are required.

Knowing the value of heat capacity, you can select equipment that can heat the entire area of the room.

Nuances when choosing a heat generator

Before purchasing heating equipment, you must:

- arrange a chimney to release toxic gases;

- think over a system of ventilation ducts for circulating heated air;

- Using the formula, calculate the power of the device.

Having completed all these steps, you can safely go shopping.

To select a high-quality gas heat generator model, you need to pay attention to the following nuances:

- type and design of the burner - relevant if a fuel change may be required;

- warranty card and technical passport - a guarantee of the purchase of original (not defective) equipment;

- high-quality components - such equipment is more expensive, but its service life is much longer.

Taking these factors into account, the selected heat generator will last for many years.

Tips for choosing reliable equipment

By following simple recommendations you can avoid purchasing low-quality goods:

- It is better to make purchases at certified points of sale. Often, at wholesale stores and on the Internet, defective products are sold under the guise of high-quality equipment. The trap is the price halved.

- If it is not possible or you did not have time to calculate the required power of the device, then the consultants in the store will do this for you. To do this, you only need to know the area of the house, the height of the ceilings and the thickness of the walls. After making calculations, specialists will offer the optimal model for your home.

- It is recommended to purchase brands that have positive reviews on the Internet. You can also find out in advance how the equipment behaves during operation and other features.

For home use, the ideal option would be models such as Airmax D 28, Titan 25 (30, 35), Fuela, TG-7.5, Dragon 12.

Requirements for installation

To connect a gas heat generator for air heating at home, you need to carry out preparatory work and purchase:

- flexible air duct, which is a galvanized tube for circulating heated air;

- tees are needed to create an air line and connect pipes;

- for taking in cold air and supplying hot air - a grille;

- to seal the line connections - aluminum tape;

- mounting fasteners;

- knife.

You should first take care of the air duct.

The ideal option is to design airways - channels at the construction stage of the building.

To install heating in a finished house, you need to erect false walls and suspended ceilings. Pipes will be disguised in the resulting niches.

Conclusions and useful video on the topic

The following video will provide additional information on the topic:

Gas heat generators for heating systems are a highly efficient and economically feasible solution. Due to safety, reliability and ease of operation, the equipment can be used in residential buildings and industrial facilities.

If a gas heat generator is installed in your home, you have additional information about the advantages and disadvantages of the equipment, or you know which generator is best to purchase for heating a private home, share your experience and knowledge with readers in the comments.