Pressure in the expansion tank of a gas boiler: norms + how to pump and adjust

A single-circuit or double-circuit gas boiler is equipment that makes our life in a house or apartment more comfortable.Manufacturers now produce a huge range of gas appliances, differing in power, functionality, and installation method. However, even the most expensive and reliable models can fail. Agree, it’s not very pleasant to be left on a winter evening without heat and hot water.

Having analyzed the possible causes of breakdowns of gas equipment, we came to the conclusion that most often malfunctions occur due to the fact that the pressure in the expansion tank of a gas boiler or water heater is incorrectly adjusted. In this article we will figure out why an expansion tank is needed, how to pump air into it yourself and set the optimal pressure.

The content of the article:

Why is an expansion tank needed?

When heated, water tends to expand—as the temperature rises, the volume of the liquid increases. Pressure begins to increase in the heating system circuit, which can have a destructive effect on gas equipment and the integrity of the pipes.

The expansion tank (expanzomat) serves as an additional reservoir into which excess water formed as a result of heating is pressed out. When the liquid cools and the pressure stabilizes, it returns through the pipes back into the system.

The expansion tank acts as a protective buffer; it extinguishes water hammer, which are constantly formed in the heating system due to frequent turning on and off of the pump, and also eliminates the possibility of air locks.

There are two different types of damper tanks: open and closed types. They differ not only in design, but also in the method and location of installation. Let's look at the features of each of these types in more detail.

Open expansion tank

An open type tank is mounted at the top point of the heating system. The containers are made of steel. Most often they have a rectangular or cylindrical shape.

The structure of the open-type tank has several outlets: for water inlet, cooled liquid outlet, control pipe inlet, and also an outlet pipe for coolant discharge into the sewer. We wrote more about the structure and types of an open tank in our other article.

Open tank functions:

- controls the coolant level in the heating circuit;

- if the temperature in the system has decreased, it compensates for the volume of coolant;

- when the pressure in the system changes, the tank acts as a buffer zone;

- removes excess coolant from the system into the sewer system;

- removes air from the circuit.

Despite the functionality of open expansion tanks, they are practically not used anymore.Since they have many disadvantages, for example, the large size of the container, the tendency to corrosion. They are installed in heating systems that operate only with natural water circulation.

Closed expansion chamber

In closed-circuit heating systems, a membrane-type expansion tank is usually installed; it is optimally suited for any type of gas boiler and has many advantages.

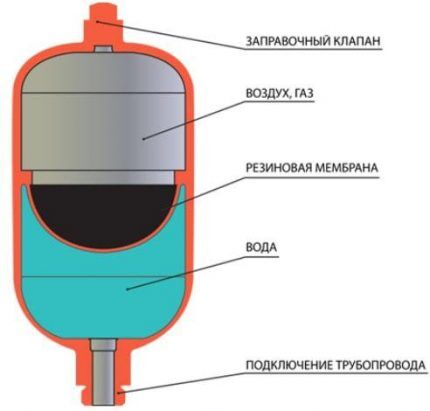

An expansomat is a hermetic container, which is divided in the middle by an elastic membrane. The first half will contain excess water, and the second half will contain regular air or nitrogen.

Compensation tanks with a membrane can be produced in the form of a hemisphere or in the form of a cylinder. Which is quite suitable for use in a heating system with a gas boiler. We recommend that you read in more detail installation features closed tanks.

Advantages of membrane types of tanks:

- ease of self-installation;

- corrosion resistance;

- work without regular addition of coolant;

- lack of contact of water with air;

- performance under high load conditions;

- tightness.

Gas attachments are usually equipped with an expansion tank. But the additional tank is not always configured correctly from the factory and can immediately start heating.

Air pressure in the expansion tank

The air or nitrogen pressure in the expansion tank will not be the same for different gas boilers; it all depends on the type of equipment and design features. The standards are indicated by the manufacturer in the product passport.

Typically, the pressure in a new damper tank is 1.5 atm. But this setting may not be suitable for a specific heating system. Factory settings are easy to reset. For these purposes, there is a special fitting in the expansion tank housing (for some manufacturers this is a spool valve for pumping), through which the air pressure is adjusted.

For the normal functioning of a gas boiler, it is necessary that the pressure in the membrane tank be 0.2 atm less than in the system itself. Otherwise, the heated water that has increased in volume will not be able to enter the container.

In small houses and apartments for closed heating systems, the pressure in the expansion tank is usually acceptable in the range of 0.8-1.0 bar (atm). But not less than 0.7 bar, since many gas boilers have protection and the device simply will not turn on.

The tank pressure level should be checked annually. If jumps are noticed heating system pressure, this means that air has come out of the damper tank and needs to be pumped up.

How to set the optimal pressure?

The heating system has pressure gauges that control the pressure in the circuit. On the expansion tank itself there is no fitting for installing a measuring device. But there is a nipple or spool for releasing and pumping air or gas. The nipple is the same as on car wheels.Therefore, you can check the pressure level and adjust it using a conventional car pump with a pressure gauge.

Before releasing excess pressure or pumping air into the expansion tank of a domestic gas boiler, it is necessary to prepare the system. The car pressure gauge shows the value in MPa; the data obtained must be converted into atmospheres or bars: 1 Bar (1 atm) = 0.1 MPa.

Pressure measurement algorithm:

- Turn off the gas boiler. Wait until water stops circulating through the system.

- In the area with the hydraulic tank, close all shut-off valves and drain the coolant through the drain fitting. For boilers with a built-in tank, the return flow is shut off, as well as the water supply.

- Connect the pump to the tank nipple.

- Pump up the air to 1.5 atm. Wait a little for the remaining water to pour out, then let the air in again.

- Close the valves of the shut-off valves and use a compressor to pump up the pressure to the parameters specified in the passport or to the level - pressure in the system minus 0.2 atm. If the tank is pumped, excess air is released.

- Remove the pump from the nipple, screw on the cap and close the drain fitting. Fill the system with water.

You can check the correct air pressure adjustment when the boiler reaches operating parameters.

If the air pressure in the expansion tank is incorrectly adjusted, the entire heating system may malfunction. If the expansion tank is over-inflated, the compensating properties will not work.Because the air will push excess heated water out of the tank, increasing the pressure in the pipes of the heating system.

And with underestimated pressure readings of the compensating tank, water will simply push through the membrane and fill the entire tank. As a result, when the coolant temperature rises, the safety valve will operate.

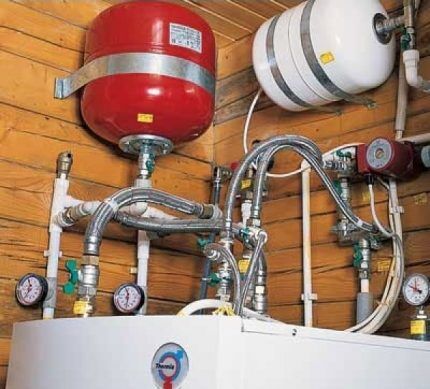

Sometimes in double-circuit gas boilers, fuses work even if the pressure of the built-in expansion tank is correctly adjusted. This indicates that the tank volume is too small for such a heating system. In this situation, it is recommended to install an additional hydraulic tank.

Purpose of an additional tank of a double-circuit boiler

As a rule, built-in compensation tanks in gas boilers have a volume of about 6-8 liters. They are designed to compensate for the expansion of 120 liters of coolant circulating in the heating system. Under normal operating conditions, such an expansion tank is enough for a small apartment or house.

If the heating area is large, install warm floor or there are many radiators in the rooms, the volume of the standard built-in tank will be small, since more water is used.

When heated, excess coolant completely fills the tank. And since there is no free space left in the tank, the water pressure increases in the heating system itself and an emergency discharge occurs safety valve. After this, it is unlikely that the gas boiler will be able to start working automatically.

To avoid such negative consequences, an additional expansion tank with a membrane is installed in the heating system in a design for a double-circuit gas boiler. When the standard tank is completely filled, the water goes into the reserve hydraulic tank. After cooling, the liquid returns to the radiators.

Calculation of expansion tank volume

It is not difficult to ensure stable operation of the heating system; the main thing is to correctly select the volume of the compensation tank. The volume of the expansion tank should be calculated taking into account the most intensive operating mode of the gas boiler. When heating is first started, the air temperature is not yet very low, so the equipment will operate at an average load. With the arrival of frost, the water warms up more and its quantity increases, requiring more additional space.

You can independently calculate the exact capacity of the expansion tank. To do this, first determine the amount of coolant in the entire heating system.

Methods for calculating the volume of water in the heating system:

- Completely drain the coolant from the pipes into buckets or other containers so that the displacement can be calculated.

- Pour water into the pipes through the water meter.

- The volumes are summed up: the capacity of the boiler, the amount of liquid in the radiators and pipes.

- Calculation based on boiler power - the power of the installed boiler is multiplied by 15. That is, for a 25 kW boiler you will need 375 liters of water (25 * 15).

After the amount of coolant has been calculated (example: 25 kW * 15 = 375 liters of water), the volume of the expansion tank is calculated.

The calculation methods are quite complex. For one-story houses, use the following formula:

Expansion tank volume = (V*E)/D,

Where

- D – tank efficiency indicator;

- E – liquid expansion coefficient (for water – 0.0359);

- V – the amount of water in the system.

The tank efficiency indicator is obtained using the formula:

D = (Pmax—Ps)/(Pmax +1),

Where

- PS=0.5 bar is an indicator of the charging pressure of the expansion tank;

- Pmax — maximum pressure of the heating system, on average 2.5 bar.

- D = (2,5-0,5)/(2,5 +1)=0,57.

For a system with a boiler power of 25 kW, an expansion tank with a volume of: (375*0.0359)/0.57=23.61 l will be required.

And although a double-circuit gas boiler already has a built-in 6-8 liter tank, looking at the calculation results, we understand that stable operation of the heating system will not be possible without installing an additional expansion tank.

Conclusions and useful video on the topic

You can learn how to independently calculate the volume of the hydraulic tank and adjust its pressure by watching the videos below.

An easy way to determine the volume of the expansion tank:

Instructions for self-adjusting the pressure level in the expansion tank:

Gas boilers must be equipped with expansion tanks. They “absorb” excess coolant resulting from heating and prevent the formation of air pockets. In double-circuit types of equipment, such devices are installed, but often their volume is insufficient for trouble-free operation of the heating.

Compensation tanks should be selected based on the pressure and volume of coolant in the system. It is important to configure the tank correctly, otherwise it will not be able to ensure uninterrupted and stable operation of the gas boiler.

Do you still have questions about pumping and adjusting the pressure in the expansion tank? Ask it in the comments block - our experts and other site visitors will try to help you.

When the boiler is turned on, the pressure rises from 1 to 1.5 and after it is turned off it drops to 0.8. This is an air lock or something.

Could there be popping noises due to improper air pressure in the expansion tank?

I think you are wrong.

I have a leopard 24 protherm boiler. The instructions clearly state that the pressure in the chamber should be 0.2 atm higher. Can you explain your point of view to me, but not in general phrases, but in something specific.

boiler master gas seoul why when you switch the temperature to 70 degrees the pressure increases, you set the temperature to 40-50, it immediately starts to drop to 0 until you add water, the added water lasts for 2 hours, and again you have to add water. What reasons?

If the air pressure is higher than the heater, then water simply cannot get into the heater; there the error should be no higher than 0.2

Good afternoon I don’t really understand the phrase “the pressure in the expansion tank should be 0.2 lower than in the system.” How is that? Why then is this tank needed? If the pressure in it is lower, it will simply be filled with coolant and that’s it. And it will not perform any functions!