Heat-resistant paints for metal up to 1000 degrees: ten leading heat-resistant products

To protect radiators, pipes, metal stoves and other elements of the heating circuit from initial manifestations of corrosion and further active rusting, it is necessary to apply and renew the coating. For this purpose, heat-resistant paint for metal up to 1000 degrees is used. It's not easy to choose. Do you agree?

In addition to protective functions, it also has purely aesthetic responsibilities. The use of a heat-resistant composition will also help give a new look to the products, which will help improve the appearance and condition of the equipment. We will introduce you to the ten best thermal paint offers, proven by practical use.

The content of the article:

Rating of the best thermal paints

The list below contains compounds that can easily be found in hardware or specialty stores.

All of them, according to user reviews, are of good quality.

1st place – Alpina Heizkoerper

The paint produced by the German DAW group is made on the basis of alkyd resin with the addition of titanium dioxide. The product is of good quality - it fits tightly, and the resulting coating is scratch-resistant. The price is quite high, but you need a little of this paint due to its insignificant consumption.

Main parameters:

- color: white (with the possibility of tinting);

- gloss type: glossy;

- permissible surface temperature (0C): 100;

- type of packaging and volume (l): can (0.75, 2.5);

- country of origin: Germany.

The main purpose is to process elements water heating system. The possibility of tinting allows you to create an original color scheme and diversify the interior of the room.

The short-term temperature of the painted object can reach 1800C. Paint can be applied by brush, roller or spray gun to steel, cast iron, aluminum, copper and other metals. Consumption ranges from 90 to 120 ml/m2.

2nd place – Elcon

After the tinting process, Elcon products are available in 250 shades. But pigmentation reduces the maximum temperature that paint can withstand. Thus, classic black enamel retains its properties up to 10000C, copper – up to 7000C, and blue – only up to 6000C.

Main parameters:

- color: black, graphite, gold, copper, etc.;

- gloss type: matte or semi-gloss;

- Maximum temperature (0C): 1000 (black), 700 (graphite, gold, copper);

- type of packaging and volume (l): can (0.52), jar (0.8), bucket (25);

- country of origin: Russia.

The presence of a large number of color solutions allows the use of Elcon enamels for complex interior designs. With its help you can create simple patterns using stencils.

In addition to painting metal products, this enamel can protect other types of surfaces - concrete, asbestos or brick. After application and drying, it is necessary to perform a thermal hardening procedure.

3rd place – Tikkurila Termal Silikonimaali

Silicone resin paint from the Finnish company Tikkurila is used to coat metal surfaces.

Main parameters:

- black color;

- gloss type: semi-matte;

- Maximum temperature (0C): 400;

- type of packaging and volume (l): can (0.1, 0.33);

- Country of origin: Finland / Russia.

One liter of paint is enough for a single-layer treatment of 16-20 m2 surface depending on its roughness. The fine structure of the solution allows you to use the sprayer without the risk of frequent clogging of its nozzle.

The quality of the products is very good, but the price is also high - this is due to the promotion of the brand. The disadvantages include the need for thermal hardening, which must be carried out for 1 hour at a temperature of 2300C.

4th place – Bosny Hi-Temp

This heat-resistant paint from a famous British brand is produced in Thailand. It is distinguished by its volume, which is atypical for Russia, and is characterized by good quality and a slightly high price.

Main parameters:

- color: silver, black;

- gloss type: matte;

- Maximum temperature (0C): 650;

- type of packaging and volume (l): can (0.4);

- Country of origin: Thailand.

Made on the basis of alkyd resins, this thermal paint can be used not only for metal, but also for wood, plastic, ceramics and other materials. It adheres well to untreated surfaces, including rusty ones.

5th place – Tikkurila Termal Silikonialumiinimaali

Tikkurila Thermal paint (silicon-aluminum) from a well-known Finnish manufacturer is distinguished by its excellent quality and high price due to the popularity of the brand.

Main parameters:

- color: aluminum;

- gloss type: semi-gloss;

- Maximum temperature (0C): 600;

- type of packaging and volume (l): jar (0.33);

- Country of origin: Finland / Russia.

Heat-resistant paint based on silicone resin, aluminum color with a slight metallic sheen. Its consumption (for one layer) depends on the type of surface to be painted and is 16 m2/l for rough and 20 m2/l for smooth areas, which is a very good indicator.

To harden the paint, it is necessary to heat the surface to a temperature of 2300C. One month after application, you can clean the painted surface with mild detergents.

6th place – Bosny Hi-Temp (color)

Acrylic-based paint with silicone pigmentation from Bosny has a lower permissible temperature than black or silver. It is characterized by good quality at an average price for products of this class.

Main parameters:

- color: red, orange, yellow, green, blue;

- gloss type: matte;

- Maximum temperature (0C): 205;

- type of packaging and volume (l): can (0.4);

- Country of origin: Thailand.

The most common application is pipe painting and heating radiators. It is also used for decorative painting of car parts. It dries quickly, does not peel off, but requires thermal hardening. Thus, it is better to paint the batteries a day or two before turning them on.

One can is enough to paint 1.5-2 m2 surfaces in 2 layers. In addition to sanding, it is advisable to prime the surface. This will significantly increase its resistance to physical damage.

7th place – Veslee

Heat-resistant, high-quality metal paint on an acrylic-epoxy base is in the middle price range.

Main parameters:

- color: black, white, red, silver;

- gloss type: matte;

- Maximum temperature (0C): 400 (black), 250 (all others);

- type of packaging and volume (l): can (0.1, 0.52);

- Country of origin: China.

The composition is intended for painting heating circuit elements (excluding fireboxes) and automotive parts (mainly the exhaust system). The availability of small-volume cans for sale is a definite plus when you need to paint a surface with a small area.

The paint is quick-drying - the drying interval between layers is 2-3 minutes.

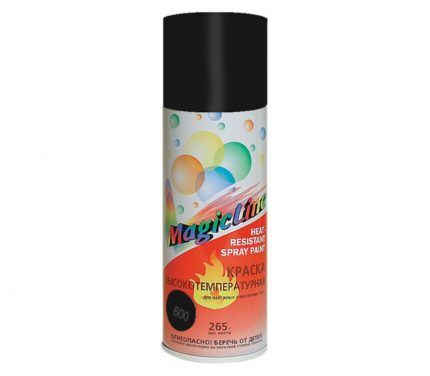

8th place – MagicLine

Spray paint made in China, based on synthetic resin, is located in the middle price range.According to consumer reviews, the temperature indicated on the label is not the maximum allowed for an indefinite period of time, but acceptable for a short-term period.

Main parameters:

- black color;

- gloss type: matte;

- Maximum temperature (0C): 600;

- type of packaging and volume (l): can (0.4);

- Country of origin: China.

Medium quality products designed for processing metal parts. Not suitable for application to high temperature objects such as the firebox door of a steel oven or hob.

9th place – Thermoxol

Russian-made paint is intended for metal surfaces. It is distinguished by good quality, four main colors, packaging of varying volumes and an average price.

Main parameters:

- color: black, white, red-brown, gray;

- gloss type: glossy;

- Maximum temperature (0C): 160;

- type of packaging and volume: jar (0.9), bucket (3, 10, 20);

- country of origin: Russia.

The paint contains formaldehyde resin and an acid thinner, so the area must be well ventilated. It can be used for processing ferrous and non-ferrous metals, as well as alloys. The composition can be applied to tightly adherent rust.

Short-term (up to 5 hours) heat resistance – 2100C. The main purpose is painting heating radiators and pipes.

10th place – Decorix

This enamel can often be found in stores and retail outlets. It has a low price and acceptable quality.

Main parameters:

- color: white, aluminum, black;

- gloss type: glossy;

- Maximum temperature (0C): 800;

- type of packaging and volume (l): can (0.52);

- Country of origin: China.

Decorix enamel is available in the three most popular colors for metal coating. The mass fraction of paint for such a volume is insignificant - only 0.315 kg (usually 0.34 - 0.36 kg).

The sprayer leg is soldered into the can, so if the composition dries out, it will not be possible to replace the mechanism. Therefore, it is better not to leave partially used paint for a long time.

Rules for selection and use

To choose the right paint, you need to determine the maximum temperature of the surface on which it will be applied. You also need to calculate the area and make a choice between a spray in a can and a liquid consistency in a jar. But there are still some rules that you need to know.

Specific nuances in terminology

Many salespeople in their advertising campaigns are very frivolous with the terminology adopted for compositions that can be applied to surfaces with high temperatures. There is no normatively established gradation according to the correspondence between the name of the composition and its maximum permissible heating temperature.

However, three established terms are usually used:

- high temperature;

- heat resistant;

- heat resistant.

High-temperature paints for metal include compositions that can withstand prolonged surface heating up to 2000C. They are used for processing radiators and heating pipes, brick stoves and fireplaces.In addition, they are suitable for automotive parts such as engine, muffler and exhaust system.

Heat-resistant compounds are used for surfaces with temperatures up to 6500C.

These paints are used for the following metal objects:

- sides and bottoms of furnaces;

- barbecues;

- pipes for exhausting combustion products;

- the junction of the water circuit pipes to the furnace or boiler.

Heat-resistant paints and enamels often contain pigments that give them color, so they can be used to create original interior design solutions.

Heat-resistant paint is designed to cover surfaces that are heated to temperatures above 6500C. First of all, these are cooking stoves and furnace fireboxes, as well as grates wood stoves and fireplaces.

Some types of thermal paint have an additional feature - fire resistance. This means that the painted surface may be in direct contact with the flame. Among household metal objects, this is relevant for the fireplace grate and the inside of the barbecue.

Theory and practice of thermal hardening

Heat-resistant paint is essentially heat-resistant enamel. To create an impermeable barrier, it is necessary to perform a thermal hardening procedure. In the process of heating the surface with the composition applied to it, polymerization of the layers occurs, after which the access of air to the painted metal is stopped.

It is after thermal hardening that neither oxygen, which causes the rusting process, nor moisture can penetrate under the enamel. Before this, the paint has only a decorative and, partially, protective function from physical impact.

Moreover, after creating an impermeable layer, the evaporation of substances contained in the paint into the room air stops. Therefore, ideally, it is necessary to wait until the specified period of complete drying, which is indicated on the label or in the instructions, and then immediately carry out the thermal hardening procedure.

Typically the temperature at which enamel polymerizes is 200-2500C. This leads to one common mistake that is often made by people who have leftovers after painting their stove.

Cannot be applied heat-resistant composition, which requires thermal hardening, on radiators and heating pipes, since the degree of their heating is insufficient to complete the process. For slightly hot objects, you need to use ordinary high-temperature paint.

Theoretically, the thermal hardening process should take place at a constant temperature for 30-60 minutes. However, in practice, such “laboratory” conditions are impossible to achieve.

That's why wood stoves, barbecues and fireplaces are not heated to full capacity and their heating is gradually increased. Typically a test run takes 1.5-2 hours. Another option is heating with an industrial hair dryer.

Conclusions and useful video on the topic

Painting the hob and firebox door. Preparatory work, applying paint with a brush and thermal hardening using a hair dryer:

How to paint cast iron radiators using a roller:

Painting a barbecue from a spray can:

Nowadays it is easy to find paint that can be applied to a metal surface heated with different intensities.The choice of product must be made taking into account the temperatures reached by the object, the appropriate application method and some other features.

It is also necessary to pay attention to the nuances and precautions specified by the manufacturer when working with the composition.

Would you like to talk about how you selected paint to renew or restore the coating of a metal sauna stove or barbecue? Tell us which option you chose and why. Please write comments in the block below, ask questions, post photos on the topic of the article.

I used heat-resistant paint from Tikkurila. I can say that the paint is normal, although, of course, it costs a lot. But, on the other hand, if you buy cheap paint, because of which you will have to repaint it later, it will turn out to be even more expensive. As they say, the miser pays twice. And Tikkurila fits well, without stains, without any other problems. Has good durability. In general, I'm pleased.

There is logic in your words, but Tikurilla is a very expensive helmet. And it would be nice if there was no alternative at all, but our Elcon copes with the task quite well, having a significantly lower cost.

Come on, “Top 10”))) Some unknown Chinese paints. Tikkurila at an astronomical price... And where is the budget KUDO? Where is the Certa where Lemax paints its boilers?