Baxi boiler error codes: what the codes on the display mean and how to fix typical faults

Baxi brand boilers are one of the best options for equipment used in arranging heating systems.Various configurations of this modern thermal equipment have been developed; accordingly, potential users are provided with fairly comfortable operating conditions.

However, like any other electronic-mechanical devices, this type of equipment is not completely immune from malfunctions. Technical documentation mentions possible failures of various types at least 99 times.

How are faulty phenomena expressed, what numbers accompany Baksi boiler errors, and how can you fix the problem at home? Let's look at this issue in our article.

The content of the article:

- Documented codes and their decoding

- Code E01 and E04 - flame control sensor

- Code E02 - thermostat-fuse against overheating

- Code E03 - traction sensor

- Codes E05-09 - control of DHW and burner flame

- Code E10 - minimum pressure switch

- Codes E12 and E13 - DGP malfunction

- Codes E21-22 and E97-99 - electrical and electronics

- Codes E25-27 and E32 - temperature defects

- Codes E35-36 and E40-43 - flame control and GDC

- Codes E50 and E62 - NTC sensor and flame control

- Code E55 - gas supply valve malfunction

- Conclusions and useful video on the topic

Documented codes and their decoding

Modern household appliances are notable for the extensive use of microcontrollers in their design. The use of these electronic elements allows you to control equipment efficiently and effectively without human involvement.

The controllers also make the monitoring function effective, organize timely detection of failures and accurately diagnose faults.

All this applies to heating equipment – household gas boilers. The electronic control system is capable of detecting malfunctions of a Baxi domestic boiler and informing the user (mechanic) about suspected errors in the operation of the equipment.

Judging by the technical documentation, it is possible to detect almost any system error with a specific number displayed on the display.

Then, using the error number issued by the system, the owner of the equipment or an invited mechanic will be able to quickly determine the location of the failure and eliminate the emergency situation.

All existing error codes for Baxi household boilers are presented in a list with at least a hundred options. To clearly describe each of them, one article is clearly not enough. Therefore, we will consider the main ones - those that are often encountered in practice.

Code E01 and E04 - flame control sensor

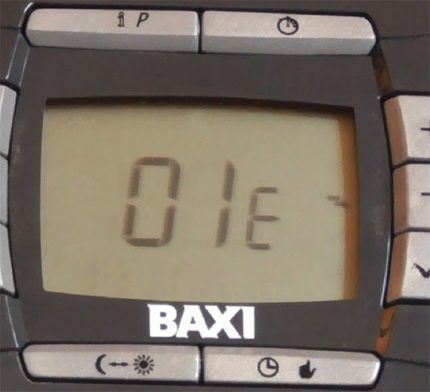

A situation typical for most models is related to the functionality of blocking the boiler ignition system. The classic error code for such cases is “E01” or “01E” (and also “E04” or “04E”), displayed on the information display.

If the design does not provide for a display, the same error is identified by the corresponding LED indicator.

Relationship between error and possible situations:

- no gas supply;

- the contact on the flame sensor is broken;

- the flame control sensor is dirty;

- malfunction of the ignition system;

- on the power line, phase and zero do not correspond;

- malfunctions of the gas tap, electronics, coaxial chimney.

Accordingly, based on possible malfunctions, you should check all of the specified components (elements) to ensure correct operation, and if not, carry out repair measures.

Code E02 - thermostat-fuse against overheating

The manifestation of this error, displayed on the display as “E02” or “02E”, can also be accompanied by various variations of defects.

In particular, the following defects may appear:

- the temperature of the main circuit water is exceeded;

- the circuit temperature sensor is faulty;

- no contact on the heating circuit temperature sensor;

- the coolant circulation in the primary heat exchanger circuit is insufficient;

- clogging of the filter, heat exchanger, presence of air in the system;

- defect circulation pump;

- fault on the electronics board.

The same errors are typical for boiler models that do not have a display. They are determined by the presence of a glowing indicator with a temperature marker.

Code E03 - traction sensor

The appearance of this error is preceded by malfunctions associated with the traction sensor, thermostat or pneumatic relay. The error code is displayed as "E03" or "03E".

The situation is typical both for equipment that uses a closed combustion chamber and for equipment that uses an open combustion chamber.

Possible faults:

- the length of the chimney is large;

- the chimney is narrowed or blocked by a foreign object;

- Venturi injector faulty;

- there is no connection between electronics and pneumatic relay;

- fan malfunction or no contact;

- incorrect connection of the pneumatic relay.

Monitoring of the same error on models equipped with LED indication is carried out taking into account the “star” or “house” markers.

Codes E05-09 - control of DHW and burner flame

The group of marked sensors actually perform related operations related to controlling the temperature of the hot water supply or controlling the flame of a gas burner.

Errors “E05”, “E06” (coolant temperature), “E07”, “E08”, “E09” (flame and flue gas control) are typical for boilers of the “Main5” and “ECO-5” models, as well as others.

Malfunctions can manifest themselves in various ways:

- malfunction of the DHW temperature sensor;

- there is no contact between the sensor and the electronic board;

- overestimation or underestimation of limit temperatures;

- electronics malfunction;

- heating circuit sensor defect;

- flue gas sensor defect;

- open circuit of the electronic board.

Most of the noted problems can be eliminated by simply testing the circuits with a measuring device or by replacing the supposed faulty element with another serviceable one.

Code E10 - minimum pressure switch

A functional component of the system - a minimum pressure switch - is used in almost all designs of Baxi boilers, including models EcoFour, Fourtech, Main Four, Navola, etc.

True, for some models this functional component may be referred to as a differential pressure switch (MPS) microswitch.

Error "E10" ("10E") traditionally appears on the display or is indicated by an LED when:

- CO water pressure is too low;

- there is no relay contact with the electronic board;

- defective minimum pressure switch;

- non-working TIR;

- the TIR rod is jammed;

- the pump is faulty;

- circulation of the heat exchanger or primary heat exchanger (PH) is disrupted;

- contamination of the water outlet tube;

- membrane defect (no pressure difference).

Elimination of error E10 is carried out by checking all components noted in the list and eliminating any identified defects. The units are cleaned, individual parts or entire units are replaced.

Codes E12 and E13 - DGP malfunction

The appearance of code “E12” (“12E”) or “E13” (“13E”) on the boiler display clearly indicates malfunctions associated with the operation of the differential hydraulic pressure switch.

The reasons for the appearance of the marked code may be:

- stopping the pump;

- presence of air in the hot water system;

- low circulation rate;

- there is no contact on the TIR or a “stuck” contact;

- membrane damage or filter clogging;

- Impulse tubes are clogged.

Accordingly, a technical check should be carried out to determine the malfunction of a specific element.

And in order to eliminate the problem, it is necessary to replace the faulty element or carry out preventive restoration work.

Codes E21-22 and E97-99 - electrical and electronics

Both codes - "E21" and "E22" - indicate faults associated with the electronic board. Code “E22” may appear if the supply voltage drops below the control value (162V).

The same code is displayed on the display if the quality of energy supplied to the boiler does not meet the stated standards.

For code “E21”, a characteristic point is the scattering of controller parameters and disruption of normal gas combustion. If you lack experience and relevant knowledge, it is better to entrust board repair to a specialist.

Errors “E97”, “E98”, “E99” - all three codes are usually associated with defects in the electronics - electronic board.

Code “E97” indicates the frequency of the supply voltage does not comply with the standard. The code “E98” indicates defects that are present specifically on the electronic board.

The simplest defect is loss of electrical contact on the gas valve relay. In other cases, the board usually needs to be replaced.

Codes E25-27 and E32 - temperature defects

The appearance of any of these codes - “E25”, “E26”, “E27”, “E32” - is usually preceded by temperature changes in the heating circuit, occurring at a faster rate than set by the control system.

For example, if the temperature of the heating circuit (HC) increases by more than 1 degree per second, the code “E25” (“25E”) is displayed on the boiler display. For code “E26” (“26E”) to appear, the temperature exceeding the set temperature by 20 °C is usually sufficient.

Reasons that traditionally cause such codes:

- blocking the circulation pump;

- filter clogging;

- air inside the system;

- defective temperature sensor KO;

- electronics malfunctions;

- Incorrect installation of the DHW sensor.

To eliminate it, it is necessary to carry out preventive measures aimed at checking and testing DHW and CO units. Air in the system is removed using standard plumbing practices.

The performance of the circulation pump is checked by electrical and mechanical parts.

Codes E35-36 and E40-43 - flame control and GDC

This set of codes mainly indicates malfunctions of the gas burner flame control systems and flue gas control systems. So, the code “E35” (“35E”) shows a discrepancy in the arrival of the flame presence signal.

Code "E36" ("36E") usually indicates a malfunction of the NTC sensor. Codes "E40", "E41" and "E42", "E43" remind the user of GDC flue gas and ionization current test failures.

The appearance of these codes is usually accompanied by:

- moisture entering the area of the electronic board;

- residual combustion after closing the burner;

- inconsistency in the quality of the supply network;

- defective NTC sensor (flue gas sensor);

- lack of connection between the sensor and electronics;

- electronic defects;

- lack of gas pressure;

- contamination or malfunction of the flame control sensor;

- gas valve malfunction;

- too long chimney.

Some of the listed defects can be corrected by the user himself.

However, other issues, such as electronic malfunctions and sensor testing, require specialist intervention.

Codes E50 and E62 - NTC sensor and flame control

The automation of Baksi boilers is adjusted to certain parameters of combustion stability, as well as to a certain temperature range of flue gases.

Error E62 - burner flame control sensor

If any of the two parameters (or both at once) goes beyond the settings, the automation is activated, and the code “E62” (“62E”) appears on the control display screen.

Traditional reasons:

- faulty or dirty flame control sensor;

- faulty NTC sensor;

- electronic board defects.

Sensors are tested by replacing them with known good ones, and electronics are tested with instruments designed for such purposes.

Error E50 - NTC temperature sensor

The occurrence of the “E50” error is typical for boilers of the ECO-5 and Main 5 models. The “E50” code is usually displayed on the control display due to the detection by the flue gas heating temperature sensor above 180 °C.

In turn, a rise in temperature above the set limit may be due to:

- low coolant circulation rate;

- clogged filters;

- the appearance of hydraulic resistance in the system;

- low concentration of antifreeze;

- circulation pump defects;

- system contamination or air ingress.

Also, the fault code “E50” (“50E”) is displayed on the display when the NTC sensor breaks down, due to electronic malfunctions, due to incorrect settings of the gas supply valve.

Accordingly, elimination is ensured by consistent testing of the designated units and carrying out the necessary work.

Code E55 - gas supply valve malfunction

Often this code - “E55” - makes itself felt due to incorrect calibration of the gas supply valve.

To eliminate the error, a calibration procedure must be performed. Usually this work is performed by a specialist, but if you wish, you can try to calibrate it yourself, following the instructions.

Conclusions and useful video on the topic

The author of the video below examines another possible error that is not included in the list of the current publication. In particular, the video demonstrates a malfunction marked with code “E00”:

The electronic system for detecting errors in the operation of the Baksi boiler with subsequent display of the corresponding code on the control screen is a very user-friendly service.

This is a significant help for mechanics when they have to deal with rather complex faults that require additional testing of equipment before and after repair.

If you have questions about the topic of the article or have valuable information that you can supplement our material with, please leave your comments in the block below.

Everything is written here in an interesting way. But error E26 may appear for another reason. You definitely won’t find such a breakdown in the book. Here is how it was! I turned on the hot water, it started to heat up, everything was fine. The wife washed the dishes and turned on the tap. The water stopped flowing, but for some reason the burner did not go out and gas continued to flow. Then some kind of overheating protection worked and the boiler switched off, error E26 appeared.

I looked into the book, but it only stated that the pump could be blocked and contact the service organization. What organisation? - I thought. We don’t even have normal craftsmen. I went online and searched several forums, but to no avail.

And then I decided to figure it out myself. I immediately discarded the blockage of the pump, because it was working during heating. The problem was in the hot water circuit. I started to slowly take it apart. I removed the tap, next on the list was a hot water flow sensor with a ferromagnetic ring. This is where the whole problem was hidden. There is a mesh there, like a filter. For some reason it broke. I don’t know why, most likely because of our bad water. So the ferromagnetic ring was stuck in the upper position and gave a constant signal, so the burner worked constantly. I disassembled the sensor itself, cleaned it of rusty deposits and that’s it! The boiler started working as before. Perhaps my information will be useful to someone.

The same organization that connected your boiler and carries out annual maintenance. In general, it is better not to climb into the boiler yourself.

After turning off the hot water, something clicks in the boiler for 10 seconds or more. Doesn't show any error