Rinnai gas boiler errors: fault codes and how to fix them yourself

The Japanese corporation Rinnai has established itself as a global manufacturer of reliable gas boilers.But like any gas-using appliances, for some reason they can malfunction. To identify possible malfunctions, errors in the Rinnai gas boiler are displayed on the display in the form of indicators or numbers and make it possible to accurately identify the causes for quick troubleshooting.

If you think that all this is very difficult, then you are mistaken. In fact, there is nothing complicated in automatic diagnostics, and thanks to these numbers, if you have at least a little technical knowledge base on heating units, you can fix many malfunctions yourself without calling a technician.

And we will help you - we will describe the most common errors of boilers of this company, possible ways to eliminate them, and also post some manuals for the convenience of identifying those codes that are not in our article.

The content of the article:

Installation of Rinnai gas boilers

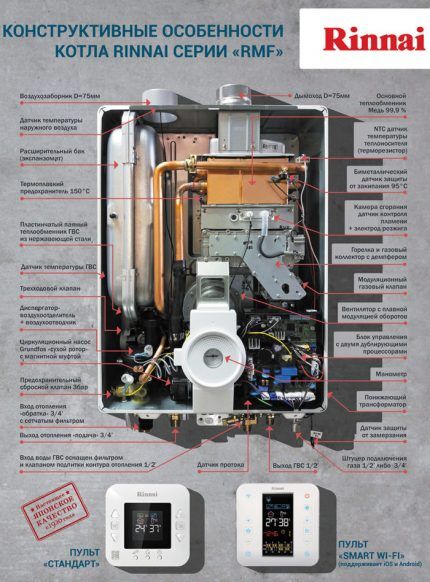

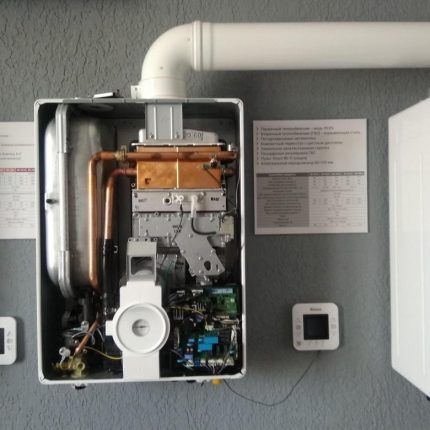

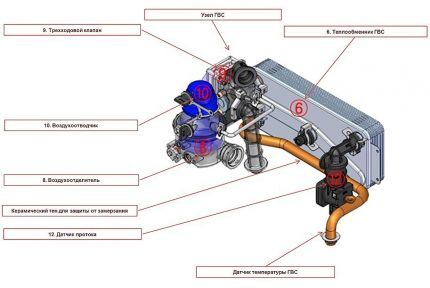

Typical device of dual-circuit devices This company, for all its functionality, is quite simple. If you understand at least a little about the structure of heating boilers, it will not be difficult for you to find one or another element for its diagnosis.

So, 2 branches extend from the top of the device body. One pipe is an exhaust pipe, and the second is an air intake pipe. Both elements go to coaxial type chimney. Accordingly, through it both the intake of oxygen for combustion and the removal of combustion products occurs.

There are also 2 pipes coming out of the bottom - gas and water supply.

The closed combustion chamber has a three-stage burner.

Above the nozzle is the main heat exchanger with copper plates. The secondary, consisting of copper and stainless steel plates, is located below, it is used to heat the hot water supply system, and a three-way valve is connected to it.

There is an expansion tank at the top, and a circulation pump at the bottom, which usually works universally for open and sealed systems.

Now comes the fun part. This is a remote control with display. Thanks to this technological device, the temperature regime for both heating and hot water is adjusted. And in addition, self-diagnosis indicators are displayed on its high-contrast display.

How is the error output?

As already mentioned, the error is identified by displaying the remote control panel.

The first and second digits are the error code. For example, 16. The third digit (separated by a space from the first two) is the boiler power.

It is designated by numbers from 2 to 6, and reads something like this:

- 2 = 167;

- 3 = 207;

- 4 = 257;

- 5 = 307;

- 6 = 367.

And the last, fourth digit, chimney type: 2 - ME, 3 - MF.

If a malfunction occurs, the remote control begins to signal (beep) the owner about difficulties in the system and displays an error code on the screen.

The most common errors in series devices RB RMF, we’ll look at it with you now, and let’s start with prevention so that you encounter such problems less often.

Troubleshooting and preventive diagnostics

If you have any problems with the heating and hot water supply of Rinnai boilers or you want to check the operation of this system, you will need to perform several diagnostic steps.

Here is a brief overview of the general work involved in this procedure:

- Necessary inspect the gas valve — GSA VALVE and the state of its performance. Typically, with such problems, error 11 is displayed.

- Check the opening status of electronic valves 1 and 2.

- Measure the voltage on the piezo source (AC 220V).

- Pay attention to the connection of the proportional valve. In this case, error 52 occurs

Another valve to inspect is the warm water valve. By the way, its minimum working quantity is approximately 1.7 l/min and it is also recommended to check this parameter.

IN errors 15 and 16 We will look at fault options related to boiling and overheating.

To diagnose such problems you need to:

- Inspect the electronic valve for functionality and water supply. Their operating voltage is 220 Volts, when stopped it is zero;

- pay attention to the pump.It may stop due to contamination; also in the case of this element, a breakdown of the relay and contact of the capacitor wires can be considered;

- check the heat exchanger for blockages and rinse it if necessary;

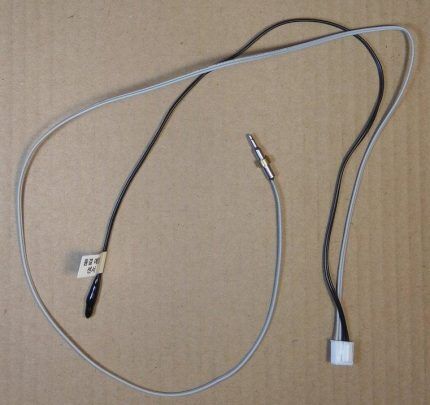

- If the temperature rises sharply, pay attention to the thermistor malfunction.

It should be noted that these recommendations do not apply to those boiler owners who have a very poor understanding of the structure and operating principles of gas-using equipment.

Now let’s look at the most common error codes and options for eliminating them.

Rinnai boiler error codes

A flashing heating light indicates a blockage in the system, in which case the filters need to be cleaned.

Error 7 in hot water mode. The boiler thinks, or it actually is, that hot water is continuously used for 8 hours.

If you don't do this, first of all:

- pay attention to the water flow sensor - is there a PULSE mode, is the “drop of water” indicator on the remote control lit when using hot water;

- check whether the taps are turned off;

- inspect hoses and pipes for water leaks;

- if the answer is positive, fix the leak;

- restart the boiler via the control panel.

Error 11 associated with ignition problems. Its symptoms include the absence of a flame on the burner or its short burning, that is, the inability to light a gas boiler.

The reason may be low pressure of the incoming gas, in which case you just need to light the gas stove to check.

If everything is in order with the gas pressure and the valves leading to the unit on the main pipe are not blocked, then you need to diagnose and repair the Rinnai gas heating boiler, which should be entrusted to professionals.

To diagnose the equipment you will have to check:

- the presence of all boiler connections, which include proportional control valves and electromagnetic (operating voltage: 220 V, stop - 0 V) fan, ignition electrode, and so on;

- check the loads during ignition, triggered in order;

- find out if the heat exchanger plates are clogged.

- check the bimetallic thermal fuse;

- Be sure to inspect the chimney connection and its condition.

There is also a possibility of a problem with the electronics unit.

Error 12 occurs when the boiler is turned off more than 20 times. Symptom: The flame lights up and goes out immediately. Possible reasons are a leak of “blue fuel”, blockages in the filtration system, insufficient pressure. It is necessary to check the primary pressure and whether the filters are clogged.

Error 14 indicates that you have problems with the temperature sensor; for some reason, the connection with the temperature fuse or electronic safety module has been lost.

What a person with experience working with gas boilers can do is check the connection at the terminal and the fuse for a short circuit. But in most cases, a specialist visit is required to replace the electronic module.

Error 15 associated with malfunctions that occur with the overheating sensor, the absence or problem of the circulation movement of the coolant in the heating system.

What do we have to do:

- Check whether there are leaks in the device or the system as a whole and, if there are shortages, fill them (in particular, low pressure on the pressure gauge).

- Inspect the filter.

- Check the mains voltage and the condition of the thermistor.

- Restart the boiler after all actions.

- Check if there are problems after restarting.

Error 16 characterizes overheating in the system when the coolant temperature is more than 95 degrees for 3 seconds or more.

In this situation it is necessary:

- check whether the heating system taps are closed - valves for opening and distribution;

- are there any air pockets in the pipeline;

- eliminate the possibility of blockages in the line and return filter;

- check the presence and level of coolant;

- inspect the condition of the three-way valve and thermistor, measure the resistance at the thermistor terminals;

- It is imperative to check the functionality of the pump.

Error 17 indicates a water leak and occurs after 3 water refill signals.

Occurs between 24 and 64 hours after heating starts.The error is eliminated after diagnostics - checking for water leaks in the device itself, the pipeline system, and inspecting for air in the system.

Error 18 connected directly to the power supply of the device. A ground fault is detected. It is necessary to diagnose the voltage in the network between the third pin of the electronics module and the “ground”, inspect the boiler wiring for exposed insulation, a short circuit on the device operation line, and the condition of the control panel

Error 20 — Dip SW switches are set incorrectly or are not detected. For reference, this is a manual type control. To troubleshoot the problem, it is recommended to check their correct location according to the instructions.

Error 28 indicates that a problem has occurred in the control panel. And in this case, you just need to check its communication, the state of connections.

Error 31 - these are problems with the thermistor that occur when it breaks or short circuits.

Error 32 typical for problems with the freezing thermistor, which occurs when it breaks or short circuits.

Error 34 for the thermistor at the DHW input.

Error 35 and again the thermistor, only this time the one that scans the room temperature. This occurs when the contact circuit is broken or short circuited.

Error 43 appears in hermetically sealed boilers and occurs when the electrodes detect a lack or complete absence of coolant for 43 seconds. Of course, you need to immediately check the coolant level.

And then:

- determine the contact of the wiring with the sensor electrodes;

- inspect the system for clogging;

- find out if there are any problems with the functionality of the make-up solenoid valve;

- see if the recharge system as a whole is working.

Also, to eliminate the malfunction, if the coolant level is low, open the water supply tap, turn on the make-up, and then close the DHW valve. When the pressure reaches 0.5-1.5, turn off the make-up.

Error 44. These are problems with the level gauge when it starts to glitch. That is, when there is water, but there is not much of it and he detects that there is no water at all, when there is too much of it and he detects it continuously for 30 seconds (in a leaky type system).

It is necessary to check the condition of the connection of the level gauge electrodes and whether the water separator in the upper part is clogged. If it is impossible to fix it yourself, call a specialist from the service or gas department.

Error 52 Suitable for problems with modulating gas valve, proportional control valve. You can read more about how to repair a gas valve in this material.

Error 56 in open-type systems, it shows problems with water replenishment of the solenoid valve when it does not complete the cycle 5 minutes after the supply starts.In this case, it is recommended to check the voltage, water sensor and call a technician to troubleshoot the valve if you cannot do it yourself.

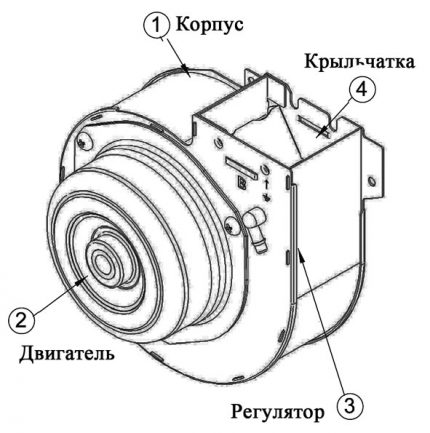

Error 61 indicates a problem with the fan. According to the official representative of the boiler manufacturer Rinnai in Russia, it is necessary to check correct installation of the chimney, remove the blockage if there is a blockage, measure the voltage and try to restart the boiler. If the error is not resolved, be sure to call a technician.

Error 71. If these numbers appear on the display, know that they indicate a problem with the solenoid valve, its displacement or misalignment with the gas outlet point. If the problem recurs when restarting the boiler, turn off the gas supply and call a technician.

Error 72 indicates problems with the solenoid valve, as well as difficulties in recognizing the ionization sensor. In this situation, gas is not supplied to the burner during an attempt to ignite, and the flame is fixed.

Experts advise checking whether the valve on the gas supply is open and if everything is in order, immediately shut off the supply and call a professional diagnostician from the service center or from the company with which the contract is concluded. service contract gas equipment.

Error 89 indicates that the sensors have detected freezing of the system. This problem also requires a specialist to solve.

Error 90 recognized as a defect during the initial fan current, during pre-purge. The reason may be a clogged chimney or voltage problems.

If after a restart, if it is not detected and cannot be fixed on your own, the problem recurs, call a technician.

Error 96 connected to the hot water supply. It is recognized during a test run of the hot water supply and is characterized as unfinished air release after 10 minutes.

Error 97 refers to heating functions. Again, when during a test run the air comes out longer than 120 minutes after turning on the heating. What to do - check the coolant access, measure the pressure and try to restart your gas-using appliance.

Error 99 - chimney and related faults. This error relates to security functions. This could be a depressurization of the chimney, blockages in it or the fan, and so on. If an error occurs, it is necessary to check the functionality of the fan, the heat exchanger for blockages and the chimney.

Rules for safe operation

Any gas boiler is used to process fuel that is dangerous to the life and health of consumers in the event of its leak, the release of its disposal products and the leak of the coolant heated by it.

All work on repair and replacement of gas-using equipment should be carried out by specialists from the service department or gas distribution department. Otherwise, you may face a gas supply cutoff at best, or a threat to your health and life at worst.

Moreover, the cost of such devices, especially from well-known manufacturers, is not always budgetary, and the warranty is long. Intrusion into the system of gas boilers can be regarded as a violation of warranty immunity and, accordingly, you should not expect free repairs and replacement of individual elements from the service department.

But again, it is quite possible to fix some issues in boiler malfunctions yourself, or knowing them, you can determine what work to call a specialist for and ask how much the repair will cost.

Conclusions and useful video on the topic

More details about error 99, cleaning the fan:

Basically, malfunctions of most models of Rinnai gas boilers are easy to fix. Knowing the decoding of error codes and having in hand a manual for the operation of a specific device, you can easily diagnose, if not the breakdown itself, then at least the area in which it appeared.

Have you had any problems with Rinnai heating units? Maybe you saw a code that is not in our article? Share your experience and ask questions in the comments.

This happened to me with a boiler. During the day the electricity was cut off for 8-9 hours. After that, when the power was turned on, it lit itself and worked normally. In the morning I switched off completely. I looked for the reason and found it. It was the switch on the remote control that was turned off. The question arises: why can they turn off automatically? It happens?

Hello. I’m getting error 99. What can I do?

This happens in winter when there is severe frost due to the difference in temperature, condensation forms, it freezes, limiting, blocking the access of air. Treatment: Connect the flexible pipe, let the air be taken from the room until the pipe thaws.

In the summer, the air duct may become clogged with dust, which is another pleasure, it clogs everything

Dust kills the pump and its bearings

The fan and heat exchanger are clogged

The control panel itself either goes out or lights up, the heating is completely gone