What are fittings for sewer plastic pipes - a short cheat sheet

With the development of polymer materials technology, gradually plastic pipes are replacing steel pipelines. Steel can be connected by flanges, bends, or welding. While polymer communications can only be spliced using fittings for plastic pipes. Otherwise, the joint is not reliable enough to withstand mechanical loads.

The content of the article:

- What are the advantages of fittings for plastic pipes?

- Types of fittings for plastic pipes

- How fittings for plastic pipes work

- What are fittings for sewer plastic pipes?

- What types of sewer pipe fittings are most commonly used?

- How fittings for plastic pipes are installed

- Features of plastic line wiring

- How to install fittings for plastic pipes of sewer systems

What are the advantages of fittings for plastic pipes?

The use of fittings makes it possible to:

The main advantage is an increase in joint strength. On fittings, plastic pipes for water supply systems can withstand pressures of up to 25 atm. Sewer lines can function for many years without losing their tightness.

Types of fittings for plastic pipes

For plastic communications, two types of fittings are used - for pipe joining under pressure and assembling sewer systems. The first are thick-walled plastic products, often with metal inserts.

The characteristics and design depend on the functions that the fittings perform. The latter, on the contrary, are thin-walled, often with grooves for rubber sealing rings.

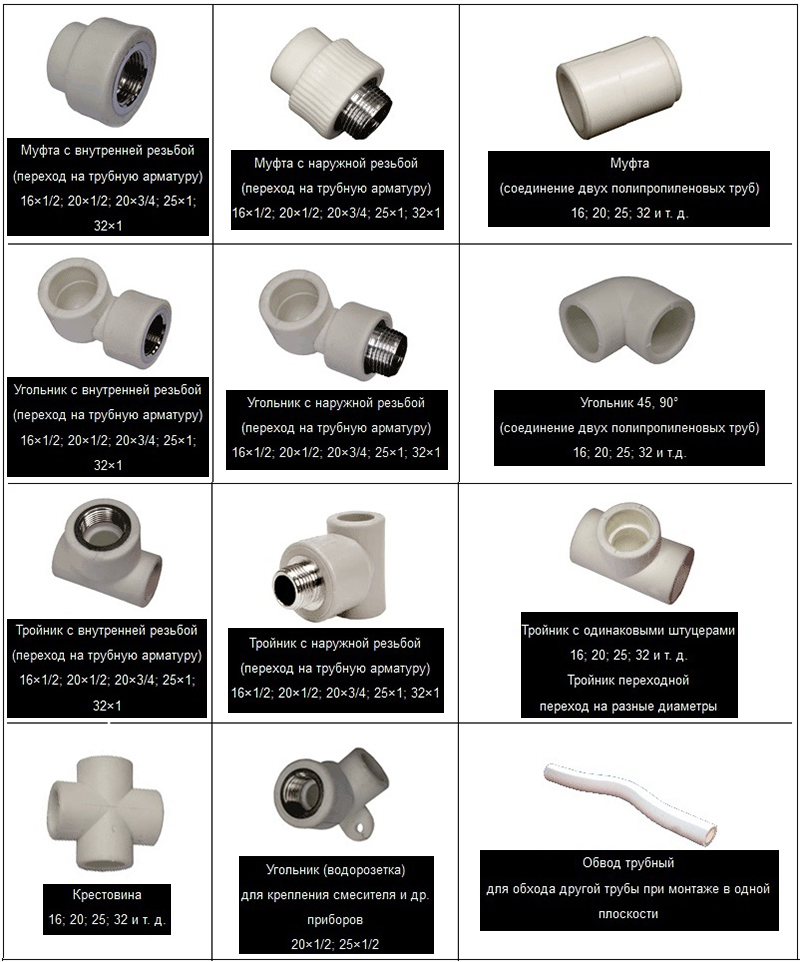

The group for high-pressure plastic pipes includes:

- fittings for simple connection of pipes made of PP, HDPE and PVC. This includes couplings, adapters used to splice lines of different diameters;

- transition couplings for connecting consumers, connecting the line to the collector, central heating pipes;

- corners, tees, bends that allow turning or branching of plastic pipes.

Depending on the connection technology, fittings are divided into solder-welded, American, crimp, glued and rubber ring. Joining by soldering or compression crimping is used on polypropylene communications and pipes made of low-density polyethylene. “American” can be used on PVC and HDPE. Glued ones are used for PVC fittings. Docking under the ring is used exclusively when assembling sewer lines.

How fittings for plastic pipes work

Regardless of the type of connecting device, whether it will be used to simply join two plastic pipes, turn or branch, the fitting body includes a polymer base, plus one or two parts that provide a threaded connection. With one exception - the cheapest solder models are entirely cast from plastic.

Compression (crimp)

This type includes couplings in which at least one of the connected pipe blanks was fixed by mechanical compression of the walls on a metal base.

In essence, this is a linear coupling, on one side of which there is a plastic spacer made of polypropylene for a solder joint. At the opposite end there is a metal nipple with a crimp nut. The nipple is inserted with slight force into the plastic pipe being connected and tightened with a crimp nut.

Compression couplings for joining plastic pipes made of cross-linked polyethylene and polypropylene are constructed using the same principle.

If metal-plastic pipes are used in the heating or water supply system, then the connection, connection to shut-off valves or polypropylene lines can be made using a plastic fitting with a metal conical nipple and a union nut.

A rubber gasket is placed inside under the nut. The nipple is made with a “socket” outward. As a result of crimping the fitting, the edge of the metal-plastic pipe is crimped. To prevent the plastic section soldered on the reverse side from turning, a hex key is made on the coupling body.

Cast

For joining pipe blanks, couplings cast from polypropylene or cross-linked polyethylene are most often used. The simplest solder connector is a molded body with two ring grooves.

In addition to the classic “barrel”, the connection uses fittings for soldering pipes of different diameters, for example, according to the “internal-external” joining scheme or an adapter with internal soldering for the connected sections.

Plastic fittings are also cast in the form of corners, crosses, and contours to allow pipes to bypass obstacles.

All cast fittings are assembled by soldering, the only exceptions being plastic pipes and PVC couplings; they can be joined using glue.

Detachable

In addition to simple joining of pipes, couplings are used to connect plastic pipelines to heating or pumping equipment. For these purposes, polypropylene adapters are used with a solder groove on one side, a nipple, and a union threaded nut on the other.

If, according to technical conditions, it is necessary to make a collapsible connection on an arbitrary section of the pipe, then use a threaded coupling. Essentially, these are two halves made of nickel-plated brass with external and internal threads, respectively.

Plastic inserts are pressed inside. Each half is welded to the end of the pipe with a standard soldering iron. If necessary, the connection can be disassembled and reassembled an unlimited number of times.

Couplings for connecting consumers

In addition to simple connections, fittings are used to remove fittings and create connection points for plumbing fixtures and faucets using flexible hoses. In the classic version, the outlet is made in the form of a plastic tee made of polypropylene with a side metal insert.

But there are also more complex devices, for example, with a built-in tap or check valve for water supply.

What are fittings for sewer plastic pipes?

Modern sewerage is assembled from thin-walled plastic pipes with a diameter of 50 mm or 100 mm.The individual segments are joined together according to an insertion pattern, sealing the joint with a rubber ring or spliced using glue.

The sewer fitting is a thin-walled plastic injection molding. More like a piece of pipe with a soldered outlet. The ends of the mini-pipe are of different diameters. The one with the ring spacer is larger, the opposite end is smaller by twice the wall thickness. The outer surface is made with a slight taper.

There is an outlet on the body of the sewer fittings. It will also be made with a ring spacer. This design makes it possible to insert a fitting one into another or into a sewer pipe, and collect an unlimited number of them. If the assembly of the plastic sewer system is completed, a plug must be installed at the cut of the pipe section.

Three types of plastic are used to make parts:

For sewer drains of aggressive liquids, pipes and fittings made of polyisobutylene are used, but they are more expensive than PP, HDPE or PVC, they are not widely used, and there is no particular need to use an expensive polymer in domestic sewerage. On sale you can find products made from a cheaper analogue based on polybutylene.

The specific version of the “pipe-fitting” pair is selected depending on the load, the nature of the sewerage and the installation location, whether it will be an external or internal sewer.

What types of sewer pipe fittings are most commonly used?

In a private house or apartment of modern construction, connecting elements account for 15-20% of all sewer plastic.The smaller the housing area, the greater the share of connectors in the total plastic sewerage wiring.

List of most used fittings:

- Tee with angled outlet. Used to connect to sewer risers. Fittings with a diameter of 50 mm are used to connect plastic corrugations of a sink or sink.

- Tee couplings. Used to connect plastic siphons of a shower cabin or bathtub.

- Angular turns. Used for sewage plant in the house.

- Revision block. Used for cleaning pipes.

- Adapter from pipe 50 mm to 100 mm. It is used at the end sections of the sewer system.

- Tees with bends for 30O and at 45O. Used in arranging branching sewer sections.

In addition to the above, push-in couplings, crosses, and plugs are used slightly less frequently in home sewers.

Rubber ring fittings for internal PVC sewerage

PVC couplings for assembling sewer pipes are easily distinguished by their characteristic gray color. For internal sewerage, fittings with single-layer walls up to 2.2 mm thick are used. The surface of PVC plastic products has a smooth, almost glossy surface, which facilitates easy drainage of sewage without additional pressure on the pipe walls, especially at the joints on the couplings.

Sealing at the joints is carried out using a rubber ring-cuff. A characteristic feature of the ring is the presence of annular grooves on the inner surface. Ring diameter 55-110 mm.

Rubber ring fittings for external sewerage

There are two types of external sewage disposal systems - pressure and non-pressure.They differ in the material used, wall thickness and connection method. For private households, non-pressure systems are used, respectively, fittings with pipes are connected to a seal with a rubber ring.

Plastic fittings and pipes for external sewerage are painted orange; the body may have several layers of polypropylene, PVC or cross-linked low-density polyethylene. Typically the inner layer is made from the most durable vinyl. The wall thickness is greater than that of couplings intended for internal sewer lines.

Fittings for sewer system for adhesive installation

Glue is used for joining pressure plastic pipes with fittings. More often these are external sewer lines laid in areas with complex, rugged terrain. The adhesive method of connecting fittings to the sewer system is also recommended for private housing construction with two or more floors.

The design of fittings for an adhesive connection differs from the “rubber seal” design only in the presence of mounting pipes no less than 50 mm long, without any spacers or annular grooves for the seal. Otherwise, the design of the couplings corresponds to the design of the “rubber” models.

How fittings for plastic pipes are installed

Assembly of polypropylene and polyethylene parts is carried out by soldering. The pre-cut workpiece together with the coupling is heated on an electric soldering iron, after which the parts are brought into contact, pressed and held for 10-15 seconds until cooled. If the technology is followed, a strong, cast connection is obtained; the structure of the weld seam does not differ from the parent material.

You can also solder water pipes with fittings made of polyvinyl chloride. This method is not recommended for drinking water, as it requires heating to a temperature of 260 ℃, at which PVC can release organochlorine compounds.

It is easier to connect the PVC section to the coupling using glue. It is enough to lightly remove the gloss from the end of the workpiece to be glued, degrease, apply glue and insert the pipe inside the tee or coupling. The connection will be ready for use in 2.5 hours.

Features of plastic line wiring

Planning plastic water pipes no different from working with steel lines. There is only one feature - when laying out plastic communications, you need to take into account the high coefficient of thermal expansion of the polymer. This means that the plastic will expand when heated. This means that it will be necessary to make compensation loops, “pockets” that would compensate for the elongation of the pipe.

Therefore, first we select places for installing and connecting fittings, couplings, taps, bends, and only then solder or glue sections of PVC or PP pipes between them. It is clear that the workpieces must be cut with a length allowance for each soldering point.

It is because of thermal expansion that home sewerage is performed on rubber sealing rings. Each section is cut with a small margin of 25-30 mm in length, depending on the length of the drain. Thus, the absence of a rigid connection allows the plastic to “play” without breaking the joint.

You cannot assemble long-distance sewer systems using elastic bands with additional sealing with sealant or adhesive. If there is a strong temperature difference, the seal can be squeezed out of the annular groove.

How to install fittings for plastic pipes of sewer systems

Initially, you need to collect the sewer dry. The workpieces are cut with a margin of length, couplings and tees for adhesive joints are temporarily seated without glue. If the connection is on the cuffs, then the sealing rubber bands are placed in the grooves and lubricated with liquid soap.

After the sewerage system has been assembled, drain levels have been set, the length of each section has been determined, marks for cuts have been marked, points for mounting clamps have been marked on the walls, the system can be disassembled.

Next we carry out the final assembly. Each workpiece must be cut with a hacksaw to the size according to the risk, remove the burrs, carefully wipe the soap on the rubber and insert the section. Next, extend the section by 2-3 mm so that a thermal gap remains, after which we secure the joint with tape and move on to the next coupling or tee.

If the sewage system is assembled with glue, then each fitting-pipe joint is glued “tightly”, secured with tape and immediately secured to the wall with a clamp. At the same time, the orientation and direction of the bends are set.

Fittings for plastic pipes simplify the installation of water pipes and sewer drains. In addition, any technical system is not immune from breakdowns or defects; in this case, the problem is solved by simply replacing the fitting with a short section of pipe.

Elements for connecting polypropylene pipes (polypropylene fittings): video.

Have you ever assembled a pipeline using fittings? Write in the comments.Save the article to bookmarks and share it on social networks.

Plastic pipes and fittings are easy to work with. All you need is a good soldering iron. And then you can connect them without any problems. I myself have already assembled 2 pipelines - in the apartment and in the country.

There is no substitute for steel pipes. They are practically eternal. But I don’t trust these plastic ones.