How to install a septic tank “Tver”: an overview of installation technology

Owners of country houses and country houses are faced with the problem of cleaning and recycling wastewater.There are many ways to solve the problem, but the best can be considered the installation of a septic tank, which can remove up to 80% of contaminants from wastewater.

Among such units, the local Tver facilities have proven themselves well, providing multi-stage waste treatment.

But, you see, before you decide to buy, you need to find out how the unit works, how the Tver septic tank is installed, and what are the features of its operation.

All these points are described in detail in the article. The information provided will help you decide on a suitable septic tank model and independently install and start the unit.

The content of the article:

- The principle of operation of a septic tank

- Model range of cleaning equipment

- Where to place the installation: norms and rules

- How to determine soil water absorption

- Methods for disposing of treated wastewater

- Preparing for installation of a septic tank

- Cleaning equipment installation technology

- Conclusions and useful video on the topic

The principle of operation of a septic tank

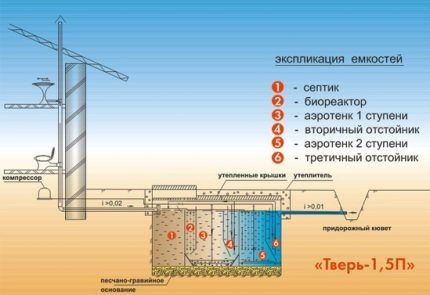

Cleaning equipment under the Tver brand It is an aeration-type septic tank with sufficiently high productivity.

Used in any soil with different groundwater levels.

All modifications of the device include six main elements.

Let's look at each element separately:

- Primary settling tank. It accepts wastewater containing solid fractions. Anaerobic bacteria ferment the incoming sewage slurry. Heavy large inclusions settle to the bottom of the container. Lighter particles rise to the upper part of the sump and, together with the liquid, flow into the second compartment of the device.

- Bioreactor. Here the processes of converting a difficult-to-oxidize fraction into an easily oxidizable one take place. Under the influence of gravitational forces, heavy inclusions move in the bioreactor from top to bottom, gradually undergoing changes.

- Aerotank. In this zone, the easily oxidized fraction coming from the lower compartment of the bioreactor is mixed with biologically active sludge, which contains aerobic bacteria. The procedure is carried out by blowing air through the silt deposits throughout the entire aeration tank. To increase the efficiency of the aerator, expanded clay is added to the container.

- Secondary settling tank. Collects expanded clay balls and silty foam. Here the expanded clay is separated, which is collected in the lower outlet and sent back to the aeration tank. The clarified liquid accumulates in the upper part of the container, from where it is discharged to the next zone.

- Aerotank bioreactor. Partially treated wastewater with a minimum amount of solid inclusions arrives here. Here they decompose into gas and water. This happens under the influence of an aerator through which air is pumped. Solid particles tend to sink to the bottom of the container; air bubbles prevent them from doing this.They pick up elements of the solid fraction, lift them up, from where the particles fall down again. The process is repeated until the organic matter is completely decomposed.

- Tertiary settling tank. Almost completely purified liquid enters this compartment. It contains only particles of limestone, with which it was mixed in the aeration tank. In the sump, they go down, and clean water flows into the outlet pipe and leaves the septic tank.

To speed up the decomposition process, crushed limestone is placed at the bottom of the compartment so that the aerator is under the layer of material. Sedimentary rock adsorbs the solid fraction of wastewater well and retains phosphates, which are contained in detergents.

Model range of cleaning equipment

The manufacturer produces eight septic tank models of different sizes. They can process from 0.75 to 10 m3 /day. For example, the most productive modification Tver 10 designed for processing wastewater coming from a small cafe or hotel.

Lowest productivity Tver 0.75. This septic tank is designed to serve residential buildings inhabited by no more than 3 people.

In addition to performance, the equipment also differs in design features. About four to five modifications of each model are produced, differing in housing dimensions, number of compressors, etc.

The location of the inlet pipe also varies, which can be located at a depth of 0.6 m or 0.3 m. Depending on this, the dimensions and shape of the inspection well change.

The design features of septic tanks are indicated by letters that are present in the names of the models. For example, modifications with the letter P made of polypropylene. The inlet pipe in these models is located 0.34 m above ground level.

Variations with a compartment for a drainage pump are marked Mon. Septic tanks with a compartment for the fecal pump are designated NP, and the marking NPN indicates the presence of two pump compartments at once.

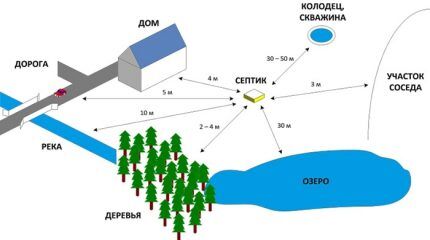

Where to place the installation: norms and rules

Septic tanks are among the objects that are potentially hazardous to the environment. Their installation requires permission from the SES. To obtain it, you need to draw up a project for the placement of equipment, which must take into account all current requirements and standards.

If everything complies with the regulations, permission will be obtained. The project takes into account not only the location of the installation, but also its volume.

The latter figure should not be less than the three-day maximum volume of wastewater. The place where the septic tank is installed must be as far away as possible from the well or from the well, if they are on the site.

Despite the fact that the treatment equipment is sealed, it is theoretically possible that an emergency could occur, as a result of which wastewater could enter the aquifer.

To avoid such problems, regulations regulate the distance from the treatment plant to the well or well for each type of soil. The minimum is 20 m.

On average, if there is loamy, sandy loam or sandy soil on the site, this distance ranges from 50 to 80 m. There are certain standards that apply when laying water pipes. They must be placed at a distance of at least 10 m from the septic tank.

This completely eliminates the risk of water contamination in the event of pipeline depressurization. One more nuance: when choosing a site for installing a septic tank, you need to remember that relative to the water source, its location level should be lower.

In addition, it is necessary to take into account the standards regulating the distance between treatment facilities and the place of residence of people. There must be at least 5 m from the foundation of the house to the septic tank.

However, too large a distance between objects is highly undesirable, since a long sewer pipeline is more susceptible to blockages. It is important to choose the optimal length of the structure correctly. If you use a modification of the Tver septic tank with forced pumping of technical water, you can place it closer to the house.

In such cases, the ventilation riser is installed at the entrance to the external sewer branch and attached to the wall of the house. The supply sewer pipe can be about 1 m.

The type of discharge and the length of the outgoing pipe depend on the geological and hydrogeological situation in a particular area. In any case, the external sewer network must be equipped inspection wells.

It must be remembered that when choosing a location for a septic tank, the interests of not only the owner of the land plot, but also his neighbors must be taken into account. Therefore, the distance from the installation to the fence cannot be less than 2 m.

If there is a road nearby with fairly heavy traffic, the septic tank cannot be installed closer to it than 5 m. The distance from the foundation of outbuildings for any purpose to the septic tank should not be less than 1 m.

Professionals advise planning the installation of treatment equipment in an area with soft soil, which will significantly facilitate excavation work. In addition, care must be taken to ensure easy access to the device for regular maintenance.

All of the above requirements must be taken into account when choosing a location for a septic tank.

How to determine soil water absorption

Before installing a new septic tank, it is advisable to find out how well the soil on the site absorbs water. The method of disposing of treated wastewater largely depends on this.

Experts recommend conducting a water absorption test, which is quite easy to do yourself. He will also help determine ground water level, which is very important when arranging such structures.

To carry out the test, we sequentially perform the following activities. First, we drill a hole or dig a hole to a depth below the freezing level of the soil. On average, this is approximately 1.5 m. When removing the dump from the excavation, we try to determine the type: sandy slurry, sand, etc.

During the digging process, water may appear in the hole. This means that the first layer saturated with water from the day surface has been exposed.

Usually, at this depth, perched water appears, which appears during periods of heavy precipitation and snowmelt. If it appears at a depth of more than 1 m, then the container will need to be installed 15-20 cm above the recommended level.

The bottom of the pit will need to be filled with a concrete screed and, without waiting for the solution to harden, install mounting loops into the screed. They are needed to anchor the container - to secure it to a concrete slab with a cable, which will prevent it from floating up during floods.

If clay soil appears at the bottom, the purified waste mass will need to be discharged into a drain. Loams and sandy loams do not allow water to pass through, so for discharge you will have to install a fairly long pipeline, and to stimulate the movement of liquid through it you will need to purchase a pump.

If the bottom and walls of your exploration mine are composed of sand with thin layers of sandy loam and loam, you need to determine the filtration qualities of the soil. To do this, you need to pour water into the pit or well, recording the volume of liquid and the time it took to absorb it.

It is possible that the liquid will not be completely absorbed, but will remain motionless at some level. This means that it will not go lower or will be absorbed too slowly. We carry out the filling operation 5 or 6 times to obtain more objective data on water absorption. Each time we determine the volume of liquid poured and the rate of its absorption.

It may turn out that there will be water at the bottom of the pit. If she doesn’t go away after a few hours, we can assume that this will happen permanently. This means that under the layer of sand you uncovered there is a clay layer that will not allow the liquid component of the waste to pass through.

Filtration properties must be taken into account when deciding on the method of disposing of treated wastewater. For example, there is no point in installing a filter well on clay rocks, because the liquid will not flow out of it.

It cannot be constructed if the distance between the conditional bottom of the soil filter and the roof of the underlying aquifer is less than a meter.

For a device on a clay base, filtration fields, which are a system of pipes with holes through which purified water seeps into the surrounding soil, are not suitable. They are laid in sandy soils that readily absorb liquid discharged from the system.

By analogy with the construction of an absorption well, there must be at least a meter between the bottom of the perforated pipes and the water-saturated layer.

Methods for disposing of treated wastewater

Before installing a septic tank in Tver, it is important to decide on the method of drainage of purified water. It is assumed that there may be several options. You just need to choose the right method that is optimal for your site.

This takes into account many factors: features of a specific septic tank model, soil type, equipment installation depth, presence/absence of a drainage ditch, and more.

Discharge of technical water by gravity

Tver treatment facilities provide a high degree of wastewater treatment, so it is possible to organize the discharge of liquid into the ground, roadside ditch, or use it for technical needs, for example, for irrigation.

Diversion by gravity is the most budget option.In this case, the most inexpensive device from the range of septic tanks of the appropriate capacity can be used without any additions in the form of a pump.

The most important condition for successful operation of the system in the case of gravity flow is that the discharge point of treated wastewater should be located below the level of the septic tank outlet pipe. In this case, all recommended pipeline slopes on the way to the discharge site must be observed.

It is possible to connect not one, but several buildings to the septic tank. But even in this case, all the above conditions must be met.

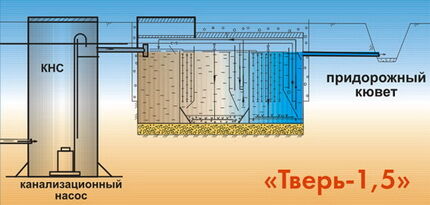

Discharging purified liquid using a pump

If the discharge point of clarified waste is located above the level of the septic tank outlet pipe, you can use the option of connecting a pump. It is desirable that the purchased modification of the Tver septic tank have a pump compartment.

With a pump, it will be much easier to arrange the removal of the purified mass over long distances for disposal outside the populated area.

If you have already purchased a structure designed to drain water by gravity, you will have to purchase additional equipment.

This can be an additional storage module or a caisson, from where purified water will be pumped. The costs of their purchase, maintenance and installation will significantly increase the cost of the entire project.

It must be remembered that vertically oriented septic tanks do not have a modification with a pump compartment. When using the pump method of water removal, the range of its supply is limited only by the performance of the pump.

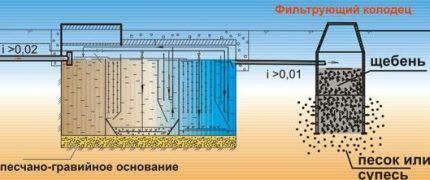

Discharge of technical fluid into a filter well

It is assumed that water will be supplied by gravity or pump to a special absorption well. This design is an independent drainage structure, in which additional purification of the liquid occurs.

Construction of such a well is possible only in sandy soils, peats and plastic sandy loams with a low content of clay particles.

In loams and hard sandy loams, installing such a system is pointless, since water will not drain from it. The depth of the structure should be such that there is at least a meter between the top of the crushed stone filter and the inlet pipe, which is necessary for normal accumulation and filtration of wastewater.

Discharge of purified water to the filtration field

In this case, the purified liquid will be discharged to drainage filtration field. The structure will help to evenly distribute process water and provide additional purification.

The dimensions of the filtration field depend on the performance of the septic tank and must be determined by specialists. Errors in calculations will inevitably lead to disruptions in the operation of the septic tank.

This method of discharging purified water is absolutely not suitable for areas with typical seasonal floods. In such situations, the drains will flood in the spring/winter and the surrounding soil will not be able to absorb the drainage.

The liquid will begin to stagnate, causing the discharge to stop, and as a result, the septic tank will not work. In addition, stagnant water will become a source of unpleasant odor and contamination of soil and water in the area.

Preparing for installation of a septic tank

Having decided on the method of discharging treated wastewater, you need to arrange an area for its reception: a drainage ditch, a filtration well or a field. Another important point: preparing the area where wastewater enters the septic tank.

If the sewer outlet from the building is deep enough, it may be necessary to equip pumping station. Contaminated liquid will flow into it by gravity.

Further fecal pump it will be pumped into the septic tank for treatment. Pumping equipment is not needed if the sewer outlet is not too deep.

In most cases, you will not need special equipment to install a septic tank Tver. Its weight is low. The largest building with full “equipment” in the form of expanded clay, limestone, etc. weighs about 390 kg, which makes it possible to lower it into the pit with the help of several people.

Of course, it is more comfortable to work with special equipment, but if necessary, you can do it without it. The installation depth of the pit is small. For standard models it is only 1.65 m, which greatly simplifies the work.

That is why the Tver brand is readily chosen for installation in areas with high groundwater level. You can dig a pit using special equipment or yourself.

Cleaning equipment installation technology

Work begins with preparing a pit for a septic tank. Its dimensions should be 0.3-0.4 m larger than the installation dimensions. The bottom of the pit is leveled and compacted. A cushion of compacted sand or crushed stone about 15 cm high is placed on it.

Now we are making connections to the septic tank. We lay pipes with a diameter of 100 mm with a slope of at least 0.02 or 2 cm per linear meter. It is advisable to lay the highway without turns.

If they do exist, they must be performed inside the inspection well. The diameter of the structure should be 70 cm, the radius of the tray should be 30 cm.

If the pipeline route crosses heaving soils, they will need to be removed to a depth of 40 cm from the lower edge of the pipe and replaced with compacted sand. The connection points between sewer pipes and pipes are sealed.

The home sewer system must be equipped with one or two sewer risers. Without it, the correct operation of the septic tank is impossible.

Coming out through the roof sewer ventilation riser Under no circumstances should it be connected to the indoor ventilation system. It is connected to the building's sewer line.

An air duct from the compressor is laid inside the trench next to the supply pipe. It should be laid with a slight slope towards the septic tank. The power cable is also installed here. We arrange the outlet main in the same way.

Its slope depends on the chosen method of purified water. For example, if it flows by gravity, the pipe slope is chosen to be no less than 0.01, i.e. 1 cm per linear meter.

If forced pumping of liquid is selected, the slope should be “reverse”. That is, when the pump stops, the water must return to the septic tank. After the pipeline installation work has been completed, you can begin installing the device body.

The container is lowered into the pit and carefully placed on the base. Using a level, you need to check the horizontal installation. If violations are detected, they should be corrected by adding sand under the edge of the housing.

Next, the container is anchored. For this purpose, the body has special loading protrusions at the ends. Then all communications, including electricity, are connected to the device.

Now you need to fill the housing to the level of the spillways with clean water. Simultaneously with filling, the external backfill of the housing should be carried out with clean sand without clay inclusions.Backfilling is carried out on all sides to a height of about 30 cm.

It is important to control the correct installation using a level. The body must stand strictly horizontally. Next, you can begin insulating the septic tank.

The upper part of the device is covered with any insulation. More often, mineral wool is used for these purposes. It is fixed to the body, after which the septic tank is backfilled with soil.

For a test run, wastewater is supplied to the septic tank while the compressor is turned on at the same time. An important condition for performing the operation is positive air temperature outside.

The temperature of the wastewater used for the first start-up should not be lower than 12ºС, otherwise the device will not “work”. Then you need to start the aeration system and, following the instructions, adjust the supply of the required volume of air to the corresponding equipment compartments.

If everything was done correctly, then after 3 or 4 weeks the liquid leaving the septic tank will reach the specified degree of purification.

To make sure of this, you will need to take samples several times and analyze them. Externally, the liquid should be transparent, odorless, colorless and without any visible inclusions. If the degree of purification is insufficient, the operation of the septic tank must be adjusted.

It is unlikely that you will be able to do this on your own; it is best to invite service specialists from the cleaning equipment manufacturer.

Conclusions and useful video on the topic

How the Tver septic tank works and works:

Self-installation of a local wastewater treatment plant Tver:

Features of installing a septic tank in Tver in winter:

Septic tanks "Tver" are a practical solution to the problem of wastewater disposal. This rather complex equipment with a high degree of purification can operate effectively only if it is properly installed and commissioned. If you have doubts about your own abilities, it is better to seek help from specialists.

Do you have experience installing or operating a Tver septic tank? Please share information with our readers, tell us about the features of installation and maintenance of the unit. You can leave comments in the form below.

This summer we vacationed for a week in a hotel cottage on the shore of a lake in Karelia. I noticed the good functioning of the water supply and sewerage systems. All sanitary equipment was no different from urban equipment either in type or in quality of work. The owners take care of sewerage cleaning. There was no smell anywhere. Fish are caught in the lake directly from the shore of the cottage village. At each cottage, the manhole covers of installed septic tanks were visible from the ground.

The septic tank is excellent, there cannot be two different opinions here, I think. When we bought our country house, there were no septic tanks in the yard. The sewer pipe went into a regular waste well with reinforced walls. It’s good that they thought of placing this “charm” far from home. And after installing the Tver septic tank, I no longer worry that the well may unexpectedly overflow and the waste will flow back into the house.

There are no ideal septic tanks.“Tver”, at a minimum, is not very cheap, plus you will have to give up most detergents and other chemicals, otherwise you will kill bacteria.

How does such a septic tank behave in winter? Will I need to insulate it somehow or will it be enough to just bury it below the soil freezing line?

As practice shows, in winter you will have to turn off the compressor of such a septic tank. In this case, the water in the septic tank will not freeze; a crust of 2-3 cm may form on the surface, but it does not in any way affect normal operation.

The container itself does not need to be insulated, but the communications that go to it (pipes) need to be insulated. It definitely doesn’t make sense to lay them below the freezing level of the soil. Also, if necessary, you can insulate the upper part of the septic tank with polystyrene foam if there are severe frosts in your region.

When installing one edge of the septic tank is 1cm higher than the other, what are the consequences?