Repairing an electric heated towel rail: a review of popular breakdowns and methods for repairing them

Electric heated towel rail - This is a convenient and practical household appliance.It provides a comfortable microclimate in the bathroom, prevents the appearance of fungus and allows you to quickly dry towels. It lasts for a very long time. But sometimes force majeure circumstances occur, which you can fight with your own hands.

We will tell you how to identify a breakdown and then repair the electrical heated towel railwhich has ceased to perform its functions. Here you will learn not only about the rules for restoring working capacity, but also about a simple option for improving the operation of the device.

Taking into account our recommendations, you can independently repair a heated towel rail connected to the power supply to fully restore its functions.

The content of the article:

- Why doesn't my electric heated towel rail work?

- Troubleshooting Electrical System Problems

- Work to replace the heating element

- Modernization of a cheap Chinese model

- Depressurization of the system and loss of working fluid

- Rules for installation and operation of equipment

- Conclusions and useful video on the topic

Why doesn't the electric one work? heated towel rail?

Cause of breakdown or incorrect functioning heated towel rail often becomes a chain of nodes connecting the device to the power grid.

The search for a problem begins with examining the outlet. The plug is removed and the inlet openings are carefully inspected.

If there is no visual damage, the node is examined using an indicator screwdriver. If there is no current, the socket is replaced with a working one, but when there is current, they proceed to checking the thermostat.They carefully rotate it and listen to the sound. A faint click is heard, indicating that the contacts are triggered and means that the device is working properly.

Next, the fault is looked for in the power line. When there is increased load on the network, it becomes hot and the device automatically turns off. In such a situation, the equipment is reconnected to the power supply and closely monitored.

Repeated knocking out of the breaker plug clearly indicates that there is a short circuit in the connection system that needs to be detected and eliminated.

Diagnostics of the system for short circuit is carried out using multimeter. It is configured to fix the DC resistance level.

Connection cord heated towel rail to the mains, remove it from the socket, and then measure the resistance heating element and wires. Indicators heating element should tend to zero and be slightly less than 1 Ohm. The resistance of the wire should approach infinity, since the circuit connecting the neutral and phase conductors is open.

If the device display shows other numbers, the damaged liner must be replaced. This takes a minimum of time and effort, provided that it is mounted openly.

If a hidden laying method is used, to eliminate the problem, it is necessary to remove fragments of the external wall decoration for a while, carry out the necessary repair work, and only then return the decorative elements back.

Detection of damage in the electrical circuit

According to the rules of safe operation heated towel rail, installation of an outlet directly in the bathroom is carried out only if it is connected to the system through safety devices. On a network that complies with all regulations PUE, put circuit breaker, device RCD and wiring leading to the outlet.

To locate the fault area, first check the position of all circuit breakers:

- Disabled main circuit breaker when switched on RCD indicates a short circuit in the system.

- Main circuit breaker turned on when turned off RCD signals a decrease in the level of insulation resistance by Heating element device.

- If when disconnected from the outlet heated towel rail both disconnected machines turn on easily and do not knock out; problems should be looked for in the device itself. When one of them turns off the protective system immediately after switching on, the problem lies in the liner.

- If when plugged in heated towel rail The machines turn on, but one of them is knocked out, the fault is in the towel dryer.

A unit that is not working with two circuit breakers on clearly indicates that it may be partially burning out or has already completely burned out. heating element and it needs to be replaced.

Internal malfunctions of the electrical appliance

Electrical heated towel rails are divided into two types. Some are called solid-filled and use graphite as a heating substance. The second - liquid - operate on special mineral oil, water or antifreeze.

When solid filled or liquid heated towel rail stops functioning, first of all indicate the area of the malfunction. If the wiring and external power network have been checked and are in perfect order, then it is most likely that the problem lies in the equipment itself.

A detailed search begins with determining whether it heats heated towel rail weaker or does not heat at all. To do this, turn on the device in standard mode, and after 5-7 minutes check the heating level in the area of the main heating element.

When in this place the unit becomes simply warm, but not fiery, they try to increase the temperature by additionally adjusting the thermostat.

When heated towel rail warms up as much as possible only in the area heating element, and then remains barely warm or even cold, there is a possibility that it is simply clogged and needs high-quality cleaning. They do it with their own hands at home.

The device is disconnected from the network, removed from the wall and turned over so that the heating liquid does not leak out. Using a wrench, unscrew the main valve and clean the inlet hole with wire.

Then the unit is assembled, checked for leaks, returned to its usual place and connected to the power supply. Normal operation of the device in standard mode means that the repair was successful.

If heating element does not heat up at all, the source of the problem is sought in the electrical part of the unit.

Troubleshooting electrical system

When it is already known for sure that the problem is not working heated towel rail lies not in the electrical network, but in the device itself, you need to urgently find the location of the malfunction. Devices operating on the basis of a heating cable, in most cases, cannot be repaired or require complete replacement of the main element.

Almost all heating elements new the units can be repaired without problems and after servicing they operate normally in standard mode.

To diagnose heating element, you need to get to the contacts connecting it to the system power supply. To do this, first remove the casing covering the contact part. This process is carried out differently in each model and is usually described in the user manual included with the product. heated towel rail.

Wires connecting heating element with a common system, soldered or bonded with special contacts. They are carefully disconnected. Then using multimeter they call separately, first the wire, and then itself heating element.

The measurement scale is set to “Ω” and the maximum value is indicated. The measurement is made between three passing wires and the indicator is recorded. It should be as high as possible. Data tending to 0 indicates the presence of a short circuit in the system.

If between the outlet and heating element There is some kind of control equipment; before measurement it is turned off and tested separately. Ignoring this item results in receiving incorrect data.

The examination of the heating element begins with checking the circuit between the power contacts. Then the presence and level of resistance between the power contacts and the housing is determined. If there is no circuit between the power contacts, then either the heating element, or thermostat.

Low resistance value between the power contacts and the housing heating element indicates its damage or breakdown. In such a situation, the element is removed and replaced with a new one.

Replacement work heating element

Configuration of most electric models heated towel rails involves replacing a failed heating element with a new one. The procedure is not too complicated and can be done at home with your own hands using a screwdriver, pliers and a set of wrenches.

Before starting repair work, you need to find out what type heating element used in the model heated towel rail. The most common are “wet” heating elements, in which the heating element is in contact with the coolant liquid.

Before repairing such units, they are removed from the wall, turned over, the inlet valve is unscrewed and the working fluid (water, oil, distillate solution) is drained. Then unscrew the threaded connections holding the element to the body and replace the faulty one heating element to ensure that it is operational, fill in the heat-carrying liquid, close the outlet openings and check the installation for leaks.

In “dry” versions, where the heating element and coolant are separated from each other, a faulty heating element Simply unscrew it from the body and put a new one in its place.

Upon completion of work multimeter they call heating element entirely and only if positive results are obtained in all areas, the equipment is installed back on the wall and the equipment is connected to the power supply system.

Modernization of a cheap Chinese model

Let's look at an example of improving a budget electric drying model installed by a budget-conscious developer. According to the home handyman who implemented this option, most of these appliances in the new house failed. We will analyze not only the idea, but also the mistakes he made, so as not to step on the “rakes” already tested by the owner.

The cause of common breakdowns has been found. When hanging wet things on the device, which it is actually intended for drying, the cheap Chinese product simply burns out due to excessive temperature and melting of the wiring. To eliminate such negative situations, it was decided to install a thermostat.

Depressurization of the system and loss of working fluid

The cause of unit malfunction is a violation of the integrity of the coolant container and, as a consequence, leakage of the working fluid. The culprits of this problem are usually sealing rings that have worn out during intensive use or have simply expired.

The easiest way to detect damage is. A puddle of leaked oily yellow or dark liquid forms on the bathroom floor directly under heated towel rail and clearly indicates the presence of a malfunction.

To fix a breakdown heated towel rail disconnected from the system power supply, remove from the wall, unscrew the valve at the inlet, drain the working fluid and carefully disassemble it at the point of depressurization using an adjustable wrench or a special tool provided by the design of the model.

The damaged o-ring is removed and a new one is installed in its place, which comes complete with device.

If all branded o-rings have already been used, the product is purchased at a specialized store. For heated towel rail Inexpensive spacer elements made of solid and semi-solid rubber are suitable.

They remain operational at temperatures from -40 to +80°C, and some more modern types do not lose their physical characteristics even at temperatures from -20 to +90°C.

The only drawback of rubber gaskets is their fragility. During use, they quickly lose their elastic structure, delaminate or crack. Installing them in heated towel rail, It should be borne in mind that they will have to be changed quite often.

Sealing and gasket products made from paronite are more practical and can easily withstand system pressures of up to 64 bar. Unlike rubber options, they can easily withstand high thermal loads (up to +200°C), are resistant to sudden temperature changes and are not afraid of strong pressure typical of heating systems.

However, paronite contains chrysolite asbestos, which is considered harmful to human health. It contains some types of carcinogens that can provoke malignant and benign formations. In the Eurozone countries, asbestos is prohibited, so professionals do not recommend using paronite gaskets for home appliances.

Silicone gaskets are non-toxic and perform well, but their price is quite high.In addition, in hermetically sealed systems at temperatures above +150°C, the material softens, becomes porous, loses hardness and loses its original strength.

Details from fluorine-containing polymers are more expensive, but have unsurpassed physical, anti-friction and electrical properties. Fluoroplastic demonstrates complete harmlessness to humans and instantly extinguishes upon spontaneous combustion.

Gaskets and seals made from this progressive material practically do not age, withstand record high loads, work efficiently in aggressive conditions, and withstand operating temperatures up to +150°C and pressure up to 160 bar.

After replacing the gasket, the drained working fluid is poured into the unit. If its volume is not enough, the required amount is added from a spare container. If desired, the heat-conducting composition is completely changed to a new one. To prevent the system from breaking, be sure to leave an air “cushion” of 3 to 5 centimeters.

At the end of the service, the unit is reassembled, the incoming valve is tightened, checked for leaks, hung in its usual place and connected to the electrical network. Heated towel railoperating normally means that the repair was successful.

PRules for installation and operation of equipment

To ensure that the equipment works efficiently and does not fail, when installation of an electric heated towel rail and operation of the device, you should follow some simple rules:

- The unit should not be placed in close proximity to a place where water flows.To avoid problems, you should hang the household appliance as far as possible from the bathtub or shower stall.

- When connecting a device to the system power supply you need to use a liner that can withstand intense current loads.

- For correct and safe operation heated towel rail Residual current devices should be installed. Differential circuit breaker, circuit breaker and RCD will protect equipment from burnout and ensure normal operation even during unauthorized power surges.

- The presence of a grounding contact is the most important position when installing electrical heated towel rail. In case of insulation breakdown, it will prevent electric shock to the user.

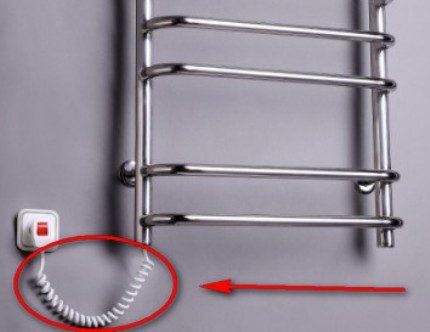

The connection socket must not be built-in, but external and must moisture-proof. If possible, it is better to place it outside the bathroom by drilling through it in a suitable place on the wall.

Conclusions and useful video on the topic

The video clearly demonstrates the process of replacing the phase wire of an electric dryer:

Troubleshooting and subsequent repairs heated towel rail can be done at home. This requires multimeter, screwdriver, adjustable wrench and pliers.

When carrying out work, you must observe basic safety rules and follow the advice contained in the instructions included with the equipment. If you have doubts about your abilities, you should contact the company’s warranty service center or call a qualified specialist to your home. He will quickly detect the problem area and fix any problems that may arise.

You can write a post about how you repaired an electric dryer with your own hands and attach a photo in the block located under the text of the article.Please comment on the information we provide, ask questions, and provide useful information on the topic.

Our heated towel rail is equipped with an automatic programmable on/off and temperature maintenance device. This is such an ambush, I don’t recommend it to anyone. It turns on on its own when not needed, and is always reset to factory settings when there is a power outage. It is impossible to turn off guaranteed during the holidays. The heated towel rail must be connected to a separate machine. It's better to have a mechanical temperature controller.

Rita, you have exactly the situation where the best is the enemy of the good. Everyone then suffers with these programmable toys)

Our situation with the electronic heated towel rail was just described; it stopped working. When the technician arrived and diagnosed the power line, it turned out that the shutdown was due to overheating and a short circuit in the system. I realized that it is not possible to identify the problem without special equipment and that it cannot be eliminated on my own without special knowledge.

Hello! I have a heated towel rail with a TERMO brand control unit model KTX-3. When turned on, “E7” is displayed on the display and the heating element does not heat up, you cannot select the desired program, you cannot select the temperature... it feels like there is some kind of error. Maybe someone knows what the reason is?

it was the same thing, I changed the heating element (heating element), the error disappeared, it started working normally

Heated towel rail not working

Not an article, but absolute nonsense! A set of recommendations from a person who has no idea not only about the topic of the article but also about elementary physical laws.However, after the phrase “The plug is removed and the entrance holes are carefully inspected,” there was no need to read further. I read it to laugh. You still need to look for more illiterate rubbish! Author, if the resistance of the heating element approaches zero, what current will flow through the circuit? Google Ohm's Law, Master!

Can anyone tell me where it can be repaired? When I press the power button, the temperature indicators light up, but when I release the button, everything goes out, it was such that it heated up to warm, but then cooled down.