Ceiling socket under a chandelier: instructions for installing the socket on the ceiling

One of the most impressive ways to decorate a chandelier at the connection point is a ceiling rosette, which allows you to stunningly design a ceiling lighting fixture. It perfectly hides electrical wires, mounting clips and hooks. But you don’t know which model to choose, how to install and secure it?

We will help you understand these issues. Taking into account our recommendations, you will have the best ceiling rosette for a chandelier. The article discusses popular models sold on the modern market.

We invite you to familiarize yourself with step-by-step instructions for installing and fastening sockets made of various materials with visual photos of each step. We will also tell you what installation features should be taken into account when connecting. The article is equipped with video tips on the selection, subtleties of decor and installation on your own.

The content of the article:

Options for ceiling roses

A ceiling rosette is a monolithic or prefabricated structure mounted on a substrate, which covers the unsightly place where the chandelier is attached to the surface and the connection point of the electrical wires leading to it.

The concept of “socket” was borrowed from the French.At the dawn of their appearance, ceiling models looked like symmetrical stylized flowers or wreaths of greenery with leaves diverging diametrically from the center.

Today, the choice of textures and color options is much wider. These can be heraldic ornaments, geometric patterns, abstract compositions with unpretentious designs that fit perfectly into modern style solutions. For those who prefer a more laconic and modern style, ceiling roses made to order by trusted companies are ideal.

The form can be very diverse:

- round;

- oval;

- square;

- polygonal;

- with curved edges.

If in earlier times such functional decorative elements were used exclusively to decorate ceilings, today they are often used to decorate side lighting.

Using several small rosettes of different sizes, but with a similar repeating pattern, it is convenient to create original installations.

Main types of connection points

Stylized rosettes can be perfectly combined with cornices, borders and fillets, acting as a worthy addition to the interior, or take on the role of a bright decorative accent.

No. 1 - classification of products by type of material

The first models of ceiling rosettes were made mainly of plaster, less often of wood. The production of modern gypsum products is based on centuries-old traditions. The only difference is that special modifying additives are used to improve the plasticity of the material.

Sockets made of gypsum are famous for their excellent technical characteristics. They are “indifferent” to the effects of the environment and do not require serious care. Synthetic products are no less popular: polyurethane and foam rosettes for the ceiling.

The synthetic polymer is resistant to deformation under the influence of temperature changes, so sockets made from it can be installed in unheated and damp rooms.

The main advantage of polymer materials is their lightness, which greatly simplifies the installation process. But they do not have such clear detail of the drawing as plaster models.

The only drawback of polymer products is their short service life. After just five years they begin to turn yellow.The defect can be eliminated only by applying a new layer of paint, or by completely replacing the element that has lost its presentability.

A separate niche in the market is occupied by products that have the texture of noble stone, for example, marble.

Models made from natural materials are used to embody traditional architectural forms that were characteristic of royal castles and palaces in a modern interior.

No. 2 - division into types according to installation method

Depending on the installation method, there are:

- Overhead sockets for masking electrical points, they are products with a smooth base on which decorative elements are located.

- Mortise models are patterns laid out on a substrate, which, after installation is completed, are perceived together with the ceiling surface as a single whole.

Mortise-type models have the advantage over their overhead counterparts in that, due to the inconspicuousness of the joints, they look like a natural extension of the ceiling.

No. 3 - for decoration

Depending on the decorative design, ceiling rosettes come in two types:

- Profile models with smooth surface. They are made on the basis of a stretched profile and are a form that includes several flat geometric shapes of different sizes, inscribed into each other.

- Rosettes with molded surface and relief shapes. In models of this type, the smooth base of the product is decorated with individual details and decorative elements.

By installing an electrical outlet decorated with many elements, you can construct a three-dimensional picture or a lace ceiling under a chandelier. Beautifully designed stucco molding will easily disguise all the errors and imperfections in the design and layout of the room.

Dome-type sockets are also often found on sale. They have a concave shape. But such models are mounted only in suspended structures, thereby creating the illusion of vast space and at the same time improving the acoustics of the room.

Concave ceiling rosettes in the form of a square, diamond or rectangle look interesting. Such structures are called caissons. They are installed like a cassette ceiling.

Criteria for choosing a model correctly

Select sockets for the ceiling in accordance with the dimensions of the lighting fixture. Ideally, the boundaries of artificial stucco should not extend beyond the projection of the chandelier. The choice of a functional decorative element depends on the area of the room and the height of its ceilings.So, for rooms with an area of 15 square meters and above, it is worth choosing models with a diameter of 40 cm.

But even when choosing small voluminous stucco moldings, you should give preference to products with clear detailed drawing. Detailing the ornament will create the desired effect and draw attention to a small but expressive decorative element in a small room.

In addition, the socket must be harmoniously combined with other decorative elements used in the design of the walls and ceiling.

The choice is determined by the ultimate goal of the room style being created:

- Wooden sockets Perfect for decorating living rooms and hallways in houses made of timber or logs. They will harmoniously combine with a wooden staircase and other interior decoration elements made from the same natural material.

- Foam and polystyrene sockets suitable for decorating rooms in modern styles, for example, high-tech, modern or art deco. They lend themselves well to painting, easily taking on the shine of all applied layers of coating.

- Rosettes made of plaster and marble chips will look impressive in rooms with high ceilings. They often act as a kind of symbol of luxury and wealth, emphasizing the exclusivity of the design.

Products used to decorate the ceiling are selected from the same type of material, remembering that, for example, gypsum stucco molding looks tasteless against the background of the same foam baguettes.

Connection point installation technology

Gypsum ceiling rosettes do not require the installation of an additional fastening system. The main thing is to ensure reliable fixation.

To install a ceiling rosette under a chandelier, you need to prepare:

- plastic chops;

- couplings;

- Victory drill;

- self-tapping screws;

- screwdriver;

- pliers;

- gypsum mortar;

- small spatula;

- insulating tape;

- container for mixing the solution.

To hang the lighting fixture from the ceiling, you will need a metal hook or a standard mounting strip.

When carrying out work, you will also need a stable stepladder or table that can support the weight of an adult. Do not use stools stacked on top of each other as a stand. This may be hazardous to your health.

Stage #1 - carrying out preparatory work

Before starting installation, it is necessary to de-energize the room by turning off circuit breaker the corresponding lighting and power branch in the distribution panel. To make sure there is no voltage in the network, you need to touch the exposed ends of the wires with an indicator screwdriver. It shouldn't glow.

After this, by applying the socket itself to the surface, the ceiling is marked.

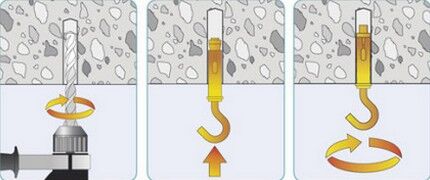

To install the hook in the intended location, first use a pobedit drill to make a hole 7-8 cm deep. A plastic chopper is buried into it so that it fits as tightly as possible to the walls, and then a metal hook is screwed in.

To attach the mounting strip, it is first applied to the installation site so that it does not interfere with the wiring connections, and the points of the holes for the dowels are marked.

When planning to hang a massive chandelier, we recommend using a cross-shaped mounting strip. It has a larger coverage area and a larger number of holes for fixing to the ceiling.

A correctly fixed mounting plate will guarantee the reliability of fastening of the installed lighting device.

Stage #2 - laying the electrical cable

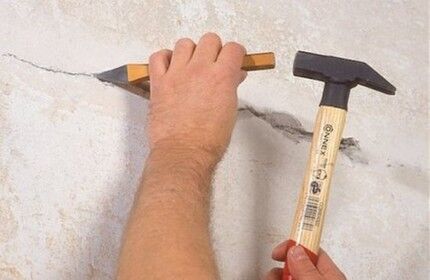

For installation of internal wiring a groove is made in the ceiling surface using a wall chaser or an ordinary chisel. The electrical wire is placed in a special casing, which will subsequently be closed during finishing work.

If it is necessary to extend the wire, use heat-shrinkable tapes or special couplings.

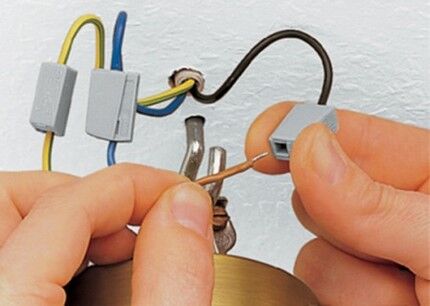

The wires are connected in one of the following ways:

- Using couplings. The wires coming out of the ceiling are inserted into couplings and secured with bolts.

- By twisting wires between themselves. But it is worth considering that such twisting will oxidize over time, and as a result, sooner or later it will begin to heat up.

When connecting the ends of an electrical cable, it is important to ensure their correspondence - connect wires of the same type into pairs.

Helps determine which cable belongs to color of polymer insulation. The phase wire is usually hidden in red or brown insulation, the neutral wire is in blue or cyan, and the ground wire is in a yellow-green sheath.

Some beginners connect electrical wires each other by bending their ends into hooks. But to obtain a strong connection and create normal contact, the exposed ends of the electrical cable must be twisted or soldered.

After installation is completed, exposed sections of wires must be insulated using high-quality insulating tape.

How to connect a ceiling lighting fixture to a two-key switch is described in detail in one of popular articles our site.

Stage #3 - fixing the gypsum base

To secure the base, a gypsum solution is applied to it from the reverse side. The easiest way to evenly distribute the solution over the surface is to use a spatula.

The base with the applied solution is pressed to the surface and fixed in this position for several minutes until it acquires the desired strength. You can use a support for fixation. To minimize damage to decorative relief elements, soft rags are placed under the support.

If it is necessary to hang a massive product, 10 cm long self-tapping screws are used for additional fixation. They are screwed at 6-10 points at an equidistant distance. When screwing in the screws, they try to deepen the cap so that later it can be easily masked with gypsum mortar.

Features of installation of mortise sockets

To secure the mortise socket, the base of the product is applied to the surface and marks are made along the contour with a pencil.

All potholes and cracks formed during the cutting process can be easily repaired with gypsum mortar. To secure gypsum elements to a reinforced concrete base, screws supplemented with wire wrap are used.

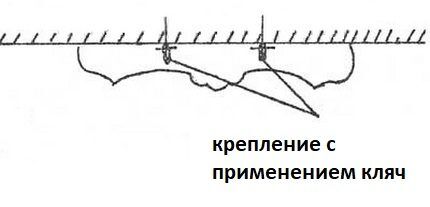

To secure heavy structures, fastening systems called nags are used. The place for installing the nags should be level, devoid of relief ornaments.

The work is performed in the following sequence:

- To install fasteners, through holes are drilled in the socket, and grooves 15 mm deep are made in the front part of the product.

- Self-tapping screws are screwed through the holes.

- Screws of galvanized wire are screwed to the heads of the screws so that the “whiskers” diverge in different directions.

- The installed structure is covered with a layer of gypsum mortar.

- The “whiskers” diverging in two directions are inserted into the holes and secured. Excess wire is cut off. The grooves are covered with gypsum mortar.

The number of such nags is determined based on the weight of the socket and the design features of the ceiling itself.

To avoid corrosion, it is advisable to coat the cut ends of the wire with a layer of varnish. The gaps between the installed rosette or ceiling base are filled with gypsum mortar.The grooves formed after the gypsum has hardened can be easily eliminated by sanding them down with sandpaper.

Fastening polyurethane products

Ceiling rosettes made of polyurethane foam are attached to the base with glue. For work, use “liquid nails” or a special glue created for stucco molding made of polyurethane foam.

The ceiling itself at the location where the socket is installed is covered with a layer of deep penetration primer. Working with polyurethane foam products is quite easy. The soft material is easy to cut and convenient to attach to the surface.

The diameter of the hole is made small so that the fastening system is completely covered by the cap. The gluing of the stucco molding is carried out after the primer composition has completely dried. To do this, polymer glue is applied to the back side of the base in an even layer.

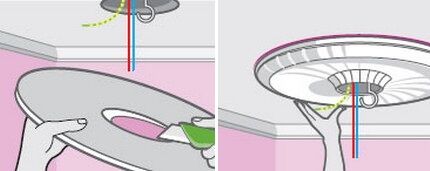

The stucco molding, with a hook and an electrical wire passed through the hole, is applied to the ceiling. To ensure adhesion strength when the glue hardens, the stucco molding must be pressed as tightly as possible to the surface. Excess glue protruding along the edges must be immediately removed with a brush dipped in water or a cotton napkin.

After the glue has hardened, the chandelier is hung on a mounting strip or hook. The wires are connected using one of the methods described above.

Testing the structure for strength

Before hanging the chandelier, you need to check the quality of the fastening for the strength of both the hook and the ceiling rosette itself. To do this, hang a load on the plaster molding, the weight of which is gradually increased.

The structure must be able to withstand a load whose mass is approximately equal to the weight of the lighting fixture being installed.

If during the 10-minute test, as the weight of the load increases, the structure does not shift or move away from the ceiling, then the fastening is strong.

Conclusions and useful video on the topic

Video #1. Stages of installing gypsum stucco:

Video #2. Plaster rosette cast from a mold:

Video #3. Design options for ceiling roses:

The technology for installing prefabricated ceiling sockets, including several connection points, is no different from installing conventional ones. Difficulty can arise only when cleaning the seams to maintain a single plane of the decorative elements assembled into the composition.

We are waiting for your stories about how you installed a ceiling rosette yourself. Perhaps you have any questions while reading the article or want to comment on the information we have presented? Please leave comments in the feedback block below.

The guys and I spent the entire spring and June renovating apartments. I'll tell you that these types of rosettes, with various shapes, especially with artificial stucco and additional decorations, have only been encountered once. And then in the apartment of a person with very ambiguous taste. I tried to make a Hermitage out of a 3-room apartment with a salary, i.e. It’s clear what the quality of workmanship and “decor” is like there. However, I noticed at the same time that very, very many people began to use simple LED lamps and, oddly enough, LED strips, especially young people, for lighting their apartments. Even a year ago I had not yet noticed such a trend.

How to remove this very hook? It's in a hole in my ceiling. It does not come down as shown in the picture. The chandelier is light, hangs stupidly on it, without covering the hole. A terrible sight. Every time you rub or touch the chandelier, it wobbles and the light blinks. I try not to breathe on her at all. I wouldn't want to drill anything, the ceiling is after renovation. Is the option for liquid nails appropriate? What other method of fastening is there?

Good afternoon, Nikolay. Such hooks usually have side folding diverging elements. When the hole is drilled, the elements fold and do not interfere with the passage of the suspension device. Then they unfold using a screwdriver.

Some hooks are suspended from a transverse axle, which is pre-placed on the hole on the inside of the hole. The first option is more practical.

Some chandeliers are equipped with overhead strips with fasteners. There is no need to drill/hollow the ceiling for them, but there will still be a hole for the wires to pass through. I have attached screenshots of the suspension options.

This, of course, is all very beautiful and looks incredibly expensive. But I struggled with this for quite some time. Since the work is very labor-intensive, it requires at least a little training and experience in this part of the finishing. When we installed all this in the living room, we had to ask the help of a master. But everything turned out so luxuriously that I wanted such a chandelier in the room. I already did everything myself, it turned out great)

Are there sockets that are composed of two segments? On my chandelier the skirt is rigidly fixed, i.e. It is impossible to lift it to the ceiling, and there is a two-centimeter gap between the skirt of the chandelier and the ceiling.