Grease trap under the sink: operating principle, types of structures and features of their installation

A clogged drain in the kitchen is a common occurrence.Remains of food and fatty deposits accumulate on the walls of the canal and prevent the free outflow of water. To clean pipes, you have to use chemicals that harm plumbing fixtures, or resort to mechanical methods - using a cable or plunger.

It is quite possible to reduce the likelihood of clogging by placing a grease trap under the sink - the device filters the drains and prevents grease from seeping deep into the sewer. The unit is quite useful, but before you decide to buy it, you need to learn more about such a separator, don’t you agree?

The article discusses in detail the design, characteristics, operating principles and modifications of grease traps. Recommendations for choosing a device, its installation and maintenance are also provided.

The content of the article:

Types of grease traps for sinks

There are quite a few types of grease traps, and they all have different performance and equipment. This equipment can be classified according to the body material and design features.

Grease traps can be plastic, fiberglass, metal.

Plastic. Both industrial and the simplest household models of grease traps are made from polypropylene and polyethylene. They are durable, cheap, lightweight and do not require special maintenance. Most grease traps under the sink are made of this material.

Fiberglass. These models have increased strength and resistance to chemicals, so they can be installed outdoors and dug into the ground.

Metal. Stainless steel grease traps can be easily washed with hard brushes without fear of damaging the surface. They look aesthetically pleasing, but are not cheap. Models made of stainless steel and aluminum are almost eternal, unlike products made of galvanized and painted steel, which can rust over time.

Separators in private homes can be made independently, and there are not many design requirements for them, so there are countless options for the design of this equipment.

However, they can still be divided into the following types:

- Grease traps under the sink. They will be discussed in detail below. Such equipment is manually serviced and installed in apartments, houses, and small cafes.

- Industrial (shop) models. They are used in catering units designed for hundreds of people, in boarding houses and sanatoriums, as well as in food industry enterprises. Often such models are equipped with fill sensors.

- Automatic. They have an electric mechanism for automatic grease collection, which facilitates maintenance and prevents clogging of the inlet and outlet pipes.

- Located below the sewer level. Such models are installed in the basement or in the ground. They have a built-in electric pump that pumps purified water to the level of the sewer drain.

- Well. These are large industrial grease traps in the form of a cylinder that can be installed in special external wells. Their maintenance is carried out through the hatch.

For household needs, it is enough to purchase a regular grease trap for the sink, which you can service yourself once every few weeks. These small devices have a simple design and structure.

Technical characteristics of grease traps

To choose a separator that will fit into the space under the sink, you need to know not only its overall dimensions and structure, but also its functionality. When choosing a device, the individual characteristics of the apartment and the diet of its residents are of considerable importance.

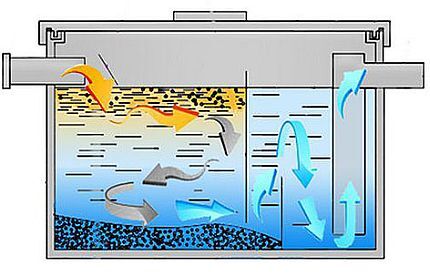

Device diagram and operating principle

Household waste from the kitchen sink contains a lot of grease, which gradually settles in the sewer pipes. After a few years, this can lead to clogging of the pipeline, the appearance of a persistent unpleasant odor from the decomposition of organic matter and the need sewer flushing.

Old fat deposits are difficult to remove even plumbing cable, so their removal may require complete dismantling of the sewer system.

These problems can be solved by installing a grease trap under the sink.

Such equipment consists of the following elements:

- Rectangular body with two openings (inlet and outlet) located at opposite ends of the grease trap.

- One or more partitions. They slow the flow of water through the system, preventing grease and solids from entering the drain.

- Tight-fitting lid. It should have a rubberized gasket to prevent air from entering the kitchen from the interior of the grease trap.

- Inlet pipe in the form of a short knee.

- Exhaust pipe in the form of a tee open on all sides. It has a long part that goes down almost to the bottom of the body and a short part that ends under the lid.

- Ventilation outlet (optional).

The design of the grease trap also determines the principle of its operation. Contaminated water enters the receiving chamber of the grease trap. The entrance can be either side or top. This part of the space is fenced off with one or two partitions. Due to the difference in the densities of water and fats, the latter rise upward and accumulate there.

If there is one wall, then it usually covers the lower 2/3 of the cross section of the grease trap, and if there are two, then they are located alternately from below and from above: the first cuts off solid particles, and the second cuts off fat.

Behind the partitions there is a second chamber, from the lower part of which water, already cleared of fat and impurities, is discharged into the sewer.

The fat fraction gradually fills the upper part of the internal space of the device, so it is necessary to clean it in a timely manner, without waiting for the moment when the accumulated fats begin to enter the outlet pipe.

Formulas for calculating the required performance

There is no point in hoping that the smallest grease trap will be enough for an apartment. It is better to calculate the required equipment performance in advance, so as not to regret the wasted funds later.

A simple formula is used for calculation:

P = n*Ps,

Where:

- R – productivity in liters per second;

- n – number of connected sinks;

- PS – rate of water flow into the separator in liters per second.

Ps can be calculated independently using a bucket or pan with a known volume. To do this, you need to fully open the water tap and note the time it takes for the container to fill. Then calculate how much water will flow out if the tap is open for one second.

The calculation is performed using the formula:

Ps=V/T,

Where:

- T – time of collecting water into the container in seconds;

- V – capacity of the container in liters.

After determining the required performance of the grease trap, you can find out its recommended volume.

Volume calculation formula:

V=60*P*t,

Where t — fat floating speed, the value of which for household separators is 6.4 min.

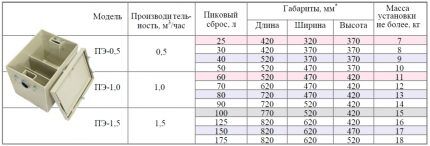

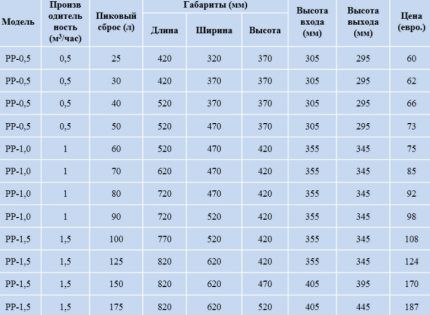

Grease traps for sinks with a capacity of 0.145 l/s and a volume of 50 l or more are available on the market.The smaller capacity of the device simply physically will not allow it to effectively perform the functions of cutting off fat, so there is no point in purchasing such models.

Operational requirements for the separator

When operating a grease trap, you must follow a number of rules that increase the efficiency of the equipment and help avoid unpleasant odors and flooding in the kitchen.

Recommendations for using the device:

- Water drains must not contain mineral or synthetic oils.

- It is unacceptable to connect a grease trap to the toilet.

- Pumps cannot be installed in front of the equipment because they form a poorly settling emulsion.

- Inlet pipes should be as close as possible to the sink and have a minimum slope of 2°C.

- Purified water must be sent directly to the sewer system.

- It is advisable to connect the grease trap to the ventilation - fan pipe, if there is a corresponding outlet on the device cover.

To produce quality products, manufacturers must adhere to the standards for the manufacture and installation of grease traps EN 1825 and DIN 4040-100. Access to the texts of these standards costs around $100.

What are the benefits of grease traps?

The volume of the grease separator for wastewater, although small, in apartments it occupies an entire section of the cabinet under the sink. Therefore, there must be compelling reasons for installing such equipment.

Owners of grease traps note the following advantages:

- Simplicity of design. You can assemble the separator yourself from an old plastic tank.

- Easy to install. To connect the device to the siphon and sewer, simply connect two pipes by hand without using a tool.

- Ease of maintenance. It is enough to remove the top fat once every few weeks. The cleaning process takes 2-3 minutes.

- Protecting pipes from clogging. When using a grease trap, the sewer system will last for decades without the need for cleaning.

- Compactness and the ability to install equipment under the sink.

A sensor for filling the tank with grease can be connected to the grease trap.

The main task of a grease trap is not the general purification of water, but the separation of particles from it that can settle in sewer pipes and narrow their lumen.

How to choose a device for your home

The initial stage of choosing a grease trap is carried out not in a hardware store or on the Internet, but in the planned location of its installation. Before purchasing a device, you need to decide on a number of parameters that will help you narrow down your options to a few models.

First of all, it is worth assessing:

- Dimensions of free space under the sink. It should be taken into account that there should be space at the top for removing the cover, and at the sides for connecting pipes.

- Diameter of sewer pipes in the kitchen. It is better to buy a grease trap with the same hole size so as not to use additional plastic adapters.

- Number of sinks served. When calculating productivity, it is necessary to take into account the simultaneous flow of wastewater from all open taps.

- Effluent characteristics. If there is a large amount of solid particles in the drained water, it is recommended to install grease trap models with several partitions.

- Availability of sewer riser or a drain pipe near the sink - the channel is necessary to prevent failure water seal on siphon. Models with an air duct are preferable, but the possibility of connecting them to a sewer riser is not available in every apartment or house.

- Availability of free space for equipment maintenance work. When removing grease, unpleasant-smelling waste may end up behind the grease trap body, so it must be possible to clean this space

- Housing material. For installation under the sink, a regular plastic grease trap will be sufficient, but if it is open for viewing, you can buy a more expensive and aesthetic model made of stainless steel.

- Washing volume. Sometimes you need to dump water from a fully filled sink in one gulp. This amount of liquid is one of the characteristics of the grease trap and must be indicated in the instructions.

After taking into account all the nuances described above, you can begin to directly select a suitable device from the options offered on the market.

The price of plastic models depends mainly on the volume of the tank and the complexity of the internal structure. Given the same parameters, it is better to choose the cheaper option, because a more expensive model is unlikely to be of better quality.

Installing a grease trap under the sink

Installing a grease trap under a sink does not require any special skills or tools. All necessary connecting parts can be purchased at the same store where the device itself is purchased. Additional polypropylene fittings and tubes may only be needed to connect the grease trap to the sewer and siphon.

The separator is usually sold assembled, that is, connecting pipes or rubber adapters are already inserted and sealed into its holes. All that remains is to open the lid and take out the operating instructions from the tank.

After this, you can carry out the final installation of the grease trap:

- Prepare a work space under the sink.

- In some equipment models, the elbow for water inlet and the tee for water drainage are included separately, so they need to be inserted into the appropriate holes, pre-lubricated with silicone.

- Screw adapters to the separator if necessary.

- Place a grease trap under the sink.

- Lubricate outside plumbing sealant sewer and siphon pipes that will connect to the grease trap.

- Connect all necessary pipes to the separator and wait for the sealant to harden.

- Connect the air duct to the sewer riser, if there is one.

- Open the water tap and check the tightness of the tank and pipe connections.

If there are no leaks, then the grease trap is ready for use.

Since the effectiveness of the grease trap is greatly influenced by the water temperature, it is not advisable to install it next to an actively used oven. It is also necessary to protect the separator from exposure to negative temperatures when there is water in it, as this can lead to rupture of the tank.

Separator maintenance and monitoring

Servicing a grease trap is not the most pleasant procedure, but it is much more unpleasant to clean out clogged sewer pipes.

The frequency of cleaning a household separator depends on several parameters:

- volume of the grease trap tank;

- family diet, which determines the composition of wastewater;

- temperature of the water used.

Due to these factors, the frequency of separator cleaning may vary from several weeks to several months.

Close attention to the level of wastewater must be paid in the first weeks of operation. It is necessary to periodically open the grease trap lid and check the level of solid waste. If the bottom layer of fat reaches the level of the outlet, it may become clogged, causing the tank to overflow and flood the room.

It is advisable to remove the fat mass when it reaches a level 4-5 cm above the lower edge of the water drainage pipe.To remove fat, you need to open the tank lid and pull out the top viscous layer using gloves, a ladle or other available device.

After inspecting the grease trap, you can rinse it with hot water for several minutes.

When the approximate period of safe operation of a grease trap has already been established experimentally, you can look into it much less often.

More details about the different types of grease traps for sewage, an overview of popular models, as well as the specifics of installing the separator indoors and outdoors are described in this article.

Conclusions and useful video on the topic

To better understand the internal structure of the grease trap, its operating features, installation and maintenance rules, it is recommended to watch the videos below. They will summarize the knowledge gained and allow you to see the operation of the device in dynamics.

Installing a grease trap under the sink:

Grease trap operation:

Cleaning the grease separator:

Purchasing and installing a grease trap under the sink helps avoid many problems when the drain is clogged. To install the equipment, it is enough to have free space under the sink, because the process of putting the separator into operation is simple and does not require much time.

Are you looking for an effective grease trap for your kitchen sink? Or do you have experience using such installations? Please leave comments on the article and share your impressions of using grease traps. The contact form is located in the lower block.

In my opinion, installing a grease trap at home, no matter in an apartment or in a private house, is stupid and wasteful. An ordinary siphon will cope with its function.But if you are preparing pies for sale, or boldly pouring fat from the deep fryer straight into the sink, then yes, it is necessary.

But for public catering, especially street food, it is needed. In general, it seems to me that it is needed wherever there is little water, poor sewerage and there is a problem of the impossibility of draining waste into separate containers.

Victor, in apartments this is really not necessary, but in some private houses you cannot do without a grease trap. My house is old, the sewer comes from the neighbors and clogs instantly. Previously, you had to call specialists every three months to clean it, but after installing a grease trap, this happens a maximum of once every six months. It turns out to be a good saving.

On the contrary, a grease trap is a very profitable device. Especially if it's metal.

A model of this type is made of stainless steel and is environmentally friendly and eternal, thereby confirming its quality.

Its metal body looks stronger, for one simple reason: it is not exposed to detergents and iron brushes and does not absorb odors, unlike plastic. After all, after prolonged use, any plastic begins to emit odors that cause inconvenience.

Odors will not disappear even after cleaning the grease trap.

A stainless steel grease trap will pass any sanitary epidemiological and fire safety inspection. An important point is that the installation of plastic models is now prohibited. It is only recommended to install separators made of steel.

I think that now no one has extra money to pay money again for such equipment just because you are using plastic. It’s better to pay a couple of thousand rubles for steel equipment.

Having purchased it, you will have peace of mind, as it is equipped with a drain, which provides a simple and convenient way of self-service.

A grease trap is a good thing. Excellent prevention, ensuring normal operation of plumbing drains and sewer pipes. It is worth using so that there are no blockages and the lumen of the pipeline does not become overgrown with insoluble sediment.

My brother and I have a roadside cafe, the sanitary and epidemiological inspection forces us to install this grease trap. And most importantly, prices for such nonsense start at 9-10 thousand. They profit from everything.

I have been monitoring the manufacturers and market of grease traps for a very long time. All the time I was in search of the optimal solution for my private home. My choice was always between whether to take a plastic type product or a metal one. I had a lot of conversations with my friends, acquaintances and business colleagues. Everyone agrees - take the metal one. I thought long and carefully about which one to buy. Stainless steel is a sign of durability. Just what I need. There is simply no time or desire to replace plastic that has burst for unknown reasons every time. Two years in operation and I don’t know any grief.