Sewerage installation in a country house: arrangement diagrams + installation instructions

The times when a private home did not have basic amenities are long gone.A summer cottage and a country cottage should delight their owners with comfort. A well-thought-out sewer system in a country house is a task that, with the right approach, can be accomplished by anyone, even a novice master.

Before starting to develop a project, it is necessary to familiarize yourself with the possible options for organizing an autonomous system, select the type of treatment facility, and study the intricacies of installing internal and external sewer networks. The answers to all the above questions are described in detail in the article.

The content of the article:

General design principles

Ideally, the drainage system should be laid out at the design stage of the building. But the arrangement of a bathroom capable of providing an urban level of comfort can be completely organized in an old building.

It’s great if it is possible to connect communications to a centralized village or city highway. In the absence of one, the problem will have to be solved by creating an autonomous sewer system.

An autonomous sewage system includes two interdependent parts of the system:

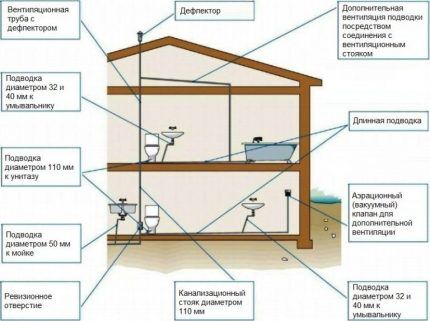

- Indoor system. Its constituent components are water inlets and pipelines. If it is a two- or three-story house, then the system includes a vertical riser with horizontally laid pipes connected to it through fittings, which are connected to plumbing fixtures.

- Outdoor system. It is represented by a pipeline laid horizontally at a certain slope. It receives wastewater from intra-house pipes and diverts it to an autonomous treatment facility or to a centralized main.

When installing sewerage in a house under construction, the installation of bathrooms and kitchens should be designed in one part of the building, placing them closer to the wall where the sewerage goes out onto the street.

There are two ways to remove wastewater from the system: gravity and pressure. The first option is easier to implement. But in this case, it is necessary to correctly calculate the angle of creation of the inclined plane of the pipes.

If it is planned to place several bathrooms in the house, having installed a complex sewer system, to ensure uninterrupted operation it will be necessary to use a powerful sewage pump. The installation of this unit will also be relevant if the site does not have any slope.

Key points to consider when planning outdoor sewerage:

- Landscape of the site. To ensure unhindered drainage of waste liquid, the cesspool or septic tank must be located at the lowest point of the site.

- Soil type and groundwater level. The choice of the type of treatment structure and the depth of the external pipeline depend on this parameter.

- Area and location of the site. It is necessary to provide access for carrying out repairs and access for sewage disposal equipment.

When designing internal sewerage, it should be taken into account that horizontal pipes from devices to the riser must run at a slope.

On average, the length of the pipeline from the drain to the vertical riser is about 3 m. According to standards, the furthest plumbing fixture can be 5 m away from the riser. The distance of the connection point from the toilet to the riser is 1 m.

You can handle the construction of internal sewerage with your own hands:

Options for design of treatment facilities

When installing an autonomous sewer system, when it is not possible to connect to a centralized pipeline, one of three types of structures can be used:

- cesspool - the most budget-friendly and easiest-to-execute option. It can be realized by creating a pit, the bottom and walls of which are lined with concrete rings, stone or building bricks. The only “minus” of the design is the need to regularly pump out the contents using sewage disposal equipment.

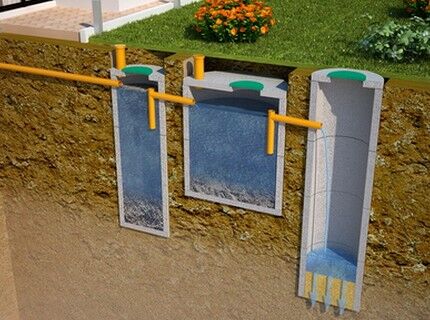

- Septic tank - a more efficient structure with which you can not only collect, but purify wastewater mechanically and biologically, making it suitable for technical purposes.

- Autonomous station - the best option, providing the highest degree of purification using a biological method, thanks to which water can be reused for technical needs.Due to the forced air supply, aerobic bacteria living inside the tank quickly and effectively decompose organic matter.

A conventional cesspool does not meet environmental requirements, as it creates a risk of wastewater entering the ground. Therefore, this option is chosen only for small country houses intended for seasonal living.

For year-round homes, it is better to install a multi-chamber septic tank or a local biological treatment station.

Can pick up a septic tank, or build it yourself. It comes in one-, two- and three-chamber versions.

Initially, the purification of the liquid inside the walls occurs due to separation and sedimentation. Then the destruction of solid impurities present in it is carried out due to the activity of aerobic bacteria.

The owner’s task is to remove the silt that has settled on the walls of the well as it accumulates.

The easiest option is to purchase a finished product made of heavy-duty polymer.You can make a septic tank yourself by pouring concrete formwork or by erecting brick or stone masonry.

Want to make things easier for yourself? Use 3-4 concrete rings, the cost of which is not high on the market.

The volume of the septic tank is calculated based on the fact that 200 liters of wastewater per household per day. The capacity of the treatment plant must be no less than the total three-day volume of wastewater.

Important point! The use of a filtration well is possible only if the groundwater level in the area is low.

On clay soils and at high groundwater levels, it is better to place a biofilter or install an above-ground filter cassette.

Main stages of installation of internal sewerage

In order to correctly calculate the required amount of materials and prevent installation errors, you should order a project.

Are you sure that you can carry out the calculations yourself, taking into account the requirements of building codes and at the same time want to save on expenses? Then limit yourself to drawing up a diagram of the sewerage system.

You can design the system in a computer program, or by performing all the calculations and drawings manually.

Selection of required materials

When arranging both external and internal sewage systems, polyvinyl chloride or polypropylene pipes are most often used.

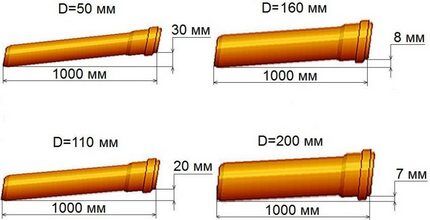

Waste diameter internal sewerage pipes must be larger than the size of the installed drain pipes.

The cross-section of the pipes used to construct the riser, provided that the toilet will be connected to it, must be 100 mm. The size of the fan pipe is similar to the diameter of the riser. The connection to the riser is made with pipes D 50 mm.

It is convenient to use corrugation for installing external communications. It ensures the reliability of the system during seasonal movements of the earth, but due to the presence of stiffening ribs, the corrugation is not subject to deformation.

In addition to pipes for sewerage installation, you will also need:

- elbows of various configurations for forming corners;

- triple and quadruple fittings for branching the system;

- transition couplings for joining elements of different diameters;

- inspection hatches for the ability to clean the system in different areas;

- sets of rubber seals.

To cut pipes to size and create chamfers on their ends, you will need a plastic scoring saw and a sharp knife. To treat joints, prepare sealant in advance.

Installation of vertical risers

Installation of internal sewerage begins with the installation of vertical risers. They are laid from the base to the roof, passing through the interfloor ceilings. Underwater pipes are connected to the installed riser through oblique tees.

The riser with horizontal pipes connected to it is lowered to the level of the plinth or basement. There, external pipes are connected to it, leading into the building through a hole in the foundation.

To minimize damage to the pipe under the influence of pressure from the walls of the building, a metal or concrete sleeve is installed at the place where it is laid.

It must pass through the base of the building, protruding 15 cm on both sides. The diameter of the sleeve must exceed the size of the external sewer pipe.

The insulation is also placed in the cavity of the liner, filling the voids formed after laying the outlet pipe.It will reduce the likelihood of freezing and prevent loosening of the pipe inside the sleeve.

At the final stage, after connecting the floor-by-floor pipes to create a noise and waterproofing layer, the risers are covered with a screen made of moisture-resistant plasterboard and wrapped with pieces of rolled materials.

Installation and connection of plumbing

First thing connect toilets, after which - all other devices. To eliminate the possibility of waste liquid getting into the drains of plumbing fixtures, it is better to connect them above the point of the toilet. Several plumbing fixtures are allowed per outlet.

When laying a pipeline, if it becomes necessary to turn the pipe 90° to reduce pressure in the system and prevent blockages, the connection must be made as smooth as possible. For this purpose, 3 elbows are installed, each with an angle of 30°, or 2 elbows with an angle of 45°.

If it is not possible to create “soft corners”, after a sharp bend it is recommended to place a tee equipped with a cover. Through it you can clear possible blockages.

Pipes of smaller diameter are connected to larger elements using adapters.

Each plumbing fixture is connected to the sewer pipeline through a U-shaped siphon, the main purpose of which is to form a water seal.It will act as a barrier that prevents the spread of foul odors from the sewer into the room.

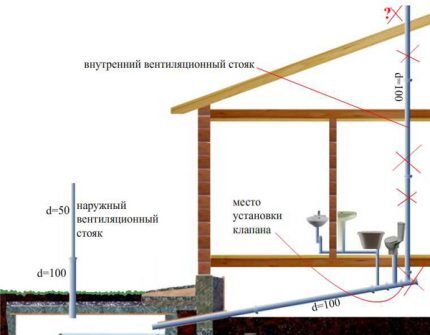

Installation of sewer ventilation

Water masses, abruptly drained from the same toilet cistern, form an area of rarefied space behind them as they move through the pipe.

If you do not ensure the forced entry of air into the system, then water from the siphons begins to “leave” after the flows. As a result, unpleasant odors appear. The problem can only be solved by constructing ventilation.

For ventilation arrangement You can also mount an aeration valve at the top point of the riser. It will provide access to air flows, thereby preventing the vacuum of air in the pipe.

Laying external sewerage

The arrangement of external sewerage is also divided into two main stages: construction of a treatment structure and laying of a pipeline. When performing each of them, there are a number of points to consider.

Photo example of the construction of a sewer system

In order to get a clear idea of the process of constructing the external part of an autonomous sewer system, we invite you to familiarize yourself with the stages of work shown in the photo:

The preparatory work has been successfully completed, now we proceed to the actual assembly of the system, the installation and connection of the treatment station, as well as the arrangement of the site:

Construction of a treatment structure

The first step is to dig a pit for installing a septic tank. The minimum distance between a residential building and the treatment structure is 5 m, the maximum is 20 m. The most optimal option is 10 m.

Having decided on the location of the septic tank, they dig a pit 2.5-3 m deep. Its dimensions depend on the dimensions of the structure.

The size of the septic tank depends on how many households live in the cottage and how often they use the plumbing. So, when building a septic tank from concrete rings for a company of 4 people, it is quite enough to install a structure of three rings measuring 1 * 1.5 m.

If the sewerage is carried out in a country house where the family gathers from time to time, 2 rings D 1000 mm will be enough.

The bottom of the pit is leveled and lined with a sand “cushion”, making it 150-200 mm thick.

After 4-5 days, when the concrete acquires the desired strength, the walls of the septic tank are erected, installing concrete rings on top of each other or laying bricks in rows. When installing a finished container, it is important to ensure its reliable fixation by attaching it to the concrete floor using cables.

Important point! There should be a distance of 100-150 mm from the edges of the pit to the walls of the tank. After the construction of the structure, the voids will need to be filled with clay mixed with broken bricks.

A ventilation pipe is removed from the septic tank. According to the standards, its upper end should rise above the ground at a height of 80-100 cm.To protect against precipitation and small debris getting into the ventilation, the upper end of the vertical outlet is equipped with a “mushroom”.

A concrete cover equipped with a hole for a hatch is placed on top of the septic tank.

Technology installation of a filter well not much different from the design of a septic tank. In order for treated waste to be naturally absorbed into the soil, the walls of the well can consist of concrete rings with perforations or be built with brickwork.

To create a drainage “cushion,” the bottom is covered with a meter-long layer of gravel or crushed stone.

Laying a pipeline to a septic tank

A ditch is dug to the location of the treatment structure for laying the supply pipe. This can be done manually or by renting special equipment.

Work on laying the external pipeline is carried out in the following sequence:

- Dig a trench. Its depth should be below the soil freezing level. When determining the width of the ditch, it is important to consider that the outlet pipe will need to be additionally insulated.

- Setting up a “pillow”. The bottom of the trench is compacted and lined with a sand layer, making a slope of 2-3% towards the treatment plant. So for a pipe 10 meters long, the slope between the top and bottom points will be 20-30 cm.

- Laying pipes, placing the bells down. When assembled into a single structure, the elements are connected using special glue.For greater reliability, the composition is applied to the ends of both joined elements.

- Installation of inspection hatches at the point of connection to the house and at pipeline turns.

- Sewerage elements are joined. The pipe is led to a hole made in the wall of the septic tank. The joint area from the outside is covered with cement mortar.

If in your region the level of soil freezing reaches about 2 meters and deepening the external pipeline to such a level does not seem appropriate, it must be carefully insulated.

An excellent solution in this case would be the option when a plastic pipe is placed inside a cast iron pipe, and the insulation acts as a layer between them. Some owners use for this purpose heating electric cord.

To protect the indoor sewage system from sewage from the street, as well as from rodents entering the house through pipes, it is recommended to place a check valve at the outlet of the pipeline from the house.

When laying an external pipeline, complex turns and right angles should be avoided. It is better to equip pipes at turning points inspection hatches.

When all the pipes are laid and connected, in order to check the correct operation of the system and the tightness of the structure, all that remains is to perform the first water supply.

Conclusions and useful video on the topic

Useful videos will help you quickly cope with the installation of a septic tank, pipeline and plumbing fixtures.

How to lay a pipeline correctly:

Option for arranging a septic tank:

By competently completing the design, you will ensure the uninterrupted operation of the autonomous system and create comfort in your country house. And by carrying out the installation correctly, you will protect yourself from additional hassle of servicing the system and carrying out repair work.

Do you have personal experience in designing and installing sewerage systems in a country house? Do you want to share your accumulated knowledge or ask questions on the topic? Please leave comments and participate in discussions - the feedback form is located below.

In the twenty-first century, it is almost impossible to surprise someone with communications on your site. The rapid pace at which technology is developing indicates a turbulent future. We are a generation that knows what it’s like to go to the only well or pump for water in the entire village. Now, if the hands grow from the right place, you can bring the flow of water directly into the house.

The angle of inclination of horizontal sewer pipes is very important. That's why SNiPs exist. Many people neglect this parameter, making a bias by eye, and then pay the price. If the angle is made smaller, the water will flow slowly, and over time, the process of waterlogging in the pipes will begin, especially at turns. If the slope is made larger, the water will quickly drain, and all the debris will remain in the pipe.

According to SNiP, I need to make the sewer pipe slope 0.02. But the fact is that the natural slope of the site exceeds this value. What to do in this case? Or is the calculation relative to the horizontal, and not the slope of the site?

Hello.The passage of sewerage pipes is calculated not along the horizon, but at an angle from it, calculated according to the standards. If the angle is too large, it can clog the sewer system.

In this case, the maximum slope of the pipelines should not exceed 0.15 (with the exception of branches from devices up to 1.5 m long).