Types of welding machines - subtleties of choice and application features

Choosing a high-quality and inexpensive unit is not as easy as it might seem.The market is overflowing with offers, and not all types of welding machines are equivalent to each other. Each has features, advantages and disadvantages. You shouldn’t give in to the persuasion of sales managers - it’s better to understand the structure and parameters of welders yourself, then it will be easier to make a choice.

The content of the article:

- Types, differences, pros and cons

- Spot welding machine

- What parameters should you use to choose one or another type of welding machine?

- Parameter 1. Power

- Parameter 2. Welding current range

- Parameter 3. Electrode diameter

- Parameter 4. Open circuit voltage

- Parameter 5. Duty cycle

- Parameter 6. Device weight

- Parameter 7. Maximum power of the device

- Parameter 8. Cable length and cross-section

- Parameter 9. Type of current

- Parameter 10. Additional indicators

- What types of welding machines are suitable for home

- Popular manufacturers

Types, differences, pros and cons

Until recently, the demand for compact transformerless welders was enormous. Certain types of manual welding machines were created at home, and conversion models produced by defense industry enterprises were purchased.

Today the market is oversaturated with offers. The designs of welding machines have become more diverse. But this made the models more advanced. All modern welders are based on the same old circuits, but on a new element base.

By type, devices can be divided into several basic models:

- transformer structures;

- inverter circuits;

- welding machines for DC welding;

- structures for welding in a protective gas environment;

- spot welding devices;

- gas welding units.

All of the above applies only to devices whose circuit and design allow connection to a household power supply of 220 V. This is a basic limitation for all household models.

When choosing the type of welding machine (except gas welding), it is necessary to realistically evaluate the capabilities of the electrical network. Modern semiconductor-based models can work in a country house or in a garage, where the network voltage can be in the range of 150-240V. Older devices with transformer voltage conversion have to be redone.

This will come in handy! Welding machine for polypropylene And polyethylene pipes.

Transformers

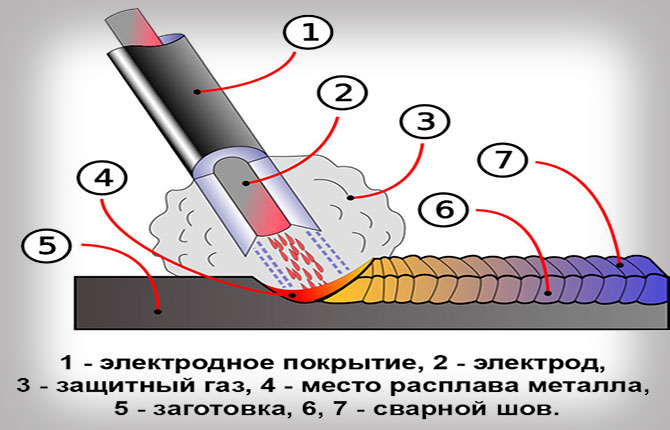

The most ancient type of welder. Actively used for more than a hundred years. The basis of the device is a heavy (up to 20 kg) and powerful (up to 5 kW) transformer, which converts the mains voltage of 220 V at the input into a working alternating voltage of 50-60 V.

For high-quality welding of metal, the transformer must have a certain type of current-voltage characteristic, often steeply falling. A regular power transformer removed from industrial equipment is not suitable for welding.

Before starting work, the welding transformer is adjusted to certain characteristics - current and arc intensity. By moving the ballast resistor or reactor with your hands, it is possible to achieve a steeply falling voltage-current characteristic. This means that from the moment the arc is ignited, the voltage will decrease significantly with increasing current, the amount of energy is released evenly, so there will be no burns or lack of penetration.

Positive sides:

- simple design, easy repair;

- affordable price;

- high welding current – up to 250A;

- reliability.

The service life of a welding transformer wound from high-quality copper wire is 20-25 years. In practice, with careful handling, the service life is limited only by the reliability of the insulation. A wire in proprietary rubber insulation can provide 30-40 years of trouble-free operation.

Disadvantages of the device:

- heavy weight;

- complexity of setup;

- limited use;

- strong interference created by the transformer in the network.

It is not recommended to carry out work using a transformer welder near high-rise buildings in order to avoid conflicts with residents.

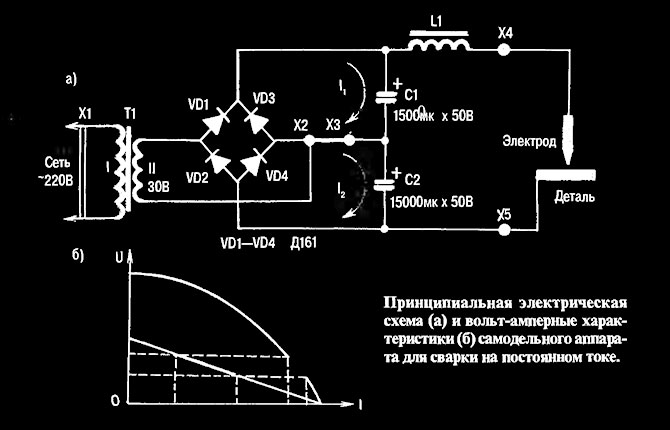

Rectifiers

Certain types of materials, such as stainless steel or cast iron, are welded using direct current. For this you need a rectifier. Essentially, this is the same welding transformer, additionally equipped with control systems and a block of semiconductor valves that convert current from alternating to direct. All types of regulators with a transformer are assembled in a compact but heavy housing (10-12 kg).

A control board based on thyristors is used as a mode regulator. With its help you can adjust the current value. The block of rectifying silicon diodes is unregulated. The type of welding current is constant.

For certain types of welding work that require long-term continuous load, instead of a thyristor regulator, a magnetic shunt installed on the secondary winding is used. It is opened or closed using the handle on the front panel of the device.

The unit is considered reliable in operation, but this type of welder is not popular among amateurs due to the difficult selection of operating modes.

Inverters

This type of welding equipment assembled using electronic components. In the design of the device, voltage conversion is provided by an electronic generator based on controlled switches. There is a transformer, but this type of converter works with high-frequency voltage. Therefore, the weight and dimensions of the device are small. The weight of the inverter rarely exceeds 5 kg.

Inverter welders are assembled on two types of element base - MOSFET transistors and newer IGBT elements. The first type of semiconductors has been produced for more than 50 years; they are distinguished by their reliability and low price. There are about 20 of them in one inverter. They overheat quickly; already at 60 ℃ the protection often trips.

The new IGBTs can withstand temperatures up to 90℃, and an inverter requires up to 10 of them. Such elements are more expensive and do not allow all types of repairs. The size of the semiconductor package is small and it is difficult to desolder it from the board.

All types of inverter welding machines work according to the same scheme:

- alternating current coming from the network, voltage 220 V, is rectified on a block of powerful diodes;

- in the second stage, the filter eliminates interference. At the same time, this type of protection blocks interference from getting back into the network, so you can cook with an inverter even in an apartment;

- after the filter, the generator converts direct current into alternating current with a frequency of about 100 kHz.This makes it possible to use small compact parts and elements;

- the signal from the generator is fed to a high-frequency transformer, where it is reduced to a voltage of 50-60 W, after which it is rectified by high-frequency valves.

In addition to its small size, the welding machine is interesting because of its ability to precisely adjust the current in the electric arc.

Positive sides:

- light weight;

- ability to weld thin-walled parts;

- easy setup;

- no network interference.

Most inverters have additional options that improve the quality of welding by untrained workers. For example, turning on Anti Stick prevents the electrode from sticking when the arc is ignited. The Hot Start system increases the current and voltage at the moment the arc ignites, making it easier to start work.

The negative points are that the inverter requires careful handling. If used incorrectly, the high-frequency generator easily fails. Most types of welder repair require the qualifications of an electronics specialist.

Semi-automatic

A fundamentally new type of welding machine, it has been widely used for decades in industrial production and during repair work in specialized workshops. Semi-automatic welding machines became available with the advent of compact inverters.

The device may have one or two housings. The first block contains an electrical converter, similar to an inverter or rectifier. In the second, there is a reel system for feeding copper-plated welding wire through a flexible rubber sleeve to the welding point. There is a current supply cable inside.

If this is a mobile, portable type of device, then all the elements, except the sleeve, are collected in one block. In addition, CO gas is supplied into the sleeve2 from a cylinder with a gas reducer.

At the end of the hose there is a pistol burner with a button for turning on the gas and wire supply. During operation, the protrusion of the wire electrode is only 4-5 mm, so the welding zone is completely immersed in the flow of shielding gas.

The advantage of the semi-automatic machine is the high quality of the seam. All types of thin sheet steel can be welded.

Despite the fact that, according to statistics, 60% of amateur welding work is performed semi-automatically, the device has many negative aspects:

- consumables - wire and gas of good quality, are not cheap;

- heavy weight of the welding system;

- rapid filling of the workplace with carbon dioxide or carbon monoxide;

- Periodically you need to adjust the operation of the gas valve and wire feed reel.

Of all types of welding work, a semi-automatic machine is justified for car body repairs, the manufacture of large-volume metal tanks, and minor repairs of metal furniture.

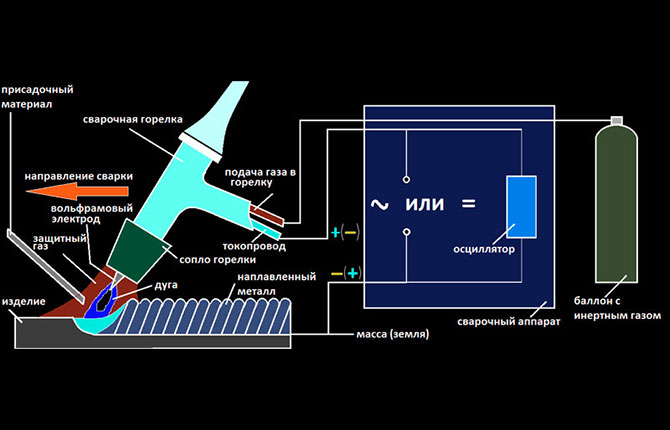

Argon arc welding machine

Argon welding differs from other types in that it uses a torch with an argon supply nozzle and a non-consumable tungsten electrode. The remaining elements are made in the same way as those of the semi-automatic device, but without copper-plated wire.

The essence of the argon arc apparatus is to create a soft, stable arc over a weld pool of molten metal. The melting zone is only a few millimeters. Therefore, unlike other types of welding, the seam is thin and uniform, with a small, barely noticeable wave. To compensate for the “sinking” of the seam, a filler material in the form of a rod with alloying additives is added to the bath.

Disadvantages of using argon:

- the cost of argon is an order of magnitude higher than carbon dioxide;

- professional skills in handling argon are required;

- Argon sprayed into the air can cause asphyxiation or lung damage.

Usually the unit is classified as one of the types of welding machines without electrodes, but this is not entirely true. A tungsten rod with a diameter of 2-3 mm burns slowly, but it also needs to be changed periodically.

The advantage of an argon arc welding machine is the ability to weld thin (<1 mm) parts without overheating or deformation of the product. In addition, non-ferrous metals, especially aluminum and copper, are cooked with argon. The strength and tightness of the welded seam is only slightly inferior to the original metal.

Spot welding machine

Due to the pliers protruding from the body, it does not look like a traditional welder. A welding machine is used to perform one operation - welding two thin sheets of steel at one point.

The operating principle is simple:

- the blanks are folded into a bag and secured with a clamp with gaskets;

- selecting a location for the welding point;

- bring the pliers to the point, press with manual force so that reliable electrical contact is ensured between the electrodes and the steel;

- Steel heated by electric current passes into a plastic state and is welded.

The pliers must remain compressed. The device operates from a regular 220 V network and does not require special protective clothing, masks or additives. Welding speed reaches 10 points/min.

Gas cutting and welding machine

The gas welding installation consists of two high-pressure cylinders, one of which is filled with oxygen, the second with hydrocarbon gas. Previously it was acetylene, now methylene or propane is used. The weight of the cylinders is 10-12 kg. Gas outlets from the cylinders are fed through pressure reducers through hoses to the gas burner, where mixing and combustion of the mixture occurs.

Gas welding is considered the most versatile of all types of welding. It can be used for:

- gas cutting and steel welding. If you have the skills, you can weld both massive parts and thin-walled sheets;

- thermal cleaning and firing of metal surfaces of all types and types of products;

- for heat treatment, heating before hardening, tempering, joining parts by hot fit;

- welding and soldering of small parts with hard solders.

Gas welding does not require connection to an electrical network, but gases will have to be pumped at a specialized station. Refills are inexpensive. Cylinders will need to be pressure tested before filling.

Gas welding is the only type of welding that requires prior training in handling the torch, reducer, valves and cylinders.

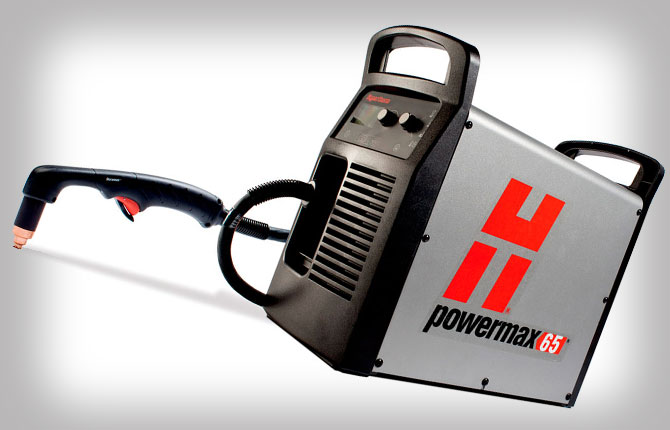

Plasma welding

The most modern type of welding technology. The device consists of a block in which a welding inverter and an air compressor are located. The purified air stream, sometimes enriched with water vapor, is fed into a hand burner. Inside the burner device there are two specially shaped electrodes, and an electric arc burns between them.The air flow is heated to the state of plasma and blown through a cooled nozzle onto the surface to be welded.

Plasma can cut all types of materials and weld any metals and alloys. The seam is thin and durable, the quality depends on the correctly selected filler rod.

Plasma welding machines are used mainly for welding thin-sheet stainless steel, cast iron, copper, and precision cutting of sheet blanks.

What parameters should you use to choose one or another type of welding machine?

The decision must be made based on application practice. A specific model of welding machine was developed for a specific type of task. If you just want to have a tool in your house with which you can weld a bicycle frame, pipe, bracket, then a Chinese welding machine in the form of a drill will do. It cooks for a maximum of 5 minutes, but it is quite possible to boil a seam of 3-4 cm.

On the other hand, the Chinese “drill” is compact and lightweight, so you can easily find a place for it even in an apartment.

Parameter 1. Power

The first thing you need to know when choosing a welding machine is the state of the electrical network. If in a private house, in a garage, or in a country house, the voltage remains stably at least 210 V, then you can buy a rectifier. The transformer is recommended only for cases where welding work is carried out constantly in one place, with the same material.

If the power “jumps”, then an inverter or plasma will do. In the latter case, you may have to purchase an additional stabilizer. It is also not good to carry out welding work with an inverter machine with a “jumping” voltage, since the efficiency drops and the electronics overheat. But an inverter is the only type of welding machine that can operate with unstable power supply.

Parameter 2.Welding current range

Doesn't really matter. All types of modern welders have a range of 20-130A. This is enough for household work.

An exception may be a transformer or rectifier. Their secondary winding consists of one or two winding sections, by switching which it is possible to reduce or increase the welding current. In addition, you will need to purchase a reactor and a set of ballast resistors for the secondary winding. If you know how to choose the right ballast for the secondary winding to limit the current, then the quality of the seam will be ideal.

Parameter 3. Electrode diameter

A universal solution would be to purchase a medium power inverter. A high-quality device with a built-in cooling system is capable of working with any electrode up to 5 mm in diameter. You can use twos to make tacks, fours or fives to make the main seam.

| Electrode diameter, mm | Metal thickness, mm | Welding current, A |

| 1,6 | 1-2 | 25-50 |

| 2 | 2-3 | 40-80 |

| 2,5 | 2-3 | 60-100 |

| 3 | 3-4 | 80-160 |

| 4 | 4-6 | 120-200 |

| 5 | 6-8 | 180-250 |

| 5-6 | 10-24 | 220-320 |

| 6-8 | 30-60 | 300-400 |

If a welding machine is needed for specific types of work, then it is better to use a good rectifier. For example, when welding metal frames from a steel profile or angle, the inverter welder will quickly overheat and turn off.

You cannot cook with a reduced direct current; the depth of penetration, and therefore the strength of the joint, will be small, although the seam may look perfect. For work with a 5 mm electrode, the best option would be a welding transformer.

Parameter 4. Open circuit voltage

Inverters are recommended for beginners. They have several built-in functions that prevent electrode sticking and stabilize the arc during ignition. In this case, the electronics artificially raise the open-circuit voltage above 60 V at the beginning of the process, then instantly reduce it to 45-50 V, while simultaneously increasing the current.

The only negative is that the built-in anti-stick and arc stabilizer systems often fail, and then it can be more difficult to cook with an inverter than with a rectifier.

In simple transformer models, the open circuit voltage is 50-60 V, depending on the electrode used. For semi-automatic machines, the idle speed is even lower - up to 35 V.

Parameter 5. Duty cycle

Typically, the manufacturer of welding equipment indicates in the passport the parameters “operating time at maximum current” and “time for cooling”. For an average inverter, the operating cycle is 10 minutes of operation and 5-6 minutes of cooling with a working fan. This is enough for amateur work. For welding installation, the operating cycle corresponds to the burning time of one or two electrodes.

For a transformer and rectifier, the cycle depends on the diameter of the electrode and the operating current. Semi-automatic, argon and plasma devices are limited by the gas pressure at the outlet of the reducer.

Parameter 6. Device weight

The best indicator is for portable options, inverter models - 3-5 kg, rectifiers and plasma - up to 10 kg. It makes sense to buy heavier welding machines if the equipment is used in professional activities.

The increased weight of the inverter or rectifier indicates that the manufacturing company did not skimp on installing cooling radiators. For a transformer, a large weight often indicates good quality of the core, copper strands of the primary and secondary windings.

For other types of welding machines, weight does not matter, since they are attached to gas cylinders and are used in a stationary mode.

Parameter 7. Maximum power of the device

The welder must be powerful.The optimal power of a welding machine for household work is 3-5 kW for transformers, rectifiers, spot welding systems, 3-4 kW for inverters. For semi-automatic machines, argon and plasma models - 2-2.5 kW.

There are many techniques and ways to reduce the welding current, adapt the operation of a semi-automatic machine at minimum power, and weld thin metal. But if the power of the welding machine, regardless of its type, is not enough to weld the metal to its full depth, then this is a disaster.

The idea of welding a seam in several passes is good, but not for the household level, as it requires professional training, experience and knowledge. The more powerful the welding machine, the longer the service life.

Parameter 8. Cable length and cross-section

For electrical devices with transformer voltage conversion, the cross-section and length of cables, or in other words, welding “hoses,” are a problem. The only exceptions will be semi-automatic, plasma, argon and spot welding.

Most manufacturing companies complete their products with “hoses” of 2.5-3 m, with a cross-section of 30-50 mm2. This is enough to weld a small seam on a workbench, provided that the welding machine is on the floor under your feet.

If we are talking about more complex work, for example, machine repair, welding a corner on the roof of a canopy, then the length of the “welding hoses” should be 3-5 m, with a cross-section of at least 100 mm2 in heat-resistant rubber insulation. And even such a cable heats up to 70-100 ℃ after 10-15 minutes of intensive work.

Parameter 9. Type of current

Ideally, the design of the welding machine should allow operation on alternating and direct current. Alternating is used for welding ferrous metals; constant welding is used for welding cast iron, stainless steel, and sometimes thin-walled structures.

If you can’t choose, then it’s better to take a welding machine with direct current.

Parameter 10. Additional indicators

In addition to technical data, when choosing a welding machine, you need to pay attention to endurance and workmanship. When choosing, you can collect reviews about different types and models, and see the opinions of professionals. If the welder has a reputation for being indestructible, then this is the best recommendation to choose.

The durability of a welding machine is directly related to the quality of workmanship and the parts used. For example, if the case contains a 120 mm computer cooler instead of a special fan, then it is better to refuse the purchase.

What types of welding machines are suitable for home

An inverter with a power of 3 kW is suitable for the average person. Fans of making homemade products choose devices of a similar type, but with slight modifications. They change the fan and toggle switches, install longer and thicker welding hoses.

For an apartment, an inverter unit of 1.8-2.5 kW is sufficient. This is enough to weld hinges on a door or a bicycle frame. For a private house or cottage, the best solution would be an inverter rectifier up to 5 kW.

If you are engaged in technical creativity, then the best solution would be plasma; it is an expensive and versatile welding machine, but it can cope with any materials.

Combinations of several types of welding machines are possible. Refrigerators use gas or argon welding. To repair cars you will need a set of a semi-automatic machine and a gas burner. If you repair the body, then also spot welding.

Argon welding machines are used to repair automobile engines, aluminum cookware and glass frames of all types.

Popular manufacturers

There are many models of welding machines, it is difficult to understand them, so you have to focus on the reputation and features of the welding machine manufacturers.

Let's look at the most popular manufacturers of welding machines and create our own rating.

Aurora-PRO

Lightweight, compact, holds the arc well. Welding machines are assembled from components from China and Europe. Supplied with a storage case.

Among the shortcomings is the low quality of welding cables, handles break. On the plus side, there is a 2-year warranty.

BlueWeld

An Italian brand that has long been known in Russia. Welding machines of all types are assembled in Italy. The price is moderately high. Conventional rectifiers are in demand. Inverters cost almost twice as much as competitors.

Brima

German brand, specialization - welding machines of all types. Components are produced in Southeast Asia, assembly - in Europe. The quality is not bad, it is distinguished by endurance and the ability to work for a long time at maximum currents.

Among the disadvantages are the control knobs that easily break down and the high cost of inverters.

Elitech

Russian brand. But welding machines of all types are produced in China. They are characterized by increased weight and short cables. Control knobs often break. The welding quality is high, the cost is lower than that of European analogues. Poorly repaired.

Eurolux

The main part of the company's product range consists of welding machines with inverter converters. An excellent option for an apartment. Beautiful design, good seam quality. There are many fakes on the market.

FoxWeld

Italian brand for welding machines of all types.All production and assembly are located in China. Welders are characterized by high reliability of electronics, low quality handles and welding hoses. The design is not the best. There is a network of warranty workshops in Russia.

Fubag

A company registered in Germany and manufactured in China. It produces mainly inverters. The welding quality is average. The products are clearly overpriced.

The hardware design is at a high level, the welders are well assembled. There is a network of warranty workshops, but repairs are expensive.

Kedr

A Russian company that produces all types of welding equipment, from argon welding to inverters and semi-automatic machines. Two year warranty. The design level is “C”.

Most products are characterized by increased weight and poor quality welding cables. The welding quality is high and works flawlessly even in extreme weather conditions.

Patriot

Famous American brand. Produces inverter welders, semi-automatic and argon welders. Warranty 1 year and 3 years.

Welding machines are superior in quality and reliability to European brands.

RedVerg

American manufacturing company. It produces welding machines of all types - professional and amateur level. The products on the market are mainly represented by high-quality inverter models and carbon dioxide semi-automatic machines. Sold at a price below average, it is distinguished by its reliability and high quality welding seam.

Resanta

The brand is registered in Latvia, electrical equipment is produced in China. The main sales of all types of welding equipment are carried out in Moscow.The quality of the devices is noticeably inferior to European and American ones, but better than Chinese ones.

Stavr

Russian brand of welding rectifiers and inverter machines. The Stavr equipment is distinguished by a well-thought-out layout, but low reliability of mechanical wire feeding.

The welding seam is not satisfactory, but to work as Stavr you need to have at least basic welding skills.

Svarog

Russian company. It produces welding equipment with the Shenzhen Jasic Technology concern. Large-scale assembly is mainly carried out from imported components, so the quality of welding machines of the main types is high.

Wester

Trademark registered in the UK. The company of the same name produces and sells all types of welding equipment, with warranty repairs for its products.

The level of quality is evidenced by the fact that the devices have a warranty of up to 5 years.

All main types of welding machines have long been optimized in design and tested many times in practice. However, even well-known brands have problems. Therefore, before purchasing, you need to conduct an analysis, comparing the negative and positive aspects of the selected models.

Article for you! 10 best masks for welders: review, photo, price. TOP 10 best welding electrodes.

Welding inverter FUBAG IQ 160. First impressions after purchase: video.

Share your experience of choosing such devices in the comments. Save the article to bookmarks and share it on social networks.

Take only straighteners; the machine is reliable, although a little heavy. It will work for twenty years. Inverters are all junk; they break down after a year or two of use. In ten years there will be no more microcircuits, there will be nothing to repair.

There are few frankly bad welders on the market; usually these are fakes of branded models, so I would not dare to buy a “brand” one. The best option is a Russian brand, but the “stuffing” of the welder is assembled from imported parts, definitely not Chinese.