Replacing a gas hose with your own hands: rules for installation work

There are a number of good reasons for replacing a gas hose, including simple wear and tear of the hose.According to technical standards, a gas service worker must be called to perform this work. But what to do if the need arises in a country house, for example, where you can’t hope for a prompt arrival from gas workers? Act on your own!

However, first you need to understand the technological nuances according to which this work is performed. We will tell you how to replace a gas hose with your own hands. Using the information, you can competently remove the old hose and install a new one, without fear for the safety of your family and neighbors.

We have described in detail all types of hoses approved for use in the gas industry. As an example, the process of installing a new gas stove with a full set of equipment is given. The information presented for consideration will be useful both to those who decided to carry out the replacement themselves and to customers of gas workers’ services.

The content of the article:

Types and features of gas hoses

After purchasing a new gas stove or when replacing old equipment, you will need to change the flexible hose. There are only five types of these communication devices on sale, but they are not the most popular.

The reasons for the low level of demand for certain types of gas hoses lie in the complexity of installation work. And in some cases it will not be possible to do without calling a specialist.

The most popular flexible models include the following eyeliners:

- rubber;

- rubber-fabric;

- rubber, reinforced with metal threads;

- bellows metal.

In addition to flexible models, you can find steel and copper pipes. The requirements for connecting this type of hose are very different compared to flexible models.

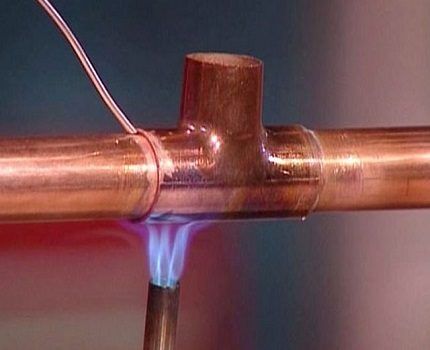

Methods also vary soldering of copper pipes. If installation is carried out using hard solder, it is necessary to use exclusively copper-phosphorus contacts PMFS6-0.15 and PMFOTSr6-4-0.03. Soft soldering is not allowed in this case.

Another way to contact gas pipes is to install copper fittings by pressing. Compression fittings for hoses are selected based on the pressure coefficient of the pipe. If the pipe diameter is not more than 54 mm, the use of a fittingless connection method is allowed.

Despite the reliability of connecting such hoses to gas appliances, they have a number of disadvantages:

- it will not be possible to install without special equipment, so you will need to call a specialist;

- the placement of the slab will be stationary, without the ability to move it;

- labor-intensive installation process.

Such methods are used infrequently and are unreasonably expensive. The financial investment will be many times higher than when using popular flexible hoses. It is also worth considering the duration of the work - during this time there will be no access to gas supply.

Features of rubber sleeves

A rubber hose, intended mainly for transporting oxygen, is considered a rare option, although you can easily find it on the market. It has many advantages: pressure resistance of 20 atmospheres, affordable price, ease of installation and good electrical insulation.

However, despite all the positive qualities, the device requires special vigilance during operation. Contact of a section of the hose surface in contact with air and the slightest drop of oil can lead to overheating of the hose, and, accordingly, rapid failure.

You should avoid using an oxygen hose - it is considered a relic of the past, when there were no more advanced and safe products. Its installation in the kitchen of an apartment in a multi-storey building is especially dangerous - the owner risks not only his own life, but also hundreds of unsuspecting people.

If at the dacha, i.e.place of temporary location, such a product is used, you need to be especially careful and pay attention to its marking, where the following parameters should be indicated: product class, internal diameter, maximum permissible pressure.

A visual inspection of the presence of defects in the form of swellings, cracks and punctures of the fiber frame will also be required - the presence of bare areas is not allowed.

Characteristics of rubber-fabric products

The rubber-fabric hose deserves good recommendations. These are ease of use, inexpensive price, high degree of flexibility, wide range of sizes (almost any length and diameter), excellent electrical insulation.

The disadvantages include the weak rigidity of the material - the product is made from rubber reinforced with fabric threads. Despite this, modern technologies used to make the model will help it last up to 10 years.

Another negative quality is that after a short period of time, cracks appear in the rubber, which are conductors of gas leakage. Despite the good strength indicators, experts do not recommend using such a hose for more than two years. This type of eyeliner is in demand for gas cylinders in a private house.

Specifics of reinforced liner

The type of product reinforced with metal mesh has much in common with water pipes - the thin-wire braided steel provides structural strength.Two fittings and threaded rivets located at the ends of the hose act as fasteners for the hose and gas stove.

The clear advantage of this type of connection is reliability. And to ensure its safety, dielectric inserts should be placed between the hose and the stove. In addition, during installation, gaskets made of copper, aluminum or other soft metals must be used.

Reinforced hoses are inexpensive and easy to use. The flexibility of rubber and the strength of metal are successfully combined in this product, which has contributed to the growth of its popularity for use in domestic conditions. Experts in our country recommend gradually abandoning their use in favor of a more advanced option.

Reliability of bellows metal connection

The most reliable and durable option is a bellows metal hose. It is used to connect the stove to the gas main and has a high coefficient of flexibility, which is achieved due to the corrugation made of stainless steel.

At the same time, at the moment of bending, there is no deformation of the internal section of the sleeve. The hose can be extended up to four times the size. All this is reflected in its price category - the cost of the product is quite high.

The standard length of this type of hose is 1.5-2 m, thread diameter is ½ or ¾ inch.Due to the fixation method, a distinction is made between hoses with nut-to-nut and nut-to-fitting fastenings. In addition to a highly flexible surface, they are able to withstand pressure of 6 atmospheres, and can also be in contact with temperatures from –50 to +200 °C.

The only drawback is the price range, which is five times higher than its competitors.

Flexible bellows hoses are divided into conventional and with a metal base made of stainless steel. The latter are protected by a two-layer polymer coating, providing high-quality electrical protection. It protects the material from corrosive and acidic effects, as well as from the high-temperature conditions of the furnace device.

The material used to manufacture this type of gas line is stainless steel, which meets all technical requirements of GOST. Due to the polymer coating, the product is protected from various forces.

The hose guarantees the integrity of the gas supply system for a long period - up to 25 years. The electrical resistance of the material reaches 1500 V, which is important, because modern stoves are equipped with rich electrical functionality.

Rules for choosing a gas hose

Any equipment, including connections for blue fuel devices, must have a quality certificate guaranteeing the specified service life.

This type of product should only be purchased in specialized stores.Do not forget about the differences between a water hose and a gas hose: a yellow mark on the braid indicates that this is a hose designed for gas, a blue-red mark is for water supply.

Details about choosing a hose for connecting gas equipment, written here. We recommend that you read our proposed article.

Connection Security Basics

Any gas equipment, including related ones, must be connected in compliance with safety rules. Gas is an explosive substance, when working with which you should be extremely careful.

This requirement also applies to devices for its connection, which must be of high quality and provide the appropriate level of protection:

- It is not recommended to hide the gas hose; it is important to ensure access to it.

- The product cannot be painted.

- When installing, you should pay attention to the tension of the sleeve - it should sag a little.

- During the installation process, do not bend or twist the eyeliner too much.

- Metal parts of the product must be protected from condensation.

To install a flexible hose, only tools, materials and components designed for working with gas equipment are used. This is worth paying special attention to, because many parts are almost identical to materials for plumbing.

Gas stove connection diagram

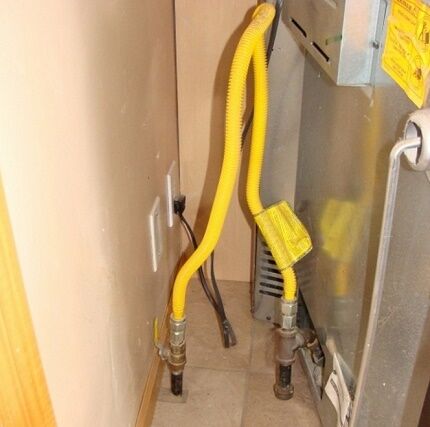

Schematically connecting the stove to gas looks like this: a gas riser passes through the kitchen room, from which comes a branch pipe with a tap at the end, which is connected to the stove. This piece is also called a drop or tap.

A rubber-fabric hose is screwed into the faucet, through which gas is supplied. For old houses, it is common to place the slab on a metal pipe. This method is inappropriate to use, because in this case the location of the device will be stationary.

In remote areas of the private sector, where there is no access to a main gas pipeline, gas is used in cylinders. Only a gas service specialist is allowed to connect to such equipment.

Instructions for self-connection

Paying a gas technician for installation work is not too high, but many home craftsmen prefer to do everything themselves. This is a feasible task that requires the purchase of components and theoretical knowledge.

To connect, you will also need to prepare the following tools and buy materials:

- keys: gas No. 1, adjustable 22-24;

- a screwdriver for tightening the clamp, if required;

- sealants (Loctite 55 thread, flax, FUM - tape);

- gasket ½;

- gas sleeve;

- ball valve 1/2′;

- a brush and soap solution, which will be required to control the work.

A rag and a plastic stopper will also come in handy. The rag will be used as a temporary seal against gas leaks. The narrowed edge of the plug must be adjusted to fit the hole in the supply pipe. If during the extraction process a homemade part gets stuck, you can easily remove it with a corkscrew.

Step #1: Removing the old slab

Shutting off the crane when lowering is a primary task to ensure the safety of the work being performed.Next, you need to unscrew the locknut located on the outlet and remove the coupling. If the old slab has a coupling and locknut that were previously painted, this will significantly complicate the process of dismantling them.

Sometimes it is not possible to complete this procedure, then you will need to cut the eyeliner with a grinder.

In the process of unscrewing the squeegee located in the lowering valve, it is necessary to hold the valve itself with a key. You don't have to remove it unless you plan to. faucet replacement. When they plan to delay the installation of the slab, an additional plug is installed on the lower side.

Step #2: Replace the faucet

There are situations when the wall is located very close to the tap and there is no way to dismantle it. In this case, it is necessary to bend the fastening and install a wedge between the wall and the pipeline. However, this is done in such a way that it is possible to continue doing the work.

It is necessary to prepare a piece of rag sufficient to completely block the pipe after dismantling the old tap. The next thing will be to tear it off without completely unwinding it. You will also need to prepare the selected type of seal. Do not forget to thoroughly ventilate the room during work to eliminate gas vapors.

After unscrewing the tap, the outlet from the pipe is tightly fixed with a finger and then with a wet rag. The main actions are aimed at eliminating gas escape from the pipe as much as possible. In this case, the thread on the branch should not be closed, since it will be covered with the selected sealant.

Before winding the seal, the threads on the lower end must be thoroughly cleaned. Next, its winding is carried out directly. This process ensures a reliable and airtight fixation of the new faucet, which is then tightly screwed on. The last step is to install the previously removed handle on the faucet.

If gas equipment is connected to the mains for the first time, you will definitely need to call a gas technician. In his presence, the equipment is checked for gas leaks when the valve is open. If the gas service worker does not find any violations, he must enter the established brand of stove into the register.

Step #3: Connecting the Flex Hose to the Stove

The external thread of the hose fitting is wrapped with a sealant. After this, it must be screwed into the tap on the branch pipe. The flexible hose is connected to the manifold at the finishing stage.

Next, the stage of test opening the tap on the lower side is mandatory to check for gas leaks. Using soap foam, the joints are treated with a brush. If foaming occurs when opening the gas tap, the work must be redone.

If the work of replacing a gas hose is carried out in a private house where bottled gas is used, an additional replacement of the nozzle with a smaller diameter will be required.If this is not done, the burners will produce too much soot, which likes to settle on furniture and dishes in the kitchen.

What you need to know: valuable tips

Before purchasing a flexible hose, it is necessary to check the size of the thread at the outlet of the plate, its classification and whether it is straight or angular. If the outlet is of a direct type (directed into the wall), you must purchase a sleeve with a square at the end.

The gas hose should not be painted - this will accelerate its cracking. A more attractive look can be created by covering it with special paper or oilcloth.

It is also strictly forbidden to tightly seal gas communications with false plasterboard panels and other structures - this will make it difficult to carry out service work on individual elements.

To camouflage the gas supply system, use collapsible box, which can be easily dismantled if necessary. In this case, there will be constant access to all structural elements of the gas system.

If to connect gas water heater or the stove has been called by a specialist, it is necessary to check that the work is being done correctly: the excess tap from the tap on the lower side must be unscrewed, the flexible line must be directly connected exclusively to the tap located on the branch pipe, and its other end - only to the outlet of the gas stove.

It is also possible to use an adapter. Any additional installations are prohibited.

Conclusions and useful video on the topic

Video recommendations on the selection and operating rules of gas hoses:

About connecting a gas stove in the video:

Video with recommendations for installing purchased hoses:

The correct connection of a gas stove, in accordance with the necessary technical standards, is subject to mandatory verification by the gas control service, especially if the stove is new and this is being done for the first time.

If a person has never encountered this type of work, and their knowledge is extremely superficial, the best option would be to contact a specialist.

Do you have useful information on the topic of the article? Would you like to tell us about how you changed the gas hose in your home? Please write comments, ask questions, share your opinion and photos in the block below.

We often offer a rubber hose for a gas hose in accordance with GOST 9356-75, class III. I do not recommend it to anyone for these purposes. Yes, it really can withstand pressure of 20 atmospheres, but it is designed to supply oxygen! I had one like this, it was all cracked and started leaking. If you decide to choose such a sleeve, then take class I, the price will be a penny more expensive, but the quality will be different. When installing, it is also better to use yellow FUM tape; it is specially designed for gas work.

I was especially pleased with the paragraph about replacing the gas tap. But someone, after reading it, might try it. The article is of no interest to gas workers. For everyone else, the most correct statement is in the last sentence - “The best thing to do is contact a specialist.” I believe that in an apartment building complex and dangerous work, and even more so operations with gas, should be carried out by a specialist. A better proven one, it’s a shame it’s hard to find one like that.

Sergey, it’s like the joke: “Dad can do it, but a bull is better.” Specialists often take advantage of our technical illiteracy and determine the cost of repairs depending not on the complexity, but on their arrogance and greed. Now specifically about replacing the gas valve. In private houses there is another one, on the street! Close it and do what you need to do. The risers in apartment buildings are also blocked; for this you will have to call the gas workers and it is advisable to notify the neighbors.

Yes, specialists come in different levels, and sometimes they act no better than the average person, but for this there are recommendations from friends. Do you understand that gas equipment is not an area of our life that we should delve into on our own, simply by reading material on the Internet?

Only recently, due to some misfortune of gas workers, an apartment building exploded and collapsed, killing many people. I read the material just to know how the replacement is made in principle, so that with this knowledge I can control the work of the specialist and ask questions if necessary. I will never change it myself.

Hello. I agree, but only partly. It is possible to replace hoses and taps for gas-using equipment yourself; even a woman or a person with no experience can handle this. However, if you are not sure, then it is, of course, better to invite a specialist. But personally, the gas workers laughed at me when I called them to replace the hose for 300 rubles. My mother already changed it on her own and successfully. There is nothing complicated. But considering the risks, yes. Is it dangerous.