Laying a gas pipeline in a case through the wall: specifics of the device for entering the gas pipe into the house

Connecting gas to a private home is not an accessible procedure for everyone, but thanks to the inexpensive cost of natural fuel, it will pay for itself in the coming years. Almost all work, with the exception of excavation and some installation work, is carried out by gas service employees according to a predetermined price list.

To save money, homeowners take on some of the work themselves - for example, digging a trench from the highway to the house. They can also take part in a process such as laying a gas pipeline in a case through a wall. If you figure it out, you can handle this procedure yourself, while representatives of Regional Gas Agency charge 8-10 thousand rubles for this.

For those who decided to arrange the gas pipe entry into the house with their own hands, we have collected all the information about lining in one place. You will learn everything from the regulatory framework to practical advice from our article. Our advice will be useful to independent owners of country property.

The content of the article:

Features of introducing a gas pipeline into a house

The lining process itself is accessible to anyone who has held a hammer drill in their hand and participated in the construction of a house. But there are a number of nuances that are required for any work with gas connection and with gas equipment. This is due to both the protection of the pipeline and the safety of residents.

First, let's look at what a gas pipe case is and why it is needed, and then we'll take a closer look at the process of laying a gas pipeline through a wall.

At what stage is the case installed?

Gas system located from the point of insertion to the central gas distribution line to the equipment installed in the house is called an internal gas pipeline. Simply put, this is not only a wiring installed inside the house, but also a branch located in the yard - underground, above the ground and in an area near the wall of the building.

An underground gas pipeline, accordingly, is included in the project for connecting gas to the house. According to the standards, low pressure gas is supplied to residential buildings - this is important when choosing equipment.

The question arises: when and where is it better to install a casing for introducing the pipe into the house? Theoretically, this can be done immediately after the project is approved, when the exact locations of the installation of gas equipment and the exit of the pipeline from the ground are known.

Usually they strive to reduce the distance between these two points, that is, the gas line is brought out as close as possible to boiler room at home or other non-residential premises where it is planned to install or have already installed gas units - water heaters, boilers, stoves.

It is best to make a hole in the wall when the gas pipeline outlet from the ground to the outside is already equipped. If the main line is above ground, then after connecting it to the house, in order to more accurately determine the entry point. In other words, the most favorable moment for laying a gas pipeline in a case is the completion of internal and external work.

Why is lining necessary?

According to regulatory requirements, carry out any communications - gas, water supply, heating, sewer pipes, chimneys and ventilation ducts – through walls without additional reinforcement is prohibited.

The protective structure is a case or sleeve - a durable metal casing that protects the pipe from mechanical damage.

The main task of the casing on a steel internal gas pipeline is to take the stress of the wall and relieve the load from the pipeline. The use of cases is typical for work on the installation of gas mains.

For example, it is required when laying gas pipes under road or railway tracks, as well as in soils that do not fully meet the installation conditions - heaving or flooded.

The wall mounting case is different from the special equipment placed when installing distribution lines, however, it must also be durable and wear-resistant.

For this reason, it is prohibited to use polystyrene, polyethylene or other polymers as a sleeve - only steel, stainless or additionally treated against corrosion, is suitable.

The regulatory framework is the basis of work

What to do if you are not sure about the choice of material or representatives of the inspection authority have any complaints? It is better to play it safe and carry out installation work based on legally accepted standards.

You just need to refer to the document SP 42-101-2003, or rather, to paragraph 6.7, which precisely specifies the nuances of choosing material and installation:

- as an insulating material that serves as a gasket between the pipe and the case, rubber bushings, tarred tow or other material with similar characteristics are used;

- the gap on the outside of the case is tightly sealed with concrete mortar;

- the distance from the pipe wall to the wall of the case is at least 10 mm, with the exception of pipes with a diameter of <32 mm - at least 5 mm;

- the sleeve should not extend beyond the boundaries of the wall, but if the pipe crosses a horizontal ceiling, the sleeve should protrude 50 mm on both sides.

Another very important condition is that the pipe enclosed in the case should not have either detachable or welded joints.

The aesthetics of the building will not be affected, since after the work is completed, the installation site of the case is decorated with finishing material on the outside, and with plaster on the inside. If the house is made of wood and there are no plans for cladding, we recommend that the cladding work be carried out more carefully.

Making or buying?

You can find a large number of ready-made solutions on sale - from inexpensive stamped 20-ruble sleeves of small diameter to products made of thick-walled structural steel.Almost all cases are universal, that is, they are used for making penetrations for any communications, including gas ones.

But if you don’t want to use a purchased part, and you have a lot of material left over from building a house, then you can make a sleeve with your own hands. A large diameter pipe is suitable, according to the standards - exceeding the gas pipe by about 20 mm.

A fragment is cut from the pipe, equal in length to the width of the wall - its edges should not protrude beyond the surface. The ends are cleaned so that they do not have burrs or sharp edges. Then the workpiece is coated with protective paint for metal, preferably in 2 layers - the sleeve is ready.

Installation instructions for the case

The process of installing the case is simple and takes little time. It is necessary to prepare in advance a tool for punching the wall and material for sealing the cavities between the sleeve and the wall.

Step-by-step instruction:

- Make a hole in the wall with a diameter exceeding design diameter of the gas pipeline, in a place determined by the project.

- Place the sleeve inside the hole and check if it is the right size.

- Fill the gap between the sleeve and the wall tightly with concrete mortar.

- Wait until the solution dries and check the stability of the installation.

The remaining work is usually carried out by gas service employees - they lay the gas pipeline and insulate it.

If the house is wooden, then a large hole in the beam can be made with a drill, drilling around the perimeter or using a large-diameter crown.

Differences in introducing bottled gas

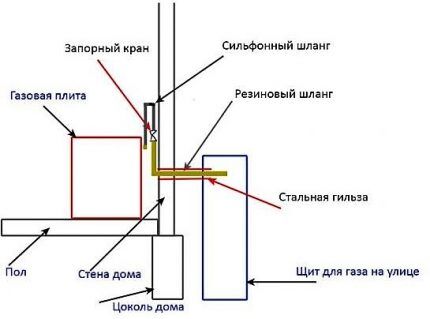

Gas cylinders are placed in a metal box outside the house, and the connection to the stove is made through a flexible rather than metal hose.

The house is made of timber, and gas supply hose – small diameter, so making a hole and installing the case is easy.

You cannot install the sleeve between beams or logs; it is recommended to drill a hole in the middle.

Conclusions and useful video on the topic

How not to lay a gas pipe through a wall:

DIY sleeve installation:

Using the brick wall case:

Passing a pipe through a wall is not the most difficult and time-consuming stage in the process of gasification of a private house, but it requires both compliance with regulatory requirements and accuracy in work.To avoid problems with the gas service in the future, we recommend that you act strictly according to the project and coordinate all work with the employees of the regulatory authority.

Would you like to talk about your own experience in constructing a sleeve for introducing a gas pipe into your house? Do you have useful information on the topic of the article? Please write comments in the form below, ask questions, post thematic photographs.

I have an old house, from the 70s. The gas workers ask if I have a sleeve? I suspect not. So now, in order to lay it, I need to hollow out the wall, take out the existing gas pipeline, and then reintroduce it?